Professional Documents

Culture Documents

Flex I Gauge

Flex I Gauge

Uploaded by

head_masterOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flex I Gauge

Flex I Gauge

Uploaded by

head_masterCopyright:

Available Formats

Flexigauge

Flexigauge is a precision manufactured plastic strip

It is available in four sizes and is used to check clearance of main and connecting rod bearings, and is suitable for Automotive,

Marine, and Industrial applications.

The Four sizes available together cover clearances from .001 in to .016 in or .025mm to .406mm and as follows :

Reference Description Covers Clearance Between

AG-1 Flexigauge Green .001”-.003” (0.025mm-0.076mm)

AR-1 Flexigauge Red .002”-.006” (0.051mm-0.152mm)

AB-1 Flexigauge Blue .004”-.009” (0.102mm-0.229mm)

AY-1 Flexigauge Yellow .008”-.016” (0.203mm-0.406mm)

Flexigauge strips are 12” inches long (309.8mm) and are packed in individual envelopes, which are marked in appropriate gradu-

ation one side in thousandths of an inch and the other side in millimetres. Ten strips in their envelopes are packed in their appro-

priate colour coded carton.

Directions for use, which are printed on the outside of each carton for easy reference, are as follows :

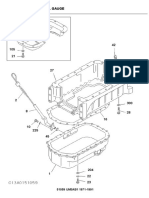

1. Remove the bearing cap, wipe the journal and bearing shell clear of all oil

2. Place a piece of Flexigauge across the bearing at the crown (see fig 1)

3. Install the bearing cap and using a torque wrench tighten the bolts to the correct tension.

DO NOT ROTATE THE SHAFT OR BEARINGS.

4. Remove the Bearing cap. The Flexigauge will be adhering either to the bearing or shaft.

5. Compare the width of the flattened Flexigauge with the graduation of the envelope. The figure within the graduations

indicates the clearance in thousands of an inch or millimetres, depending on which side of the envelope is used. (fig 2)

6. Taper is indicated when Flexigauge is wider at one end than the other, the amount of taper being the difference between

the readings. The widest part of the flexigauge represents the area of least clearance. “Barrelling” of the shaft happens

when the Flexigauge is wider in the centre of the bearing.

Precaution

When checking main bearings, with the CAP supporting the crankshaft, the weight of the crankshaft and

flywheel must be taken off the the bearing caps to avoid inaccurate results. This can be done, for example, by

‘jacking’ on the crankshaft balance weight.

Main and connecting rod bearing clearances should be checked on the area of least journal wear. Main

bearing checks should be made with the adjacent crankpin situated about 30 degrees after bottom dead

centre.

You might also like

- Fletcher 2100 ManualDocument27 pagesFletcher 2100 ManualLaura Stolfi67% (3)

- Triumph 69-73 Trident Workshop ManualDocument248 pagesTriumph 69-73 Trident Workshop Manualhead_master100% (1)

- Motor Hyundai D4eb-Diesel 2.2Document91 pagesMotor Hyundai D4eb-Diesel 2.2Igatech Diesel82% (11)

- Component: The 4-Way Protection Valve Cannot Be Disassembled!Document16 pagesComponent: The 4-Way Protection Valve Cannot Be Disassembled!Herman100% (1)

- Job Hazard Analysis For Crane DismantlingDocument2 pagesJob Hazard Analysis For Crane DismantlingKamlesh Bule Lonari100% (2)

- Serie 60 Informacion AdicionalDocument51 pagesSerie 60 Informacion AdicionalMauricio Campos Quiros100% (1)

- BMW M5254 Checking Camshaft Timing (M52TU - M54)Document6 pagesBMW M5254 Checking Camshaft Timing (M52TU - M54)head_masterNo ratings yet

- CC 7502 - INSTRUMENT INSTALLATION & HOOK-UP INSPECTION CHECKLIST - Rev 3Document2 pagesCC 7502 - INSTRUMENT INSTALLATION & HOOK-UP INSPECTION CHECKLIST - Rev 3samboopathiNo ratings yet

- ACL FlexigaugeDocument2 pagesACL Flexigaugejuanmanuel_4615958No ratings yet

- Drive Shaft O&M April 2010Document4 pagesDrive Shaft O&M April 2010elperrote3No ratings yet

- Montaje de Ventilador Cooling Tower 2Document12 pagesMontaje de Ventilador Cooling Tower 2Ale HqzNo ratings yet

- OguideDocument15 pagesOguidephantuan080213No ratings yet

- OWI 1000 DrawworksDocument54 pagesOWI 1000 DrawworksÖnder Büyükişcan100% (1)

- Seals: V-Ring PackingsDocument6 pagesSeals: V-Ring PackingsRtfjrjgr Xefwwxebge XsjlkzxzlsjxsjNo ratings yet

