Professional Documents

Culture Documents

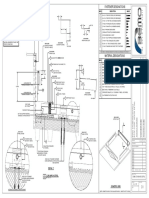

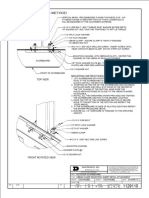

23 Ridge-Hip (Floating) Detail

Uploaded by

Ahmed Saber NassarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

23 Ridge-Hip (Floating) Detail

Uploaded by

Ahmed Saber NassarCopyright:

Available Formats

NOTES:

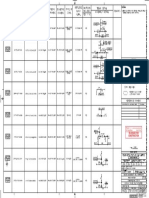

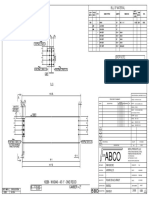

FASTENER DESIGNATIONS

D1

THE SKY'S THE LIMIT

1. SPACING MAY NEED TO BE REDUCED PER REQUIRED WIND MARK DESCRIPTION IMAGE

LOADS; CONSULT MANUFACTURER.

2. FLASHING DIMENSIONS CAN VARY DEPENDING ON

1 #14-10 x 7" DEKFAST SCREW (OR COMPARABLE)

THERMAL MOVEMENT REQUIREMENTS.

3. A = AS REQUIRED FOR THERMAL EXPANSION. B = A + 1/4". 2" 10 1/ 2 #14-10 x 2" DEKFAST SCREW (OR COMPARABLE)

4. ALL FASTENERS MUST PENETRATE 3/4" MIN. THROUGH 10 1/ E) (SEE 2"

2 A BOV NOT

E 3 1/4"-14x 1 1/2" HWH TEK-3 (W/ BONDED WASHER)

SUBSTRATE. OTE 2 AB

(S EE N OVE

) 4 1/4"-20x 3/4" STAINLESS STEEL BOLT ASSEMBLY

5 1/4"-14x 7/8" HWH TEK-1 (W/ BONDED WASHER)

2"

ANGLE 6 #10x 3/4" PANCAKE HEAD SCREW

(SEE NOTE 2 ABOVE)

PER PLANS

7 1/4"Ø BULB-TITE RIVET (W/ BONDED WASHER)

FLOATING 1/2"

RETURN 8 3/16"Ø CLOSED END S.S. RIVET

###-##-#####

2 1/4" RIDGE CAP FLASHING 2 1/4" 9 #14-10x 1" SELF-TAPPING (W/ BONDED WASHER)

10 1/4"-14X 1" TEK-3 STAINLESS STEEL SCREW*

3" MIN. 3/8" O/O

11 #12-14x 1 1/2" TEK-3 STAINLESS STEEL SCREW*

3/8" AT 45°

SEE NOTE 2 ABOVE SEE NOTE 2 ABOVE 12 1/4"-14x 3" PANCAKE HEAD 316SS TYPE "B" FASTENER

###-##-#####

PEAK FLASHING CLEAT O/P HEM O/P HEM

* (1000 HRS OF CORROSION RESISTANT COATING IN ACCORDANCE WITH ASTM B117)

EXP.

RETURN MATERIAL DESIGNATIONS

MARK DESCRIPTION

3/8" I/I

7 PER PROJECT CALCS.

3/8" AT 45°

(SEE NOTE 1 ABOVE) 1 BEMO HOOK CLIP W/ GALV. BASE

2 1/4"

O/P HEM 2 BEMO FIXED HOOK CLIP

(SEE NOTE 2 ABOVE)

3 BEMO GABLE HALTER CLIP (30" O.C. MAX.)

###-##-#####

4 BEMO METAL/FOAM PROFILE CLOSURE

FLOATING FLASH RIDGE CAP FLASHING

5 KEYHOLE CLOSURE

10 1/

(SEE 2" 6 EXPANDING FOAM TAPE (18 L.F. ROLLS)

(2) AT EACH RIB (1) AT CENTER 5 NOT

E 2 AB "GRIP-STRUT" WALKWAY PLANK, 11 7/8" W x 12'-0" LG (2 PLANK WALKWAY)

OF CLOSURE (BEYOND) OVE 7

)

###-##-##### 8 BEMO 300-H OR 300-V STAINLESS STEEL UTILITY CLAMP

45° BETWEEN CLEAT & 11 CONTINUOUS RIDGE

CLOSURE (TYP) 9 1/8"x 1" WIDE SEALING TAPE (65 L.F. ROLLS) - (BY OTHERS)

3/8" SUPPORTS (20GA. MIN.)

