Professional Documents

Culture Documents

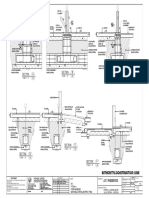

B20024s S01 Structural Notes-S01

Uploaded by

Joel Koma EmesangeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B20024s S01 Structural Notes-S01

Uploaded by

Joel Koma EmesangeCopyright:

Available Formats

GENERAL CONCRETE

G1 This building is situated in an earthquake zone and has been designed and detailed C1 All workmanship and material shall be in accordance with PNG 1002. B10 Corefilling is to be placed for the full height in lifts of not more than 800mm in height. T8 Steel Components shall comply with PNGS 1003 Steel grade 250.

to resist seismic forces. Any variation to either structural or non-structural elements A minimum delay period of one hour and max, three hours shall be observed between lifts.

may significantly alter the earthquake response of the building and impair its safety. C2 Minimum cover (mm) to all reinforcement unless otherwise shown shall be as follows: All cores are to be filled unless noted otherwise. T9 Bolt holes are to be of same nominal diameter as bolts, drilled

through assembled timber.

ANY PROPOSED ALTERATIONS MUST BE REFERRED TO THE STRUCTURAL DESIGN ENGINEER. REINFORCEMENT COVERS B11 Corefilling shall be thoroughly compacted into place with the aid of small immersion

vibrators. T10 Washers, unless noted otherwise, shall be provided under all bolt

G2 These drawings shall be read in conjunction with all Architectural and other consultants Minimum reinforcement cover requirements to be in accordance with AS3600 - 1988 heads and nuts as follows:

Drawings and Specifications and with such other written instructions as may be issued Exposure classification listed below: B12 The corefilling at the top of each lift shall be kept down at a distance of 25mm from Against timber, 65 x 65 x 5 square washers.

during the course of contract. All discrepancies shall be referred to Superintendant for the top of the blockwork and this surface shall be thoroughly scabbled before any further Against steel, standard round washers.

decision before proceeding with the work. Exterior faces of members (above ground) : B1 blocks are laid or concrete poured.

Interior faces of members : A1 T11 All bolts, nuts and washers shall be galvanized in accordance

G3 All dimensions relevant to setting out and off-site works shall be verified by the Members below ground : A2 B13 Masonry walls shall be cured for at least three (3) days before corefilling is placed. with AS 1214.

Contractor before construction and fabrication is commenced. The Engineers drawings shall

not be scaled. In addition reinforcement cover shall not be less than : B14 All masonry must be approved by the Superintendant before corefilling takes place. T12 All bolts shall be retightened at completion of construction.

G4 During construction the contractor shall be responsible for maintaining the structure in a FOOTINGS : 65mm

B15 Vertical reinforcement at any level shall be correctly positioned and securely tied to T13 Where necessary timber shall be chamfered locally to just clean

stable condition and ensuring no part shall be overstressed under construction activities. PEDESTAL : 65mm fillet welds connection plates, etc.

starters projecting from construction below prior to placing blocks.

G5 Workmanship and materials are to be in accordance with the relevant current PNGS and SLABS : 30mm TOP

BEAMS Exposed Face B16 Reinforcement is to be left undisturbed for at least 12 hours after corefilling. Any T14 Preservative treatment is to be provided as follows : dip diffused.

SAA standards including all amendments and the local statutory Authorities, except : 40mm reinforcement showing signs of seperation from the corefilling may render that section of

where varied by the the contract documents. Interior Faces : 25 mm

the wall liable to rejection.

COLUMNS In Ground : 65mm

G6 Requirements to comply with a particular code or standard is deemed to refer to the B17 Minimum cover to reinforcement : 12mm from inside face of block.

latest edition with all relevant amendments and to include all other codes or standards Out of Ground : 40mm

associated with or referred to in the noted code or standard. C3 Sizes of concrete elements do not include thickness of applied finishes.

DESIGN LOADS

B18 Vertical bars shall be placed with laps at not less than 1600mm centres, unless noted

G7 No holes or chases other than those indicated on the structural drawings shall be made otherwise.

