Professional Documents

Culture Documents

Series 2000 - Magnahelic Differential Pressure Gauge

Uploaded by

Koteswara RaoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Series 2000 - Magnahelic Differential Pressure Gauge

Uploaded by

Koteswara RaoCopyright:

Available Formats

PRESSURE

MAGNEHELIC® DIFFERENTIAL PRESSURE GAGES

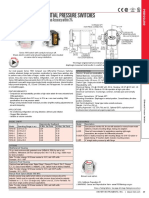

Indicate Positive, Negative or Differential, Accurate within 2% RUBBER PRESSURE RELIEF PLUG

WILL UNSEAT ITSELF WHEN GAGE

IS OVERPRESSURIZED

[3] 6-32 X 3/16 [4.76] DEEP

HOLES EQUALLY SPACED ON

.025 [.64] SPACE CREATED BY 3 SPACER A Ø4-1/8 [104.78] BOLT CIRCLE

PADS WHEN SURFACE MOUNTED. FOR PANEL MOUNTING

DO NOT OBSTRUCT. PROVIDES PATH 17/32

FOR RELIEF OF OVERPRESSURE. [13.49] 1/8 FEMALE NPT

1/8 FEMALE HIGH PRESSURE

NPT HIGH CONNECTION

PRESSURE 1-3/4

1-1/4 [31.75] CONNECTION [44.45]

Ø4-1/2 1/8 FEMALE

[114.3] NPT LOW

PRESSURE 1/2

CONNECTION [12.70]

Ø4-3/4 15/32 [11.91]

[120.65] 1/8 FEMALE NPT LOW

1-11/16 [42.86] 7/16 [11.11] 11/16

[17.46] PRESSURE CONNECTION

17/32

[13.49] ø4-3/4 [120.65] 1/8 FEMALE NPT

1-1/4 PANEL CUTOUT HIGH PRESSURE

[31.75] CONNECTION

ø5

[127] 1-3/4

ø4-47/64 [44.45]

ø4-1/2 [120.27]

[114.3] 1/2

[12.70]

ø5-1/2 15/32 11/16 1/8 FEMALE

Scan here NPT LOW

to watch [139.70] [11.91] 2-17/32 3/16 [17.46]

MOUNTING RING [64.29] [4.76] PRESSURE

product video CONNECTION

Select the SERIES 2000 Magnehelic® Gage for high accuracy--guaranteed within SPECIFICATIONS

2% of full scale--and for the wide choice of 81 models available to suit your needs Service: Air and non-combustible, Size: 4˝ (101.6 mm) diameter dial face.

precisely. Using Dwyer’s simple, frictionless Magnehelic® gage movement, it quickly compatible gases (natural gas option Mounting Orientation: Diaphragm in

indicates low air or non-corrosive gas pressures--either positive, negative (vacuum) or available). Note: May be used with vertical position. Consult factory for other

differential. The design resists shock, vibration and over-pressures. hydrogen. Order a Buna-N diaphragm. position orientations.

Pressures must be less than 35 psi. Process Connections: 1/8˝ female NPT

FEATURES/BENEFITS Wetted Materials: Consult factory. duplicate high and low pressure taps -

• Easy to read gage through undistorted plastic face permits viewing from far away Housing: Die cast aluminum case and one pair side and one pair back.

• Patented design provides quick response to pressure changes means no delay in bezel, with acrylic cover. Exterior finish Weight: 1 lb 2 oz (510 g), MP & HP 2 lb

Differential Pressure Gages

assessing critical situations is coated gray to withstand 168 hour salt 2 oz (963 g).

