Professional Documents

Culture Documents

The Use of Bacterial/viral Filters During Artificial Airway and Invasive Mechanical Ventilation

Uploaded by

Marcelo Alejandro0 ratings0% found this document useful (0 votes)

22 views6 pagesOriginal Title

Filters

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

22 views6 pagesThe Use of Bacterial/viral Filters During Artificial Airway and Invasive Mechanical Ventilation

Uploaded by

Marcelo AlejandroCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

Intensive Medicine REVISIONS

2013 - 30 Nº 1

The Use of bacterial/viral

filters during artificial

airway and invasive

mechanical ventilation

Sebastián Fredes, Emiliano Gogniat, Gustavo Plotnikow, Roger

Rodrigues-La Moglie

Chapter of Kinesiology in Critical Patient, Intensive Care Argentine

Society

Correspondence:

Lic. Gustavo Plotnikow

gplotnikow@gmail.com

Conflicts of Interests: None.

Key words Abstract

Medical gases that go towards the patient in mechanical ventilation, and

■ Bacterial/viral filters those which exit to the environment should always be filtered. The particle

■ Filtration removal by filtration can be achieved by different mechanisms of action,

either with mechanical or electrostatic filters.

■ artificial airway and

mechanical ventilation The use of bacterial/viral filters should apply to all patients who required

artificial airway and mechanical ventilation in intensive care units.

■ Interfaces

INTENSIVE MEDICINE - 2013 - 30 Nº 1

INTRODUCTION from the toxicologically point of view. Most of the

particles less than 8 µm diameter could impact above

Medical gases that go towards the patient by artificial larynx without reaching the lungs. Particles from 1 to 8

airway and mechanical ventilation and those which exit to µm diameter could be deposited into the upper airways

the environment should always be filtered. The particle and lower airways as well into the alveolus . The particle

removal by filtration can be achieved by different between 1 and 2 µm diameter is the particle which reaches

mechanisms of action, either with mechanical or the major alveolus deposit level.

electrostatic filters. The objective of this summary is to

describe the main technical features in bacterial filters Mechanical ventilation circuits used in the Intensive Care

used in the Intensive Care Unit, both their indications and Unit are open and they liberate the exhaled air to the

contraindications of use and their limitations. Intensive Care Unit’s atmosphere. That creates a potential

way of hospital-acquired infections among patients.

Visitors and health workers are at risk of exhaled particles

of exposure.

Materials and Methods

A filter is a device commonly composed of an external

The Chapter of Kinesiology of Intensive Care rigid structure which has a laminar made of fibers.

Argentine Society developed a bibliographic Particles are captured by the fibers material when the gas

search so as to make this summary. The flows thorough the sinuous path created by the hollow

search was made in LILACS, MEDLINE interconnected spaces inside the filter structure. That is to

Cochrane Library and SciELO data base with say, as gas moves through the filter, particles are being

the following key words: viral-bacterial deposited over the material. .

filters, filtration, mechanical ventilation,

interfaces. The most relevant articles were

selected from the search according to authors’

criteria. Filtration mechanisms

Particles removal by filtration can be achieved by 6

Development different mechanisms of action:2

Interception takes place when a particle which is

The term “Filtration” is defined as the act of or process following a gas streamline comes within one particle

of filtering or, more specifically, as the process of passing radius of a filter fiber. The particle touches the fiber and is

liquids or gases through a filter in order to remove solid captured, thus being removed from the gas. This

particles.1 Filters are employed to prevent the entry of mechanism occurs with medium rank particles, that is to

undesirable particles into the patient through inspired say, from 0.1 to 1 millimeter or bigger which are big

gases and, potentially, remove particles from the exhaled enough so as to have a significant inertia but too small so

gases. The gas exhaled by infected critical patients might as to diffuse into gas flow.

contain viral or bacterial pathogens which can be Inertial Impaction: The particles subjected to inertial

transmitted to other patients, healthcare workers or impaction are usually greater between 0.3 a 1 mm.

visitors.