10 BEMO "40 MIL HT MEMBRANE" (3'x 65' ROLLS)

B

BETWEEN PANEL RIBS; 4 11 "APPROVED" SEALANT (15 L.F. COVERAGE - TUBES) - (BY OTHERS)

EXPANSION RETURN A

SET ON TAPE

12 4"x 6" BEARING PLATE (AT EACH CLIP)

###-##-#####

A

RIDGE CAP CLEAT

RIDGE/HIP (FLOATING) DETAIL

BEMO ROOF

PANEL SYSTEM

BEMO STANDARD DETAILS

###-##-#####

RIDGE CAP FLASH

PER PROJECT 1

CALCS. ###-##-#####

RIDGE CAP CLEAT

PROJECT ADDRESS

CONTINUOUS 9

CUSTOMER NAME

ARCHITECT NAME

BOTTOM AND SIDES

###-##-#####

RIDGE SUPPORT

# CONT. SUPPORT

AT PAN END

DRAWN: D. GOSS 1/25/21

3" MIN. FOR CHECKED:

THERMAL MOVEMENT

PROJECT NUMBER:

11 CAULK BOTTOM, SIDES

7

AND BACKSIDE

10 UPTURN PANEL 6

SUBSTRATE AT PEAK

5

5/8" THICK SUPPORT MATERIAL;

4

DENSDECK, PLYWOOD OR SIM.

3

HOOK CLIP ATTACHMENT FASTENER

VARIES DEPENDING ON APPLICATION 2

AND SUBSTRATE 1 RIDGE (FLOATING) DETAIL 1

D1 REF. ARCH. DET. -

B NO. REVISION / ISSUE DATE

A A DWG TITLE

BEMO STANDARD DETAIL

SCALE DWG NO.

THIS DETAIL IS GENERAL IN NATURE 1' = 1'-0"

AND WILL BE MODIFIED TO MEET JOB

SPECIFIC CONDITIONS

ISOMETRIC VIEW REV D1

ASSEMBLED FLOATING FLASH

[NOTE: ISOMETRIC VIEW IS FOR VISUALIZATION ONLY - OBJECTS NOT TO SCALE]

You might also like

- S3-0-0 - Typical Slab On Grade Details PDFDocument1 pageS3-0-0 - Typical Slab On Grade Details PDFVictor Miranda AcuñaNo ratings yet

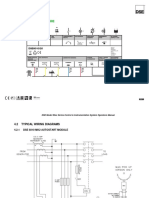

- DSE6010MKII DSE6020 MKII Wiring Diagram PDFDocument1 pageDSE6010MKII DSE6020 MKII Wiring Diagram PDFDumebi100% (1)

- F 519 - 17 PDFDocument19 pagesF 519 - 17 PDFMahdi abanNo ratings yet

- Dse601020 Wiring Diagram PDFDocument3 pagesDse601020 Wiring Diagram PDFNasredine AlainNo ratings yet

- DSE7110MKII DSE7120 MKII Wiring Diagram PDFDocument3 pagesDSE7110MKII DSE7120 MKII Wiring Diagram PDFNave GanteNo ratings yet

- Lathe and VMC Cycle Time CalculatorDocument5 pagesLathe and VMC Cycle Time CalculatorDhanus KodiNo ratings yet

- Michael Harris: ONG NternationalDocument25 pagesMichael Harris: ONG NternationalAjaya KumarNo ratings yet

- Egypt Construction Cost 8-2023Document3 pagesEgypt Construction Cost 8-2023Ahmed Saber Nassar100% (1)

- Igcse Electrochemistry Review PDFDocument7 pagesIgcse Electrochemistry Review PDFbilly ogadaNo ratings yet

- 09 High Uplift DetailDocument1 page09 High Uplift DetailAhmed Saber NassarNo ratings yet

- 31 Roof Curb - Sidepan DetailsDocument1 page31 Roof Curb - Sidepan DetailsAhmed Saber NassarNo ratings yet

