Professional Documents

Culture Documents

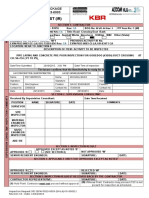

QA-F004 SAFETY INVESTOR ASSESSMENT SHEET Minh

Uploaded by

Lê Tiến Hải0 ratings0% found this document useful (0 votes)

13 views3 pages1. This document contains an assessment of Bui Hoai Linh to serve as a Safety Investigator. It reviews his educational background, training, licenses and experience.

2. The assessment contains a document review to ensure Linh meets requirements, a multiple choice test on technical and regulatory issues, and a practical/oral assessment on 39 safety and quality control procedures.

3. The QA Director approves Linh as a Safety Investigator, provided he passes all assessments, with the approval valid for a specified period of time.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. This document contains an assessment of Bui Hoai Linh to serve as a Safety Investigator. It reviews his educational background, training, licenses and experience.

2. The assessment contains a document review to ensure Linh meets requirements, a multiple choice test on technical and regulatory issues, and a practical/oral assessment on 39 safety and quality control procedures.

3. The QA Director approves Linh as a Safety Investigator, provided he passes all assessments, with the approval valid for a specified period of time.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views3 pagesQA-F004 SAFETY INVESTOR ASSESSMENT SHEET Minh

Uploaded by

Lê Tiến Hải1. This document contains an assessment of Bui Hoai Linh to serve as a Safety Investigator. It reviews his educational background, training, licenses and experience.

2. The assessment contains a document review to ensure Linh meets requirements, a multiple choice test on technical and regulatory issues, and a practical/oral assessment on 39 safety and quality control procedures.

3. The QA Director approves Linh as a Safety Investigator, provided he passes all assessments, with the approval valid for a specified period of time.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 3

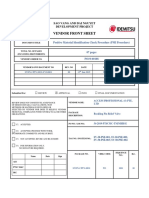

QUALITY ASSURANCE DEPARTMENT QA-F004

SAFETY INVESTOR ASSESSMENT SHEET

PHIẾU ĐÁNH GIÁ NHÂN VIÊN SAFETY INVESTIGATOR

Name: BÙI HOÀI LINH Date of birth: 26/06/1983

Vaeco ID: VAE02208 Mobile phone: 0902070808

Division: STAFF QUALIFYING DIVISION

Licence: EASA FAA VAR 5 Others

Number: 44995-AMT Category: A B1 B2 C ARS

On A/C Type/: A330(PW4000) Expiry date: 30/09/2022

Type of approved: Initial Renewal

I. DOCUMENT REVIEW

Not

Educational/ Training/ Experience Requirement Satisfied

satisfied

1 Basic training

2 SMS training

3 Human Factor training

4 MOE & SOP training

5 Working experience

Date: Assessor (name and signature):

II. MULTIPLE CHOICE ASSESSMENT

Assessment Assessor name/

Subject Result Remark

date signature

Technical

Reg.& Pro.

Date: Assessor (name and signature):

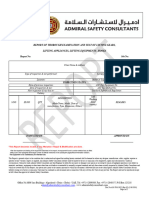

III. PRACTICAL/ ORAL ASSESSMENT

No. Description Reference Pass Fail

SOP 10.22

MAINTENANCE ERROR/ VIOLATION DETECT AND

1. SOP 10.14

RECTIFICATION

SMS Chap. 11

2. QUALITY NOTICE SOP 10.15

REPORTING OF OCCURRENCES/ DEFECTS TO THE SOP 10.12

3. COMPETENT AUTHORITY, OPERATOR AND

SMS Chap. 8

MANUFACTURER

4. HAZARD INDENTIFACATION AND RISK ASSESSMENT SMS Chap. 9

ISS. 01; REV. 00 - DATE: 20 OCT 2017 PAGE: ....../........

