Professional Documents

Culture Documents

EAG 315 Wrong Disc Assembly

Uploaded by

Durai NaiduOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EAG 315 Wrong Disc Assembly

Uploaded by

Durai NaiduCopyright:

Available Formats

WHEELS INDIA LTD, PADI, CHENNAI - 8D Response Report

CUSTOMER EFFECT: Aesthetics Date Open: 07.08.2020 8D No.: #01/2020

Customer

Company: Komatsu Initial Response: 08.08.2020 Complaint No.:

Address: JAPAN Target Close Date: 10.09.2020

Location: Awazu Revision Date(s):

Part No./Code EAG 315 8D Initiator: Venkateswaralu Dhara

Customer

Reported thro' email dated 7th Aug'20 8D Initiator's Spvr: G.Durai

complaint ref

Product Name: 15x24 rim

INTERNAL or ✘ EXTERNAL Actual Close Date:

D1 TEAM MEMBER NAMES/TITLES:

Champion: Mr. Balaji P

Team Leader: Mr.Balamurugan

Team Members: Vijayakumar.L, Kanniyappan.C,vaisak ,Anand, EAG 315 RIM assembled with EAG 372 disc -1 piece

Nandakumar, Niranjan,

%

D3 CHOOSE AND VERIFY INTERIM CONTAINMENT ACTION(S) (ICA): Effective:

Target Date: Actual Date:

Inhouse stock -inspected for wrong disc and rim assembly and found rims (12 nos) are ok Completed 08.08.2020

Production personnel and QA personnel were appraised about the defect and Quality alert displayed Completed 09.08.2020

D4 DEFINE AND VERIFY ROOT CAUSE(S): % Contribution:

Wrong disc assembly observed due to similarities of Disc Bolt hole size,PCD,Bore dimensions of EAG 372 and EAG 315 Disc

100%

thickness and insert differs. EAG 372 (16x24) disc thickness is 12.7mm and EAG 315 (15x24) disc thickness is 16mm.

D5 CHOOSE AND VERIFY PERMANENT CORRECTIVE ACTION(S) (PCA): % Effective:

1.Groove identification on DISC OD for 16mm thick disc's for easy idendification and differentiation of same PCD discs.

2.Disc inset inspection at rim to disc assembly made 100% instead of sampling inspection. 100%

3. Feasibility of poke yoke under study to control rim width ,inset at assembly stage

D6 IMPLEMENT AND VALIDATE PERMANENT CORRECTIVE ACTION(S) (PCA): Target Date: Actual Date:

1.Groove identification on DISC OD for 16mm thick disc's for eas idendification and differentidation of same PCD discs.

2.Disc inset inspection at rim to disc assembly made 100% instead of sampling inspection and feasibility of poke yoke under study. 1.& 2 10.09.2020

3-30.09.2020

D7 SYSTEM PREVENTION ACTIONS TO PREVENT RECURRENCE: Mistake

Target Date: Actual Date:

Proofing: How are you going to ensure it can't happen again?

1.Disc drg to be updated for 1mm groove on OD for 16mm disc's

05.10.2020

2.WI to update and display details on disc thickness vs rim sizes of models

HAS CORRECTIVE ACTION/IMPLEMENTATION BEEN REVIEWED AGAINST DOCUMENTS?:

Check boxes that apply: ✘ Process flow ✘ FMEA ✘ Control Plan ✘ Work Instr.✘ Add to Product/process/Dock

Product/Process/Dock Audit

✘ Insp. Instruction ✘ Training Limit Sample ✘ In-coming Inspection _______________________

D8 TEAM AND INDIVIDUAL RECOGNITION: Recognize the collective efforts of the team.

✘ Mfg E&D Purchase ✘ Mfg-QA QPT ✘ CQA Pune / Bawal / Rampur

✘ Customer

Copy to:

EFFECTIVENESS VERIFICATION

The effectiveness of the corrective actions implemented will be monitored in the forth coming shipments.

