Professional Documents

Culture Documents

Compound Data Sheet

Uploaded by

Luis ReyesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Compound Data Sheet

Uploaded by

Luis ReyesCopyright:

Available Formats

FICHA TECNICA

PARTIDA No. 5 A LA 24

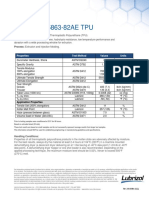

COMPOUND DATA SHEET

Parker O-Ring Division, North America

MATERIAL REPORT

Report Number: 92880

Date: 3/13/2013

Title: Evaluation of Parker Compound VM835-75

Elastomer Type: Fluorocarbon (FKM)

Purpose: To obtain typical test data

Specification: ASTM D2000 M2HK710 A1-10 B38 E078 Z1 (Shore A Hardness

75 +/-5), Z2 Elongation 125% min, Z3 (Specific Gravity), Z4 (TR-

10)

Color: Black

Recommended Temperature -40°F to 400°F

Range:

Recommended For: Mineral oil and grease, ASTM No. 1 oil, IRM 902 oil, IRM

903 oil, nonflammable hydraulic fluids, silicone oils and

greases, aliphatic hydrocarbons (propane, butane,

natural gas), aromatic hydrocarbons (benzene,

toluene), chlorinated hydrocarbons (trichloroethylene

and carbon tetrachloride), gasoline, high vacuum,

ozone, weather, and aging resistance.

Not Recommended For: Glycol based brake fluids, ammonia gas, amines,

alkalis, superheated steam, and low molecular weight

organic acids (formic and acetic acids).

Additional Approvals: FDA 21 CFR 177.2600

EC1935:2004

REACH – SVHC Compliance

RoHS – ELV Compliance

Parker O-Ring Division

2360 Palumbo Drive

Lexington, Ky 40509

(859) 269-2351

1 of 2

FICHA TECNICA

PARTIDA No. 5 A LA 24

REPORT DATA

Test Spec Test

Original Physical Properties Method Limits Results

(Z1) Hardness, Shore A, pts. ASTM D2240 75 ±5 78

ISO 7619

Tensile Strength, PSI (Mpa) ASTM D412 1450 (10) 3059 (21)

ISO 37

(Z2) Ultimate Elongation, % ASTM D412 125 230

ISO 37

(Z3) Specific Gravity ASTM D297 as received 1.85

ISO 2781

Fluid Resistance (Basic

Requirement)

IRM 903, 70 hrs @ 302°F

Volume Change, % ASTM D471 +10 +2

(A1-10) Heat Age

70 hrs. @ 482°F

Hardness Change, pts ASTM D573 +10 +3

Tensile Strength Change, % -25 -22

Ultimate Elongation Change, % -25 +8

(B38) Compression Set (Plied)

24 hrs. @ 347°F

Percent of Original Deflection, ASTM D395 50 10

Max Method B

ISO 815

(E078) Fluid Resistance

Service Fluid 101, 70 hrs @

392°F

Hardness Change, pts. ASTM D471 -15 to +5 -8

Tensile Strength Change, % -40 -6

Ultimate Elongation Change, % -20 -1

Volume Change, % 0 to +15 +11

(Z4) Low Temperature

Resistance

TR-10, temperature °F , C ASTM D1329 report -22 (-30)

"Purchaser use only. Reproduce only in full. Data pertains to items referenced only."

"The recording of false, fictitious, or fruaudulent statements or entries in this report may be

punishable as a felony under federal law."

Parker O-Ring Division

2360 Palumbo Drive

Lexington, Ky 40509

(859) 269-2351

2 of 2

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- K3M 2008 - Form 6Document15 pagesK3M 2008 - Form 6SeanNo ratings yet

- Chapter 3 - Transducer and Sensors Part 1Document46 pagesChapter 3 - Transducer and Sensors Part 1Zersh EthioNo ratings yet

- Parker O-Ring VM835-75 Compound Data SheetDocument2 pagesParker O-Ring VM835-75 Compound Data SheetBrandon TrocNo ratings yet

- Material Report: Compound Data SheetDocument3 pagesMaterial Report: Compound Data SheetRanja SarkarNo ratings yet

- Material Report: Compound Data SheetDocument2 pagesMaterial Report: Compound Data SheetPriyadarshini KrishnaswamyNo ratings yet

- Marco Material Datasheet Parker S0469 40Document2 pagesMarco Material Datasheet Parker S0469 40alanNo ratings yet

- Material Report: Compound Data SheetDocument2 pagesMaterial Report: Compound Data SheetDouglas GonçalvesNo ratings yet

- Parker O-Ring V0709-90 Compound Data SheetDocument3 pagesParker O-Ring V0709-90 Compound Data SheetBrandon TrocNo ratings yet