Multiple bacteria (both inhaling and exhaling ones)

have been isolated from ventilator circuits as well in

humidifiers) Some of the isolated bacteria are

Pseudomonas maltophilia, Pseudomonas aeruginosa,

Klebsiella pneumoniae, Proteus mirabi-lis, Enterobacter

cloacae, Enterobacter agglomerans, Citrobacter diversus,

Candida albicans, Flavobacte-rium meningosepticun,

different kinds of Proteus y Streptococcus. The respiratory

tract is the commonest entry route inside human body. The

shedding of viral particles into the lungs depends on

Physical principles such as Sedimentation, Impaction and

Diffusion. All particles less than 10 micrometers diameter

(µm) diameter (1 µm = 0,001 millimeters) are potentially

active biologically speaking in susceptible patients

Gravitational settling: Large particles in slow-moving Types of filters:

air do not follow gas streamline is more than one particle

There are two types of filters for bacteria/viruses

radius from the fiber. As a result, these particles will be

available to filter inspired gases. Mechanical filters stop

adhered to the fiber This principle affects to bigger

physically particles, due to their small pores which are the

particles, usually bigger than 10 mm.

result of filter’s design; electrostatic filters are

Diffusional impaction: Particles’ Kinetic activity plays

electrostatically charged so they attract and capture

an important role in filtration. All particles are in

charged particles. 3

continuous random movement colliding each other. This

mechanism affects smaller particles, especially those Mechanical filters: They consist in a sheet of resin

lesser tan 0.1 millimeters. The smaller the particle is the bonded glass fibers- (Figure 1).4 The fibers are packed

slower the gas flow is and there is a greater chance that the densely and the sheet has a high-resistance to gas flow

particle may be adhered to the filter. because of the high density of their fibers. A sheet with a

Electrostatic attraction: Some filter material is large surface area is used to reduce the resistance to the

electrostatically charged during manufacture in order to gas flow to an acceptable level. The glass fiber sheet is

enhance its ability to capture particles. There aret then pleated to minimize the required volume and hence

mechanisms of capture: charged particles in the gas stream dead space for the housing.

are attracted to a charged fiber as the electric field on the

fiber induces a dipole in the particles (positive and Glass fiber laminar is hydrophobic and under normal

negative charges on opposite sides of the particles) and clinical conditions does not absorb water. (Figure 2).

charged particles are attracted to neutral fibers by inducing

image forces on the fibers. Electrostatic filters: Unlike glass fiber filters,

Electrostatic filters use a flat layer of fiber material as a

Sieving: Sieving is produced when particles are barrier (Figures 3 y 4).4 Fiber density of electrostatic

physical unable to pass through openings in the filter filters is lower than in glass fiber filters; therefore,

structure and are captured due to their greater size. That is electrostatic filters provide a lower resistance to gas flow

to say, the air stream carries a particle between two fibers, per unit area. Filtration performance is enhanced by

but the particle is larger than the gap, so it becomes applying an electrostatically charged material which

ensnared. attracts and binds any particle which passes through

the filter material. Filter material does not need to be

pleated to increase surface area because of its lesser

resistance to gas flow and electrostatic particles attraction.

For that reason, these filters offer a less dead space. 2

There are two kinds of electrostatic filters:

a. Tribocharged filters: an electrostatic charge can be

induce don two dissimilar fibers by rubbing them

together during the manufacturing process, so that one

type becomes positively charged and the other type

negatively charged (tribocharging) One such filter

material is made from fibers of polypropylene and

modacrylic which can be converted into a non woven

felt

Figure 1. Mechanical filter

Intensive Medine - 2013 - 30 Nº 1

Figure 2. Mechanical filter pleated sheet

Figure 3. Electrostatic filter.