• Durable and rugged housing and high-quality components combine to provide long- spray corrosion test. Standard Accessories: Two 1/8˝ NPT

service life and minimized down-time Accuracy: ±2% of FS (±3% on -0, plugs for duplicate pressure taps, two

-100PA, -125PA, -10MM and ±4% on 1/8˝ pipe thread to rubber tubing adapter,

APPLICATIONS -00, -60PA, -6MM ranges), throughout and three flush mounting adapters with

• Filter monitoring range at 70°F (21.1°C). screws. (Mounting and snap ring retainer

• Air velocity with Dwyer pitot tube Pressure Limits: -20 in Hg to 15 psig† substituted for three adapters in MP &

• Blower vacuum monitoring (-0.677 to 1.034 bar); MP option: 35 psig HP gage accessories.)

• Fan pressure indication (2.41 bar); HP option: 80 psig (5.52 bar). Agency Approvals: Meets the technical

• Duct, room or building pressures Overpressure: Relief plug opens requirements of EU Directive 2011/65/EU

• Clean room positive pressure indication at approximately 25 psig (1.72 bar), (RoHS II). Note: -SP models not RoHS

standard gages only.u approved.

Temperature Limits: 20 to 140°F*

(-6.67 to 60°C). -20°F (-28°C) with low

temperature option.

Note: For applications with high cycle rate within gage total pressure rating, next

higher rating is recommended. See Medium and High pressure options.

*Low temperature models available as special options.

ACCESSORIES

Model Description

A-432 Portable kit; combine carrying case with any Magnehelic®

gage of standard range, except high pressure connection.

Includes 9 ft (2.7 m) of 3/16˝ ID rubber tubing, standhang

bracket and terminal tube with holder

A-605 Air filter gage accessory kit; adapts any standard

Magnehelic® gage for use as an air filter gage. Includes

aluminum surface mounting bracket with screws, two 5 ft (1.5

m) lengths of 1/4˝ aluminum tubing, two static pressure tips

and two molded plastic vent valves, integral compression

fittings on both tips and valves

A-605B Air filter gage accessory kit; air filter kit with two plastic A-432 A-605

open/close valves, two 4˝ steel static tips, plastic tubing and

mounting flange

A-605C Air filter gage accessory kit; air filter kit with two plastic

open/close valves, two plastic static tips, plastic tubing and

mounting flange

uOver Protection Note: See page 5 (Series 2000)

4 DWYER INSTRUMENTS, INC. | www.dwyer-inst.com

PRESSURE

®

MAGNEHELIC® DIFFERENTIAL PRESSURE GAGES

Indicate Positive, Negative or Differential, Accurate within 2%

Bezel provides flange for flush mounting in panel. O-ring seal for cover assures pressure integrity of case.

Clear plastic face is highly resistant to breakage. Provides OVERPRESSURE PROTECTION

undistorted viewing of pointer and scale. Blowout plug is comprised of a rubber plug on the rear

which functions as a relief valve by unseating and venting

Precision litho-printed scale is accurate and easy to read. the gage interior when over pressure reaches approximately

25 psig (1.7 bar). To provide a free path for pressure relief,

Calibrated range spring is flat spring steel. Small there are four spacer pads which maintain 0.023˝ clearance

amplitude of motion assures consistency and long life. It when gage is surface mounted. Do not obstruct the gap

reacts to pressure on diaphragm. Live length adjustable for created by these pads.

calibration. The blowout plug is not used on models above 180˝ of

water pressure, medium or high pressure models, or on

Red tipped pointer of heat treated aluminum tubing is easy gages which require an elastomer other than silicone for the

to see. It is rigidly mounted on the helix shaft. diaphragm.

The blowout plug should not be used as a system

Pointer stops of molded rubber prevent pointer over-travel overpressure control. High supply pressures may still

without damage. cause the gage to fail due to over pressurization, resulting

in property damage or serious injury. Good engineering

“Wishbone” assembly provides mounting for helix, helix practices should be utilized to prevent your system from

bearings and pointer shaft. exceeding the ratings of any component.