Month Invoice Ref. WIL Code Qty Shipped from WIL

To be Signed by: HOD-Manufacturing HOD-Quality Assurance HOD-Sales Mfg

Balaji P Venkateswaralu Dhara S. Karthick Balamurugan

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Why America Would Lose A Trade War With China: Unfortunately For Trump, It's Not The 1980s AnymoreDocument3 pagesWhy America Would Lose A Trade War With China: Unfortunately For Trump, It's Not The 1980s AnymoreDurai NaiduNo ratings yet

- 545 7489 (Eag349) - MsaDocument1 page545 7489 (Eag349) - MsaDurai NaiduNo ratings yet

- 545 7489 (EAG349) - Process FlowDocument1 page545 7489 (EAG349) - Process FlowDurai NaiduNo ratings yet

- 7swe (R0) Weld Conformance Audit - Readiness: Score 1.0 Step 1-Weld Engineer 1.1 NoDocument15 pages7swe (R0) Weld Conformance Audit - Readiness: Score 1.0 Step 1-Weld Engineer 1.1 NoDurai NaiduNo ratings yet

- Production Process Change: Application FormDocument1 pageProduction Process Change: Application FormDurai NaiduNo ratings yet

- 3P Rim Tyre Disassembly ProcedureDocument7 pages3P Rim Tyre Disassembly ProcedureDurai NaiduNo ratings yet

- Part # 3734068 - Air Leak Sample Rim Inspection ProcedureDocument9 pagesPart # 3734068 - Air Leak Sample Rim Inspection ProcedureDurai NaiduNo ratings yet

- 4Q17 Caterpillar Inc. ResultsDocument29 pages4Q17 Caterpillar Inc. ResultsDurai NaiduNo ratings yet

- BMP Rim Rib Thickness VariaitonDocument3 pagesBMP Rim Rib Thickness VariaitonDurai NaiduNo ratings yet

- MDS Report Substances of Assemblies and Materials: 1. Company and Product NameDocument3 pagesMDS Report Substances of Assemblies and Materials: 1. Company and Product NameDurai NaiduNo ratings yet

- Roundtest (Roundform Measuring Instruments)Document1 pageRoundtest (Roundform Measuring Instruments)Durai NaiduNo ratings yet

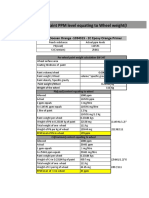

- PB, CR Paint PPM Level Equating To Wheel Weight (Doosan Orange Primer - EW 347 Wheel)Document1 pagePB, CR Paint PPM Level Equating To Wheel Weight (Doosan Orange Primer - EW 347 Wheel)Durai NaiduNo ratings yet

- PB, CR Paint PPM Level Equating To Wheel Weight (Doosan Orange Primer - EW 347 Wheel)Document3 pagesPB, CR Paint PPM Level Equating To Wheel Weight (Doosan Orange Primer - EW 347 Wheel)Durai NaiduNo ratings yet

- Limits, Fits and Surface Properties: ISO Standards HandbookDocument3 pagesLimits, Fits and Surface Properties: ISO Standards HandbookDurai NaiduNo ratings yet

- HD Rim Valve Guard PorosityDocument3 pagesHD Rim Valve Guard PorosityDurai NaiduNo ratings yet

- KtagDocument3 pagesKtagDurai NaiduNo ratings yet

- Demounting Flange Serail NoDocument1 pageDemounting Flange Serail NoDurai NaiduNo ratings yet

- Application: Supplier NCM View: 09. All NCM's/by NCM Number Exported By: b0612s0dg On: Jan 6, 2021 10:25 AMDocument5 pagesApplication: Supplier NCM View: 09. All NCM's/by NCM Number Exported By: b0612s0dg On: Jan 6, 2021 10:25 AMDurai NaiduNo ratings yet

- Substance List GADSL Reference List 2020ver.1.0Document59 pagesSubstance List GADSL Reference List 2020ver.1.0Durai NaiduNo ratings yet

- Part Current Issues: Wrong Rim Supply (Look A Likes - Inset Difference, Bore Id Differences Etc)Document4 pagesPart Current Issues: Wrong Rim Supply (Look A Likes - Inset Difference, Bore Id Differences Etc)Durai NaiduNo ratings yet

- Paint (Good Example: Ingredients After Curing Are Entered For The Paint Bad Example: Ingredients Before Curing Are Entered For The Paint)Document43 pagesPaint (Good Example: Ingredients After Curing Are Entered For The Paint Bad Example: Ingredients Before Curing Are Entered For The Paint)Durai NaiduNo ratings yet

- Summary of The JAMA/JAPIA Standard Material Datasheet Version Upgrade (For Ver .2.11)Document7 pagesSummary of The JAMA/JAPIA Standard Material Datasheet Version Upgrade (For Ver .2.11)Durai NaiduNo ratings yet

