Professional Documents

Culture Documents

CV 41

CV 41

Uploaded by

Alfredo Bautista HernándezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CV 41

CV 41

Uploaded by

Alfredo Bautista HernándezCopyright:

Available Formats

CV41-0616

CHECK VALVE f WAFER TYPE f DUAL DISC

TITAN

ANSI CLASS 150 f DUCTILE IRON BODY

TITAN FLOW CONTROL, INC.

S I Z E S 2 " ~ 6 " P ROV I D E

MODEL: CV 41-DI

D U A L P R E S S U R E S E RV I C E

ANSI CLASS 150/300

(Scalloped Design)

Body: Ductile Iron

Seats: Buna, Viton & EPDM

Discs: Stainless Steel & Aluminum Bronze

s

F

F E ATURES

cost efficient design

SIZES: 2" ~ 24"

LARGER SIZES AVAILABL E U P O N R E QU E S T

Sizes 2" ~ 12"

l o w w e i g h t a n d s h o rt l ay i n g l e n g t h p ro d u c e s av i n g s i n i n i t i a l c o s t ,

T

s pa c e r e q u i r e m e n t s , a n d i n s ta l l at i o n w h e n c o m pa r e d to f u l l - b o dy ,

s w i n g - t y p e c h e c k va lv e s .

s minimal head loss TECHNICAL

c o n to u r o f b o dy p ro v i d e s a s h o rt a n d s t r a i g h t f l o w pat h t h at

g e n e r at e s v e ry l i t t l e t u r b u l e n c e . a d d i t i o n a l ly , t h e s p r i n g - l o a d e d

d i s c s a r e d e s i g n e d w i t h v e ry l o w c r a c k i n g p r e s s u r e w h i c h r e d u c e s t h e PRESSURE/ TEMPERATURE RATING

a m o u n t o f e n e r g y r e q u i r e d to o p e n t h e va lv e . DI - ASTM A536 - CLASS 150 - 2" ~ 24"

s quick c l o s u r e to r e d u c e wat e r h a m m e r

WOG (Non-shock): 250 PSI @ 100 °F

s h u t - o f f i s a c h i e v e d v i a t h e f u l ly a u to m at i c , s p r i n g - a s s i s t e d d i s c s t h at

c l o s e n e a r z e ro f l o w v e l o c i t y . the lightweight, split disc design PRESSURE/ TEMPERATURE RATING

c r e at e s a p o s i t i v e s h u to f f p r i o r to f l o w r e v e r s a l a n d h e l p s to k e e p DI - ASTM A536 - CLASS 300 - 2" ~ 6" only

s l a m m i n g a n d s u r g e s to a m i n i m u m .

WOG (Non-shock): 640 PSI @ 100 °F

s ductile i r o n b o dy

d u c t i l e i ro n b o dy m a i n ta i n s t h e a n t i - c o r ro s i v e p ro p e rt i e s o f c a s t i ro n SEAT MATERIAL

TEMPERATURE RANGE

w h i l e a c h i e v i n g a y i e l d s t r e n g t h c o m pa r a b l e to c a r b o n s t e e l . ductile

i ro n a l s o o f f e r s h i g h e r p r e s s u r e /t e m p e r at u r e r at i n g s t h a n c a s t i ro n . EPDM: -20 ~ 300 °F

BUNA-N: -20 ~ 250 °F

s resilient s o f t s e at s

VITON: -40 ~ 400 °F

r e s i l i e n t s o f t s e at s ( e p d m , v i to n o r b u n a ) e n s u r e a b u b b l e t i g h t s e a l

t h at m e e t s o r e x c e e d s a p i 5 9 8 t e s t r e q u i r e m e n t s . SPRING MATERIAL

MAXIMUM TEMPERATURE

s v e r s at i l e design

s i z e s 2 " t h ro u g h 6" a r e d e s i g n e d to f i t b o lt c i r c l e pat t e r n s f o r b ot h Series 300 Stainless Steel: 450 °F

c a s t i ro n a n s i c l a s s e s 125/300 a n d d u c t i l e i ro n a n s i c l a s s e s 150/300 .

