Professional Documents

Culture Documents

BS 01052 1980 1999 Scan

BS 01052 1980 1999 Scan

Uploaded by

Krishan Rodrigo0 ratings0% found this document useful (0 votes)

10 views10 pagesOriginal Title

BS-01052-1980-1999-scan

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views10 pagesBS 01052 1980 1999 Scan

BS 01052 1980 1999 Scan

Uploaded by

Krishan RodrigoCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 10

ISH STANDARD

Specification for

Mild steel wire for

general engineering

purposes

Es bag

CONTROLLED issue

THT

Issue To!

BS 1052:1980

Incorporating

‘Amendment No. 1

‘This Brideh Standen, having

taenpropared under the

incon ofthe Tron sn Seal

Standards Committe, wae

Dubiebed under the avcority

Uf tbe ecutive Board snd

ones into eect on

‘0 Apa 1980

©8107-1999

Fro: publised Jay 1942

Firotrevsin Apel 1880,

‘The lloing BSI references

anise

1 Commits reference 18/25

raf for eorument 1177761 DC

siEN0 580 11525 x

Cooperating organizations

‘The preparation of this British Standard was entrustod by the Iron and Steel

Standards Policy Committee (ISM/.) to Technical Committee ISM26, upon

which the following bodies wore reprosentod:

Aluminium Federation

Bicycle Association of GB

British Cable Makers’ Confederation

British Rubber Manufacturers’ Association

British Steel Industry

Federation of Wire Rope Manufacturers of Great Britain

Forostry Commission

Health and Safety Executive

Sheffield Stainless Stee! Manufacturers’ Association

Society of Chain Link Fencing Manufacturers

Society of Motor Manufacturers and Traders Limited

Spring Research and Manufacturers’ Association

Stainless Steel Fabricators’ Association of Great Britain

Stainless Steel Wise Industry Association

Welding Manufacturers’ Association (BEAMA Ltd.)

Woven Wire Association

Zine Development Association

‘The following bodies were also represented in the drafting of the standard,

through subcommittees and panels:

Electricity Supply Industry in England and Wales

Fencing Industry Association

Wire Products Association

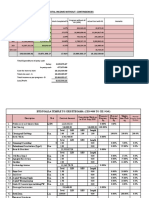

Amendments issued since publication

Amd.No. [Dateofissue | Comments

6530 ‘May 1997 | Indicated by a sideline in the margin

BS 1052:1980

ee

Contents

Page

Cooperating organizations Inside front cover

Foreword is

Section 1. Genoral requirements

i 1 Scope 1

2 References 1

3 Definitions 1

“ 4 Information to be supplied by the purchaser 1

5 General 1

. 6 Quality of wire 1

7 Condition of supply 1

8 Finish 1

9 Costing 2

10 Selection of test pisces 2

11. Method of testing 2

42 Retests 2

13 _ Packaging and marking 2

Section 2. Specific requirementa

14 Dimensions and tolerances 3

15. Tensile strength 3

16 _Ductlity 3

Tabi 1 — Tolerances on Ulameter for round wire of finish other

than galvanized 3

Table 2— Tolerances on diameter of galvanized round wire 3

a

‘Table 3 — Limits for ranges of tensile strongth values

inside back cover

Publications referred to

sng sg sts} 71998

BS 1052:1980

Foreword

‘This Britieh Standard has been prepared under the direction ofthe Tron and Steel

Standarda Committee and was criginally issued in 1942 as a war emergency

iseue. In view ofits general and continuing use this revision has been prepared,

‘The standard is now technically updated and metriested and details of

dimensional tolerances have been revised in Keoping with current manufacturing

practices. Provision is now made for three conditions of supply and five different

‘conditions of fnieh,

BS 1062:1942 i withdrawn on publication of this revision,

A British Standard does not purport to include all tho necessary provisions of a

contract. Users of British Standards are responsible for their correct application

Compliance with a British Standard does not of itself confer immu

from legal obligations.