- Fastener and material designations for roof panel penetrationsDocument1 pageFastener and material designations for roof panel penetrationsAhmed Saber NassarNo ratings yet

- 08 Sliding Detail (Halter Clip) Ins.Document1 page08 Sliding Detail (Halter Clip) Ins.Ahmed Saber NassarNo ratings yet

- 32 Roof Curb - Apron DetailDocument1 page32 Roof Curb - Apron DetailAhmed Saber NassarNo ratings yet

- 07 Fixing Detail (Halter Clip) Ins.Document1 page07 Fixing Detail (Halter Clip) Ins.Ahmed Saber NassarNo ratings yet

- 25 Vented Ridge DetailDocument1 page25 Vented Ridge DetailAhmed Saber NassarNo ratings yet

- 37 Valley DetailDocument1 page37 Valley DetailAhmed Saber NassarNo ratings yet

- 24 Ridge (Fixed) DetailDocument1 page24 Ridge (Fixed) DetailAhmed Saber NassarNo ratings yet

- 33 Roof Curb - Backpan DetailDocument1 page33 Roof Curb - Backpan DetailAhmed Saber NassarNo ratings yet

- Continuous Level Transmitter: Customize To Fit Application, 316 SS or Buna-N FloatsDocument1 pageContinuous Level Transmitter: Customize To Fit Application, 316 SS or Buna-N FloatsMohamed HammamNo ratings yet

- Transformer Submittal-Block 216 Food HallDocument9 pagesTransformer Submittal-Block 216 Food HallNaqib NaeemiNo ratings yet

- Access - Catalog.805b.Color - DP&Casing Tools-45Document1 pageAccess - Catalog.805b.Color - DP&Casing Tools-45RICHARDNo ratings yet

- Ec4-02 Miscelaneous DetailsDocument1 pageEc4-02 Miscelaneous DetailsSEDFREY DELA CRUZNo ratings yet

- 01-20-2021 Brown Residence - Aluminum TrellisDocument3 pages01-20-2021 Brown Residence - Aluminum TrellisdianaNo ratings yet

- Screened inner cover construction plansDocument3 pagesScreened inner cover construction plansneossj7No ratings yet

- Ss 400 61 orDocument1 pageSs 400 61 orBrian Aplin0% (1)

- Serie 2000Document2 pagesSerie 2000Fredy MurilloNo ratings yet

- Dodo - STD VP C 001Document1 pageDodo - STD VP C 001xer tieNo ratings yet

- 77 Series Drive HeadDocument3 pages77 Series Drive Headcentaury2013No ratings yet

- Simple Drip IrrigationDocument2 pagesSimple Drip IrrigationHarry JouleNo ratings yet

- Magnehelic Differential Pressure Gages: SolutionsDocument2 pagesMagnehelic Differential Pressure Gages: Solutionsdaniel GasperinNo ratings yet

- 9134001EC Decorum Sink ENDocument2 pages9134001EC Decorum Sink ENInterplan Puerto RicoNo ratings yet

- 004 005 D PDFDocument2 pages004 005 D PDFRangga Prasetya BaitullahNo ratings yet

- Corn Cooker - Macerator (12!07!21)Document1 pageCorn Cooker - Macerator (12!07!21)martin ciriacoNo ratings yet

- FMT18 Conventional Room DrawingDocument2 pagesFMT18 Conventional Room DrawingMr. AlegríaNo ratings yet

- ABH 1000A Series Concealed Overhead Holders and Stops 10-3-2018Document1 pageABH 1000A Series Concealed Overhead Holders and Stops 10-3-2018rodney_massieNo ratings yet

- TB135483 008 00F1Document1 pageTB135483 008 00F1Rene HebaNo ratings yet

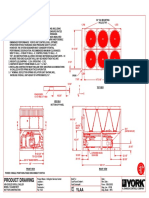

- Product Drawing: Power Entry 13 1/2" WIDE X 7" HIGHDocument1 pageProduct Drawing: Power Entry 13 1/2" WIDE X 7" HIGHsamersibaniNo ratings yet

- Gambar Mesin HydraulicDocument3 pagesGambar Mesin HydraulicSiprianus GamurNo ratings yet

- Conduit Plan LayoutDocument4 pagesConduit Plan LayoutEngr M.Arshad KhalidNo ratings yet