b u n a - n p r o p e rt i e s : m o s t w i d e ly u s e d e l a s to m e r . g o o d f o r m o s t p e t ro l e u m o i l s a n d f l u i d s , s i l i c o n e

APPLICATIONS

g r e a s e s a n d o i l s , a n d c o l d wat e r . e x c e l l e n t c o m p r e s s i o n s e t , t e a r , a n d a b r a s i o n r e s i s ta n c e . p o o r w e at h e r

r e s i s ta n c e a n d m o d e r at e h e at r e s i s ta n c e . n ot r e c o m m e n d e d f o r s e v e r e o z o n e - r e s i s ta n t a p p l i c at i o n s .

A

v i to n p r o p e rt i e s : o f f e r s a b ro a d r a n g e o f c h e m i c a l r e s i s ta n c e a n d e x c e l l e n t h e at r e s i s ta n c e . good

m e c h a n i c a l p ro p e rt i e s a n d c o m p r e s s i o n s e t r e s i s ta n c e . o f t e n u s e d i n a p p l i c at i o n s w h e r e n ot h i n g e l s e w i l l

wo r k . fa i r l o w t e m p e r at u r e r e s i s ta n c e a n d l i m i t e d h ot - wat e r r e s i s ta n c e a n d s h r i n k a g e .

e p d m p r o p e rt i e s : p ro b a b ly t h e m o s t wat e r r e s i s ta n t r u b b e r ava i l a b l e . i t h a s g o o d r e s i s ta n c e to m i l d

a c i d s , a l k a l i s , s i l i c o n e o i l s / g r e a s e s , k e to n e s , a l c o h o l s a n d ot h e r p o l a r s o lv e n t s . i t i s n ot r e c o m m e n d e d

f o r u s e w i t h p e t ro l e u m o i l s , d i - e s t e r l u b r i c a n t s , m i n e r a l o i l s , n o n - p o l a r s o lv e n t s o r a ro m at i c f u e l s .

The above data represents common market and ser vice a p p l i c a t i o n s . N o re p re s e n t a t i o n o r g u a ra n t e e , e x p re s s e d o r i m p l i e d , i s g i v e n d u e t o t h e n u m e ro u s v a r i a t i o n s

of concentrations , temperatures and flow conditions tha t m a y o c c u r d u r i n g a c t u a l s e r v i c e .

TITAN FLOW CONTROL, INC.

YOUR PIPELINE TO THE FUTURE!

Tel: 910-735-0000 s Fax: 910-738-3848 s titan@titanfci.com s www.titanfci.com

290 Corporate Drive s PO Box 7408 s Lumberton, NC 28358

CV41-0616

CHECK VALVE • WAFER TYPE • DUAL DISC

TITAN FLOW CONTROL, Inc. ANSI

290 Corporate Drive E-mail: titan@titanfci.com MODEL: CV 41-DI (Ductile Iron Body) Class

TITAN Lumberton, NC 28358 Web: www.titanfci.com Buna-N,Viton, or EPDM Seats

Tel: 910.735.0000 Fax: 910.738.3848 Stainless Steel or Bronze Discs 150

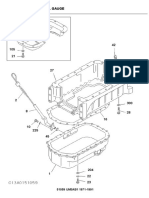

BILL OF MATERIALS (1) 7

No. PART CV 41-DI (3)

1 Body Ductile Iron ASTM A536 5 6

FLOW

2 Seat Buna-N, Viton, or EPDM

3 Disc Aluminum Bronze or Series 300 Stainless Steel 4

ØD

ØC

ØB

ØE

4 Spring (2) Series 300 Stainless Steel

2

5 Shaft/Stop Pin Series 300 Stainless Steel 3

6 NPT Plug Commercial Steel

7 Eye Bolt (4) Commercial Steel 1

Class 300 Flange A

1. Bill of Materials represents standard materials. Equivalent or better

materials may be substituted at the manufacturer's discretion. 6 Class 150 Flange

2. Denotes recommended spare parts.

Outlet Side Top View - Cutaway

3. Ductile Iron bodies are epoxy painted.

4. Eye Bolt is available on larger sizes only. CAD illustration is representative of sizes 2' through 6". Sizes 8" through 24" are not scalloped.