Summary of pages

‘This document comprises a front cover, aa inside front cover, pages i and ii,

pages I t» 4, an inside back cover and a back cover.

This etandart has beon updatod (coe copyright dato) and may have had

amendments incorporated. This will be indicated in the amendment table on the

inside front cover

© BSI OT 1999

BS 1052:1980

Se

Section 1. General requirements

1 Scope

‘This British Standard specifies the requirements for

mild steel wize, of round and other cross-sectional

shapes, between 0.122 mm and 13.2 mm diameter

‘or equivalent orosa-sectional area. Three conditions

‘of supply and five conditions of finish are specified.

2 References

‘The titles of the publications referred to in this

standard are listed on the inside back cover.

8 Definitions

For the purpoces of this British Standard the

following definitions apply

aL

wire

cold drawa or cold rolled mild steel wire of any

‘eross-sectional shape

32

mild drawn or rolled

lightly drawn or rolled after annealing

38

hard drawn or rolled

Drawn or rolled to final size without annealing

[NOTE ‘This definition doesnot exclad, fr fice enc of wire

fn interetage annealing testmat Bete Boal hard drawing or

‘ling

a4

coil

cone length of wire in close-packed concentric rings

35

Jength

a straight piece of wire cut toa specified length

3.6

bundle

two or more coils bound together or a number of

lengths bound together

az

consignment

‘any quantity of finished wire in coils or lengths

delivered at one time

4 Information to be supplied by the

purchaser

‘The following information shall he given on the

enquiry oF order:

2) the number ofthis British Standard,

fie, BS 1052;

) the product form (coils or lengths)

(Gee clause 3);

©) the diameter or characteristic dimensions of

the wires

4) the quantity;

©) whother the wire is required to be welded

(ee clause 6);

1) the condition of eupply (soe clause 7);

8) the finish (see clause 8);

») any requirements for special protection

(ee clause 18);

{) the tensile strength range, or, in the case of

hard drawn or rolled wire of up to 1.25 mm

diameter or equivalent cross-sectional area, the

minimum tensile strength (see clause 15);

3) any additional requirements, e.g. for

packaging,

Anexample of this information tobe supplied by the

purchaser is:

BS 1052, coils, 2.5 mm diameter wire, 500 ke,

mild drawn, bright, 840 N/mm? to 600 Nima?

5 General

‘The wire shall comply with the requirements of

section 1 and the specific requirements of section 2,

6 Quality of wire

6.1 Chemical analysis. The sulphur and

phosphorus contents of the wire shall be each not

greater than 0.05 % by cast analysis. [f the wire is

required to be welded, the carbon content shall be

not greater than 0.18 % and the manganese content

shall be not loas than 10 times the sulphur content

‘of the cast, nor greater than 1.00 %.

6.2 Defeets.The finishod wire shalt be frve from

dofects harmful to its end uso,

7 Condition of supply

‘The wire shall he supplied in one of the following

conditions specified by the purchaser:

4) finally annealed;

) mild drawn or rolled;

©) hard draven or rolled

8 Finish

‘The wire shall be supplied with one of the following.

finishes specified by the purchaser:

a) a finish produced by final annesling: to be

agreed with the manufactures:

») brights

©) galvanized;

BS 1052:1980

© coppered;

) tinned.

NOTE, Wiresmaye eupliedwithotherGaishesifagreed atthe

timc ofengsry and onder

9 Coating

9.1 Galvanized round wire, The galvanized

coating on round wire shall comply with all of the

equirements of BS 449, except that lower coating

‘weights and dips may be agreed botween the

Jurchaser and the manufacturer depending upon

the pinpone for which tho wire is required

9.2 Galvanized sections other than round.

Requiremente for the galvanized coating on sections

other than round shall be agreed between the

purchaser and the manfactarer

9.8 Coatings other than galvanized.

Requirements for coatings other than galvanized

ahall be agreod botwoon the purchaser and the

manufacturer.