- IKO Shell Needle RollerDocument25 pagesIKO Shell Needle RollermandosasdNo ratings yet

- Sure-Flex Elastomeric Couplings: EctionDocument7 pagesSure-Flex Elastomeric Couplings: EctionEdgar Joel Torres OlórteguiNo ratings yet

- Installation Manual Serial 4000 HW - Tuf-Lite IIDocument8 pagesInstallation Manual Serial 4000 HW - Tuf-Lite IIAnonymous LBwADkNZHNo ratings yet

- Design Factors When Using Small Bearings: Part 2: Mounting and FittingDocument11 pagesDesign Factors When Using Small Bearings: Part 2: Mounting and FittingankitsarvaiyaNo ratings yet

- Mini Project 3 IDocument5 pagesMini Project 3 IRavi Kiran JanaNo ratings yet

- Acoples TB Wood SDocument100 pagesAcoples TB Wood SLuis CastrovillariNo ratings yet

- SI500.11r5e - GrafoilDocument5 pagesSI500.11r5e - GrafoilHumayun NawazNo ratings yet

- Section3 o Ring BasicsDocument4 pagesSection3 o Ring Basicssteve@air-innovations.co.zaNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- Wa1 358 5674Document30 pagesWa1 358 5674MROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Mechanical Seal Installation InstructionDocument4 pagesMechanical Seal Installation InstructionSandi AslanNo ratings yet

- Catálogo de Camisas MELLINGDocument24 pagesCatálogo de Camisas MELLINGricassterNo ratings yet

- Unbalanced and Pressure-Balanced Trim: Sizing & SelectionDocument6 pagesUnbalanced and Pressure-Balanced Trim: Sizing & SelectionPratik134No ratings yet

- Dana CouplingsDocument88 pagesDana CouplingsClaudio Sanchez100% (1)

- Shiver DCDocument12 pagesShiver DCAndreas P.No ratings yet

- GRLC Grayloc Installation Maintenance Bulletin Rev JDocument4 pagesGRLC Grayloc Installation Maintenance Bulletin Rev JlsgmzNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- لقطة شاشة ٢٠٢٤-٠٣-١٢ في ١.٥٦.٥٩ مDocument8 pagesلقطة شاشة ٢٠٢٤-٠٣-١٢ في ١.٥٦.٥٩ مamer albarikiNo ratings yet

- W01 358 7442Document29 pagesW01 358 7442MROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- Piston Instrc2618Document2 pagesPiston Instrc2618Oliver TonnaNo ratings yet

- Melling Cylinder Sleeves 2014 CatalogDocument40 pagesMelling Cylinder Sleeves 2014 CatalogBzidroglioNo ratings yet

- 85245AM Sprocket Installationinstr032cDocument3 pages85245AM Sprocket Installationinstr032cfparra2777No ratings yet

- Qa-Lhb-Lifting-Roller Bearing and Wheel AssemblyDocument7 pagesQa-Lhb-Lifting-Roller Bearing and Wheel AssemblySriram SubramanianNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- W01 358 6910Document29 pagesW01 358 6910MROstop.comNo ratings yet

- W01 358 6900 Firestone Double Convoluted Air SpringDocument29 pagesW01 358 6900 Firestone Double Convoluted Air SpringMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Bearing Installation FittingDocument4 pagesBearing Installation FittingNishant GuptaNo ratings yet

- W01 358 7830Document29 pagesW01 358 7830MROstop.comNo ratings yet

- Cs 59 ManDocument22 pagesCs 59 ManLuis GpNo ratings yet

- Ball ScrewDocument4 pagesBall ScrewJohn BlackburnNo ratings yet

- Metastream TSC Coupling IOMDocument4 pagesMetastream TSC Coupling IOMthanhphamNo ratings yet

- W02 358 4001Document30 pagesW02 358 4001MROstop.comNo ratings yet

- Assembly Instruction Compression Dead End Clamp For AL, ALDREY, ACAR and AW ConductorsDocument4 pagesAssembly Instruction Compression Dead End Clamp For AL, ALDREY, ACAR and AW Conductorsyavuz772No ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Bearing SNN Sadf 3 0Document32 pagesBearing SNN Sadf 3 0Budy AndikaNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- Bearing Installation ProcedureDocument6 pagesBearing Installation ProcedureHamad KhaledNo ratings yet

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- O Ring Cat v2 LRDocument108 pagesO Ring Cat v2 LRhead_masterNo ratings yet

- Drill Thread Chart enDocument4 pagesDrill Thread Chart enhead_masterNo ratings yet

