Professional Documents

Culture Documents

Hoist Electrical System - Test (KENR8381)

Uploaded by

Pablo Cesar Poma ArrateaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hoist Electrical System - Test (KENR8381)

Uploaded by

Pablo Cesar Poma ArrateaCopyright:

Available Formats

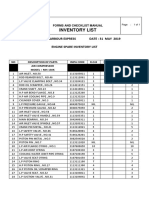

21/5/2021 SIS 2.

2012/06/12 Hoist Electrical System - Test (KENR8381)

SMCS - 1400,5050 i04926020

Note: Before performing this test, check the Vital Information Management System (VIMS) for diagnostics that are active or diagnostics that are

inactive. Make all repairs necessary to the electrical system on the truck in order to clear all events in the VIMS.

Note: If there is a problem with the electrical system for the hoist, the Chassis Electronic Control Module (Chassis ECM) will cause the hoist control

valve to remain in the HOLD position until the problem is fixed. When the problem is fixed, the hoist control must be placed in the HOLD position.

With the hoist control in the HOLD position, the Chassis ECM will reset in order to allow normal operation of the hoist control valve.

Check the Input and Output of the Chassis Electronic Control Module

1. Turn the start switch key to the ON position.

2. Lower the dump body.

3. Use the VIMS in order to view the input and output of the Chassis ECM.

4. Type "787" on the keypad for the VIMS. Press the "GAUGE" key in order to view the input to the Chassis ECM.

5. Type "788" on the keypad for the VIMS. Press the "GAUGE" key in order to view the output from the Chassis ECM.

Note: When the engine is not operating, the Chassis ECM causes the output to the hoist control valve to remain in the HOLD position. In

order to override this condition, hold the hoist control in the RAISE position for 30 seconds.

6. Place the hoist control in the RAISE, HOLD, FLOAT, and LOWER positions.

7. Compare the message center for the VIMS with Table 1.

Hoist Control Lever ECM Input (Chassis) ECM Output (Chassis)

RAISE RAISE RAISE

HOLD HOLD HOLD

FLOAT FLOAT FLOAT

LOWER LOWER FLOAT

Table 1

Check the Hoist Control Lever

Note: Caterpillar Electronic Technician (ET) or the VIMS can be used to check the hoist control lever.

1. If the ET is available, connect the ET to the truck.

2. Turn the start switch key to the ON position.

3. View the "Hoist Lever Position" on Caterpillar ET.

Note: If the VIMS is used, view the "Lever Position" for the hoist control lever on the VIMS. Type "787" and press the "GAUGE" key in order

to view the position of the hoist control.

4. Move the hoist control through the four positions RAISE, HOLD, FLOAT, and LOWER.

5. Compare the display on the VIMS or on the ET with the position of the hoist control lever.

Hoist Lever Position Sensor

The hoist lever position sensor receives 24 V from the Chassis ECM. Refer to Step 1 and Step 2 in order to check the supply voltage to the sensor.

1. Connect a multimeter between Pin A and Pin B of the connector for the hoist lever position sensor.

2. Set the multimeter to read "DC Volts".

Refer to Step 1 through Step 4 in order to check the output signal of the hoist lever position sensor.

1. Connect a multimeter between Pin B and Pin C of the connector for the hoist lever position sensor.

2. Set the multimeter to read "Duty Cycle".

3. The duty cycle output of the sensor should be approximately 5 percent to 95 percent when the lever is between the full RAISE position and

the full LOWER position.

https://sis2.cat.com/#/print-preview/service/%7B"title"%3A"Hoist Electrical System - Test (KENR8381)"%2C"formattedPublicationDate"%3A"2012%2F06%2F12"%2C"htmlContentKey"%3A"c8ff5871-b37c-4e20-841e-… 1/7

21/5/2021 SIS 2.0

4. The pull up voltage for the hoist lever position sensor should be approximately 7 V.

Note: The four positions for the hoist lever position sensor are constantly calibrated by the Chassis ECM during the operation of the machine.

Check the Proportional Solenoid Valves

Note: Using the ET to test the proportional solenoids on the hoist control valve is easier and faster than adjusting the position sensor for the dump

body. The procedure that includes adjusting the position sensor for the dump body should only be done when all other test procedures have been

completed.