Jeweled bearings are shock-resistant mounted; provide Die cast aluminum case is precision made and iridite-

virtually friction-free motion for helix. Motion damped with dipped to withstand 168 hour salt spray corrosion test.

high viscosity silicone fluid. Exterior finished in baked dark gray hammerloid. One case

size is used for all standard pressure options, and for both

Helix is precision made from an alloy of high magnetic surface and flush mounting.

permeability. Mounted in jeweled bearings, it turns freely,

following the magnetic field to move the pointer across Silicone rubber diaphragm with integrally molded O-ring

the scale. is supported by front and rear plates. It is locked and

sealed in position with a sealing plate and retaining ring.

Zero adjustment screw is conveniently located in the Diaphragm motion is restricted to prevent damage due to

plastic cover, and is accessible without removing cover. overpressures.

O-ring seal provides pressure tightness.

Samarium Cobalt magnet mounted at one end of range

spring rotates helix without mechanical linkages.

MODEL CHART

Range, Range, Range, MM Range, Dual Scale Air Velocity Units

Model Inches of Water Model PSI Model of Water Model kPa For use with pitot tube

2000-00N†•• .05-0-.2 2201 0-1 2000-6MM†•• 0-6 2000-0.5KPA 0-0.5 Range,

2000-00†•• 0-.25 2202 0-2 2000-10MM†• 0-10 2000-1KPA 0-1 in w.c./

Differential Pressure Gages

2000-0†• 0-.50 2203 0-3 2000-15MM 0-15 2000-1.5KPA 0-1.5 Velocity

2001 0-1.0 2204 0-4 2000-25MM 0-25 2000-2KPA 0-2 Model F.P.M.