- House Revit Model Size 80'-0 X 49'-0Document14 pagesHouse Revit Model Size 80'-0 X 49'-0Hanibal TesfamichaelNo ratings yet

- Packing list for AA30+3 tower reinforcement elementsDocument5 pagesPacking list for AA30+3 tower reinforcement elementsAMarïo Rod CasNo ratings yet

- WB3241210 DRC STDocument1 pageWB3241210 DRC STImpulsora DemaNo ratings yet

- CNG Station Typica-01032020-2 - 240106 - 113743Document1 pageCNG Station Typica-01032020-2 - 240106 - 113743prasadNo ratings yet

- Bill of Material: 103V2 - HSS8X8X5/16 - 17'-1 3/8" - 2 REQ'DDocument1 pageBill of Material: 103V2 - HSS8X8X5/16 - 17'-1 3/8" - 2 REQ'Dai ambaraNo ratings yet

- Slab Expansion Joint - Type ADocument4 pagesSlab Expansion Joint - Type AnvnagarajuNo ratings yet

- Alloy Core Total 306 11 317 Anode Weight (LBS) : Attachment Cable DetailDocument1 pageAlloy Core Total 306 11 317 Anode Weight (LBS) : Attachment Cable DetailTony Bou GhariosNo ratings yet

- Lennar Washburn PlansDocument16 pagesLennar Washburn Planssuraj29misNo ratings yet

- Assemble antenna reflector and mount radioDocument2 pagesAssemble antenna reflector and mount radiosusan apazaNo ratings yet

- BILL OF MATERIALS FOR STEEL BEAM AND CONNECTIONSDocument1 pageBILL OF MATERIALS FOR STEEL BEAM AND CONNECTIONSai ambaraNo ratings yet

- Bill of Material: 102B6 - W18X40 - 43'-1" - ONE REQ'D Camber 2"Document1 pageBill of Material: 102B6 - W18X40 - 43'-1" - ONE REQ'D Camber 2"ai ambaraNo ratings yet

- Technical Data: NOTES: For Use With Trim Chart On Page 28 B. Order Alarm Valve SeparatelyDocument3 pagesTechnical Data: NOTES: For Use With Trim Chart On Page 28 B. Order Alarm Valve SeparatelyTaufik KurniawanNo ratings yet

- Dse7310 20 DiagramDocument3 pagesDse7310 20 DiagramFabio LiraNo ratings yet

- Installation Guide IndexDocument9 pagesInstallation Guide IndexConstantin GubavuNo ratings yet

- Especificación de Sistema de Anclaje en EstructuraDocument1 pageEspecificación de Sistema de Anclaje en EstructuraEnmanuel BrachoNo ratings yet

- ARV-HII-ELECT-038 - XA - 28VDC Aux PWRDocument2 pagesARV-HII-ELECT-038 - XA - 28VDC Aux PWRArmando CastellanosNo ratings yet

- Gambar Listrik CilacapDocument10 pagesGambar Listrik CilacapDanang RizkiNo ratings yet

- Section A Section B: PlatformDocument1 pageSection A Section B: PlatformDewi CuantikNo ratings yet

- Bomba Hidrantes - Dimensiones Mod 344ADocument24 pagesBomba Hidrantes - Dimensiones Mod 344AsebasfarsaNo ratings yet

- SS 1610 2 16ST 31153Document1 pageSS 1610 2 16ST 31153armin_kunosic9871No ratings yet

- A51850Document1 pageA51850gicntNo ratings yet

- A20080E Digital Control Cable 13P To 13SDocument1 pageA20080E Digital Control Cable 13P To 13SFabiola RosadoNo ratings yet

- 07 Fixing Detail (Halter Clip) Ins.Document1 page07 Fixing Detail (Halter Clip) Ins.Ahmed Saber NassarNo ratings yet

- 37 Valley DetailDocument1 page37 Valley DetailAhmed Saber NassarNo ratings yet

- 34 Roof Curb - Assembly DetailDocument1 page34 Roof Curb - Assembly DetailAhmed Saber NassarNo ratings yet

- 33 Roof Curb - Backpan DetailDocument1 page33 Roof Curb - Backpan DetailAhmed Saber NassarNo ratings yet