- Marco Material Datasheet Parker E0603 70Document3 pagesMarco Material Datasheet Parker E0603 70Asad EjazNo ratings yet

- Parker Compound NL153-70 - Material ReportDocument2 pagesParker Compound NL153-70 - Material ReportWMC_PMNo ratings yet

- Driscopipe 8100 PE4710-PE100 / (PE3408) : Pipe Data SheetDocument2 pagesDriscopipe 8100 PE4710-PE100 / (PE3408) : Pipe Data SheetmariannyNo ratings yet

- Marco Material Datasheet V1005Document2 pagesMarco Material Datasheet V1005Bib GmzNo ratings yet

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliNo ratings yet

- Ensinger Tecapeek® CF30 Polyetheretherketone, 30% Carbon Reinforced (PEEK)Document2 pagesEnsinger Tecapeek® CF30 Polyetheretherketone, 30% Carbon Reinforced (PEEK)Arthur EmidioNo ratings yet

- Pellethane 5863-82AE TPU: Technical Data SheetDocument2 pagesPellethane 5863-82AE TPU: Technical Data SheetaNo ratings yet

- Technical Data Sheet Polyimide: Benefits ApplicationsDocument3 pagesTechnical Data Sheet Polyimide: Benefits Applicationssanthosha rkNo ratings yet

- Material Report: Compound Data SheetDocument2 pagesMaterial Report: Compound Data Sheetscibduser001No ratings yet

- Megolon S540 PDFDocument2 pagesMegolon S540 PDFMuhammad Shabbir AwanNo ratings yet

- Astm D4462-90Document2 pagesAstm D4462-90Priyadarshini KrishnaswamyNo ratings yet

- Marco Material Datasheet V1000Document2 pagesMarco Material Datasheet V1000FinNo ratings yet

- 3 Property R3450 EngDocument1 page3 Property R3450 EngMohit MohataNo ratings yet

- FW300Document1 pageFW300miroslava mondragonNo ratings yet

- Pds TLX SeriesDocument2 pagesPds TLX SeriesGiannis GoulasNo ratings yet

- Petrothene: Technical Data SheetDocument2 pagesPetrothene: Technical Data SheetJaime222No ratings yet

- Parker O-Ring V1238-95 Compound Data SheetDocument3 pagesParker O-Ring V1238-95 Compound Data SheetBrandon TrocNo ratings yet

- Improved Resin PE4710Document5 pagesImproved Resin PE4710Iván López PavezNo ratings yet

- Ficha Técnica - FRAYÖL GEAR S 2 EP - 680Document2 pagesFicha Técnica - FRAYÖL GEAR S 2 EP - 680Julio Oliveira Goncalves JuniorNo ratings yet

- Mirafi RS580i: Roadway Design and Performance Properties Guidance Document / Test Method Unit Design / Calibration ValueDocument2 pagesMirafi RS580i: Roadway Design and Performance Properties Guidance Document / Test Method Unit Design / Calibration ValueLuis Angel Criollo DivertidoNo ratings yet

- Standard Test Reference Chart 2016Document19 pagesStandard Test Reference Chart 2016dvtNo ratings yet

- RT-Duroid 5880 PropertiesDocument2 pagesRT-Duroid 5880 PropertiesJesus GarciaNo ratings yet

- Ge Structured Products: The Polarflex 42U Blanking Panel Uses Lexan Fr65Document2 pagesGe Structured Products: The Polarflex 42U Blanking Panel Uses Lexan Fr65Ionut DeaconuNo ratings yet

- PEPET Film (35754-E Data Sheet)Document2 pagesPEPET Film (35754-E Data Sheet)Anthony BokovNo ratings yet

- MX 4926N M.CDocument4 pagesMX 4926N M.Csubham chakrabortyNo ratings yet

- Element Warren A2LA 0038 01 Mechanical PDFDocument21 pagesElement Warren A2LA 0038 01 Mechanical PDFAndre CasteloNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Property Unit Test Method Specificatio N: Table 4.4 - Alkylate Product Specification - LPG (Butanes) (Note 1, 2)Document1 pageProperty Unit Test Method Specificatio N: Table 4.4 - Alkylate Product Specification - LPG (Butanes) (Note 1, 2)Nguyễn Hồng SơnNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Garlock GYLON Style 3510 Spec Sheet - (NA) 2016-12 ENDocument1 pageGarlock GYLON Style 3510 Spec Sheet - (NA) 2016-12 ENSu Kil SungNo ratings yet

- Ace Mersen Armylor 2 Ptfe Pfa Lined Pipes DinDocument32 pagesAce Mersen Armylor 2 Ptfe Pfa Lined Pipes DinClaire GrecoNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetingindjorimaNo ratings yet

