Professional Documents

Culture Documents

Industrial Gas Springs - Push Type GS-28

Uploaded by

Lucyan IonescuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Industrial Gas Springs - Push Type GS-28

Uploaded by

Lucyan IonescuCopyright:

Available Formats

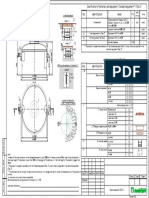

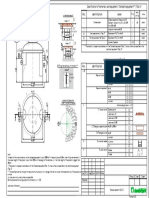

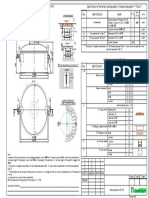

Industrial Gas Springs – Push Type GS-28

137

Valve Technology , Force range 150 N to 2,500 N (compressed up to 4,175 N)

End Fitting Standard Dimensions End Fitting

Ø 8.1 12 thick Ø 8.1

Ø 18 12 thick

A10 Eye A10

max. force 10,000 N

Radius 17 Ø 14 Ø 28 17

R9 Stroke

25 L+/- 2 mm extended 25

B10 M10x1.5 Performance and Dimensions Stud Thread B10

Stroke L extended Force Range max.

12 TYPES mm mm N 12

C10 Ø 24 Ø 16 GS-28-100 100 262 2,500 Angle Ball Joint C10

GS-28-150 150 362 2,500 max. force 1,800 N

GS-28-200 200 462 2,500

16 GS-28-250 250 562 2,500

18

GS-28-300 300 662 2,500

20 35 GS-28-350 350 762 2,500 35

M10x1.5 GS-28-400 400 862 2,500

36° GS-28-450 450 962 2,500

D10 Ø 10 GS-28-500 500 1,062 2,500

Clevis Fork D10

GS-28-550 550 1,162 2,500 max. force 10,000 N

GS-28-600 600 1,262 2,500

20 10 GS-28-650 650 1,362 2,500

GS-28-700 700 1,462 2,500

20 GS-28-750 750 1,562 2,500

12 40 40

E10 Ø 19

Swivel Eye E10

24° Ø 15 max. force 10,000 N

Ø 10

7

Ordering Example GS-28-150-EE-1200

9

Type (Push Type)

16 18

43 Body Ø (28 mm) 43

14

Stroke (150 mm)

F10 M10x1.5 AF17 Piston Rod End Fitting E10 Inline Ball Joint F10

45° AF17 Body End Fitting E10 max. force 1,800 N

Nominal Force F1 1200 N

19

25 43 43

Mounting accessories see from

page 194.

Rod Shroud W10-28

Ø 32

12

L = Stroke + 40

Adjuster Knob

DE-GAS-10

See page 171.

Technical Data

Force range: 150 N to 2,500 N (compressed up to 4,175 N)

Progression: Approx. 58 % to 67 %

GS-28 Operating temperature range: -20 °C to +80 °C

Material: Outer body: Steel coated with UV paint; Piston rod: Steel

A10 with wear-resistant coating; End fittings: Zinc plated steel

C10 Mounting: In any position. Hint: We recommend mounting with piston

D10

Issue 08.2016 – Specifications subject to change

rod downwards to take advantage of the built-in end position damping.

E10

F10 End position damping length: Approx. 30 mm to 70 mm

(depending on the stroke)

MA10

Positive stop: External positive stop at the end of stroke provided by

the customer.

E10

Note: Integrated grease chamber reduces friction and wear and

ME10

optimises lubrication.

End fittings: They are interchangeable and must be positively secured

OE10 by the customer to prevent unscrewing.

PE10

Safety instructions: Gas springs (push type) should not be installed

under pre-tension.