QUALITY ASSURANCE DEPARTMENT QA-F004

No. Description Reference Pass Fail

5. MANAGEMENT OF CHANGE SMS Chap. 15

6. SAFETY DIRECTIONS AND SAFETY TARGETS SMS Chap. 5

7. VAR Part 5, VAR Part 7, VAR Part 4, CFR 14 Part 145/43.

8. Airworthiness, continuous airworthiness, C of A, C of R

9. Authorisation privileges & responsibilities

10. Temporary authorization (Dispensation)

11. Management of tool and equipment

12. Management of spare part & material

13. General Safety Requirement

14. A/C maintenance procedures

15. Definition, control of critical task.

16. AD, SB, MOD and EO compliance control

17. Continuity of maintenance (shift/task hand-over)

18. Towing procedure

19. A/C arrival and departure

20. Technical support

21. Preliminary, in-progress, final inspection and return to service

22. Control of maintenance data

23. Maintenance record completion and handling

24. MOR/ Malfunction and defect reporting

25. Suspected unapproved parts reporting

26. VNA Tech log & Cabin Defect log checking/ handling/ entry

Definition, description, using of maintenance data as: MEL,

27. CDL...

28. ADD definition, defer of ADD, ADD list checking/ entry

29. Structural damage repair for VNA A/C

30. Control of emergency equipment on VNA A/C

31. Using of Loan component for VNA A/C

Applicable customer’s maintenance procedures:

Line maintenance check, chock/ safety cone positioning,

32.

fuelling and reporting, concession, ETOPS, RVSM, CAT

II/III….

ADDITIONAL QUESTIONS

33.

34.

ISS. 01; REV. 00 - DATE: 20 OCT 2017 PAGE: ....../........

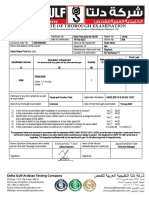

QUALITY ASSURANCE DEPARTMENT QA-F004

No. Description Reference Pass Fail

35.

36.

37.

38.

39.

Date: Assessor (name and signature):

QUALITY ASSURANCE APPROVAL

Satisfactory approved as: Safety Investigator

Approval validity: From ............................................................................ …………... to ...............................................................................................................................

Date: …………………

QA Director: Name………………………………………………...Signature: .....................................................................................................

ISS. 01; REV. 00 - DATE: 20 OCT 2017 PAGE: ....../........

You might also like

- Airman Certification Standards: Remote Pilot - Small Unmanned Aircraft Systems (2024): FAA-S-ACS-10BFrom EverandAirman Certification Standards: Remote Pilot - Small Unmanned Aircraft Systems (2024): FAA-S-ACS-10BNo ratings yet

- Chain BlockDocument2 pagesChain BlockSHARAFUDHEEN TKNo ratings yet

- RAMS For Installation and Testing of CCTV SystemsDocument23 pagesRAMS For Installation and Testing of CCTV SystemsAnandu AshokanNo ratings yet

- Ca Pre Pour 50+734 Ooredoo - RoyDocument1 pageCa Pre Pour 50+734 Ooredoo - RoyraghebomNo ratings yet

- Man Rider Winch VisualDocument6 pagesMan Rider Winch VisualRanjithNo ratings yet

- Chỉ số T1: MEDA Cause code LINE Type Error BASE Type Error Work ShiftDocument61 pagesChỉ số T1: MEDA Cause code LINE Type Error BASE Type Error Work ShiftLê Tiến HảiNo ratings yet

- PreviewpdfDocument41 pagesPreviewpdfNtli RfNo ratings yet

- ForkliftDocument2 pagesForkliftSHARAFUDHEEN TKNo ratings yet

- RAMS For Installation and Testing of Access Control SystemDocument22 pagesRAMS For Installation and Testing of Access Control SystemAnandu AshokanNo ratings yet

- 1a. Crawler CraneDocument2 pages1a. Crawler CraneSHARAFUDHEEN TKNo ratings yet

- 30.99.97.1616 Rev. 1 - ITP For Civil WorksDocument26 pages30.99.97.1616 Rev. 1 - ITP For Civil Worksshajahan eNo ratings yet

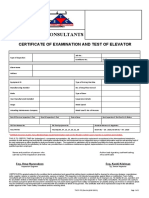

- ElevatorDocument2 pagesElevatorSHARAFUDHEEN TKNo ratings yet

- Stakeholder Analysis Tool: OverviewDocument18 pagesStakeholder Analysis Tool: OverviewLê Tiến HảiNo ratings yet