Figure 4. Flat layer of fiber material.

the filter as a percentage of the number of particles in an

aerosol challenge to the filter. The percentage is the

b. Fibrillated coronal- charged filters: An electrostatic penetration value for the filter. Although challenges of

charge can be applied to a sheet of polypropylene by microbes can be used, the standard for breathing system

using a point electrode emitting ions (corona filters specifies that the challenge should consist of a

charging). An opposite charge can be induced on the

particular quantity of an aerosol containing sodium

rear of the sheet. This type of material is often called

an electret. If the sheet of polypropylenes now chloride particles having diameters close to the most

stretched, the strength of the molecular bonds is penetrating particles size. The filter is challenged at a flow

enhanced in the direction of the stretching but reduced of 15 or 30 L. min for filters intended for use with

in a direction perpendicular to it. The sheet can then be pediatric or adult patients, respectively.

split into fibers- a process called fibrillation and made

into a non-woven filter wad.

Another method to determine filter’s efficiency is

High Efficiency Particulate Air (HEPA) which is

Efficiency, technical considered the most rigorous test. HEPA filters are

specifications and clinical classified into True HEPA and HEPA-type, with a

relevance subgroup of HEPA, called Ultra Low Penetration Air

(ULPA). ULPA filters offer an enhanced resistance but

Efficiency: The filtration efficiency of a filter is because of their resistance level is too high so as to

determined by measuring the number of particles through employ them with medical devices. HEPA filers are

HEPA filters have a pleated fiberglass which is used to

increase their surface contact and minimize the required Volume flow Range: Each manufacturer states that the

volume and dead space.5 Larger particles (larger than 0.3 product can be used safely according to the volume flow

µm) are captured through inertial (and sieving) range. The filter use in patients with flow volumes outside

mechanisms, while smaller particles are retained by the range could reduce their efficiency and affect

diffusion. 0.3 µm particles are the most difficult ones to be resistance to air flow.

captured by filtration.

Pressure drop: If there is a huge difference of pressure

There are two mechanisms accepted by HEPA in both sides of the filter because of its resistance to the air

certification: British method BS3928 Sodium Flame and flow, this will make difficult for patients with mechanical

USA Hot DOP (di-ocytyl-phthalate). BS 3928 is the ventilation to breath. Differential pressure through a filter

British standard that specfies the sodium flame test is measured according to a 15 l/min flow for pediatric

method for Hepa filters. In this test, the particle size is filters or 30 l/min for adult filters. This is stated in pascals

smaller than the particle used in USA Hot DOP. BS 3928 (100 Pa = 1.02 cmH2O).

uses a particle with 0.07 µm. In contrast, USA test

employs a 0,3 µm5 particle diameter. HEPA filters are Weight: A too heavy filter could create traction over

classified according to the percentage of particles of an ventilator circuit or the artificial airway. Filter weight

specific size which are not filtered. (See Table). stated by each manufacturer must be obtained when the

As it was already mentioned, 0.3 µm particle is the most filter is under dry conditions and with no use. Any

difficult particle size to capture by filtration. A filter condensation inside the filter when it was used could

should capture particles smaller than de 0.3 µm in increase filter’s weight.

order to be classified as HEPA FILTER. However, it is

important to take into account that HEPA is a scale with Dimensions: The large of a filter is the distance between

different filtration percentages. For instance, H10 HEPA distal ends’ connectors. Width is the maximum distance

filters could capture 85% of all particles and H14 HEPA through filter housing horizontally and height is the

filters could capture 99.995% of all particles. Table below maximum distance through its structure vertically.

shows HEPA Filters performance. Diameter must be considered for those rounded filters.

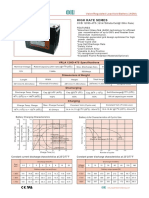

TABLE

HEPA FILTERS PERFORMANCE

TYPE Class Efficiency Penetration

HEPA H 10 85% 15%

HEPA H 11 95% 5%

HEPA H 12 99.5% 0.5%

HEPA H 13 99.95% 0.05%

HEPA H 14 99.995% 0.005%

Internal volume: Filter Internal volume must be

considered inside dead space if the distal is used as a “Y” 7. Mostofi R, Wang B, Haghighat F, et al. Performance of me-

piece. (placed between patient’s artificial airway and “Y” chanical filters and respirators for capturing nanoparticles-

piece circuit) limitations and future direction. Ind Health 2010; 48: 296-304.