2002 0-2.0 2205 0-5 2000-30MM 0-30 2000-2.5KPA 0-2.5 2000-00AV†•• 0-.25/

2003 0-3.0 2210* 0-10 2000-50MM 0-50 2000-3KPA 0-3 300-2000

2004 0-4.0 2215* 0-15 2000-80MM 0-80 2000-4KPA 0-4 2000-0AV†• 0-.50/

2005 0-5.0 2220* 0-20 2000-100MM 0-100 2000-5KPA 0-5 500-2800

2006 0-6.0 2230** 0-30 2000-125MM 0-125 2000-8KPA 0-8 2001AV 0-1.0/

2008 0-8.0 Range, 2000-150MM 0-150 2000-10KPA 0-10 500-4000

2010 0-10 CM of 2000-200MM 0-200 2000-15KPA 0-15 2002AV 0-2.0/

2012 0-12 Model Water 2000-250MM 0-250 2000-20KPA 0-20 1000-5600

2015 0-15 2000-300MM 0-300 2000-25KPA 0-25 2005AV 0-5.0/

2020 0-20 2000-15CM 0-15 2000-30KPA 0-30

2000-20CM 0-20 Zero Center Ranges 2000-8800

2025 0-25 2300-6MM†•• 3-0-3 2010AV 0-10/

2030 0-30 2000-25CM 0-25 Zero Center Ranges

2000-50CM 0-50 2300-10MM†• 5-0-5 2000-12500

2040 0-40 2300-20MM†• 10-0-10 2300-1KPA .5-0-.5

2050 0-50 2000-80CM 0-80 2300-2KPA 1-0-1

2000-100CM 0-100 Model Range, Pa 2300-2.5KPA 1.25-0-1.25

2060 0-60

2080 0-80 2000-150CM 0-150 2000-60NPA†•• 10-0-50 2300-3KPA 1.5-0-1.5

2100 0-100 2000-200CM 0-200 2000-60PA†•• 0-60 Dual Scale English/Metric Models

2120 0-120 2000-250CM 0-250 2000-100PA†• 0-100

2000-300CM 0-300 2000-125PA†• 0-125 Range, Range,

2150 0-150 Model in w.c. Pa or kPa

2160 0-160 2000-250PA 0-250

Zero Center Ranges 2000-300PA 0-300 2000-00D†•• 0-.25 0-62 Pa

2180* 0-180 2300-4CM 2-0-2 2000-0D†• 0-0.5 0-125 Pa

2250* 0-250 2000-500PA 0-500

2300-10CM 5-0-5 2000-750PA 0-750 2001D 0-1.0 0-250 Pa

Zero Center Ranges 2300-30CM 15-0-15 2000-1000PA 0-1000 2002D 0-2.0 0-500 Pa

2003D 0-3.0 0-750 Pa

2300-00†•• 0.125-0-0.125 Zero Center Ranges 2004D 0-4.0 0-1.0 kPa

2300-0†• .25-0-.25 Model Range, Pa 2005D 0-5.0 0-1.25 kPa

2301 .5-0-.5 2300-60PA†•• 30-0-30 2006D 0-6.0 0-1.5 kPa

2302 1-0-1 2300-100PA†• 50-0-50 2008D 0-8.0 0-2.0 kPa

2304 2-0-2 2300-120PA 60-0-60 2010D 0-10 0-2.5 kPa

2310 5-0-5 2300-200PA 100-0-100 2015D 0-15 0-3.7 kPa

2320 10-0-10 2300-250PA 125-0-125 2020D 0-20 0-5 kPa

2330 15-0-15 2300-300PA 150-0-150 2025D 0-25 0-6.2 kPa

2300-500PA 250-0-250 2050D 0-50 0-12.4 kPa

2300-1000PA 500-0-500 2060D 0-60 0-15 kPa

†These ranges calibrated for vertical scale position • Accuracy ±3% •• Accuracy ±4% *MP option standard **HP option standard

VELOCITY AND VOLUMETRIC FLOW UNITS ACCESSORIES

Scales are available on the Magnehelic ® that

read in velocity units (FPM, m/s) or volumetric Model Description

flow units (SCFM, m3/s, m3/h). Stocked velocity A-321 Safety relief valve

units with dual range scales in inches w.c. and A-448 3-piece magnet kit for mounting Magnehelic® gage directly to magnetic surface

feet per minute are shown above. For other A-135 Rubber gasket for panel mounting

ranges contact the factory. A-401 Plastic carry case

When ordering volumetric flow scales please A-310A 3-way vent valves. In applications where pressure is continuous and the

specify the maximum flow rate and its Magnehelic® gage is connected by metal or plastic tubing which cannot be easily

corresponding pressure. removed, we suggest using Dwyer A-310A vent valves to connect gage. Pressure

Example: 0.5 in w.c. = 16,000 CFM. can then be removed to check or re-zero the gage. A-310A

CONTACT US | U.S. 219/879-8000 | U.K. (+44) (0)1494-461707 | A.U. (+61) (0) 2 4272 2055 | China +852-23181007 5

You might also like

- Magnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 1%Document4 pagesMagnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 1%RyanNo ratings yet

- Magnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 1%Document4 pagesMagnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 1%Johan VBNo ratings yet

- Magnehelic Differential Pressure Gages: SolutionsDocument2 pagesMagnehelic Differential Pressure Gages: Solutionsdaniel GasperinNo ratings yet

- Dwyer 2000Document4 pagesDwyer 2000Saravana KumarNo ratings yet

- Dwyer 2300 250pa Pressure Gauge DatasheetDocument2 pagesDwyer 2300 250pa Pressure Gauge DatasheetGorch Marroko100% (1)

- 004 005 D PDFDocument2 pages004 005 D PDFRangga Prasetya BaitullahNo ratings yet

- Serie 2000Document2 pagesSerie 2000Fredy MurilloNo ratings yet

- MAGNEHELICDocument2 pagesMAGNEHELICCésar Arturo TorresNo ratings yet

- Magnehelic-Gage Series 2000Document2 pagesMagnehelic-Gage Series 2000Jonathan GanNo ratings yet

- Purafil Side Access BulletinDocument5 pagesPurafil Side Access BulletinPablo TorresNo ratings yet