10 Selection of test pieces

10.1 A test piece of aufficient length to enable the

relevant tests specified in section 2 of this standard

to be carried out shall be selected in accordance

‘with 10.2 from the wize in the condition in which it

will be supplied to the purchaser. Apart from

straightening the test lengths before tosting, they

shall not be treated in any way that would make

them unreprosentative of the wire.

10.2 One test piece shall be taken Srom every ten of

part often coils or bundles of lengths, if the mass of

ach coil or bundle of lengths is 50 kg or greater,

subject to a xate of not less than one test pieco

per 1 000 kg.

‘Two test pieces shall be taken from every 1.000 kg

or part of 1000 keg, ifthe individual masses of eoils

or bundles or lengths are each less than 60 kg.

11 Method of testing

11.1 Round wire. Tho procedures for mechanical

toeting of round wire shall be in accordazoe with the

requirements of BS 4545,

11.8 Wire of section other than round. The

procedures for mechanical testing of wire of section

other than round shall be in accordance with the

requirements of BS 4545. Ifa ductility test is to be

carried out, the method of testing shall be agreed by

the purchasor and the manufacturer.

11.8 Straining rate. For fixed-goar tensile-testing

machines, the straining rate shall be preset to give

arate of separation ofthe grips of not less than 25 %

‘and not greater than 50 % of the test length per

minute.

12 Retests

12.1 Ifany test piece fails any of the tests specified

in section 2, additional test pieces shall be taken and

retested,

For wire supplied in coil form, one additional test

shall be taken from oach ond of the same coil

Part of the coil may be discarded before taking the

now test pieces. Ifthe manufacturer wishes to

withdraw that coi, the two test pieces shall be taken

from another coil in the same consignment.

For wire supplied in lengths, four additional test

pieces shall be taken from randomly chosen lengths

in the same consignment.

12.2 If all the additional tost pieces pass all the

tests, the consignment shall be deemed to comply

with the requirements ofthis standard. [fany ofthe

additional test pieces faile any of the tests, the

‘consignment ehall he doomed not to comply with the

requirements of this standard

18 Packaging and marking

Consignments of wire shall be suitably protected

against corrosion during transportation. If special

proteetion is required it shall be agroed at the time

‘of enquiry and order.

Wire supplied in coils, bundles of oils or bundles of

Jongths shall be securely tied and shall carry a

suitable label or labels on which shall be marked:

‘) the manufacturer's name;

) the number ofthis British Standard,

ive, BS 1052;

NOTE, Marking 85 105209 a in relation to a producti

Cini bythe manctactrer thatthe predct hasbeen

‘tauicsed in sezordance with che ruuirempots othe

Standard. The accuracy of sucha claim therefore the

‘anufucarer cole eeponib ity.

o) the diameter or characteristic dimension of the

4) the condition of supply:

©} the finieh;

1 the nominal tensile strength.

Iadditional markings are required they shall be

‘agreed hetwoon the purchaser and the

‘manufacturer,

fe asior-ia99

BS 1052:1980

—— ee

Section 2. Specific requirements

14 Dimensions and tolerances

14.1 Round wire

14.1.1 Round wire of finish other than galvanized.

For sound wire of finish other than galvanized, the

diameter of the wire shall be within the relevant

tolerance specified in Table 1

14.1.2 Galvanized round wire. For galvanized round

wire, the diameter of the wire ehall be within the

relevant tolerance specified in Table 2.

14.2 Wire of section other than round. For wire

of section other than round, the tolerance(s) on

dimensions ehall be agroed botween tho purchaser

and manufacturer.

15 Tensile strength

15.1 With the excoption of hard drawn or rolied wire

of up to and including 1.25 mm diameter or

‘equivalent cross-sectional area, the purchaser shall

‘specify, for the relevant condition of supply, the

required range of tonsile strength within the limits

given in Table 3. The difference hetween the

minimum and maximum value of the range

specified by the purchaser shall be 160 Nimm*.