Using the Caterpillar Electronic Technician

1. Lower the dump body. Stop the engine.

2. Connect the ET to the truck.

Illustration 1 g00670472

(1) Proportional solenoid valve for the bypass to brake cooling

(2) Proportional solenoid valve for the bypass to brake cooling

(3) Control valve for the hoist and for the brake cooling

(4) Hoist control valve

(5) Proportional solenoid valve for rod end oil that is flowing from the center of hoist control valve (4) to the hydraulic tank

(6) Proportional solenoid valve for rod end oil that is flowing from the pump to the center of hoist control valve (4)

(7) Proportional solenoid valve for head end oil that is flowing from the pump to the center of hoist control valve (4)

(8) Proportional solenoid valve for rod end oil that is flowing from the center of hoist control valve (4) to the hydraulic tank

3. Install a multimeter in series with proportional solenoid valve (1).

4. A list of overrides under the menu for diagnostics in the ET contains a test that can be used to override the Chassis ECM. The ET will send a

current between 0 A and 2 A to the proportional solenoid valve that is selected.

5. Input 0 percent. The reading on the multimeter should be 0 A.

6. Input 100 percent. The reading on the multimeter should be 2.0 A.

7. Repeat Step 3 through Step 6 for proportional solenoid valve (2), and proportional solenoid valve (4) through proportional solenoid valve (8).

8. Disconnect the multimeter and the ET.

Using the Position Sensor for the Dump Body

1. Lower the dump body. Stop the engine.

Illustration 2 g00670472

(1) Proportional solenoid valve for the bypass to brake cooling

(2) Proportional solenoid valve for the bypass to brake cooling

(3) Control valve for the hoist and for the brake cooling

(4) Hoist control valve

(5) Proportional solenoid valve for rod end oil that is flowing from the center of hoist control valve (4) to the hydraulic tank

(6) Proportional solenoid valve for rod end oil that is flowing from the pump to the center of hoist control valve (4)

(7) Proportional solenoid valve for head end oil that is flowing from the pump to the center of hoist control valve (4)

(8) Proportional solenoid valve for rod end oil that is flowing from the center of hoist control valve (4) to the hydraulic tank

https://sis2.cat.com/#/print-preview/service/%7B"title"%3A"Hoist Electrical System - Test (KENR8381)"%2C"formattedPublicationDate"%3A"2012%2F06%2F12"%2C"htmlContentKey"%3A"c8ff5871-b37c-4e20-841e-… 2/7

21/5/2021 SIS 2.0

2. Install a multimeter in series with proportional solenoid valve (1).

Note: When the engine is not operating, the Chassis ECM causes the output to the hoist control valve to remain in the HOLD position. In

order to override this condition, hold the hoist control in the RAISE position for 30 seconds.

3. Move the hoist control lever to the RAISE position. Record the reading on the multimeter.

4. Move the hoist control lever to the HOLD position. Record the reading on the multimeter.

5. Use the message center for the Vital Information Management System (VIMS) to view the position of the position sensor for the dump body.

Type "787" on the keypad for the VIMS. Press the "GAUGE" key.

6. Disconnect the linkage for the position sensor for the dump body. Move the linkage in order to rotate the position sensor for the dump body to

approximately 40 degrees. Verify that the position sensor has been rotated to the second stage of the hoist cylinders on the VIMS message

center. Type "708" on the keypad for the VIMS. Press the "GAUGE" key.

Note: The hoist cylinders must be in the second stage or the dump body must be raised more than 40 degrees in order for the hoist control

valve to be in the LOWER position.

7. Move the hoist control lever to the LOWER position. Record the reading on the multimeter.

8. Move the hoist control to the FLOAT position. Record the reading on the multimeter.

9. Connect the linkage for the position sensor onto the dump body. Check the reading on the multimeter within 20 seconds. Record the reading

on the multimeter. The recorded value is for the SNUB position.

Note: After the linkage is connected to the dump body, the hoist control valve will be in the SNUB position for 20 seconds. After 20 seconds,

the hoist control valve will change to the low-power FLOAT position.

10. Disconnect the multimeter.

11. Repeat Step 1 through Step 10 for proportional solenoid valve (2), and proportional solenoid valve (4) through proportional solenoid valve (8).

12. Compare the recorded values with the values in Table 2.

Note: The proportional solenoid valves receive a maximum of 1.9 A current from the Chassis ECM when the proportional solenoid valves are fully

activated.