ACE Stoßdämpfer GmbH . PO Box 1510 . D-40740 Langenfeld . T +49 (0)2173 - 9226-4100 . F +49 (0)2173 - 9226-89 . info@ace-int.eu . www.ace-ace.com

You might also like

- Colorful Chalkboard Classroom Labels and OrganizersFrom EverandColorful Chalkboard Classroom Labels and OrganizersNo ratings yet

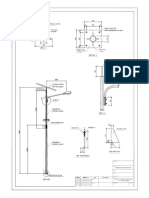

- TIANG PJU SOLARCELL H-7 ModelDocument1 pageTIANG PJU SOLARCELL H-7 ModelYUSYAFRIL ILHAMNo ratings yet

- Tiang PJU 9mDocument1 pageTiang PJU 9mHamzah NurfirdausNo ratings yet

- RF1000-R2, AISI316, FRAME AISI304 Main DWG, Rf1000: General Tolerances Scale ProductDocument1 pageRF1000-R2, AISI316, FRAME AISI304 Main DWG, Rf1000: General Tolerances Scale ProducthazemNo ratings yet

- PJU H 9mtr Tunggal PDFDocument1 pagePJU H 9mtr Tunggal PDFbgan29No ratings yet

- Drawing Enkad BF162-421GODocument1 pageDrawing Enkad BF162-421GOAgus HaryadieNo ratings yet

- Archivos 41 ADocument1 pageArchivos 41 ANazareno VieraNo ratings yet

- M-Sec-08 - Rev-ADocument1 pageM-Sec-08 - Rev-AhungNo ratings yet

- Ptfe-Lined Butterfly Valve T 212-ADocument4 pagesPtfe-Lined Butterfly Valve T 212-AJOHNNo ratings yet

- Tiang PJU Oktagonal H-06M SP (Bottom 160mm) Sock 2 Inch RevDocument1 pageTiang PJU Oktagonal H-06M SP (Bottom 160mm) Sock 2 Inch Revkusnadi st100% (1)

- BG32611PE - Layout1Document1 pageBG32611PE - Layout1Frederique VerhulstNo ratings yet

- Section 2-2 Scale 1:20: Sheet No. Client Sheet Title Consultant Planning Design Team Project TitleDocument1 pageSection 2-2 Scale 1:20: Sheet No. Client Sheet Title Consultant Planning Design Team Project TitlePrabhat BaralNo ratings yet

- Lista de Materiales: Item Diam Cant DescripcionDocument1 pageLista de Materiales: Item Diam Cant DescripcionMarcia IturraNo ratings yet

- Tiang7 MeterDocument1 pageTiang7 MeterYUSYAFRIL ILHAMNo ratings yet

- SNBC Typical Detal PDFDocument1 pageSNBC Typical Detal PDFZubair MuhammadNo ratings yet

- LS800E (Multiple Levels Large Size Alloys)Document3 pagesLS800E (Multiple Levels Large Size Alloys)Kj_bdNo ratings yet

- Fig-970-G-OLD DESIGNDocument1 pageFig-970-G-OLD DESIGNAsmaaNo ratings yet

- Specification of Materials and Equipment. Standard Equipment (Tabl.1) Pos. Identification NameDocument1 pageSpecification of Materials and Equipment. Standard Equipment (Tabl.1) Pos. Identification NameRadu GheorghițăNo ratings yet

- Gambar Shop Drawing Dengan Wiremesh PDFDocument1 pageGambar Shop Drawing Dengan Wiremesh PDFengineer jbiNo ratings yet

- 1 Strainer y Type With Flanged EndsDocument4 pages1 Strainer y Type With Flanged EndsGourav SharmaNo ratings yet

- Merlo 75 FT Steel PoleDocument1 pageMerlo 75 FT Steel Polearlene borborNo ratings yet

- AV179348Document1 pageAV179348khanh123ctmNo ratings yet

- B1-77 - A-PLATEx2 - Rev 0Document1 pageB1-77 - A-PLATEx2 - Rev 0Gedug SiswantoroNo ratings yet

- RX 3100Document2 pagesRX 3100rakhikishore143No ratings yet

- RX 3100Document2 pagesRX 3100rakhikishore143No ratings yet

- 6 Gear Pump Group AP300: M Max 230 NM Rear and Front Cover Cast Iron MadeDocument8 pages6 Gear Pump Group AP300: M Max 230 NM Rear and Front Cover Cast Iron MadeMai Văn TĩnhNo ratings yet