Lawes EG. Hidden hazards and dangers associated with the use

Connectors: Filters have two connectors: one with 15 of HME/filters in breathing circuits. Br J Anaesth 2003; 91: 249-

mm and another with 22 mm. 8. 264.

Macroscopic Monitoring

It is advisable to perform a macroscopic monitoring

filter in search of elements which could affect the device

normal functioning (impaction with secretions,

excessive condensation, visible particles, etc.)

The inclusión of a new device inside ventilator circuit

could affect any of the mechanical ventilation patient’s

parameters and measurements obtained in respiratory

revision undertaken. It is important that you can monitor

peak pressure, plateau pressure and medium pressure

parameters, that is to say, to monitor inhaling and exhaling

resistance. The increase of resistance created by a filter

could trigger the presence of intrinsic PEEP and the

consequent rise of peak pressure, plateau pressure and

medium pressure (Intrinsic PEEP occurs when the

expiratory time is shorter than the time needed to fully

deflate the lungs, preventing the lung and chest wall from

reaching an elastic equilibrium point)

Characterístics of a perfect filter

A perfect filter should have the following

characteristics:

• Small internal volume

• Low resistance (electrostatic)

• Transparent

• Lightweight

• Cheap

• High percentage efficiency

• Hydrophobic

Bibliography

1. Filtration. Spanish language dictionary . 22ª ed. 2001.

http://lema.rae.es/drae/?val=filtracion

2. Davey AJ. Ward’s Anesthetic Equipment, 5a ed. Philadelphia,

PA: Elsevier Saunders; 2005: 133-153.

3. Lee MG, Ford JL, Hunt PB, et al. Bacterial retention prop-erties

of heat and moisture exchange filters. Br J Anaesth. 1992; 69:

522-525.

4. Wilkes A. Assessing breathing-system filters. Medical De-vices

Tech 2004; 15(5): 12-14.

5. Wilkes AR. The effect of gas flow on the filtration perfor-mance

of breathing system filters. Anaesthesia 2004; 59: 278-282.

6. Trust Science Innovation. Health and safety. Mechanisms of

Filtration for High Efficiency Fibrous Filters. Application notes

ITI-041. 2008.

You might also like

- SSPC Guide 16 PDFDocument15 pagesSSPC Guide 16 PDFkishorekumar.animu100% (1)

- Denso Protal 7200 Brush Application SpecDocument2 pagesDenso Protal 7200 Brush Application SpecTino VelázquezNo ratings yet

- Air FiltrationDocument29 pagesAir Filtrationmahmoud4871100% (1)

- 832R12011 (Emerging Technologies For Wastewater Treatment - 2nd Ed.)Document188 pages832R12011 (Emerging Technologies For Wastewater Treatment - 2nd Ed.)Anonymous owMJ21JRzC100% (3)

- Unit 3Document64 pagesUnit 3Sufiyan KhanNo ratings yet

- Types of Ro MembraneDocument3 pagesTypes of Ro MembraneDane TanNo ratings yet

- 2002 07 08 - Airflow Management & Control in Pharmaceutical HVAC ApplicationsDocument12 pages2002 07 08 - Airflow Management & Control in Pharmaceutical HVAC ApplicationsHubert BonamisNo ratings yet

- E DAR Filter CatalogDocument38 pagesE DAR Filter CatalogJittiya WatcharotayangulNo ratings yet

- Electrostatic Filters Effects Against Viruses and BacteriaDocument4 pagesElectrostatic Filters Effects Against Viruses and BacteriaSorin LuminaNo ratings yet