- Infection Control NurseDocument41 pagesInfection Control NurseChris-Goldie Lorezo100% (1)

- Flight Simulation Training Device (FSTD) Desktop Evaluation ChecklistDocument5 pagesFlight Simulation Training Device (FSTD) Desktop Evaluation ChecklistAshenafi ChernetNo ratings yet

- 3.hot Water GeneratorDocument3 pages3.hot Water GeneratorSHARAFUDHEEN TKNo ratings yet

- Canteen - Risk AssessmentDocument8 pagesCanteen - Risk Assessmentjoshisunil2No ratings yet

- Bumper CarDocument2 pagesBumper CarSHARAFUDHEEN TKNo ratings yet

- Window CradleDocument2 pagesWindow CradleSHARAFUDHEEN TKNo ratings yet

- Rope Adjustment Device (Back - Up)Document2 pagesRope Adjustment Device (Back - Up)SHARAFUDHEEN TKNo ratings yet

- Chain BlockDocument2 pagesChain BlockSHARAFUDHEEN TKNo ratings yet

- Lifting GearDocument2 pagesLifting GearSHARAFUDHEEN TKNo ratings yet

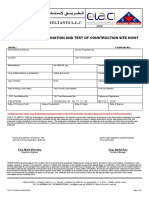

- Construction Site HoistDocument2 pagesConstruction Site HoistSHARAFUDHEEN TKNo ratings yet

- Vehicle LiftDocument2 pagesVehicle LiftSHARAFUDHEEN TKNo ratings yet

- 10.engine GeneratorDocument2 pages10.engine GeneratorSHARAFUDHEEN TKNo ratings yet

- Rope Clamp (Hand Ascender)Document2 pagesRope Clamp (Hand Ascender)SHARAFUDHEEN TKNo ratings yet

- BM-OHSE-SWMS-035-Pile Hacking WorksDocument11 pagesBM-OHSE-SWMS-035-Pile Hacking WorksyanasakaranNo ratings yet

- Rope Clamp (Chest Ascender)Document2 pagesRope Clamp (Chest Ascender)SHARAFUDHEEN TKNo ratings yet

- Top 03-2-504aDocument41 pagesTop 03-2-504agabrielkempeneersNo ratings yet

- ELEVATOR ConstructionDocument2 pagesELEVATOR ConstructionSHARAFUDHEEN TKNo ratings yet

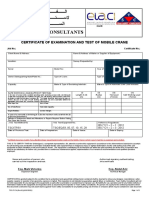

- Mobile CraneDocument2 pagesMobile CraneSHARAFUDHEEN TKNo ratings yet

- Sit Harnesses (Work Seat)Document2 pagesSit Harnesses (Work Seat)SHARAFUDHEEN TKNo ratings yet

- 4.lorry LoaderDocument3 pages4.lorry LoaderSHARAFUDHEEN TKNo ratings yet

- 10.engine GeneratorDocument2 pages10.engine GeneratorSHARAFUDHEEN TKNo ratings yet

- Concrete PumpsDocument2 pagesConcrete PumpsSHARAFUDHEEN TKNo ratings yet

- Back - Up LanyardDocument2 pagesBack - Up LanyardSHARAFUDHEEN TKNo ratings yet

- Aplication For Airworthiness Certificate RevisiDocument5 pagesAplication For Airworthiness Certificate RevisiGranita pru24No ratings yet

- Construction Site HoistDocument2 pagesConstruction Site HoistSHARAFUDHEEN TKNo ratings yet

- QP 06.03-10 Livret D'experienceDocument81 pagesQP 06.03-10 Livret D'experienceSoufiane MoussadeqNo ratings yet

- Lifting GearDocument2 pagesLifting GearSHARAFUDHEEN TKNo ratings yet

- Ofis 23059 Qa Pro NDT 00 05 Procedure For Ultrasonic ExaminationDocument39 pagesOfis 23059 Qa Pro NDT 00 05 Procedure For Ultrasonic ExaminationanandNo ratings yet

- HelmetDocument2 pagesHelmetSHARAFUDHEEN TKNo ratings yet

- Calibration Certificate - Cum-Report: FORM-04.TSD, Version 1.0Document1 pageCalibration Certificate - Cum-Report: FORM-04.TSD, Version 1.0Ashutosh NarayanNo ratings yet