- Digihelic 3 Differential Pressure Controllers: Digihelic Controller in Photohelic Gage, Square Root Output For FlowDocument1 pageDigihelic 3 Differential Pressure Controllers: Digihelic Controller in Photohelic Gage, Square Root Output For FlowAdriana Zarahi Velez HernandezNo ratings yet

- Dwyer Instruments Magnehelic Pressure Gauge Mounting DimensionsDocument1 pageDwyer Instruments Magnehelic Pressure Gauge Mounting DimensionsCésar Arturo TorresNo ratings yet

- Dwyer B - 30Document20 pagesDwyer B - 30Alex MeadowsNo ratings yet

- Magnehelic Series 2000 - CatDocument2 pagesMagnehelic Series 2000 - CatFerdian AriestaNo ratings yet

- Series 605 Magnehelic Differential Pressure Indicating Transmitter Specifications - Installation and Operating InstructionsDocument4 pagesSeries 605 Magnehelic Differential Pressure Indicating Transmitter Specifications - Installation and Operating InstructionsAlberto Angel Mora ZavalaNo ratings yet

- Magnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 2%Document2 pagesMagnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 2%SlametKhoerudinNo ratings yet

- 1910 00 ManualDocument4 pages1910 00 ManualRusty AllenNo ratings yet

- Explosion-Proof Differential Pressure SwitchDocument1 pageExplosion-Proof Differential Pressure SwitchTadau EnergyNo ratings yet

- DA-DS CatDocument2 pagesDA-DS Catsorin sorinNo ratings yet

- Series 605 Magnehelic Differential Pressure Indicating Transmitter Specifications - Installation and Operating InstructionsDocument4 pagesSeries 605 Magnehelic Differential Pressure Indicating Transmitter Specifications - Installation and Operating InstructionsKrissthian EspitiaNo ratings yet

- Continuous Level Transmitter: Customize To Fit Application, 316 SS or Buna-N FloatsDocument1 pageContinuous Level Transmitter: Customize To Fit Application, 316 SS or Buna-N FloatsMohamed HammamNo ratings yet

- Series DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsDocument2 pagesSeries DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsJuan Carlos Chara VelazcoNo ratings yet

- Photohelic Pressure Switch/Gages: 3-In-One Indicating Gage, Lo-Limit and Hi-Limit ControlDocument2 pagesPhotohelic Pressure Switch/Gages: 3-In-One Indicating Gage, Lo-Limit and Hi-Limit ControlAnonymous u0wETydFNo ratings yet

- Differential Pressure Transmitter: NEMA 4X Enclosure, 0.25% FS AccuracyDocument1 pageDifferential Pressure Transmitter: NEMA 4X Enclosure, 0.25% FS AccuracyDanielle YepezNo ratings yet

- Manometro Presion Diferencial PDFDocument1 pageManometro Presion Diferencial PDFCharlie MartinezNo ratings yet

- 616kd-11-datasheetDocument1 page616kd-11-datasheetramalho12andyNo ratings yet

- Dweyer Pressure SwitchDocument1 pageDweyer Pressure SwitchMuhamad PriyatnaNo ratings yet

- Series DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsDocument2 pagesSeries DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsJorge Renato Chirinos QuiñonezNo ratings yet

- Photo Helic Ps PDFDocument4 pagesPhoto Helic Ps PDFSoumen PaulNo ratings yet

- DWYER_1630-PRESOSTATO SWITCHDocument2 pagesDWYER_1630-PRESOSTATO SWITCHomorales.cyvsaNo ratings yet

- CO Component Description: Discharge DelaysDocument1 pageCO Component Description: Discharge DelayskiuNo ratings yet

- Anemometro Dwyer VT-200Document1 pageAnemometro Dwyer VT-200Israel Hernandez GomezNo ratings yet

- Differential Pressure Transmitter: Same Size As Standard Magnehelic Differential Pressure GageDocument1 pageDifferential Pressure Transmitter: Same Size As Standard Magnehelic Differential Pressure GageJose Antonio Yupa MedinaNo ratings yet