Sizes 2" ~ 12" Sizes 2" through 6" are designed for dual pressure service (ANSI Class 150 and 300).

Ductile Iron Application Notes:

Ductile Iron maintains the anti-corrosive properties of Cast Iron while achieving a yield strength comparable to Carbon Steel. Ductile Iron also offers higher pressure/temperature ratings than

Cast Iron. For example, Ductile Iron check valves (class 300 - sizes 2" ~ 24") are rated at 640 psi WOG. By comparison, Cast Iron check valves (class 250 - sizes 2" ~ 12") are rated at 500 psi

WOG and (sizes 14" ~ 24") are only rated at 300 psi WOG. Ductile Iron ANSI Classes 150 and 300 have the same bolting pattern as Cast Iron ANSI Classes 125 and 250 respectively.

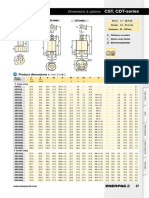

DIMENSIONS AND PERFORMANCE DATA (1)

in 2 2 1/2 3 4 5 6 8 10 12 14 16 18 20 24

SIZE

mm 50 65 80 100 125 150 200 250 300 350 400 450 500 600

A DIMENSION in 2.12 2.12 2.25 2.50 2.75 3.00 3.75 4.25 5.62 7.25 7.50 8.00 8.37 8.75

FACE TO FACE (2)

mm 54 54 58 64 70 77 96 108 143 185 191 204 213 223

ØB DIMENSION in 4.37 5.12 5.75 7.12 8.50 9.87 11.00 13.37 16.12 17.75 20.25 21.62 23.87 28.25

OUTLET OUTSIDE DIAMETER

mm 111 131 146 181 216 251 280 340 410 451 515 550 607 718

ØC DIMENSION in 2.00 2.50 3.00 4.00 5.00 6.00 8.00 10.00 12.00 14.00 16.00 18.00 20.00 24.00

INLET INSIDE DIAMETER

mm 51 64 77 102 127 153 204 254 305 356 407 458 508 610

ØD DIMENSION in 2.62 3.12 3.87 4.75 6.00 7.00 9.00 11.00 13.25 14.25 16.25 18.12 20.12 24.00

OUTLET INSIDE DIAMETER

mm 67 80 98 121 152 178 229 280 337 362 413 461 512 610

ØE DIMENSION in 0 1.26 2.36 3.425 4.567 5.315 7.48 9.45 11.26 11.26 13.70 15.63 17.638 21.97

MINIMUM BORE DIAMETER

mm 0 32 60 87 116 135 190 240 286 286 348 397 448 558

ASSEMBLED lb 4.0 5.0 7.0 14.0 18.0 26.5 43.0 70.0 108.0 175.0 200.0 258.0 345.0 460.0

WEIGHT kg 1.8 2.3 3.2 6.3 8.2 12.0 19.5 31.7 48.9 79.4 90.7 117.0 156.5 208.7

Flow Coefficient Cv 62 110 175 350 550 850 1500 2400 3700 5400 8250 10400 14200 23000

Cracking Pressure (3) psi ≤ .25 ≤ .25 ≤ .25 ≤ .25 ≤ .25 ≤ .25 ≤ .25 ≤ .25 ≤ .25 ≤ .25 ≤ .25 ≤ .25 ≤ .25 ≤ .25

1. Dimensions and weights are for reference only. When required, request certified drawings.

2. Face to face values have a tolerance of ±0.06 in (±2.0 mm) for sizes 10" and lower and a tolerance REFERENCED STANDARDS & CODES

of ±0.12 in (±3.0 mm) for sizes 12" and larger.