- Material Number, Vda Classification - ExList - Abstract - EN - 201001Document250 pagesMaterial Number, Vda Classification - ExList - Abstract - EN - 201001Durai NaiduNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Ppap WorkbookDocument80 pagesPpap WorkbookalyankaNo ratings yet

- Kuwait National Petroleum Company: Request For QuotationDocument6 pagesKuwait National Petroleum Company: Request For Quotationsatheeskumar VikramasingarajNo ratings yet

- 1517618394299Document26 pages1517618394299Nagaraju Dummu100% (1)

- Strima TWB 06 PDFDocument1 pageStrima TWB 06 PDFaleksandra_krzn5246No ratings yet

- MINERA IRL Project Gold OllacheaDocument230 pagesMINERA IRL Project Gold OllacheaJhonCordovaCruz100% (1)

- CM Chapetr 3Document60 pagesCM Chapetr 3AsisGtNo ratings yet

- Activity Based CostingDocument20 pagesActivity Based CostingPrashanth DarNo ratings yet

- USSBS Report 34, Army Air Arsenal and Navey Air DepotsDocument80 pagesUSSBS Report 34, Army Air Arsenal and Navey Air DepotsJapanAirRaids100% (1)

- Reinforcement CalculationDocument2 pagesReinforcement CalculationVekaymech100% (9)

- BS en 00259-1-2001Document14 pagesBS en 00259-1-2001Harun ARIKNo ratings yet

- Elements of An API 653 Tank InspectionDocument4 pagesElements of An API 653 Tank Inspectioncamasa2011No ratings yet

- Momenat I ProbojDocument404 pagesMomenat I ProbojSonja DragovicNo ratings yet

- Super Chipmunk-90 RF: 0.60 0 75 Cu. In. Displacement 2-Stroke 0.91 Cu. In. Displacement 4-StrokeDocument15 pagesSuper Chipmunk-90 RF: 0.60 0 75 Cu. In. Displacement 2-Stroke 0.91 Cu. In. Displacement 4-StrokejorgeNo ratings yet

- 2017 CacDocument70 pages2017 CacHorațiu FerchiuNo ratings yet

- Selecting ERPs PDFDocument17 pagesSelecting ERPs PDFlucky414No ratings yet

- Network Information Management - SunvizionDocument10 pagesNetwork Information Management - SunvizionKristofer KimblerNo ratings yet

- Cat 20 23 Minibloc6 Rom GBDocument16 pagesCat 20 23 Minibloc6 Rom GBarteorNo ratings yet

- AkzoNobel - Colloidal Silica For Adhesives BrochureDocument6 pagesAkzoNobel - Colloidal Silica For Adhesives BrochureCarlos GuerreroNo ratings yet

- Girnar Gears PVT - LTD.: Manufactures of All Gears"Document16 pagesGirnar Gears PVT - LTD.: Manufactures of All Gears"kool_kunalNo ratings yet

- MICHIGAN MOTORZ - New Engine Warranty InformationDocument2 pagesMICHIGAN MOTORZ - New Engine Warranty InformationDaddyos Marine EnginesNo ratings yet

- List Applicable WPS StructureDocument7 pagesList Applicable WPS StructureFerdie OSNo ratings yet

- BADM 2301 Spring 2014 Lab 5Document19 pagesBADM 2301 Spring 2014 Lab 5chanyoung4951No ratings yet

- CS230Document464 pagesCS230JFPacNo ratings yet

- 5620 SAM Part Number ListingDocument109 pages5620 SAM Part Number ListingSa VahidiNo ratings yet

- Bearing TolerancesDocument5 pagesBearing Tolerancesstavros stergiopoulosNo ratings yet

- GW C106Y Foil Stamping MachineDocument15 pagesGW C106Y Foil Stamping MachineMuhammadIsmail Engr.No ratings yet

- Nokia Case StudyDocument17 pagesNokia Case Studynimishasharma11No ratings yet

- No.56 Vignarajan Nagar IAF Post, Avadi Chennai-600055.: N.BalasubramanianDocument1 pageNo.56 Vignarajan Nagar IAF Post, Avadi Chennai-600055.: N.BalasubramanianbalakarnNo ratings yet

- Coa Fb-50 Plus Textile AntifoamDocument4 pagesCoa Fb-50 Plus Textile AntifoamShandy Yudha Nugraha100% (1)