- OM - DD - F - 07 Master List of DrawingsDocument10 pagesOM - DD - F - 07 Master List of DrawingssharanNo ratings yet

- Pressure Gauge AdaptersDocument10 pagesPressure Gauge AdaptersGepef ProduçãoNo ratings yet

- 1.traffic Signal PoleDocument1 page1.traffic Signal Polelibin513No ratings yet

- Fisa Tehnica Usa Batanta Dubla ELITE - ENDocument2 pagesFisa Tehnica Usa Batanta Dubla ELITE - ENsebastian.taflan86No ratings yet

- Instruction For Use S CD75GS 5 5x183 Instruction For Use PUB 5357471 000Document1 pageInstruction For Use S CD75GS 5 5x183 Instruction For Use PUB 5357471 000Marian DascaluNo ratings yet

- Wafer Type Butterfly Valve Z 411-A Wafer Type Butterfly Valve Z 411-ADocument4 pagesWafer Type Butterfly Valve Z 411-A Wafer Type Butterfly Valve Z 411-ANguyen Quang NamNo ratings yet

- Metric DIN 6885 SpecDocument4 pagesMetric DIN 6885 SpecDobrica PetrovicNo ratings yet

- GreenSpace Gen IIIDocument2 pagesGreenSpace Gen IIIAntonio Chavez GarciaNo ratings yet

- IVECO 8210SRi40.00Document6 pagesIVECO 8210SRi40.00jvega_534120No ratings yet

- Bản vẽ bình 3000L - DVADocument1 pageBản vẽ bình 3000L - DVANhật Quang PhạmNo ratings yet

- G Rease Separator GLR-5 (S 1:25) Specification of Materials and Equipment. Standard Equipment (Tabl.1) Pos. Identification NameDocument1 pageG Rease Separator GLR-5 (S 1:25) Specification of Materials and Equipment. Standard Equipment (Tabl.1) Pos. Identification NameRadu GheorghițăNo ratings yet

- Ins PT005Document1 pageIns PT005faisal hajjNo ratings yet

- ChartAccessServlet 2Document1 pageChartAccessServlet 2Alma BravoNo ratings yet

- 8420-002 - Jakarta 400m3 - Top View Rev 02Document1 page8420-002 - Jakarta 400m3 - Top View Rev 02Sigit Adi PrayogaNo ratings yet

- Modification Anagnostou (Ang) : Reference Documents / DrawingsDocument1 pageModification Anagnostou (Ang) : Reference Documents / DrawingsNikolas MNo ratings yet

- 50 10xaa1 He40 22RDCH 1016Document1 page50 10xaa1 He40 22RDCH 1016uma raneNo ratings yet

- Pt. Rahmi Ida Nusantara: Sumbagut-2 Peaker Power Plant (Electrical)Document20 pagesPt. Rahmi Ida Nusantara: Sumbagut-2 Peaker Power Plant (Electrical)Andri WahyudiNo ratings yet

- 3Document1 page3ျမတ္ သူ ေအာင္No ratings yet

- Wafer Type Butterfly Valve Z 611-cDocument4 pagesWafer Type Butterfly Valve Z 611-cJOHN100% (1)

- Manual: User SDocument7 pagesManual: User SRoberd LeeNo ratings yet

- G Rease Separator GLR-20 (S 1:40) Specification of Materials and Equipment. Standard Equipment (Tabl.1) Pos. Identification NameDocument1 pageG Rease Separator GLR-20 (S 1:40) Specification of Materials and Equipment. Standard Equipment (Tabl.1) Pos. Identification NameRadu GheorghițăNo ratings yet

- CPTC Thermistor-PPL Series For ICLDocument9 pagesCPTC Thermistor-PPL Series For ICLMohamed AmineNo ratings yet