3. Cracking pressure is for horizontal installations only. For vertical installations, please consult factory. CODE DESCRIPTION

ANSI/API 594 Valve Design and Manufacture

PRESSURE - TEMPERATURE RATINGS (1) ASME/ANSI 16.5 Flange Dimensions

Ductile Iron

250 °F Max Temp 300 °F Max Temp A536 ANSI Class 150 ASME/ANSI B16.34 Valves - Flanged, Threaded, and Welding End

Buna-N Seat EPDM Seats

700 Ductile Iron

Source:ASME B16.42-1998

400 °F Max Temp A536 ANSI Class 300 ASME/ANSI B16.42 Ductile Iron Pipe Flanges and Flanged Fittings

Viton Seat

600 Sizes 2” ~ 6” only API 598 Valve Inspection and Pressure Test

450 °F Max Temp

SS Spring FM APPROVALS CLASS 1230 Anti-Water Hammer Check Valves (2" ~12")

Pressure (PSI)

500

PRESSURE / TEMPERATURE RATING - ASTM A536

400

Body Material Class 150 (2" ~ 24") Class 300 (2" ~ 6")

300 WOG (Non-shock): 250 PSI @ 100 °F 640 PSI @ 100 °F

Sizes 2” ~ 24” only

200 SEAT AND SPRING TEMPERATURE RATING

Seat Material Range Spring Material Max

100

-50 50 150 250 350 450 550 650 EPDM: -30 ~ 300 °F Series 300 Stainless Steel: 450 °F

Temperature (°F)

BUNA-N: -20 ~ 250 °F

1. The above chart displays the pressure-temperature ratings for the valve's body material per

ASME B16.42-1998. Max temperature limits have been added for seat and spring materials. VITON: -40 ~ 400 °F

Sizes 2" through 6" are dual pressure rated for both ANSI Class 150 and 300.

Titan FCI makes every effort to ensure the information presented on our literature accurately reflects exact product specifications. However, as product changes occur, there may be short-term differences between actual product

specifications and the information contained within our literature. Titan FCI reserves the right to make design and specification changes to improve our products without prior notification. When required, request certified drawings.

You might also like

- Learn To Write Aramaic by Rudder J PDFDocument212 pagesLearn To Write Aramaic by Rudder J PDFJardel Nobrega100% (1)

- Douglas UFO DocsDocument275 pagesDouglas UFO DocsAndrew JohnsonNo ratings yet

- International Society for Rock Mechanics: List of Members 1980From EverandInternational Society for Rock Mechanics: List of Members 1980Rating: 3.5 out of 5 stars3.5/5 (2)

- Return To Index: Spare Parts List Regulated Pump HPR 210-02Document37 pagesReturn To Index: Spare Parts List Regulated Pump HPR 210-02ezeizabarrenaNo ratings yet

- RTLO-16913A Eaton FullerDocument40 pagesRTLO-16913A Eaton FullerAlvaro Escalona Gtz100% (5)

- TITANDocument2 pagesTITANSup ProyNo ratings yet

- Models: CV 42-CS CV 42-SS: TitanDocument2 pagesModels: CV 42-CS CV 42-SS: TitanRodolfo Carrillo ArenasNo ratings yet

- Titan Basket Strainer bs85Document2 pagesTitan Basket Strainer bs85FREDDY YAJAMINNo ratings yet

- Bs 85Document2 pagesBs 85Hector CachoNo ratings yet

- Y STRAINER TITAN - Ys64Document2 pagesY STRAINER TITAN - Ys64Andres BaezNo ratings yet

- BS85Document7 pagesBS85Rama SNo ratings yet

- Titan StrainerDocument2 pagesTitan Straineradewunmi olufemiNo ratings yet

- CV 31Wf-Ci Models: CV 31F-Ci: FeaturesDocument2 pagesCV 31Wf-Ci Models: CV 31F-Ci: FeaturesOscar PáezNo ratings yet

- Y Strainer CatalogDocument21 pagesY Strainer CatalogIrfan FahmiNo ratings yet

- Titan CV51Document2 pagesTitan CV51Carlos LaraNo ratings yet

- Titan Ys-61Document2 pagesTitan Ys-61JUAN ANTONIO HERNANDEZ SOSANo ratings yet

- Models: Ys 61-Cs YS 61-SS: Gauge TapsDocument2 pagesModels: Ys 61-Cs YS 61-SS: Gauge TapsNz CaNo ratings yet