C4 Reinforcement is represented diagrammatically and not neccessarily shown.

without the approval of the Superintendant. B19 Laps, unless noted otherwise, shall be : 40 x bar diameter. ROOF LEVEL

C5 Splices in reinforcement shall be made only in the positions shown or as otherwise

G8 Prior to ordering materials or carrying out any work that may be affected, the approved by the Superintendant. B20 All bars are to be cogged around openings and openings are to have a bond beam over

Contractor shall submit the following information for approval in accordance with the DEAD LOAD: 0.50 kPa

drawings and specification. These proposals shall include all information neccessary for C6 Welding of reinforcement shall not be permitted. them.

approval including the following: LIVE LOAD: 0.25 kPa

B21 At the completion of a day's work and during wet weather top and sides of all walls

C7 All reinforcement shall be securely supported in its correct position during concreting by

1) Source and supplier of materials and products. approved bar chains, spacers or support bars. shall be covered to prevent rain penetration to cores or wetting of blocks.

2) Cerificates and results of any tests already carried out. B22 Control joints in blockwork to be at 4m maximum spacing.

C8 Reinforced symbols:

"Y" denotes hot rolled deformed bars grade 410Y to AS 1302

3) Details of tests to be carried out both on and off site. "S" denotes deformed bars grade 2305 to AS 1302.

"R" denotes plain round bars grade 230R to AS 1302. STRUCTURAL STEELWORK

4) Location of any testing to be carried out off site. GROUND FLOOR

C9 Laps, unless noted otherwise, shall be : 40 x bar diameter for rounds and 350mm for S1 All workmanship and materials shall be in accordance with PNGS 1003.

5) Details of any seperate labratory, authority or other body to carry out tests. fabric.

S2 Steel grade - General: 300 MPa Columns: 350 MPa. DEAD LOAD:

The approval of substitution of materials shall be sought from the Superintendant. C10 Bending radii, unless noted otherwise, shall be to PNGS 1002.

S3 Plates, unless noted otherwise, shall be 8mm thick. - GENERAL 3.0 kPa

All dimensions are in millimetres unless stated otherwise. All levels are expressed in C11 Cover will be maintained during casting concrete by the use of plastic chairs and/or

metres. mortar blocks 1:2 mix at maximum 500mm centres in each directions. For work in contact S4 Bolts, unless noted otherwise, shall be 16mm diameter, Grade 4.6/s, bolts 20mm diameter

with the ground chairs are to be supported on sheet plates. and greater shall be Grade 8.8/s. LIVE LOAD: 2.0 kPa

G9 All props and formwork for beams and slabs shall be removed before construction of

any masonry walls or partitions on the floor. C12 Reinforcement shall not be exposed far prolonged periods such as to permit the S5 Welds, unless noted otherwise, shall be 6mm continuous fillet weld.

development of scale

G10 All Non-Load Bearing Walls shall be kept clear of the underside of beams and slabs S6 Welding electrodes shall be class E 41XX.

clearance shall not be less than 20mm unless otherwise shown. C13 Reinforcement and formwork are to be checked by the Superintendant prior to pouring.

The Superintendant is to be given 24 hours notice for a check and a futher 24 hours for S7 Welding shall be performed by an experienced qualified operator in accordance with

G11 Where proprietary products are specified they shall be manufactured and used in any remedial work required prior to concrete placement. PNGS 1016.

accordance with the manufacturer's specifications and recommendations.

C14 All conduits to be placed above bottom reinforcement and below top reinforcement S8 The contractor shall verify that all members can be assembled and erected properly, prior

G12 Design loads to Papua New Guinea Standard 1001. - minimum spacing between conduits 25mm. to erection on site.

1) Wind - Basic Design Velocity 30m/sec C15 Formwork shall be designed and constructed in accordance with AS 3610. S9 Before fabrication is commenced the Contractor shall submit copies of the shop drawings to

Terrain Category 2.5 the Superintendant for review. Review does not include checking of dimensions.