- RUNOUTDocument1 pageRUNOUTvishal.bdyNo ratings yet

- JS03 Human Resource Checklist Pesronal Records ExampleDocument3 pagesJS03 Human Resource Checklist Pesronal Records ExampleStefaniaNo ratings yet

- Vendor Front Sheet: Sao Vang and Dai Nguyet Development ProjectDocument7 pagesVendor Front Sheet: Sao Vang and Dai Nguyet Development ProjectjfdlksaNo ratings yet

- Wire Rope Slings-Report UpdatedDocument2 pagesWire Rope Slings-Report UpdatedAkhilNo ratings yet

- Quallity AssuranceDocument20 pagesQuallity AssuranceST-bluesNo ratings yet

- Hooks-Report UpdatedDocument2 pagesHooks-Report UpdatedAkhilNo ratings yet

- Pressure VesselDocument2 pagesPressure VesselSHARAFUDHEEN TKNo ratings yet

- Form GMF Q-343A R3 Oral Assessment Guide For Aircraft Certifying StaffDocument6 pagesForm GMF Q-343A R3 Oral Assessment Guide For Aircraft Certifying StaffRenaldo Dwianto FbsNo ratings yet

- Api 1Document19 pagesApi 1Siddheshwarr JabagoudarNo ratings yet

- Vehicle LiftDocument2 pagesVehicle LiftSHARAFUDHEEN TKNo ratings yet

- New R5 Inspection Report - 03.03.2021Document4 pagesNew R5 Inspection Report - 03.03.2021mithalesh kumarNo ratings yet

- Upvc Project ReportDocument39 pagesUpvc Project ReportRohit KumarNo ratings yet

- 0 EASA Type Certificate For The Pipistrel SW121 Dated 18.04.2016.Document4 pages0 EASA Type Certificate For The Pipistrel SW121 Dated 18.04.2016.rpanagNo ratings yet

- 23-1 ShackleDocument2 pages23-1 ShackleAkhilNo ratings yet

- Chainblock-Terminal 1Document11 pagesChainblock-Terminal 1YasirNo ratings yet

- Abj 89 103778 Ba 6070 00024 0000 01Document16 pagesAbj 89 103778 Ba 6070 00024 0000 01Nithin GNo ratings yet

- Satr A 2006Document8 pagesSatr A 2006Shahzad HussainNo ratings yet

- GRG-WP-IMS-005 Derating of Cranes Dump Truck (Updated)Document5 pagesGRG-WP-IMS-005 Derating of Cranes Dump Truck (Updated)Hamza NoumanNo ratings yet

- CFC2023 2398 ML 1Document2 pagesCFC2023 2398 ML 1chandra332No ratings yet

- 4.lorry LoaderDocument3 pages4.lorry LoaderSHARAFUDHEEN TKNo ratings yet

- F 01 01 02 A FORM PENDAFTARAN Rev 28-20 TRAINING IKBAL IKBAL-M-YOSDocument2 pagesF 01 01 02 A FORM PENDAFTARAN Rev 28-20 TRAINING IKBAL IKBAL-M-YOSjerrysibaoadiNo ratings yet

- CHECKLIST - FORK LIFT UpdatedDocument4 pagesCHECKLIST - FORK LIFT UpdatedAkhilNo ratings yet

- S Ocialist Republic of Vietnam: Aviation Maintenance TechnicianDocument2 pagesS Ocialist Republic of Vietnam: Aviation Maintenance TechnicianLê Tiến HảiNo ratings yet

- Qa-F002 Application FormDocument1 pageQa-F002 Application FormLê Tiến HảiNo ratings yet

- Sms Gap Analysis Checklist and Implementation PlanDocument11 pagesSms Gap Analysis Checklist and Implementation PlanLê Tiến HảiNo ratings yet

- Risk Profile Assessment Template May2020Document28 pagesRisk Profile Assessment Template May2020Lê Tiến HảiNo ratings yet

- Coping With Bullying in The Workplace: The Effect of Gender, Age and Type of BullyingDocument16 pagesCoping With Bullying in The Workplace: The Effect of Gender, Age and Type of BullyingExamination CVSNo ratings yet