- Clean Room-9Document1 pageClean Room-9CIVILNo ratings yet

- CAMFILL HEPA Ispe ArticleDocument12 pagesCAMFILL HEPA Ispe ArticleYing Kei ChanNo ratings yet

- HEPA Filter Inthe Covid 19 Era-Function and EficacyDocument3 pagesHEPA Filter Inthe Covid 19 Era-Function and EficacynoeNo ratings yet

- The Abacus HandbookDocument22 pagesThe Abacus HandbookveselieNo ratings yet

- FiltrationDocument7 pagesFiltrationKers CelestialNo ratings yet

- Overview of Current Collective Protection Filtration TechnologyDocument11 pagesOverview of Current Collective Protection Filtration Technology43No ratings yet

- Modified Indoor Air PurifierDocument6 pagesModified Indoor Air PurifierIJRASETPublicationsNo ratings yet

- Particle and Fiber Mechanics As Related To HEPA FiltationDocument12 pagesParticle and Fiber Mechanics As Related To HEPA FiltationWilliam Greco100% (1)

- Filters and Filtration: A A A A ADocument6 pagesFilters and Filtration: A A A A ASyamsul IrmaNo ratings yet

- Yang 2012Document9 pagesYang 2012povagiNo ratings yet

- SM - CH 7Document50 pagesSM - CH 7Angie Dorado RodriguezNo ratings yet

- Breathing System FiltersDocument4 pagesBreathing System FiltersNiyi ArunaNo ratings yet

- HEPA Filters Key RequirementsDocument12 pagesHEPA Filters Key RequirementsEsra YÖNDEMNo ratings yet

- Air Sanitation 2012Document6 pagesAir Sanitation 2012aleenaNo ratings yet

- HepaDocument6 pagesHepaPatricia HeraNo ratings yet

- ASPIRO TechnologyDocument19 pagesASPIRO Technologysehyong0419No ratings yet

- Reducing Airborne Exposure of COVID 19 Using Air Filtration Systems WhitePaperDocument9 pagesReducing Airborne Exposure of COVID 19 Using Air Filtration Systems WhitePaperColectibondiNo ratings yet

- Clinical and Histological Presentation After Plexr Application, Needle Shaping (Vibrance) and O.F.FDocument9 pagesClinical and Histological Presentation After Plexr Application, Needle Shaping (Vibrance) and O.F.Falejandro GonzàlezNo ratings yet

- 1 PBDocument7 pages1 PBanandhra2010No ratings yet

- Beginner Guide To Particle TechnologyDocument13 pagesBeginner Guide To Particle TechnologyAdnan KaraerNo ratings yet

- Sterilisasi GammaDocument7 pagesSterilisasi Gammadaris sauqiNo ratings yet

- ICCAP2023 Abstract TemplateDocument1 pageICCAP2023 Abstract TemplateAZIL KenzaNo ratings yet

- Sampling InstrumentsDocument20 pagesSampling InstrumentserparixitpandeyNo ratings yet

- Bpe 2Document39 pagesBpe 2Davion StewartNo ratings yet

- Clear Air Solutions - Food & Beverage IndustryDocument9 pagesClear Air Solutions - Food & Beverage Industryqsconsult.ptNo ratings yet

- Cleanroom Air Filters Controlling ContaminationDocument8 pagesCleanroom Air Filters Controlling ContaminationHassan HaniNo ratings yet

- Air Cleaners - Background and MechanismDocument4 pagesAir Cleaners - Background and MechanismKapil KapoorNo ratings yet

- High Efficiency Particulate Air (HEPA) Filters Used in Pharmaceuticals ManufacturingDocument7 pagesHigh Efficiency Particulate Air (HEPA) Filters Used in Pharmaceuticals ManufacturingPrince Moni100% (1)

- Research Article: Design and Fabrication of Smart Diapers With Antibacterial YarnDocument10 pagesResearch Article: Design and Fabrication of Smart Diapers With Antibacterial Yarnelvis bellidoNo ratings yet

