Professional Documents

Culture Documents

Monthly Fuel Tanker Inspection Checklist

Uploaded by

RabbanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Monthly Fuel Tanker Inspection Checklist

Uploaded by

RabbanCopyright:

Available Formats

ATTACHMENT 4

FUEL TANKER INSPECTION CHECKLIST Plant Location: Inspection Sticker

Number:

Saudi Aramco Inspection Form SA9505-B

Truck Number (SAG): Trailer Number (SAG): Company Name: Customer/Hauler

No.:

Driver’s Name: Saudi Aramco ID No.: Date (DD/MM/YY) Time:

Inspection Item Pass Fail Inspection Item

DRIVER

Has valid driving license and appears physically able to drive safely

Required personal safety equipment.

(i.e. mentally alert).

2. GENERAL VEHICLE

15. Tires with 2/32 inch tread across the full width of the

Valid Traffic Police Inspection Certification. Required Gov’t. Doc.

tire.

Cab doors and equipment box doors close securely and hood-latch 16. Tires with no chunks missing, bites, broken walls or

secured. objects protruding. Tire rims in good condition with no

dents

17. or warping.

Exhaust system in good condition discharging at ground

Under-seat battery(s) secure, are electrically insulated.

level for top loading operations.

External battery secure in a covered vented box and terminals shall

18. Nothing unusual protruding for falling from vehicle.

be electrically insulated or covered.

Battery connections conditions and level of acids or sights of

leakage are in good condition according to manufacturer 19. Seat belt installed and working properly.

requirements.

Battery disconnect installed. Disconnect switches and associated

20. Windshield and side-view mirrors in good condition.

wiring and battery vents cleaned.

21. Wires connected directly to the load (light) without

Air brake hoses connected, in good condition, and not leaking.

splicing. Wires/cables securely fasten and protected against

Electrical wiring secure and installed in corrugated polyamide mechanical

22. The cabledamage.

path (between the emergency valve cam and

conduits and protected against impact, abrasion and chafing during the bottom operator) is straight and free of sharp

normal operation. No additional wiring or decorative lightings are radii/bends.

installed.

Lights or light lenses. 23. Truck properly painted, labeled and clean.

All lights are operational (headlights, signals, brakes). 24. Truck fuel tanks in good condition.

Truck mounted portable fire extinguishers easily accessible and not 25. Auxiliary fuel tanks in good condition with pressure relief

“Wired on” & with valid inspection sticker. valve installed.

Fifth-wheel bolts (broken or missing). 26. Auxiliary fuel tank supply line valve closed.

3. TANK, TANK PIPING AND MISCELLANEOUS

34. Tank top access ladders in good condition and flat

27. Tank integrity (i.e. no cracks, damage, corrosion, leaks, etc.).

walkway with grating plate at the top of the tanker.

28. Piping integrity (i.e. no cracks, damage, corrosion, leaks, etc.) 35. Piping tee arrangement with operational isolation

securely mounted with end caps provided and meeting acceptable valve. Piping support brackets and hangers are welded at

UT readings allowance. least 1 inch away from both the tank shell welds and from

any pipe welding joints.

29. Piping valves securely mounted and not leaking. 36. “Dry-Break” coupling in good condition.

30. Tank covers closed securely with no leaks. 37. Valve protection box in good condition.

31. Loading rack bonding wire connection unpainted in good

38. Operational top-mounted tank vents installed.

condition and not loose.

39. Containment system holding tank installed and in good

32. Topside containment system enclosed and in good condition.

condition.

33. Topside containment system drains piping, valves and plugs. 40. Scully/Grounding system is functioning.

Pass Additional Remarks:

Final Result: Fail

Inspectors Name (Print): Inspector’s Badge No.: Inspector’s Signature: Date:

Driver Acknowledge Name: Driver Signature: Date:

15 Safe fuelling procedure

Saudi Aramco: Company General Use

You might also like

- SA 9505 Fuel Tanker Inspection ChecklistDocument2 pagesSA 9505 Fuel Tanker Inspection ChecklistRabban100% (3)

- Editable Inspection Checklist For Heavy Equipment PDFDocument1 pageEditable Inspection Checklist For Heavy Equipment PDFchassas0% (1)

- NEC and IEC ComparisionDocument123 pagesNEC and IEC ComparisionRon Rainey100% (4)