- Lesson PlanDocument45 pagesLesson PlanHarman GillNo ratings yet

- Lab Man Module 2 MidtermsDocument37 pagesLab Man Module 2 MidtermsAnne LaydaNo ratings yet

- Sociology in Our Times 9th Edition Diana Test BankDocument27 pagesSociology in Our Times 9th Edition Diana Test Bankjudithwardmrasictbjg100% (14)

- Taub - Nonunion of Mandibular MidlineDocument4 pagesTaub - Nonunion of Mandibular MidlineChristopher McMullinNo ratings yet

- Chen 2021Document13 pagesChen 2021Aitor UzkudunNo ratings yet

- Case Study of Ptsd..Document3 pagesCase Study of Ptsd..Crislyn DaepNo ratings yet

- Biomedical Waste Management & Handling) Rules, 1998Document28 pagesBiomedical Waste Management & Handling) Rules, 1998yash ajay kashidNo ratings yet

- ResumeDocument3 pagesResumeSuratmi UnnesNo ratings yet

- Food and Kitchen Hygiene Paprint Angeline1Document6 pagesFood and Kitchen Hygiene Paprint Angeline1Dang CabaticNo ratings yet

- Chapter 2 Organizational BehaviorDocument19 pagesChapter 2 Organizational Behaviorumair tariqNo ratings yet

- Y30stFZqSLY4yArZa3Ig - The Bison Brain Issue 1 Spring 2023Document10 pagesY30stFZqSLY4yArZa3Ig - The Bison Brain Issue 1 Spring 2023MED HAUSNo ratings yet

- Book Review Fresh Fruit Broken Bodies MiDocument6 pagesBook Review Fresh Fruit Broken Bodies MiRaseduzzaman RumanNo ratings yet

- BP Bartran HV 15Document10 pagesBP Bartran HV 15meldesastreNo ratings yet

- Group 2 Locsin OrlandoDocument5 pagesGroup 2 Locsin OrlandoBrent Ederson AmadoNo ratings yet

- Hartman Training CourseDocument18 pagesHartman Training CourseJuan Pablo Cortes CallejasNo ratings yet

- INSTITUTE - University School of Business DEPARTMENT - Management M.B.ADocument26 pagesINSTITUTE - University School of Business DEPARTMENT - Management M.B.ADr. Gagandeep KaurNo ratings yet

- PE 1 Chapter 1 ModuleDocument34 pagesPE 1 Chapter 1 ModuleMarc BorcilloNo ratings yet

- UntitledDocument75 pagesUntitledMelissa DrakeNo ratings yet

- Jurnal Adyas, Dika & Karbito (2019)Document11 pagesJurnal Adyas, Dika & Karbito (2019)andraNo ratings yet

- Application of Acceleration Behavioral TherapyDocument2 pagesApplication of Acceleration Behavioral TherapyCaitlin PeñeraNo ratings yet

- Sleep Disturbance: Esraa Albaqqal 371230183 Banin Alshehab 381230590 Yaqin Alkhalaf 391230503 Ahoud Alzaid 391230645Document14 pagesSleep Disturbance: Esraa Albaqqal 371230183 Banin Alshehab 381230590 Yaqin Alkhalaf 391230503 Ahoud Alzaid 391230645Banin malekNo ratings yet

- A Systematic Review and Meta Analysis of The Attachments Used in Implant Supported OverdenturesDocument14 pagesA Systematic Review and Meta Analysis of The Attachments Used in Implant Supported OverdenturesDr FarhatNo ratings yet

- Philippine Infectious Control Nurse AssociationDocument3 pagesPhilippine Infectious Control Nurse AssociationFerdinand Natividad0% (1)

- Physical Fitness Test Score Card SKILL RELATED FITDocument1 pagePhysical Fitness Test Score Card SKILL RELATED FITPaulo Victor SazonNo ratings yet

- Skeleton Keys Online Syllabus F19 - FinlaysonDocument10 pagesSkeleton Keys Online Syllabus F19 - FinlaysonirenefebriwantyangeliaNo ratings yet

- Production Engineering Lab IDocument24 pagesProduction Engineering Lab IKiran FiatthNo ratings yet