- Duct Insertion Temperature Sensor - BTT-D-04 1 - DwyerDocument1 pageDuct Insertion Temperature Sensor - BTT-D-04 1 - DwyerSigit KuncoroNo ratings yet

- Transmisor Presion Diferencial dm-2007-lcdDocument2 pagesTransmisor Presion Diferencial dm-2007-lcdhanshr87No ratings yet

- Electronic Pressure Controller: 2 Switches, Indicating Gauge, and Transmitter in One PackageDocument1 pageElectronic Pressure Controller: 2 Switches, Indicating Gauge, and Transmitter in One Packageluat1983No ratings yet

- As Sea20007e Ew 121 128 B As Ew 129Document1 pageAs Sea20007e Ew 121 128 B As Ew 129Juan RuizNo ratings yet

- Dwyer 4000 SeriesDocument1 pageDwyer 4000 SeriesMuh RenandaNo ratings yet

- Series 647 Wet/Wet Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsDocument2 pagesSeries 647 Wet/Wet Differential Pressure Transmitter: Specifications - Installation and Operating Instructionsindra_onevisionNo ratings yet

- Interruptor de FlujoDocument1 pageInterruptor de FlujoCarlos RojasNo ratings yet

- BTT-D081 Sensor Temperatura Ducto ManualDocument2 pagesBTT-D081 Sensor Temperatura Ducto ManualgerardoNo ratings yet

- Diaphragm Seal For DA Series Pressure Switch: PVC and FEP Construction For Corrosive ApplicationsDocument1 pageDiaphragm Seal For DA Series Pressure Switch: PVC and FEP Construction For Corrosive Applicationsluat1983No ratings yet

- Dwyer MagnehelicmanualDocument2 pagesDwyer MagnehelicmanualAndres GonzalesNo ratings yet

- P.O. Box 373 - Michigan City, in 46360, U.S.ADocument20 pagesP.O. Box 373 - Michigan City, in 46360, U.S.Acoolguy19895No ratings yet

- Magnehelic Differential Pressure Gage: Bulletin A-27Document2 pagesMagnehelic Differential Pressure Gage: Bulletin A-27Marco Antonio Rivera DoteroNo ratings yet

- Dwyer MSX - I PressureDocument1 pageDwyer MSX - I Pressureminh hoang DoanNo ratings yet

- Compact Low Differential Pressure Switches: Set Points From 0.07 To 20 in W.C. Repetitive Accuracy Within 3%Document1 pageCompact Low Differential Pressure Switches: Set Points From 0.07 To 20 in W.C. Repetitive Accuracy Within 3%ANGEL FLORESNo ratings yet

- 3-In-1 Differential Pressure ControllerDocument1 page3-In-1 Differential Pressure ControllerHector J. VegaNo ratings yet

- Dwyer-1910-1-Product OverviewDocument1 pageDwyer-1910-1-Product OverviewRusty AllenNo ratings yet

- WX Approval DrawingDocument18 pagesWX Approval DrawingcadamaoNo ratings yet

- Wet/Wet Differential Pressure Transmitter: Series 629CDocument2 pagesWet/Wet Differential Pressure Transmitter: Series 629CElmer Ramón Murillo MejiaNo ratings yet

- Humidity/Temperature Transmitter: Passive Temperature Outputs, Sintered Filter OptionsDocument1 pageHumidity/Temperature Transmitter: Passive Temperature Outputs, Sintered Filter OptionsMinh Nhut LuuNo ratings yet

- 23 Ridge-Hip (Floating) DetailDocument1 page23 Ridge-Hip (Floating) DetailAhmed Saber NassarNo ratings yet

- Optional parts and joints for Mitsubishi air conditioning piping systemsDocument1 pageOptional parts and joints for Mitsubishi air conditioning piping systemsJune Mark InsagNo ratings yet