16.2 For hard drawn or rolled wire of up to and

including 1.25 mm diameter or equivalent

cross-sectional area, only the roquired minimum

tansile strength shall be specified by the purchaser.

16 Ductility test

16.1 Round wire

16.1.1 Wrapping test on round wire. Tho wrapping

test shall be applied to round wire of up to and

including 4.75 mm diameter. The wire shall not

break nor chow dofects that could lead

to subsequent failure when eight complete turns of

the wire are cloge-coiled around a mandrel of

diameter equal to that of the wiro,

16.1.2 Bend test on round wire. The bend test shall

tbo applied to round wire of greater than 4.78 mm

diameter. The wire shall not crack or fracture when

bent through 90° around a mandrel of diameter

‘equal to that of the wire, During the test, the wire

shall be free to move longitudinally in the forming

device

16.3 Wire of section other than round. The

requirements for a ductility Lest on wiee of eection

other than round shall be agreed between the

purchaser and the manufacturer

‘Table 1 — Tolerances on diameter for

round wire of finish other than galvanized

[Nominal diameter Tolerance om

‘diameter

‘Over

0.22 4 0.015

o4 10 0.02

10 16 = 0.025

16 25 = 0.03

25 132 + 0.05

‘Table 2— Tolerances on diameter of

galvanized round wire

i diameter |

‘Tolerance on diameter

0.122 AAs agreed between purchaser

‘and manufacturer

03 07 |£0.02

0.7 125 |+0.03

12516 |=0.04

16 20 |=0.05,

20 25 |=0.08,

25 315 |=0.08,

[1555 [#01

{55 182 _| Asagreed betwoen purchaser

and manufacturer

‘Table $ — Limits for ranges of tensile

Strength values

] Tisits on tensile strength |

[ise | ae]

Condition of supply

Naa? | Naa? |

Finally annealed 280 500 |

[Mild drawa or rolled | 330 350 |

Hard drawn or rolled —_|600 950

F blante

BS 1052:1980

—_

Publications referred to

BS 443, Specification for testing zine coatings on steel wire and for quality requirements.

BS 4545, Methods for mechanical testing of steel wire.

gre en T1988

BS 1052:1980

BSI

380 Chiswick High Road

London

wa sAL.

BSI — British Standards Institution

BSI is the independent national body responsible for preparing

British Standards. It presents the UK view on standards in Europe and at the

intornational love It is incorporated by Royal Charter.

Revisions

British Standards are updated by amendment or revision. Users of

British Standards should make sure that they possess the latest amendments or

editions

tis the constant aim of BSI to improve the quality of our products and services,

We would be grateful if anyone finding an inaccuracy or ambiguity while using

this British Standard would inform the Secretary of the technical committee

responsible, the identity of which can be found on the inside front cover.

‘Tel: 020 8996 9000. Fax: 020 8996 7400.

BSI offers members an individual updating service called PLUS which eneures

that subscribers automatically receive the latest editions of standards,

Buying standards

Orders for all BSI, international and foreign standards publications should be

addressed to Customer Serviess, Tol: 020 8896 9001. Fax: 020 8996 7001

In response to orders for international standards, itis BSI policy to supply the

BSI implementation of those that have been published as British Standards,

unless otherwise requested,

Information on standards

BSI provides a wide range of information on national, European and

international standards through its Library and its Technical Help to Bxporters

Service. Various BSI olectronie information services are also available which give

details on all its products and services. Contact the Information Centre

‘Tel: 020 8096 7111. Pax: 020 8996 7048,

Subscribing members of BST are kept up to date with standards developments

and receive sulistantial discounts on the purchase price of standarde. For details

of these and other benefite contact Membership Administration.

Tel: 020 8996 7002, Fax: 020 8996 7001.