- Foot Valves Stainless Steel 304 Strainer & Cast Iron Body - F320Document2 pagesFoot Valves Stainless Steel 304 Strainer & Cast Iron Body - F320immanuel izaniNo ratings yet

- 2016 - DWG-DG - X - 16 - Pak Amir - Makassar - Tiang Lampu Sorot - h13 - OctagonalDocument1 page2016 - DWG-DG - X - 16 - Pak Amir - Makassar - Tiang Lampu Sorot - h13 - OctagonalHendra DarmawanNo ratings yet

- Suran Sing Schedule Rev CDocument1 pageSuran Sing Schedule Rev CNitroNo ratings yet

- 2023 - TGE - TIANG PJU H6000 OCTAGONAL - SINGLE PARABOLE - BOTTOM 110mmDocument1 page2023 - TGE - TIANG PJU H6000 OCTAGONAL - SINGLE PARABOLE - BOTTOM 110mmMuchdiana MuchtarNo ratings yet

- Curve S - AlDocument46 pagesCurve S - AlNila MustikaNo ratings yet

- 12 - Globe - 2 in To 6 in - Class 150 - WCB - Trim 16 - RF - Gl01-c020-468 Rev2Document1 page12 - Globe - 2 in To 6 in - Class 150 - WCB - Trim 16 - RF - Gl01-c020-468 Rev2satphoenixNo ratings yet

- Catalog Ava Tiger FitDocument1 pageCatalog Ava Tiger Fitazlen494No ratings yet

- Hex Nut M12 Tapping Drawing-Model1Document1 pageHex Nut M12 Tapping Drawing-Model1YB GROUP OF INDUSTRIES PVT. LTDNo ratings yet

- Asg Double CouplingsDocument3 pagesAsg Double CouplingsAndrew WatsonNo ratings yet

- Wafer Type Butterfly Valve Z 611-kDocument4 pagesWafer Type Butterfly Valve Z 611-kJOHNNo ratings yet

- 1411 00 Bal 88-10-2703 enDocument178 pages1411 00 Bal 88-10-2703 enLucyan IonescuNo ratings yet

- Component Lists and Index For Wiring DiagramsDocument53 pagesComponent Lists and Index For Wiring DiagramsLucyan Ionescu0% (1)

- Operating Manual: Clean AheadDocument200 pagesOperating Manual: Clean AheadLucyan IonescuNo ratings yet

- Service Manual Minarctig Evo 200: Kemppi OyDocument27 pagesService Manual Minarctig Evo 200: Kemppi OyLucyan IonescuNo ratings yet

- Iveco Workshop ManualDocument378 pagesIveco Workshop ManualMariam100% (6)

- Gear Pumps and Motors "B" Series Group 2,5: Technical CatalogueDocument29 pagesGear Pumps and Motors "B" Series Group 2,5: Technical CatalogueLucyan IonescuNo ratings yet

- Mir W170-170PL-W190 IngleseDocument450 pagesMir W170-170PL-W190 IngleseLucyan Ionescu89% (9)

- Komatsu PC88MR-6 Shop Manual WEBM007200Document328 pagesKomatsu PC88MR-6 Shop Manual WEBM007200Lucyan Ionescu100% (6)

- Transmision Clark 24000Document21 pagesTransmision Clark 24000Lucyan Ionescu0% (2)

- AR13H Rev 15 ManualDocument116 pagesAR13H Rev 15 ManualLucyan IonescuNo ratings yet

- TH330B Service ManualDocument1,247 pagesTH330B Service ManualLucyan Ionescu100% (3)

- Mercedes Vito 2003-2008 Service ManualDocument249 pagesMercedes Vito 2003-2008 Service ManualLucyan Ionescu100% (1)

- Genie S 85 S 80X Service and Repair ManualDocument301 pagesGenie S 85 S 80X Service and Repair ManualLucyan Ionescu100% (1)

- Lesson 4: Advanced Spreadsheet SkillsDocument15 pagesLesson 4: Advanced Spreadsheet Skillserika gail sorianoNo ratings yet