- HSE Plan TemplateDocument8 pagesHSE Plan Templatederson50% (2)

- Monthly Forklift Inspection Checklist OHS PR 009 FM 01 0412Document1 pageMonthly Forklift Inspection Checklist OHS PR 009 FM 01 0412cmrig74100% (2)

- JERP #3 Aromatics Unit Gas Test LogDocument9 pagesJERP #3 Aromatics Unit Gas Test LogSravan Pulsarboy100% (2)

- Inspection Checklist For HydraDocument1 pageInspection Checklist For HydraParthiban Venkatesan75% (4)

- Abrasive Blasting Inspection ChecklistDocument1 pageAbrasive Blasting Inspection ChecklistRísês Ãfröz67% (3)

- Daily Fuel Truck ChecklistDocument1 pageDaily Fuel Truck ChecklistTFattah0% (1)

- Sand Blasting & Painting Risk AssessmentDocument6 pagesSand Blasting & Painting Risk AssessmentNaveed Ahmed Get-Info100% (1)

- Lifting Tools & Tackles Inspection Checklist FormsDocument1 pageLifting Tools & Tackles Inspection Checklist FormsDas GobindaNo ratings yet

- Saudi Aramco Safe Fueling ProcedureDocument16 pagesSaudi Aramco Safe Fueling Procedurerana qamarNo ratings yet

- Daily Cradle Inspection Sheet: No Type of Check Operational Status RemarksDocument1 pageDaily Cradle Inspection Sheet: No Type of Check Operational Status RemarksZubair Khan100% (1)

- Compressed Gas Cylinder Safety Inspection Checklist: Sl. No Description Yes/No/NA If No - Action TakenDocument1 pageCompressed Gas Cylinder Safety Inspection Checklist: Sl. No Description Yes/No/NA If No - Action TakenRísês Ãfröz0% (1)

- Jsa Tank CleaningDocument5 pagesJsa Tank CleaningASLAM MULANINo ratings yet

- Weekly Fuel Tanker Inspection ChecklistDocument2 pagesWeekly Fuel Tanker Inspection ChecklistRabbanNo ratings yet

- Backhoe-Rock Breaker Inspection ChecklistDocument1 pageBackhoe-Rock Breaker Inspection ChecklistAlok Singh100% (1)

- Chemical Hazard Bulletin: OPT D 1127Document1 pageChemical Hazard Bulletin: OPT D 1127HaleemUrRashidBangashNo ratings yet

- Forklift Checklist: SR Inspection PointsDocument1 pageForklift Checklist: SR Inspection Pointsakshay pradeep100% (1)

- Portable Grinding Machine ChecklistDocument1 pagePortable Grinding Machine ChecklistMithlesh Singh100% (1)

- Vehicle Entry Check ListDocument6 pagesVehicle Entry Check ListcgnanaponNo ratings yet

- Synthetic Sling Inspection FormDocument1 pageSynthetic Sling Inspection FormpakistaniNo ratings yet

- Backhoe-Loader Daily Inspection ChecklistDocument1 pageBackhoe-Loader Daily Inspection ChecklistMartine OtienoNo ratings yet

- Attachment J Contractor Inspection Checklist GI 298 - 010 - WeeklDocument10 pagesAttachment J Contractor Inspection Checklist GI 298 - 010 - WeeklRabbanNo ratings yet

- Attachment J Contractor Inspection Checklist GI 298 - 010 - WeeklDocument10 pagesAttachment J Contractor Inspection Checklist GI 298 - 010 - WeeklRabbanNo ratings yet

- Attachment J Contractor Inspection Checklist GI 298 - 010 - WeeklDocument10 pagesAttachment J Contractor Inspection Checklist GI 298 - 010 - WeeklRabbanNo ratings yet

- Weekly Fuel Tanker Inspection ChecklistDocument2 pagesWeekly Fuel Tanker Inspection ChecklistRabbanNo ratings yet

- UR S2 Universal Remote Control Code ListDocument14 pagesUR S2 Universal Remote Control Code ListGary Alberto Suárez Suárez100% (1)

- Smacna Duct ConstructionDocument23 pagesSmacna Duct ConstructionKaustubh Bidkar100% (2)