- 3/4" MANUAL AIR VENT 16" Ø MANWAY 3Document1 page3/4" MANUAL AIR VENT 16" Ø MANWAY 3alquiler pisosNo ratings yet

- 24VDC Solenoid Regulator DrawingDocument1 page24VDC Solenoid Regulator Drawingnuraida hakikiNo ratings yet

- Certified: 3/23/2021 Garrett BinnsDocument1 pageCertified: 3/23/2021 Garrett Binnsjose luis rios guerraNo ratings yet

- Series 616W Differential Pressure Transmitter Specifications - Installation and Operating InstructionsDocument4 pagesSeries 616W Differential Pressure Transmitter Specifications - Installation and Operating InstructionsErwin Gonzalez MedinaNo ratings yet

- OctDocument7 pagesOctKoteswara RaoNo ratings yet

- Axial Fans CataDocument2 pagesAxial Fans CataKoteswara RaoNo ratings yet

- SafariDocument1 pageSafariKoteswara RaoNo ratings yet

- 10158676953506001Document2 pages10158676953506001LTHCB ITNo ratings yet

- Fire and Smoke Damper BasicsDocument10 pagesFire and Smoke Damper BasicsRolandNo ratings yet

- HVAC SOLUTIONS GUIDEDocument1 pageHVAC SOLUTIONS GUIDEKoteswara RaoNo ratings yet

- RefrigerationDocument10 pagesRefrigerationKoteswara RaoNo ratings yet

- 6 Bacnet Interface - Easylab: Analog Value ObjectsDocument1 page6 Bacnet Interface - Easylab: Analog Value ObjectsKoteswara RaoNo ratings yet

- HealthandSafetyRiskAssessmentmethodology 11Document21 pagesHealthandSafetyRiskAssessmentmethodology 11Koteswara RaoNo ratings yet

- ConceptofTunnelVentilationSystem RevADocument16 pagesConceptofTunnelVentilationSystem RevACheeragNo ratings yet

- Collection of Laws Regulations and Policies-129Document374 pagesCollection of Laws Regulations and Policies-129Koteswara RaoNo ratings yet

- Additional Units Schedule - NARF: S.No Description Serving Locations Tag No Description Flow rate-CFM ESP (MM of WG) QtyDocument1 pageAdditional Units Schedule - NARF: S.No Description Serving Locations Tag No Description Flow rate-CFM ESP (MM of WG) QtyKoteswara RaoNo ratings yet

- 2 - GLP and Animal Biosafety and Animal Facilities - WanlopDocument148 pages2 - GLP and Animal Biosafety and Animal Facilities - WanlopKoteswara RaoNo ratings yet

- BM Hydraulic Calculation Guide HiRes Interactive PagesDocument7 pagesBM Hydraulic Calculation Guide HiRes Interactive PagesKoteswara RaoNo ratings yet

- Curve Char ADocument3 pagesCurve Char AvantaNo ratings yet

- Ae2253 LPDocument2 pagesAe2253 LPசுஜித் குமார்No ratings yet

- Gel Phantom in Ultrasound DosimetryDocument7 pagesGel Phantom in Ultrasound DosimetrytomgrgicNo ratings yet

- ELC003 Renewable Energy Course NotesDocument231 pagesELC003 Renewable Energy Course Notesravith88100% (1)

- Tugas 5 Weld Metal Solidification & MicrostructureDocument16 pagesTugas 5 Weld Metal Solidification & MicrostructureDeepakNo ratings yet

- Climate of IndiaDocument33 pagesClimate of IndiaNeha Patwa100% (1)

- Pres 123Document31 pagesPres 123PEEYUSH GARGNo ratings yet

- Final TestDocument6 pagesFinal Testapi-254428474No ratings yet

- Pipe Expansion and Support - International Site For Spirax SarcoDocument8 pagesPipe Expansion and Support - International Site For Spirax SarcoSandi ApriandiNo ratings yet