- Usp-Nf (1229.4) Sterilizing Filtration of LiquidsDocument7 pagesUsp-Nf (1229.4) Sterilizing Filtration of Liquidsainun endarwatiNo ratings yet

- Official: Á1229.4Ñ Sterilizing Filtration of LiquidsDocument7 pagesOfficial: Á1229.4Ñ Sterilizing Filtration of LiquidsLarissa GolucciNo ratings yet

- Air SanitationDocument8 pagesAir SanitationVignesh ReddyNo ratings yet

- Research Article: Design and Fabrication of Smart Diapers With Antibacterial YarnDocument10 pagesResearch Article: Design and Fabrication of Smart Diapers With Antibacterial Yarnمحمد عليNo ratings yet

- May 2008 New Method Measuring Porous Microbial Barriers PartIDocument4 pagesMay 2008 New Method Measuring Porous Microbial Barriers PartIfabrizioalbertiniNo ratings yet

- Spallation and Particles Infusion Into The Extracorporeal Circuit During CRRT: A Preventable PhenomenonDocument9 pagesSpallation and Particles Infusion Into The Extracorporeal Circuit During CRRT: A Preventable PhenomenonNormanNo ratings yet

- An Analysis of Surgical Smoke Plume Components, Capture, and EvacuationDocument10 pagesAn Analysis of Surgical Smoke Plume Components, Capture, and EvacuationJORGE ANDRES SOTO FORERONo ratings yet

- Air Conditioning and Ventilation 1Document6 pagesAir Conditioning and Ventilation 1Fast ReinNo ratings yet

- Технічні науки - Теличко - ДВDocument3 pagesТехнічні науки - Теличко - ДВmarinatelichko1No ratings yet

- Upstream Processing - Sterilization in Bioprocess TechnologyDocument9 pagesUpstream Processing - Sterilization in Bioprocess TechnologyMark BangzNo ratings yet

- Art Huon Al Mat.-Science-Eng. 2019Document35 pagesArt Huon Al Mat.-Science-Eng. 2019hennaouisihamNo ratings yet

- Levitation of CellsDocument3 pagesLevitation of CellsEngineering and Scientific International JournalNo ratings yet

- Ans ApceDocument18 pagesAns ApcekalpNo ratings yet

- Shu 2017 IOP Conf. Ser. Earth Environ. Sci. 100 012110Document8 pagesShu 2017 IOP Conf. Ser. Earth Environ. Sci. 100 012110trebeardNo ratings yet

- Phase 2Document37 pagesPhase 2Aidan MalamugNo ratings yet

- Term Project - Geodynamics and Multi-SensingDocument9 pagesTerm Project - Geodynamics and Multi-Sensinghandikajati kusumaNo ratings yet

- Working Principle of A Laminar Air Flow ChamberDocument10 pagesWorking Principle of A Laminar Air Flow ChamberBikram MondalNo ratings yet

- Course Work Assignment: Biological TechniquesDocument22 pagesCourse Work Assignment: Biological TechniquesTwi Pei ToeNo ratings yet

- BSC TransDocument3 pagesBSC TransGrace FernandoNo ratings yet

- Amiad Self-Cleaning Strainers For Water FiltrationDocument10 pagesAmiad Self-Cleaning Strainers For Water FiltrationHari Krishna.MNo ratings yet

- Polymers 12 01714 v2Document23 pagesPolymers 12 01714 v2articlesudden7558No ratings yet

- Primary SeparationDocument34 pagesPrimary SeparationPia CabatinganNo ratings yet

- Autonomous Robot-Aided Optical Manipulation for Biological CellsFrom EverandAutonomous Robot-Aided Optical Manipulation for Biological CellsNo ratings yet

- MasterEmaco S 466 PDFDocument145 pagesMasterEmaco S 466 PDFSri KanthNo ratings yet

- BLASTING &PRIMER ProtocolDocument104 pagesBLASTING &PRIMER ProtocolSulekh GhoshNo ratings yet