- City Bus Ikarus 543.30Document2 pagesCity Bus Ikarus 543.30Kft. UnipartsNo ratings yet

- Investigations On Partial Penetration Welded NozzleDocument15 pagesInvestigations On Partial Penetration Welded NozzleAndres_Pastor1987No ratings yet

- Penthouse Summer 1986Document2 pagesPenthouse Summer 1986John M. CavoteNo ratings yet

- Ture General ZHDocument20 pagesTure General ZHwilasn1No ratings yet

- Titan YS8182 PDFDocument2 pagesTitan YS8182 PDFRajNo ratings yet

- Models: Ys 80T-Ss YS 80S-SS: TitanDocument2 pagesModels: Ys 80T-Ss YS 80S-SS: Titanthienthanh81No ratings yet

- Changes To A C System Components: 1976 ModelsDocument5 pagesChanges To A C System Components: 1976 ModelsRC VilledaNo ratings yet

- 1977 Calorimetric Studies of 7000 Series Aluminum Alloys - I. Matrix Precipitate Characterization of 7075Document7 pages1977 Calorimetric Studies of 7000 Series Aluminum Alloys - I. Matrix Precipitate Characterization of 7075yhgrinmNo ratings yet

- UT Rotary Tube TestingDocument4 pagesUT Rotary Tube Testingach soNo ratings yet

- Astm A 20Document33 pagesAstm A 20sumiransharmaNo ratings yet

- Lammeren W P A.Wageningen B-Screw S.1969.TRANS PDFDocument49 pagesLammeren W P A.Wageningen B-Screw S.1969.TRANS PDFStefanoNo ratings yet

- The Deformation Behavior of ADocument12 pagesThe Deformation Behavior of ARoger LaraNo ratings yet

- Ansi Mss SP 55Document12 pagesAnsi Mss SP 55Dedika MulyanaNo ratings yet

- Operating Instructions: FfiltttreDocument8 pagesOperating Instructions: FfiltttreAnthony RhodesNo ratings yet

- Penthouse Spring 1988Document2 pagesPenthouse Spring 1988John M. CavoteNo ratings yet

- Titanio 2Document1 pageTitanio 2Malu LoNo ratings yet

- BF 02642857Document10 pagesBF 02642857andremuniz150No ratings yet

- Iveco Cursor 13 Brochure FinalDocument2 pagesIveco Cursor 13 Brochure FinalkarijosephNo ratings yet

- Iveco Cursor 13 Brochure FinalDocument2 pagesIveco Cursor 13 Brochure FinalkarijosephNo ratings yet

- High-Voltage Spiral Generators - A Ramrus - F Rose - 1976Document6 pagesHigh-Voltage Spiral Generators - A Ramrus - F Rose - 1976Fernando FerreiraNo ratings yet

- Further Computer-Analyzed D Ata of T H E Wageningen B-Screw SeriesDocument12 pagesFurther Computer-Analyzed D Ata of T H E Wageningen B-Screw SeriesS. M. MUNAWAR MAHTAB 1603061No ratings yet

- Single Filter OV: Com Plete S Oluti On S ForliquidfiltrationDocument2 pagesSingle Filter OV: Com Plete S Oluti On S ForliquidfiltrationMarcis BalodisNo ratings yet

- Isolator - GeDocument2 pagesIsolator - Gecavolor219No ratings yet

- Electro Valves ElectrovalvulasDocument22 pagesElectro Valves ElectrovalvulasbloggusbloggusNo ratings yet

- Penthouse Spring 1985Document2 pagesPenthouse Spring 1985John M. CavoteNo ratings yet

- HI3519AV100 Core BoardDocument4 pagesHI3519AV100 Core BoardWolf JohnNo ratings yet

- 1985 - (ACO) Abernethy, D., Evaporative Roof Cooling A Simple Solution T - ETCDocument5 pages1985 - (ACO) Abernethy, D., Evaporative Roof Cooling A Simple Solution T - ETCVELAZQUEZ CARDONA CRUZ ROBERTONo ratings yet