Hoist Control Lever Solenoid (1)(1) Solenoid (2)(2) Solenoid (3)(3) Solenoid (4)(4) Solenoid (5)(5) Solenoid (6)(6)

RAISE High(7) High(7) High(7) Off(8) High(7) Off(8)

HOLD Off(8) Off(8) Off(8) Off(8) Off(8) Off(8)

FLOAT Low(9) Low(9) Off(8) Off(8) Off(8) Low(9)

LOWER High(7) High(7) Off(8) High(7) Off(8) High(7)

SNUB Low(9) Low(9) Off(8) Low(9) Off(8) Low(9)

Table 2

(1)

(2) Proportional solenoid valve for the bypass to rear brake cooling

(3) Proportional solenoid valve for the bypass to front brake cooling

(4) Proportional solenoid valve for rod end oil that is flowing from the center of the hoist control valve to the hydraulic tank

(5) Proportional solenoid valve for rod end oil that is flowing from the pump to the center of the hoist control valve

(6) Proportional solenoid valve for head end oil that is flowing from the pump to center of the hoist control valve

(7) Proportional solenoid valve for head end oil that is flowing from the center of the hoist control valve to the hydraulic tank

(8) The current for this proportional solenoid valve will be high. The proportional solenoid valve will be fully activated.

(9) The current for this proportional solenoid valve will be 0 A. The proportional solenoid valve will not be activated.

The current for this proportioning solenoid will be low. The proportioning solenoid will be modulated.

Hoist Lower Calibration

Using the Caterpillar Electronic Technician

1. Lower the dump body. Stop the engine.

2. Connect the ET to the truck.

3. Connect a pressure gauge to the front section and to the rear section of the hoist pump. Use the highest pressure of the two sections in order

to calibrate the pressure for the lower function of the hoist system.

4. On the ET screen, click File - Select ECM and choose Chassis ECM.

5. On the ET screen, click Service - Calibration - Hoist Calibration. The screen in Illustration 3 will appear.

6. Follow the instructions on the ET screen in order to set the pressure to 6890 kPa (1000 psi).

https://sis2.cat.com/#/print-preview/service/%7B"title"%3A"Hoist Electrical System - Test (KENR8381)"%2C"formattedPublicationDate"%3A"2012%2F06%2F12"%2C"htmlContentKey"%3A"c8ff5871-b37c-4e20-841e-… 3/7

21/5/2021 SIS 2.0

Note: You will be instructed to hold the hoist lever in the LOWER position. The engine speed will increase to high idle. Use the arrows on the

bottom of the ET screen to increase or decrease the pressure. The single arrow changes the pressure by 7 kPa (1 psi). The double arrows

change the pressure by 70 kPa (10 psi).

Illustration 3 g01034002

Hoist Lower Valve Adjustment Status (Snub)

Lowering the hoist is adjustable. An adjustable hoist compensates for the differences in valves. The adjustment range is -5 to +5 with zero as the

default. A positive adjustment factor will increase the lower valve command. A positive adjustment factor causes the body to come down harder. A

negative adjustment factor will decrease the lower valve command. A negative adjustment factor causes the body to come down softer.

Note: When the Hoist Lower Valve is adjusted too high, too much oil can be diverted to the hoist system. If the hoist system is in the float mode,

the brake oil heats up faster. Retarding capability is also decreased. To set the Hoist Lower Valve, follow the procedure below.

1. Raise the truck body.

https://sis2.cat.com/#/print-preview/service/%7B"title"%3A"Hoist Electrical System - Test (KENR8381)"%2C"formattedPublicationDate"%3A"2012%2F06%2F12"%2C"htmlContentKey"%3A"c8ff5871-b37c-4e20-841e-… 4/7

21/5/2021 SIS 2.0

Illustration 4 g02075237

Typical view

2. Connect the safety retaining cables to the body.

Illustration 5 g01360179

View of the 6V-7830 Tetragauge

3. Connect a 6V-7830 Tetragauge to one of the outlet ports on the hoist pump.

4. Remove the safety retaining cables from the body.

5. With the engine that is running, place the hoist lever in the body float position.

6. With the engine operating at high idle and the body in the snub position, record the pressure.

Note: If the pressure at the hoist outlet port is more than 1723 kPa (250 psi), then proceed to Step 7.

7. Start Cat "ET".

https://sis2.cat.com/#/print-preview/service/%7B"title"%3A"Hoist Electrical System - Test (KENR8381)"%2C"formattedPublicationDate"%3A"2012%2F06%2F12"%2C"htmlContentKey"%3A"c8ff5871-b37c-4e20-841e-… 5/7

21/5/2021 SIS 2.0

Illustration 6 g02162170

8. In the "Chassis 797" tab click on "Hoist System".

9. Select "Hoist Lower Valve Adjustment Status".

10. Select "Change".

Illustration 7 g02139158

11. Insert the new value in the "Hoist Lower Valve Adjustment Status" box. Click "OK". Select "OK" in the verification box.