- EDEXCEL JAN 2020 M1 [ QP + MS ]Document40 pagesEDEXCEL JAN 2020 M1 [ QP + MS ]1234567890 UnknownNo ratings yet

- RAEC GRADE 8 PHYSICS MECHANICS 1 WS SPEED VELOCITY ACCELERATIONDocument4 pagesRAEC GRADE 8 PHYSICS MECHANICS 1 WS SPEED VELOCITY ACCELERATIONadmin95No ratings yet

- A 15 CM S B 20 CM S C 30 CM S D 45 CM S: Harshana Perera (B.SC (Phy), BIT, SCJP) Revision 2013 Mechanics Turn OverDocument4 pagesA 15 CM S B 20 CM S C 30 CM S D 45 CM S: Harshana Perera (B.SC (Phy), BIT, SCJP) Revision 2013 Mechanics Turn OverharshanauocNo ratings yet

- hw3 6120Document1 pagehw3 6120YeasminNo ratings yet

- PQ 0802004769Document6 pagesPQ 0802004769alveirohmNo ratings yet

- Applied Chemistry (UCB008) : - Instructor - Dr. Soumen Basu Associate Professor, School of Chemistry and BiochemistryDocument33 pagesApplied Chemistry (UCB008) : - Instructor - Dr. Soumen Basu Associate Professor, School of Chemistry and BiochemistrySukh SindhiNo ratings yet

- Experiment No 2Document5 pagesExperiment No 2saish sakharkarNo ratings yet

- Major equipment failures causing shut-downs in ammonia plantsDocument17 pagesMajor equipment failures causing shut-downs in ammonia plantsrobertionNo ratings yet

- Record of Welder or Welding Operator Qualification TestsDocument1 pageRecord of Welder or Welding Operator Qualification TestsBalkishan DyavanapellyNo ratings yet

- Solution For Tutorial ECH3602Document23 pagesSolution For Tutorial ECH3602Prem KumarNo ratings yet

- Calculating percentage of oxygen in air after evaporating liquid nitrogenDocument2 pagesCalculating percentage of oxygen in air after evaporating liquid nitrogenlutfi awnNo ratings yet

- States of Matter Practice Test: Multiple ChoiceDocument4 pagesStates of Matter Practice Test: Multiple ChoiceL'arc WillNo ratings yet

- WAV151 Wind Vane: Optoelectronic AnemometerDocument4 pagesWAV151 Wind Vane: Optoelectronic AnemometerhurantiaNo ratings yet

- EVAPORATIONDocument11 pagesEVAPORATIONEmmanuel AtakosNo ratings yet

- New Lesson Plan in Physical ScienceDocument146 pagesNew Lesson Plan in Physical ScienceJonhdel Madahan100% (10)

- 2-Convective Mass-Transfer-E7240 PDFDocument49 pages2-Convective Mass-Transfer-E7240 PDFHasieb Alam KhanNo ratings yet

- Embedment of Spiral in ConcreteDocument11 pagesEmbedment of Spiral in ConcreteabadittadesseNo ratings yet

- Waves Exam QDocument24 pagesWaves Exam Qapi-4224287000% (1)

- Parcial Examen Final Quiz Validación Otro XDocument2 pagesParcial Examen Final Quiz Validación Otro XJuan De DiosNo ratings yet

- FLD-FNDMNTLS-FLD-FLWDocument3 pagesFLD-FNDMNTLS-FLD-FLWGerardoNo ratings yet

- 175-022501 Flanges (WN, BL, Forged Steel & As)Document2 pages175-022501 Flanges (WN, BL, Forged Steel & As)ALINo ratings yet

- Adverb PPT CO English 4 1 1Document27 pagesAdverb PPT CO English 4 1 1mizel dotillosNo ratings yet

![EDEXCEL JAN 2020 M1 [ QP + MS ]](https://imgv2-1-f.scribdassets.com/img/document/719807553/149x198/696dcb63b1/1712183779?v=1)