- Aa 6300Document20 pagesAa 6300CGFernandez2014No ratings yet

- Tiv 4 in 150 A105 SS 316Document5 pagesTiv 4 in 150 A105 SS 316Ananm NaimNo ratings yet

- Paper BOP 2Document2 pagesPaper BOP 2Della EfrianNo ratings yet

- Alsun - KOOLPANEL - 3rd EditionDocument8 pagesAlsun - KOOLPANEL - 3rd EditionTeknik produksi wikonNo ratings yet

- Vox ContinentalDocument8 pagesVox ContinentalManolis ManolakisNo ratings yet

- Rope ReevingDocument8 pagesRope ReevingKS CheeNo ratings yet

- Short Track Setup SupashockDocument1 pageShort Track Setup SupashockNic RoddaNo ratings yet

- Further Computer-Analyzed D Ata of T H E Wageningen B-Screw SeriesDocument12 pagesFurther Computer-Analyzed D Ata of T H E Wageningen B-Screw SeriesVinayak29No ratings yet

- C F T 2 2 0 0 U G: SER UideDocument37 pagesC F T 2 2 0 0 U G: SER Uidec3065638No ratings yet

- Deburring Catalog 2011Document30 pagesDeburring Catalog 2011WVPNo ratings yet

- Controlador VolumetricoDocument1 pageControlador Volumetricojquinterop74No ratings yet

- The Effects of Thermal History and Composition On The Hot Ductility of Low Carbon SteelsDocument9 pagesThe Effects of Thermal History and Composition On The Hot Ductility of Low Carbon SteelsChanthar SoeNo ratings yet

- Barlo Roundtop Radiators UK 2004Document4 pagesBarlo Roundtop Radiators UK 2004sohowestoneNo ratings yet

- Oszcilloszkóp SchleifenOszillographen 1942Document49 pagesOszcilloszkóp SchleifenOszillographen 1942Nagy PéterNo ratings yet

- Preferable Welded Joints of Plate EdgesDocument11 pagesPreferable Welded Joints of Plate EdgesSinyoe Sii DjumNo ratings yet

- 2010 TC CatalogDocument96 pages2010 TC Catalogb46550214949No ratings yet

- DN 11Document6 pagesDN 11tastaman123No ratings yet

- Is 1862Document4 pagesIs 1862mangesh sandavNo ratings yet

- 479000Document6 pages479000Alfredo Bautista HernándezNo ratings yet

- 479Document6 pages479Alfredo Bautista HernándezNo ratings yet

- 1042 BB1 Me Cal 001 - 0Document108 pages1042 BB1 Me Cal 001 - 0Alfredo Bautista HernándezNo ratings yet

- 1045-BB1-ME-CAL-001 - A ScopeDocument187 pages1045-BB1-ME-CAL-001 - A ScopeAlfredo Bautista HernándezNo ratings yet

- NOM 007 SECRE 2010 EngDocument3 pagesNOM 007 SECRE 2010 EngAlfredo Bautista HernándezNo ratings yet

- Mss sp-44 1996Document28 pagesMss sp-44 1996DsokasNo ratings yet

- 3.3 2586-4-Pi-Ga-301 - Ag Piping Plan For Interconnection Zone (1 - 4) - Rev 4 - Ifc-2Document1 page3.3 2586-4-Pi-Ga-301 - Ag Piping Plan For Interconnection Zone (1 - 4) - Rev 4 - Ifc-2Alfredo Bautista HernándezNo ratings yet

- Removing of Major PartsDocument7 pagesRemoving of Major PartsAlfredo Bautista HernándezNo ratings yet

- US-106911-01-IP-100-001 P4 - REV B-ModelDocument1 pageUS-106911-01-IP-100-001 P4 - REV B-ModelAlfredo Bautista HernándezNo ratings yet

- HIAB Error CodesDocument7 pagesHIAB Error CodesinfohidrautaNo ratings yet

- Standard Reduction PotentialsDocument5 pagesStandard Reduction PotentialsnathaloaNo ratings yet