- Techtron PPS HPV & Ketron PEEK HPV SpecificationsDocument3 pagesTechtron PPS HPV & Ketron PEEK HPV SpecificationsPeterWayNo ratings yet

- Technical Data (Spec Qualified) Perma-Slik G: Air Dry, Mos Solid Film LubricantDocument3 pagesTechnical Data (Spec Qualified) Perma-Slik G: Air Dry, Mos Solid Film LubricantSantaj TechnologiesNo ratings yet

- Hyosung Topilene J340 PPDocument1 pageHyosung Topilene J340 PPChu ChuNo ratings yet

- Product Data Sheet: Synthetic Gear OilDocument2 pagesProduct Data Sheet: Synthetic Gear OilDiegoNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetIVANCHUNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- MS - Hyprene L1200 7-25-08Document1 pageMS - Hyprene L1200 7-25-08Abe KobNo ratings yet

- Driscoplex 5300 Series Pe3608 / (Pe3408) : Geothermal Systems Data SheetDocument2 pagesDriscoplex 5300 Series Pe3608 / (Pe3408) : Geothermal Systems Data SheetmariannyNo ratings yet

- 6210GCFNC1 英文物性表 20161122Document1 page6210GCFNC1 英文物性表 20161122Sơn Nguyễn ĐắcNo ratings yet

- Certificado de Calidad - GolbalDocument1 pageCertificado de Calidad - GolbalMario Santititios ChuquillanquiNo ratings yet

- GP100ORXP enUS ASTMDocument1 pageGP100ORXP enUS ASTMRaul ArmendarizNo ratings yet

- Strip Seal Expansion JointDocument13 pagesStrip Seal Expansion JointsmithNo ratings yet

- PORON 4790-92-25041 P Extra SoftSlow ReboundSupportedDocument2 pagesPORON 4790-92-25041 P Extra SoftSlow ReboundSupportedkarpagsNo ratings yet

- AaaaDocument141 pagesAaaaDương Nguyễn TùngNo ratings yet

- Supreme foamSP-5015RDocument1 pageSupreme foamSP-5015RAdrian LeeNo ratings yet

- 3 mPE Leaflet en LH3750MDocument1 page3 mPE Leaflet en LH3750MfguastaNo ratings yet

- Metallocene Linear Low Density Polyethylene: Physical PropertiesDocument1 pageMetallocene Linear Low Density Polyethylene: Physical PropertiesAkoyoNo ratings yet

- ES8067-TS0231-V575-FKM75 Bisphenol Cured - ApprovedDocument2 pagesES8067-TS0231-V575-FKM75 Bisphenol Cured - ApprovedBogdan CăpățînăNo ratings yet

- General Purpose Manual Syringes - : 1 - 100 ML PTFE Tipped PlungerDocument4 pagesGeneral Purpose Manual Syringes - : 1 - 100 ML PTFE Tipped PlungerLuis ReyesNo ratings yet

- Rigaku Nex QCDocument12 pagesRigaku Nex QCLuis ReyesNo ratings yet

- Automax 100 Basic Module Assembly InstructionsDocument54 pagesAutomax 100 Basic Module Assembly InstructionsLuis ReyesNo ratings yet

- Sealed Lead-Acid Battery: SpecificationDocument2 pagesSealed Lead-Acid Battery: SpecificationLuis ReyesNo ratings yet

- CERTIFICADO ISO-9001-Cert PARKER HANNIFINDocument1 pageCERTIFICADO ISO-9001-Cert PARKER HANNIFINLuis ReyesNo ratings yet

- Producto Ficha Tecnica 7fad771d7Document6 pagesProducto Ficha Tecnica 7fad771d7Luis ReyesNo ratings yet

- Rigaku NEX CG Brochure Rev6smDocument6 pagesRigaku NEX CG Brochure Rev6smLuis ReyesNo ratings yet

- PST 1500 48 Samlex SpecificationsDocument1 pagePST 1500 48 Samlex SpecificationsLuis ReyesNo ratings yet

- Post Adapters Post AdaptersDocument1 pagePost Adapters Post AdaptersLuis ReyesNo ratings yet

- PST-600-48 - Samlex SpecificationsDocument1 pagePST-600-48 - Samlex SpecificationsLuis ReyesNo ratings yet

- Multicrystalline Silicon Solar Cell 158mmx158mDocument2 pagesMulticrystalline Silicon Solar Cell 158mmx158mLuis ReyesNo ratings yet

- ISO 9001 and 14001 2015 Cert Hach NADocument1 pageISO 9001 and 14001 2015 Cert Hach NALuis ReyesNo ratings yet

- Reference - Manual - INTERFASES XPRDocument94 pagesReference - Manual - INTERFASES XPRLuis ReyesNo ratings yet