C16 Concrete components and quality shall be as follows, unless noted otherwise;

2) Seismic - Zone 3 S10 Reference shall be made to the Architect's drawings for additional drillings, cleats, fixings,

Element F'c (MPa) Water/Cement Ratio etc.

FOUNDATION S11 The contractor shall provide and leave in place until permanent bracing elements are

F1 Founding levels are provisional and are subject to the Superintendant's approval of the Foundations 25 0.55 constructed, such temporary bracing as is neccessary to stabilise the structure during

bearing strata. Slabs 25 0.55 erection.

Beams 25 0.55

F2 Anticipated bearing material: Undisturbed Natural Ground. Swimming pool 40 0.55 S12 The ends of all tubular members are to be sealed with nominal thickness plates and

continuous fillet weld unless otherwise shown.

F3 Required allowable bearing strength of foundation material 100 kPa

S13 Unless otherwise specified all steelwork shall be sand blasted to remove all rust and

C17 Three test cylinders are to be taken from each sample (sampling in accordance with scaled and painted one shop coat of inorganic zinc silicate primer min. 40 micron thickness.

PNGS 1002.) One cylinder to be tested at seven days, the other two at 20 days. Members encased in concrete, fire spray or HSTF bolted connections must not be painted.

F4 All water and loose material shall be removed from the base prior to pouring any Where ready mix concrete is supplied each truck will constitute a batch in applying

concrete. PNGS 1002. S14 All base plates shall be temporarily supported and dry pack grouted with 3:1 sand cement

grout in a just wet condition.

F5 Compacted fill under slabs and minor strip footings shall comply with the following: C18 The Contractor shall submit for approval his proposals for curing of all insitu concrete

work, at least 7 days prior to any pour taking place. S15 Cold formed steelwork shall comply with AS 1530, roll formed from hot-dipped zinc-rolled

a) Material shall be selected from an approved source, shall be free of steel grade G450-Z200 to AS 1397.

vegetable matter and ball of clay, and shall comply with the following C19 Construction Joints to be cleaned of all loose and foreign materials, scabbled and wetted

requirements. immediately before continuing the following concreting. Construction Joints other than those S16 All steelwork exposed to the weather including bolts and fixings shall be hot dipped

indicated on the drawing shall not be made without approval. galvanised unless noted otherwise.

(i) CBR value after 4 days soaking, not less than 25 when compacted

to at least 95% maximum dry density as determined by AS1289 Test

No. E1.1 CONCRETE MASONRY TIMBER

(ii) Maximum linear shrinkage 6% B1 All concrete block masonry is to be executed in accordance with the current edition of: T1 Timber materials and workmanship shall comply with AS 1720.

(iii) Grading PNGS 1004 - Reinforced Masonry Structures Code. T2 Timber shall be seasoned to moisture content not exceeding 15%, unless noted otherwise.

AS 2733 - Concrete Masonry Units.

SIEVE SIZE (mm) % BY WEIGHT PASSING T3 Where unseasoned timber is specified, in no case shall timber be used having a moisture

B2 Concrete masonry blocks shall have characteristics compressive strength of F'b = 12 MPa. content exceeding 30% at the time of fabrication.

37.5 100

19.0 60 - 100 B3 All blocks shall be laid dry and wetting shall not be permitted during or after laying. T3 Timber shall have strength properties not less than that shown below:

9.5 40 - 80

4.75 30 - 60 Stress Grade - F11

2.36 20 - 45 B4 Channel stretcher blocks and lintel blocks shall be used to form bond beams and lintels Strength Group - SD4

0.425 15 - 30 respectively. Top groove blocks shall be used elsewhere where horizontal reinforcement is

0.075 03 - 15 required. Otherwise blocks shall conform to AS 2733. Joint Group - J3

In the absence of mechanical stress, grading timber shall be visually stress graded in

(iv) The fraction passing the 75 micron sieve shall not exceed B5 All blocks must be cured for minimum of 28 days before transportation to site. accordance with AS 2082.