- Ahx B195GDocument32 pagesAhx B195GAlexandre SouzaNo ratings yet

- MH325BR - Rev 3-29-10Document1 pageMH325BR - Rev 3-29-10Jorge Rosero QuevedoNo ratings yet

- Um3ab1 Oil PanDocument2 pagesUm3ab1 Oil PanBurik8No ratings yet

- Enerpac Workholding Catalogue E215eDocument1 pageEnerpac Workholding Catalogue E215eFilipe Pimenta MarquesNo ratings yet

- 2D03 Assignment 1Document5 pages2D03 Assignment 1Aisha ChaudhryNo ratings yet

- Electronic Lockstitch Button Holer: Service ManualDocument162 pagesElectronic Lockstitch Button Holer: Service ManualgeforceoozieNo ratings yet

- IEEE Recommended Practice For Testing Insulation Resistance of Rotating Machinery - IEEE STD 43-2000Document2 pagesIEEE Recommended Practice For Testing Insulation Resistance of Rotating Machinery - IEEE STD 43-2000QORINo ratings yet

- DH Series R-Tool Engineering DataDocument1 pageDH Series R-Tool Engineering Dataazze bouzNo ratings yet

- Tubing Cutters (TC1Q & TC2Q) : Parts ListDocument1 pageTubing Cutters (TC1Q & TC2Q) : Parts ListRafi UdeenNo ratings yet

- Sandvik Jaw Eng PDFDocument12 pagesSandvik Jaw Eng PDFgourave daipuria100% (1)

- Nozzle and TurbinesDocument53 pagesNozzle and TurbinesDream achieverNo ratings yet

- Akron Style 4820 NewDocument3 pagesAkron Style 4820 Newluisa fernanda ordoñez casasNo ratings yet

- 3M Packaging Solutions Guide: Right Tapes. Right System. Right PartnerDocument52 pages3M Packaging Solutions Guide: Right Tapes. Right System. Right PartnerTheodora StefanNo ratings yet

- Reduce RsDocument73 pagesReduce RsbangpaiNo ratings yet

- Asme Sec Ix (Welder Qualification)Document39 pagesAsme Sec Ix (Welder Qualification)VinodNo ratings yet

- Despiece: Codigo DescripcionDocument12 pagesDespiece: Codigo DescripcionSergioNo ratings yet

- 4.3 Prestressing SystemsDocument27 pages4.3 Prestressing SystemsEdson MilanoNo ratings yet

- Shore Protection M 03 Co AsDocument164 pagesShore Protection M 03 Co Asirfa destraNo ratings yet

- Plastic Rivets and ScrewsDocument23 pagesPlastic Rivets and ScrewsMV Research & Development TRSNo ratings yet

- Fasteners and Fastening Methods: ObjectivesDocument6 pagesFasteners and Fastening Methods: ObjectivesatiquegeeNo ratings yet

- Komatsu Shop Manual Pw160 7 German PDFDocument956 pagesKomatsu Shop Manual Pw160 7 German PDFphyanthinh100% (8)

- Conectores-de-Borna TRAFODocument4 pagesConectores-de-Borna TRAFOJunior MartinezNo ratings yet

- BarSplice - Zap Screwlok - Data SheetDocument2 pagesBarSplice - Zap Screwlok - Data SheetAntonioMartínezGrosserNo ratings yet

- Foreword: ISO 7044:2012 (En) Prevailing Torque Type All-Metal Hexagon Nuts With Flange, Style 2 - Product Grades A and BDocument4 pagesForeword: ISO 7044:2012 (En) Prevailing Torque Type All-Metal Hexagon Nuts With Flange, Style 2 - Product Grades A and BMarcelo KleinNo ratings yet

- Installation, Testing and Commissioning of VRF Indoor Unit With Required Gas Toping of Out Door UnitDocument5 pagesInstallation, Testing and Commissioning of VRF Indoor Unit With Required Gas Toping of Out Door UnitAmit MalhotraNo ratings yet

- BW Intergrated SystemsDocument2 pagesBW Intergrated SystemsKien Nguyen TrungNo ratings yet