- 24 Ridge (Fixed) DetailDocument1 page24 Ridge (Fixed) DetailAhmed Saber NassarNo ratings yet

- 25 Vented Ridge DetailDocument1 page25 Vented Ridge DetailAhmed Saber NassarNo ratings yet

- Stair Obstructing Roadway VehiclesDocument1 pageStair Obstructing Roadway VehiclesAhmed Saber NassarNo ratings yet

- Ways of Separating MixturesDocument2 pagesWays of Separating MixturesPretty SwanNo ratings yet

- CMT MidtermsDocument12 pagesCMT MidtermsMarycorNo ratings yet

- Pranesh ChandranDocument12 pagesPranesh ChandranYashwant RaoNo ratings yet

- 9 - 1 H Wood Cabinet Spec Options NelDocument8 pages9 - 1 H Wood Cabinet Spec Options NelinformalitybyusNo ratings yet

- Garment Over Dyed Orders SOPDocument3 pagesGarment Over Dyed Orders SOPMahibur RahmanNo ratings yet

- Kishan Intership ReportDocument20 pagesKishan Intership ReportBhavesh PariharNo ratings yet

- MakersManual9 EGGSHELLCERAMICS PDFDocument2 pagesMakersManual9 EGGSHELLCERAMICS PDFAndriana MoroNo ratings yet

- Steel Sections (China)Document33 pagesSteel Sections (China)Ragesh KarimbilNo ratings yet

- Diaphram Part and Lists Drawing Page 37 39Document3 pagesDiaphram Part and Lists Drawing Page 37 39Bara BarackNo ratings yet

- Building Materials Alia Bint Khalid 19091AA001: Q) What Are The Constituents of Paint? What AreDocument22 pagesBuilding Materials Alia Bint Khalid 19091AA001: Q) What Are The Constituents of Paint? What Arealiyah khalidNo ratings yet

- Strategic WarehousingDocument2 pagesStrategic WarehousingElche ManicoNo ratings yet

- Catalogo Generation Art enDocument46 pagesCatalogo Generation Art enD BNo ratings yet

- Cutting HardoxDocument20 pagesCutting HardoxapNo ratings yet

- PUR Installation Manual PUR-Slot-Filler v1 10Document5 pagesPUR Installation Manual PUR-Slot-Filler v1 10Jaime VillamizarNo ratings yet

- Investment CastingDocument6 pagesInvestment CastingSparsh DeepNo ratings yet

- UNIMIX 20 M-102 FILLING-10 Ltrs CylinderDocument2 pagesUNIMIX 20 M-102 FILLING-10 Ltrs CylinderM KopNo ratings yet

- Lecture On Workshops in Industry Rev 1Document60 pagesLecture On Workshops in Industry Rev 1Anoop SharmaNo ratings yet

- Unit 1 WorkstudyDocument7 pagesUnit 1 WorkstudyMeraj AhmadNo ratings yet

- Material and Equipment InventoryDocument1 pageMaterial and Equipment InventoryhansNo ratings yet

- Fabric Expansion Joint - 2021Document46 pagesFabric Expansion Joint - 2021cemalNo ratings yet

- Pure and Impure BookletDocument7 pagesPure and Impure BookletOokieNo ratings yet

- QUIZ TQM Part - 3 QUES ANS SHEETDocument38 pagesQUIZ TQM Part - 3 QUES ANS SHEETAjay MishraNo ratings yet

- Performance Base Approach: ISO Guam Omeawe ProcessesDocument14 pagesPerformance Base Approach: ISO Guam Omeawe Processescaesar bintangNo ratings yet

- MIP CKD Body Checksheet 권한부여 - 300323Document3 pagesMIP CKD Body Checksheet 권한부여 - 300323Isser SihiteNo ratings yet

- European Steel and Alloy GradesDocument2 pagesEuropean Steel and Alloy Gradesfarshid KarpasandNo ratings yet

- 1098 - Technical - Aspects - of - E-Waste - ManagementDocument24 pages1098 - Technical - Aspects - of - E-Waste - ManagementmmarshalzNo ratings yet

- NOCOLOK Brazing Process 2018 02Document8 pagesNOCOLOK Brazing Process 2018 02Pérsio Mozart PintoNo ratings yet