- Copper and The Copper-Base AlloysDocument32 pagesCopper and The Copper-Base AlloysVIVEK UPADHYAYNo ratings yet

- 207 HD 52505 Uv Jam PetrochemicalDocument2 pages207 HD 52505 Uv Jam Petrochemicalriza abdollahyNo ratings yet

- Crack Identification in Reinforced Concrete Beams Using ANSYS SoftwareDocument13 pagesCrack Identification in Reinforced Concrete Beams Using ANSYS SoftwarethaibinhkxNo ratings yet

- Acamprosate CalciumDocument2 pagesAcamprosate Calciumjafranco.tfsNo ratings yet

- 11-Msds Mobile SHC 624Document9 pages11-Msds Mobile SHC 624Fatimazahra SahriNo ratings yet

- DC Values Compendium - EN - 2014 PDFDocument96 pagesDC Values Compendium - EN - 2014 PDFLeandro DarquiNo ratings yet

- Background Information: Methodology: ProcedureDocument6 pagesBackground Information: Methodology: ProcedureAlexandra Ramos MNo ratings yet

- Bitesize Bio SDS-PAGE Cheat Sheet: Essential Buffer and Gel Recipes For Your LaboratoryDocument4 pagesBitesize Bio SDS-PAGE Cheat Sheet: Essential Buffer and Gel Recipes For Your LaboratoryCristian RuizNo ratings yet

- Toxicity of Common Laboratory Chemicals To Human Red Blood Cells Laboratory ActivityDocument4 pagesToxicity of Common Laboratory Chemicals To Human Red Blood Cells Laboratory ActivityKuven Malig-onNo ratings yet

- High Rate Series: CCB 12HD-475Document1 pageHigh Rate Series: CCB 12HD-475orunmila123No ratings yet

- Cystatin CDocument4 pagesCystatin CГалина МиловановаNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument7 pagesSafety Data Sheet: 1. IdentificationGan Chai SInNo ratings yet

- The Influence of Methanol Concentration To Biodiesel Yield and QualityDocument5 pagesThe Influence of Methanol Concentration To Biodiesel Yield and QualityOniNo ratings yet

- Flootank® Catalogue 2022Document21 pagesFlootank® Catalogue 2022Anindra Ahmad FarrasNo ratings yet

- Sample Questions For Anaphy and PhysiologyDocument90 pagesSample Questions For Anaphy and PhysiologyMaria Jeorgia SalinasNo ratings yet

- Kerala PET 2014 PaperDocument40 pagesKerala PET 2014 PaperSonu YadavNo ratings yet

- Chemistry Form 6 Sem 2 05 WebDocument56 pagesChemistry Form 6 Sem 2 05 WebNg Swee Loong StevenNo ratings yet

- Metabolism Exam 2 - GIFT - Spring 2016Document9 pagesMetabolism Exam 2 - GIFT - Spring 2016shafa_nathani100% (2)

- 01 Introduksi Material KompositDocument45 pages01 Introduksi Material KompositAdita EvalinaNo ratings yet

- Magnetic Terms and UnitsDocument3 pagesMagnetic Terms and UnitsDeepak Choudhary DCNo ratings yet

- ELIX & WHITTON 1983 Recent Progress in The Chemistry of Lichen SubstancesDocument132 pagesELIX & WHITTON 1983 Recent Progress in The Chemistry of Lichen SubstancesLeFlochNo ratings yet

- ứng dụng de novo trong điều trị SAR-CoV-2Document35 pagesứng dụng de novo trong điều trị SAR-CoV-2Beo NguyễnNo ratings yet

- Sample Problem 1: X Direction X Direction XDocument4 pagesSample Problem 1: X Direction X Direction XHarold MangaNo ratings yet

- Acid SlurryDocument8 pagesAcid SlurryVinod GoelNo ratings yet

- RWTSSGDocument54 pagesRWTSSGObscuredSolutionsNo ratings yet