- Rolls Royce / Bentley Service Handbook 1955Document1,283 pagesRolls Royce / Bentley Service Handbook 1955head_masterNo ratings yet

- Stategen Lister-Petter Hr2-3 Parts ManDocument274 pagesStategen Lister-Petter Hr2-3 Parts Manhead_master100% (1)

- Riley 2.5 - ADocument26 pagesRiley 2.5 - Ahead_masterNo ratings yet

- A32 emDocument75 pagesA32 emLevin Tan HtNo ratings yet

- Project: AV006 - CHH Master Drawing Deliverables: 1 Front End Engineering DesignDocument1 pageProject: AV006 - CHH Master Drawing Deliverables: 1 Front End Engineering DesignAlleo MarquezNo ratings yet

- Alfa Laval Unique SSV Aseptic Manually Operated Valve Product Leaflet PDFDocument8 pagesAlfa Laval Unique SSV Aseptic Manually Operated Valve Product Leaflet PDFMahendra WedastamaNo ratings yet

- Load CombinationDocument3 pagesLoad CombinationAsaru DeenNo ratings yet

- MP II - Lecture 3 - Thread and Gear ManufacturingDocument57 pagesMP II - Lecture 3 - Thread and Gear ManufacturingArif Hossain100% (1)

- Dewalt Onsite Offers Oct 2020 - Jan 2021Document15 pagesDewalt Onsite Offers Oct 2020 - Jan 2021Phong DuongNo ratings yet

- Foundations of BuildingDocument19 pagesFoundations of BuildingNovia Dwi CahyantiNo ratings yet

- (PDF) Machining Operations and Machine ToolsDocument31 pages(PDF) Machining Operations and Machine ToolsKishwatNo ratings yet

- Steam Turbine Diaphragm Repair StrategyDocument8 pagesSteam Turbine Diaphragm Repair StrategyEliyanto E Budiarto100% (2)

- Um3ab1 Oil PanDocument2 pagesUm3ab1 Oil PanBurik8No ratings yet

- Fit Up Report Format-1Document1 pageFit Up Report Format-1BalkishanDyavanapellyNo ratings yet

- Aductor y AbductorDocument44 pagesAductor y AbductormiguelNo ratings yet

- Flow Control: Weir Specialty PumpsDocument4 pagesFlow Control: Weir Specialty PumpsAlexander RivillasNo ratings yet

- Australia Farm Innovations Design Parameters Project Name: LocationDocument65 pagesAustralia Farm Innovations Design Parameters Project Name: LocationJing BuenafeNo ratings yet

- Borello-Bolted Steel Slip-Critical Connections With Fillers I. PerformanceDocument10 pagesBorello-Bolted Steel Slip-Critical Connections With Fillers I. PerformanceaykutNo ratings yet

- Continuous Machinery SurveyDocument7 pagesContinuous Machinery SurveyEko Prasetiyo100% (1)

- Marker C&P Line - Manual - Servicio - 90x60RDocument18 pagesMarker C&P Line - Manual - Servicio - 90x60Rbryan.cassonNo ratings yet

- 10001-A30-22-Rev-B - Technical Report - Asera Rahabangga - LRBDocument15 pages10001-A30-22-Rev-B - Technical Report - Asera Rahabangga - LRBandhika maulana100% (1)

- IOGP - Recommended - Practice - ScaffoldingDocument2 pagesIOGP - Recommended - Practice - ScaffoldingMohd Kazi Abdul RahmanNo ratings yet

- DC Motor InstDocument3 pagesDC Motor InstJimmy JamesNo ratings yet

- Gagemaker: Functional Diameter Thread GaugesDocument12 pagesGagemaker: Functional Diameter Thread GaugesCarlos LucioNo ratings yet

- 3 - WHP5-Tailor-Made-Gear-PumpsDocument61 pages3 - WHP5-Tailor-Made-Gear-PumpsMarinko Knezevic Crtica KarasNo ratings yet

- CVH Series PDFDocument9 pagesCVH Series PDFhendrabudimanNo ratings yet

- HMA-36509 - Reclaim Feeder Manual RevcDocument111 pagesHMA-36509 - Reclaim Feeder Manual RevcAbdul HamidNo ratings yet

- Layher Allround 2005Document32 pagesLayher Allround 2005chakshu mottaNo ratings yet

- Ii Mech - Cia - I - QPDocument33 pagesIi Mech - Cia - I - QPMURALI KRISHNAN RNo ratings yet

- Ge Ge752 User Manual 61 62Document2 pagesGe Ge752 User Manual 61 62RICHARDNo ratings yet

- NTO05 - ETOPS Maintenance Procedures Manual Rev3Document53 pagesNTO05 - ETOPS Maintenance Procedures Manual Rev3diegopospo97No ratings yet