2/3 that passing the 425 micron sieve.

B6 Clean out blocks are to be used for core filled cavities and all mortar droppings are to T4 The Contractor is required to submit details of the proposed species of timber for

(v) The fraction retained on the 2.36mmm sieve shall consist be removed from the bottom cavities before grouting. approval. If unidentified species are proposed, evidence must be provided from the Papua

of hard durable particles or fragments of stone, gravel New Guinea Office of Forestry of identification and compliance with the specified properties.

or sand and shall not include any material that breaks B7 Mortar shall comply with AS 1475. Part 1, Appendix A. The mix proprtions of table A1

up when alternately wetted and dried. shall be adjusted to give an average compressive strength of 8 MPa. T5 All sizes quoted are the final dressed sizes of finished timber unless noted otherwise.

(vi) The fraction passing the 425 micron sieve shall have a B8 Mortar joints to be 10mm thick with blocks fully bedded and perpends filled. T6 The Contractor shall verify that all members can be assembled and erected properly.

liquid limit not greater than 30 and a plasticity index

not greater than 10. B9 Grout for corefilling shall comply with AS 1475, Part 1, Section 2. T7 Any variations shall be referred to the Superintendant for approval.

F6 Over excavating under footings shall be made good with 10 mPa mass concrete.

Characteristic compressive strength F'c = 15 MPa Slump 225. Batching by volume is not

permitted. AUTHORITY&CONSTRUCTION ISSUE

COPYRIGHT REVISIONS SCALE: Project No.

CLIENT: PROJECT:

THE COPYRIGHT FOR THE DESIGNS CONTAINED IN THIS

DRAWING ARE

Date: No. Description

A.T.S WAREHOUSE Documentation Team

Sheet No.

HELD BY KOMAGIN LIMITED OFFICE.

ANY USE OF THESE DESIGNS MUST BE WITH EXPRESS

S.K CAD Documentation:

Project Engineer:

PERMISSION OF

THE HOLDERS OF THE COPYRIGHT.

P.O.Box x DRAWING TITLE: Checked:

Revision No. Date:

LEGAL ACTION WILL BE TAKEN ON ANY INFRINGEMENT OF PORT MORESBY Signed:

THIS RIGHT.

NATIONAL CAPITAL DISTRICT, PNG. Date:

You might also like

- B20024s S04 Details Foot & Slab-S04Document1 pageB20024s S04 Details Foot & Slab-S04Joel Koma EmesangeNo ratings yet

- B20024s S00 COVER SHEET-S00Document1 pageB20024s S00 COVER SHEET-S00Joel Koma EmesangeNo ratings yet

- BA 07 BLD Sect-A07Document1 pageBA 07 BLD Sect-A07Joel Koma EmesangeNo ratings yet

- A-104 - Huli Wig DrawingsDocument1 pageA-104 - Huli Wig DrawingsJoel Koma EmesangeNo ratings yet

- Crown Plaza Hotel Microbrewery: Structural Drawing ScheduleDocument13 pagesCrown Plaza Hotel Microbrewery: Structural Drawing ScheduleJoel Koma EmesangeNo ratings yet

- Ats SHPDWG 201215 SD 02Document1 pageAts SHPDWG 201215 SD 02Joel Koma EmesangeNo ratings yet

- Approved dwgs-01Document14 pagesApproved dwgs-01Joel Koma EmesangeNo ratings yet

- B20024s S07 Elev - Sect Build-S07Document1 pageB20024s S07 Elev - Sect Build-S07Joel Koma EmesangeNo ratings yet

- Telue Engineers LTD: Proposed Maprik District HospitalDocument1 pageTelue Engineers LTD: Proposed Maprik District HospitalJoel Koma EmesangeNo ratings yet

- C-20021 s07 - Proposed Brewery Roof Layout Plan-S07 - PrintDocument1 pageC-20021 s07 - Proposed Brewery Roof Layout Plan-S07 - PrintJoel Koma EmesangeNo ratings yet