- Ansi C37.72-1987 PDFDocument25 pagesAnsi C37.72-1987 PDFIvanNo ratings yet

- Corning SMF-28 DatasheetDocument2 pagesCorning SMF-28 DatasheetsusyheunaNo ratings yet

- Be It Enacted by The Senate and House of Representative of The Philippines in Congress AssembledDocument36 pagesBe It Enacted by The Senate and House of Representative of The Philippines in Congress AssembledGina Portuguese GawonNo ratings yet

- Binary and Decimal Number Systems: Addressing The Network - Ipv4Document3 pagesBinary and Decimal Number Systems: Addressing The Network - Ipv4Mase Astrid C. BarayugaNo ratings yet

- TX IrhsDocument1 pageTX IrhsvelizarkoNo ratings yet

- GD200A Manual EnglishDocument269 pagesGD200A Manual Englishtran dieuNo ratings yet

- My Lovely ResumeDocument3 pagesMy Lovely ResumeJanicz BalderamaNo ratings yet

- BH MobileDocument6 pagesBH MobileleostojcicNo ratings yet

- FPFH Standar InstallationDocument13 pagesFPFH Standar InstallationYulius IrawanNo ratings yet

- DIN EN 179 I 1125 PDFDocument3 pagesDIN EN 179 I 1125 PDFDushan RomicNo ratings yet

- Manual Operacion Compresores de AireDocument204 pagesManual Operacion Compresores de AireHugo RodriguezNo ratings yet

- POCLP010101 Wood PelletsDocument1 pagePOCLP010101 Wood PelletsPratiwi CocoNo ratings yet

- 24 - Counting of Bottles - Solution - ENGDocument3 pages24 - Counting of Bottles - Solution - ENGhaftu gideyNo ratings yet

- S5 ManualDocument39 pagesS5 ManualAleena ShajuNo ratings yet

- Atlas Copco ZT55 Instruction ManualDocument90 pagesAtlas Copco ZT55 Instruction ManualRafael Martin Anaya Figueroa100% (4)

- Diffusion of Helium Through QuartzDocument5 pagesDiffusion of Helium Through QuartzElenaNo ratings yet

- NeuCardio E12Document2 pagesNeuCardio E12Daniel ParNo ratings yet

- Deepwell Submersible Motor 50HzDocument38 pagesDeepwell Submersible Motor 50HzSujanto WidjajaNo ratings yet

- Lesson 5 Digital Technology and Social ChangeDocument14 pagesLesson 5 Digital Technology and Social ChangeIshang IsraelNo ratings yet

- Husic GuideDocument3 pagesHusic Guideth1mkNo ratings yet

- African Music Re-Examined in The Light of New Materials From The Belgian Congo and Ruanda Urundi Akab P Merriam African Music Re-ExaminedDocument9 pagesAfrican Music Re-Examined in The Light of New Materials From The Belgian Congo and Ruanda Urundi Akab P Merriam African Music Re-Examinedberimbau8No ratings yet

- Laporan Beton 1Document80 pagesLaporan Beton 1Seulgi BearNo ratings yet

- Summary Key ParameterDocument18 pagesSummary Key ParameterAndry JatmikoNo ratings yet

- Training Report at TATA MotorsDocument28 pagesTraining Report at TATA MotorsAkarsh60% (5)

- Sts Lesson 6Document13 pagesSts Lesson 6Ivy Joy BelzaNo ratings yet

- Information: Reading Images - The Grammar of Visual DesignDocument5 pagesInformation: Reading Images - The Grammar of Visual DesignAndang Prasetya Adiwibawa BernardusNo ratings yet

- Rahul BhartiDocument3 pagesRahul BhartirahuldearestNo ratings yet

- G700 03 603333 1Document382 pagesG700 03 603333 1Jorge CruzNo ratings yet

- Bank of AmericaDocument3 pagesBank of AmericamortensenkNo ratings yet