12. Repeat Step 5 through Step 11 until the pressure is below 1724 kPa (250 psi).

Note: When the pressure is greater than 1724 kPa (250 psi), the adjustment is set too high. If the adjustment is too high, too much oil can be

diverted to the hoist valve. Too much oil to the hoist valve causes the brake oil to overheat when the body is in the body float position. Reduce the

Hoist Lower Valve Adjustment in ET. Repeat Step 1 through Step 6 in order to lower the pressure below 1724 kPa (250 psi).

Note: The body down snub function cushions the shock when the body hits the bed of the truck. When the body is lowered, the body position

sensor detects the position of the body. When the body is close to the rail of the truck, the ECM will go into snub mode. When the operators

request is less than the snub mode, the ECM will use the operators request. When the ECM uses the operators request, the ECM ensures that the

snub function will never cause the body to go down faster than the hoist lever modulation. The body snub function will be canceled as the operator

moves the hoist lever out of the body float position or the body lower position. The body snub function will not start until the body is raised above

the body position sensor activation point.

5YW1-UP, JSM1-UP, LAJ1-UP, LTZ1-UP, WSP1-UP

PSP-00043039

2021/05/21

13:29:23-05:00

i01108152

© 2021 Caterpillar Inc.

https://sis2.cat.com/#/print-preview/service/%7B"title"%3A"Hoist Electrical System - Test (KENR8381)"%2C"formattedPublicationDate"%3A"2012%2F06%2F12"%2C"htmlContentKey"%3A"c8ff5871-b37c-4e20-841e-… 6/7

21/5/2021 SIS 2.0

Caterpillar:

Confidential Green

https://sis2.cat.com/#/print-preview/service/%7B"title"%3A"Hoist Electrical System - Test (KENR8381)"%2C"formattedPublicationDate"%3A"2012%2F06%2F12"%2C"htmlContentKey"%3A"c8ff5871-b37c-4e20-841e-… 7/7

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Piston Pump - High Pressure Stall - Steering 950 GC Wheel Loader M5K00001-UP (MACHINE) POWERED BY C7.1 Engine (SEBP6716 - 29) - DocumentaciónDocument5 pagesPiston Pump - High Pressure Stall - Steering 950 GC Wheel Loader M5K00001-UP (MACHINE) POWERED BY C7.1 Engine (SEBP6716 - 29) - DocumentaciónPablo Cesar Poma ArrateaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Pilot Pressure To The Main Control Valve - Check - 950 GC Wheel Loader M5K00001-UP (MACHINE) POWERED BY C7.1 Engine (SEBP6716 - 29) - DocumentaciónDocument6 pagesPilot Pressure To The Main Control Valve - Check - 950 GC Wheel Loader M5K00001-UP (MACHINE) POWERED BY C7.1 Engine (SEBP6716 - 29) - DocumentaciónPablo Cesar Poma ArrateaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document48 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Pablo Cesar Poma ArrateaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Brake Accumulator - Test 950 GC Wheel Loader M5K00001-UP (MACHINE) POWERED BY C7.1 Engine (SEBP6716 - 29) - DocumentaciónDocument5 pagesBrake Accumulator - Test 950 GC Wheel Loader M5K00001-UP (MACHINE) POWERED BY C7.1 Engine (SEBP6716 - 29) - DocumentaciónPablo Cesar Poma ArrateaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Relief Valve (Load Sensing Signal) 950 GC Wheel Loader M5K00001-UP (MACHINE) POWERED BY C7.1 Engine (SEBP6716 - 29) - DocumentaciónDocument6 pagesRelief Valve (Load Sensing Signal) 950 GC Wheel Loader M5K00001-UP (MACHINE) POWERED BY C7.1 Engine (SEBP6716 - 29) - DocumentaciónPablo Cesar Poma ArrateaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Required Parts: Table 2Document7 pagesRequired Parts: Table 2Pablo Cesar Poma ArrateaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Position Sensor (Body) - Calibrate (KENR8396)Document4 pagesPosition Sensor (Body) - Calibrate (KENR8396)Pablo Cesar Poma ArrateaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Speed/Timing - Test: TroubleshootingDocument20 pagesSpeed/Timing - Test: TroubleshootingPablo Cesar Poma ArrateaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- System Overview TroubleshootingDocument18 pagesSystem Overview TroubleshootingPablo Cesar Poma ArrateaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Speed Control - TestDocument5 pagesSpeed Control - TestPablo Cesar Poma ArrateaNo ratings yet

- Valvulas ICM 793Document17 pagesValvulas ICM 793Pablo Cesar Poma ArrateaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Quick Guide To JAF Services: Road ServiceDocument14 pagesQuick Guide To JAF Services: Road ServiceSamael_X9No ratings yet