- Telue Engineers LTD: Proposed Maprik District HospitalDocument1 pageTelue Engineers LTD: Proposed Maprik District HospitalJoel Koma EmesangeNo ratings yet

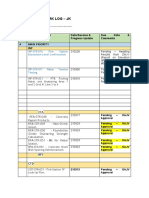

- JK & HJ - Structural WORK LOGDocument2 pagesJK & HJ - Structural WORK LOGJoel Koma EmesangeNo ratings yet

- A201 - Floor Plan - Pathology Blood Bank A&e Maternal ChildDocument1 pageA201 - Floor Plan - Pathology Blood Bank A&e Maternal ChildJoel Koma EmesangeNo ratings yet

- Ats SHPDWG 201215 SD 02Document1 pageAts SHPDWG 201215 SD 02Joel Koma EmesangeNo ratings yet

- Developed Design: C1 C1 C1 C1 C1Document1 pageDeveloped Design: C1 C1 C1 C1 C1Joel Koma EmesangeNo ratings yet

- RE: CTSL Taurama Commercial Centre - RFT AAL 010121 Addendum 1Document1 pageRE: CTSL Taurama Commercial Centre - RFT AAL 010121 Addendum 1Joel Koma EmesangeNo ratings yet

- AWC DES413 1 ShearWallExamples 1hr 140822Document66 pagesAWC DES413 1 ShearWallExamples 1hr 140822Joel Koma EmesangeNo ratings yet

- R1-Work Log - Week (1-5 Feb 2021)Document3 pagesR1-Work Log - Week (1-5 Feb 2021)Joel Koma EmesangeNo ratings yet

- Work Log - Week (1-5 Feb 2021)Document3 pagesWork Log - Week (1-5 Feb 2021)Joel Koma EmesangeNo ratings yet

- Work Log - Week (8-12 Feb 2021)Document3 pagesWork Log - Week (8-12 Feb 2021)Joel Koma EmesangeNo ratings yet

- LRFD Design Example PDFDocument648 pagesLRFD Design Example PDFchinna_kanna5098100% (1)

- NA Topic 2 Bridge Design Seminar Colombo March 2016Document152 pagesNA Topic 2 Bridge Design Seminar Colombo March 2016alex abrhaNo ratings yet

- Work Log - Week (22-26 Feb 2021)Document3 pagesWork Log - Week (22-26 Feb 2021)Joel Koma EmesangeNo ratings yet

- Work Log - Week (8-12 Feb 2021)Document3 pagesWork Log - Week (8-12 Feb 2021)Joel Koma EmesangeNo ratings yet

- Design of A Prestressed Concrete Bridge and Analysis by CsibridgeDocument15 pagesDesign of A Prestressed Concrete Bridge and Analysis by CsibridgeJoel Koma EmesangeNo ratings yet

- BDP 4Document56 pagesBDP 4yenebeb tarikuNo ratings yet

- 3W-700 - Furniture LayoutDocument1 page3W-700 - Furniture LayoutJoel Koma EmesangeNo ratings yet

- 3W-302.Consolidated Plan - Power & Data-CommsDocument1 page3W-302.Consolidated Plan - Power & Data-CommsJoel Koma EmesangeNo ratings yet

- Official tutorials - CSiBridge installation and exampleDocument7 pagesOfficial tutorials - CSiBridge installation and exampleN TNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Roles of ManagerDocument14 pagesRoles of ManagerNurul Ain AisyaNo ratings yet

- Tall Buildings Case Studies of John Hancock Centre and Sears TowerDocument75 pagesTall Buildings Case Studies of John Hancock Centre and Sears TowerShanikAromgottilNo ratings yet

- Nyeri County Youth PolicyDocument59 pagesNyeri County Youth Policyomondi bonfaceNo ratings yet

- Admin Upload Food Processing Industry in India August 2013Document31 pagesAdmin Upload Food Processing Industry in India August 2013pv1977No ratings yet

- Al Nafi Affiliate PolicyDocument12 pagesAl Nafi Affiliate PolicyIftikhar AliNo ratings yet