Copyright

Copyright subsisto in all BSI publications. BSI also holds the copyright, in the

UK, of the publications of the international standardization bodies. Except as

permitted under the Copyright, Designs and Patenta Act 1988 no extract may be

reproduced, stored in a retrieval system or transmitted in any form or by any

means ~ electronic, photocopying, recording or otherwise ~ without prior written

permission from BSI,

‘This does not preclude the free use, in the course of implementing the standard,

of necessary detaile such as symbols, and size, type or grade designations. If those

dotails axe to be used for any other purpose than implementation then the prior

written permission of BS] must be obtained.

‘Ifpermission is granted, the terms may include royalty payments or a licensing

agreement. Details and advice can be obtained from the Copyright Manager.

‘Tel: 020 8996 7070,

You might also like

- Agreement - KerawalapitiyaDocument42 pagesAgreement - KerawalapitiyaKrishan RodrigoNo ratings yet

- Agreement - Earth Work - LAnwa CementDocument20 pagesAgreement - Earth Work - LAnwa CementKrishan RodrigoNo ratings yet

- 2024 02 15 Fe Webinar Disruption WebsiteDocument26 pages2024 02 15 Fe Webinar Disruption WebsiteKrishan RodrigoNo ratings yet

- MS 004 - Structural Excavation and BackfillingDocument16 pagesMS 004 - Structural Excavation and BackfillingKrishan RodrigoNo ratings yet

- Health & Safety Manual For Minimize The Spread of Infections in Light of COVID-19Document8 pagesHealth & Safety Manual For Minimize The Spread of Infections in Light of COVID-19Krishan RodrigoNo ratings yet

- MS 002 - Excavation and EmbankmentDocument19 pagesMS 002 - Excavation and EmbankmentKrishan Rodrigo100% (2)

- Matecconf Iconbee2019 03023Document6 pagesMatecconf Iconbee2019 03023Krishan RodrigoNo ratings yet

- MS 001 - Clearing - Ruwanpura ExpresswayDocument14 pagesMS 001 - Clearing - Ruwanpura ExpresswayKrishan RodrigoNo ratings yet

- MS 002 - Excavation and EmbankmentDocument19 pagesMS 002 - Excavation and EmbankmentKrishan RodrigoNo ratings yet

- MS 005-Slope Protection Part 01Document12 pagesMS 005-Slope Protection Part 01Krishan RodrigoNo ratings yet

- Contemporary Weather Records - Nikaweratiya SiteDocument13 pagesContemporary Weather Records - Nikaweratiya SiteKrishan RodrigoNo ratings yet

- Kurunegala - Site Expenses: in HandDocument22 pagesKurunegala - Site Expenses: in HandKrishan RodrigoNo ratings yet

- MS 003-Rock Blasting - Ruwanpura ExpresswayDocument11 pagesMS 003-Rock Blasting - Ruwanpura ExpresswayKrishan Rodrigo100% (1)

- Physical & Financial (%)Document6 pagesPhysical & Financial (%)Krishan RodrigoNo ratings yet

- 1+000-1+300 ShoulderDocument4 pages1+000-1+300 ShoulderKrishan RodrigoNo ratings yet

- Used of ABC Up To 06th of October 2020Document6 pagesUsed of ABC Up To 06th of October 2020Krishan RodrigoNo ratings yet

- Physical & Financial (%) Upto 16th OctDocument6 pagesPhysical & Financial (%) Upto 16th OctKrishan RodrigoNo ratings yet

- Agreement For MaterialsDocument6 pagesAgreement For MaterialsKrishan RodrigoNo ratings yet

- Material SummaryDocument56 pagesMaterial SummaryKrishan RodrigoNo ratings yet

- Rate Analysis For Basic Work Items: Price Code Labour Component Unit Quantity Rate AmountDocument2 pagesRate Analysis For Basic Work Items: Price Code Labour Component Unit Quantity Rate AmountKrishan RodrigoNo ratings yet

- DBST MSDocument8 pagesDBST MSKrishan RodrigoNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)