- Safe. Reliable. Easy.: Thermo Scientific Hotplates, Stirrers and Stirring HotplatesDocument3 pagesSafe. Reliable. Easy.: Thermo Scientific Hotplates, Stirrers and Stirring HotplatesLuis ReyesNo ratings yet

- LCM IvDocument1 pageLCM IvLuis ReyesNo ratings yet

- Aquamax KF: ReagentsDocument3 pagesAquamax KF: ReagentsLuis ReyesNo ratings yet

- Partida 85 Jeringa 50 MLDocument2 pagesPartida 85 Jeringa 50 MLLuis ReyesNo ratings yet

- 1741 - Long Span Structures ReportDocument5 pages1741 - Long Span Structures ReportHuzefa SayyedNo ratings yet

- E1 Tensile TestDocument13 pagesE1 Tensile TestFirzana AmiraNo ratings yet

- EMD Tools1Document55 pagesEMD Tools1Vladimir ArsicNo ratings yet

- MC33067P PWM+Fonte+PrincipalDocument16 pagesMC33067P PWM+Fonte+PrincipaljhonwesleihotmailcomNo ratings yet

- Lab ReportDocument17 pagesLab ReportHabtamu BaynekawNo ratings yet

- Siemens Connect Box Dispozitiv Supraveghere Monitorizare CWG Box Eu FT EngDocument14 pagesSiemens Connect Box Dispozitiv Supraveghere Monitorizare CWG Box Eu FT EnggeorgenikitaNo ratings yet

- The Said and The UnsaidDocument19 pagesThe Said and The UnsaidOzana BudauNo ratings yet

- SAE AS4059F Table1Document2 pagesSAE AS4059F Table1CherryNo ratings yet

- Visoturb 900-P Portátil DigitalDocument2 pagesVisoturb 900-P Portátil DigitalleonardoNo ratings yet

- SP 187 BDocument4 pagesSP 187 BBryan CarvacheNo ratings yet

- RCI Profile.Document10 pagesRCI Profile.quaiser_nikoNo ratings yet

- ECOS Data Report 3063Document13 pagesECOS Data Report 3063Sarra Chouchene0% (1)

- Short Physical Performance Battery Protocol and Score Sheet: 1. Balance TestsDocument8 pagesShort Physical Performance Battery Protocol and Score Sheet: 1. Balance Testsruth lopezNo ratings yet

- Advanced IC Engines: Prof. R. Devaraj Dr. S. Ramachandran Dr. A. AndersonDocument61 pagesAdvanced IC Engines: Prof. R. Devaraj Dr. S. Ramachandran Dr. A. AndersonGopi KrishnanNo ratings yet

- 2 and Lehr Panzerdivison PDFDocument38 pages2 and Lehr Panzerdivison PDFLeonte Daniel100% (1)

- Decomposition of Diacetone AlcoholDocument3 pagesDecomposition of Diacetone Alcoholaryajs2017No ratings yet

- The Anatomy and Physiology of The Stomach: Ian R. Daniels and William H. AllumDocument21 pagesThe Anatomy and Physiology of The Stomach: Ian R. Daniels and William H. Allummutia aNo ratings yet

- Aft MPM Cafs 01Document2 pagesAft MPM Cafs 01Forum PompieriiNo ratings yet

- Test 5-11-2019 Excretory System - Pharmacist Zaheer AbbasDocument3 pagesTest 5-11-2019 Excretory System - Pharmacist Zaheer AbbasabbaszaheerNo ratings yet

- SRT Ts Trainingbooklet 2016 PDFDocument44 pagesSRT Ts Trainingbooklet 2016 PDFAde YahyaNo ratings yet

- Final Thesis RandaDocument175 pagesFinal Thesis RandaAhmi KhanNo ratings yet

- Favipiravir Tablet Manual: Please Read The Instructions Carefully and Use Under The Guidance of A PhysicianDocument4 pagesFavipiravir Tablet Manual: Please Read The Instructions Carefully and Use Under The Guidance of A Physicianchard xuNo ratings yet

- Type Abz PDFDocument15 pagesType Abz PDFle khánhNo ratings yet

- Farm and Home Visits Are An Essential Part ofDocument16 pagesFarm and Home Visits Are An Essential Part ofChariss VerdidaNo ratings yet

- Intercrystalline CorrosionDocument24 pagesIntercrystalline Corrosionlu190765No ratings yet

- Florence Nightingales Environmental TheoryDocument5 pagesFlorence Nightingales Environmental TheoryRoshin Tejero100% (1)

- Unit Homework Momentum Its Conservation Ans KeyDocument6 pagesUnit Homework Momentum Its Conservation Ans KeyKristyne Olicia100% (1)

- Boscolastic TDSDocument2 pagesBoscolastic TDSSasi KumarNo ratings yet