- Book13 - Roller Screen Gear Box R87 RR1439 - P0EBD72Document180 pagesBook13 - Roller Screen Gear Box R87 RR1439 - P0EBD72Cuộc Sống MàNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- He Air Compressor Inventory 1905Document2 pagesHe Air Compressor Inventory 1905Zulhusni Bin Mohd RashidNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- National Academic Reference Standards (NARS) For EngineeringDocument68 pagesNational Academic Reference Standards (NARS) For EngineeringAhmed NafieNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- EmaDocument14 pagesEmaSAKTHIVEL SELVARAJNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- SS FG230 enDocument2 pagesSS FG230 entolisNo ratings yet

- d11t, SERV1845 - 01 - TXTDocument203 pagesd11t, SERV1845 - 01 - TXTDiego Alonso Huaraca Baleriano100% (4)

- 2005 2006 2007 2008 Toyota Tacoma Factory Service ManualDocument12 pages2005 2006 2007 2008 Toyota Tacoma Factory Service ManualmarranNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- WholesaleProductGuide Release6Document165 pagesWholesaleProductGuide Release6panchoNo ratings yet

- US Press Information: 2006 BMW 3 Series Coupes & Convertibles Technical SpecificationsDocument6 pagesUS Press Information: 2006 BMW 3 Series Coupes & Convertibles Technical SpecificationsAsil Can BozoğluNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Operation & Maintenance Manual S175 Skid-Steer Loader: S/N A3L520001 & AboveDocument190 pagesOperation & Maintenance Manual S175 Skid-Steer Loader: S/N A3L520001 & Abovekaled ben abdallahNo ratings yet

- Pallet Jack ReferenceDocument2 pagesPallet Jack ReferenceDPKO NA COENo ratings yet

- Fitting Iintinstructiontins Super Light Clutch Utinit Fionr T-MAX 500 / 530 EVODocument6 pagesFitting Iintinstructiontins Super Light Clutch Utinit Fionr T-MAX 500 / 530 EVOGustavo Fleischfresser MüllerNo ratings yet

- Ficha Tecnica Winche TulsaDocument1 pageFicha Tecnica Winche TulsamarcoNo ratings yet

- Codici Errore CitroenDocument109 pagesCodici Errore Citroenamedei linoNo ratings yet

- Study of Awareness of Welfare Schemes and Working Conditionsat Ashok Leyland, Pantnagar, UttarakhandDocument11 pagesStudy of Awareness of Welfare Schemes and Working Conditionsat Ashok Leyland, Pantnagar, UttarakhandRohit KumarNo ratings yet

- Materials and Technologies For Automotive Use: AbstractDocument18 pagesMaterials and Technologies For Automotive Use: AbstractLuqman Al HakimNo ratings yet

- Denso InjectorDocument20 pagesDenso Injectoraddelyn_robescu8794100% (7)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Item CodeDocument370 pagesItem CodeVishvesh UpadhyayNo ratings yet

- Turcont Catalogue EnglishDocument23 pagesTurcont Catalogue EnglishHusain EbrahimNo ratings yet

- Workshop ManualDocument26 pagesWorkshop Manuallucy.morrisNo ratings yet

- Aisin Atf-0t4 Technical DataDocument1 pageAisin Atf-0t4 Technical DatalarconeNo ratings yet

- Fist Assurance Company LTDDocument30 pagesFist Assurance Company LTDThomas domingo100% (1)

- Group 2 Main Control Valve: A. ALP165 1. StructureDocument46 pagesGroup 2 Main Control Valve: A. ALP165 1. StructureJuan GarciaNo ratings yet

- SKS (Sensor Coupling System) : Advantages at A Glance Technical FeaturesDocument2 pagesSKS (Sensor Coupling System) : Advantages at A Glance Technical Featurestito del pinoNo ratings yet

- Ashcroft ZF4HP22Document15 pagesAshcroft ZF4HP22Felipe Mercado SandyNo ratings yet

- Mpraus0008 00 Parts Ecd45b 20111213Document288 pagesMpraus0008 00 Parts Ecd45b 20111213roland100% (1)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- HST Assignment FAIZAN 5Document8 pagesHST Assignment FAIZAN 5patel noorNo ratings yet

- R&I Oil Pump 186 Eng. #2Document4 pagesR&I Oil Pump 186 Eng. #2basheer almetwakelNo ratings yet

- OF 68029-BGV 4 Manual - InglDocument24 pagesOF 68029-BGV 4 Manual - InglKevin FloresNo ratings yet