- Introduction To Computer L-1Document51 pagesIntroduction To Computer L-1Md Safayet IslamNo ratings yet

- Soal PAS 2019 Kelas X IPA-IPS FIXDocument8 pagesSoal PAS 2019 Kelas X IPA-IPS FIXJessica JolieNo ratings yet

- Xerosis CutisDocument6 pagesXerosis CutisHadi FirmansyahNo ratings yet

- THE DIGESTIVE SYSTEM 22 (Autosaved)Document141 pagesTHE DIGESTIVE SYSTEM 22 (Autosaved)Jairus ChaloNo ratings yet

- Process Analyzer Sampling System TrainingDocument3 pagesProcess Analyzer Sampling System TrainingPhilNo ratings yet

- F. Rizal Trip To MadridDocument2 pagesF. Rizal Trip To MadridAdrian MarananNo ratings yet

- NITI AayogDocument6 pagesNITI Aayogs100% (1)

- Marketing Report For Wonder Bread PakistanDocument22 pagesMarketing Report For Wonder Bread PakistanM Abdullah PerachaNo ratings yet

- AP10 - Q2 - Mod3 - Mga Dahilan at Epekto NG Migrasyon PDFDocument1 pageAP10 - Q2 - Mod3 - Mga Dahilan at Epekto NG Migrasyon PDFZyral Alliyah SantiagoNo ratings yet

- Appendix D - Correction SymbolsDocument2 pagesAppendix D - Correction SymbolsnhanhoangNo ratings yet

- Around The DubaiDocument11 pagesAround The DubaiGayane HovhannisyanNo ratings yet

- Well Construction Journal - May/June 2014Document28 pagesWell Construction Journal - May/June 2014Venture PublishingNo ratings yet

- Construction Contract SummaryDocument2 pagesConstruction Contract SummaryKerwin LeonidaNo ratings yet

- HTML5 Student BookDocument297 pagesHTML5 Student BookJovent FalloyNo ratings yet

- ResumeDocument2 pagesResumeAbhinav kaliaNo ratings yet

- Here are the answers to the questions:1. Country or nation2. Archipelago 3. Peninsula4. Island5. Mainland6. Seven7. Asia8. ColonyDocument8 pagesHere are the answers to the questions:1. Country or nation2. Archipelago 3. Peninsula4. Island5. Mainland6. Seven7. Asia8. ColonyShiela Mae FernandezNo ratings yet

- HelmenthsDocument38 pagesHelmenthsKarwanNo ratings yet

- U2000 & PRS Operation Introduce V1.0Document25 pagesU2000 & PRS Operation Introduce V1.0Nam PhamNo ratings yet

- Ameama Zubair 70080433 Poem: Goe, and Catche A Falling Star: Poem: The Sunne RisingDocument2 pagesAmeama Zubair 70080433 Poem: Goe, and Catche A Falling Star: Poem: The Sunne RisingAsma KhanNo ratings yet

- 2309 The Memory Tree BookDash FKBDocument19 pages2309 The Memory Tree BookDash FKBuyhgjhNo ratings yet

- Monitor Pressao Arterial ProCheck - IB-WW1YB-3Document58 pagesMonitor Pressao Arterial ProCheck - IB-WW1YB-3jpmarques19660% (1)

- How Children Learn LanguageDocument8 pagesHow Children Learn LanguageFakhruRozyNo ratings yet

- Bioworld Naruto Classic Uzumaki Naruto Cosplay Zip-Up Hoodie, Multicolored, Medium Amazon - Ca Clothing, Shoes & AccessoriesDocument1 pageBioworld Naruto Classic Uzumaki Naruto Cosplay Zip-Up Hoodie, Multicolored, Medium Amazon - Ca Clothing, Shoes & AccessoriestonydidlyNo ratings yet

- E. Philip Davis, Dr. Benn Steil - Institutional Investors-The MIT Press (2001)Document370 pagesE. Philip Davis, Dr. Benn Steil - Institutional Investors-The MIT Press (2001)German StefanoffNo ratings yet