- Fuel Truck Monthly Inspection ChecklistDocument1 pageFuel Truck Monthly Inspection ChecklistRabbanNo ratings yet

- Wheel Loader Daily Inspection ChecklistDocument2 pagesWheel Loader Daily Inspection Checklistazer Azer100% (1)

- M/S Sekar Constructions: Gas Cutting Set Inspection Checklist Project/Location: Date: Job NoDocument1 pageM/S Sekar Constructions: Gas Cutting Set Inspection Checklist Project/Location: Date: Job NoRísês ÃfrözNo ratings yet

- 364 Pre Job Check List High Pressure Hydro Jetting Rev 000Document2 pages364 Pre Job Check List High Pressure Hydro Jetting Rev 000asan100% (1)

- Monthly Walk Aroung Fuel Tanker Inspection ChecklistDocument1 pageMonthly Walk Aroung Fuel Tanker Inspection ChecklistRabban100% (1)

- VL-HSE-008-R00 Compressed Gas Cylinder ChecklistDocument1 pageVL-HSE-008-R00 Compressed Gas Cylinder ChecklistRiju Scaria/EMD/QTRNo ratings yet

- 006 Mobile Crane Pre-Use Checklist - NO NEED FOR UPDATEDocument1 page006 Mobile Crane Pre-Use Checklist - NO NEED FOR UPDATELijo JohnNo ratings yet

- General Instruction ManualDocument1 pageGeneral Instruction ManualGeorge ZormpasNo ratings yet

- Job Safety Analysis Worksheet: JSA No: JSA For Chemical Cleaning of WWT TreatmentDocument5 pagesJob Safety Analysis Worksheet: JSA No: JSA For Chemical Cleaning of WWT TreatmentlokreddiNo ratings yet

- Safety Harness ChecklistDocument1 pageSafety Harness Checklistagung100% (1)

- Cherry Picker Inspection Checklist for Emami Cement Grinding UnitDocument1 pageCherry Picker Inspection Checklist for Emami Cement Grinding Unitsanjeev kumarNo ratings yet

- Load Test Checklist (Feb 05)Document3 pagesLoad Test Checklist (Feb 05)hastmishNo ratings yet

- 2 Tower Crane Checklist PDFDocument3 pages2 Tower Crane Checklist PDFAzaim AnaqiNo ratings yet

- Sling Belt & Wire Rope Inspection ChecklistDocument2 pagesSling Belt & Wire Rope Inspection ChecklistRaymondGomezBlanco100% (5)

- 10.a. Welding Machine Inspection (Electric, Travo Type)Document1 page10.a. Welding Machine Inspection (Electric, Travo Type)Adhy DarmawanNo ratings yet

- 01 - Gas Cutting Set Inspection ChecklistDocument1 page01 - Gas Cutting Set Inspection Checklistsanjeev kumar100% (1)

- Monthly Chemical Storage Safety ChecklistDocument1 pageMonthly Chemical Storage Safety ChecklistAbdul HadiNo ratings yet

- 06 Portable Grinding MachineDocument1 page06 Portable Grinding MachineGyanendra Narayan NayakNo ratings yet

- 127 - Hse Inspection Checklist-Compressed Gas CylinderDocument1 page127 - Hse Inspection Checklist-Compressed Gas CylinderEr Ajenk88% (8)

- Grader Daily Inspection ChecklistDocument2 pagesGrader Daily Inspection Checklistazer Azer100% (2)

- Checklist of Gas Cutting SetDocument3 pagesChecklist of Gas Cutting SetSafety DeptNo ratings yet

- Bar Cutting MachineDocument1 pageBar Cutting Machinesaurav roy100% (1)

- Yms Shem P 0810 - (Yms Oms P 31610) - 221216 - 102800Document117 pagesYms Shem P 0810 - (Yms Oms P 31610) - 221216 - 102800vinay kumarNo ratings yet

- Hand and Portable Power Tools Pre Use Inspection ChecklistDocument1 pageHand and Portable Power Tools Pre Use Inspection ChecklistRoselyn SharronNo ratings yet

- 05 Check List For Gas Cutting Set-1-1Document1 page05 Check List For Gas Cutting Set-1-1Gyanendra Narayan Nayak100% (1)

- DIN Project Work Handover FormDocument2 pagesDIN Project Work Handover FormRaza Muhammad Soomro100% (1)

- Truck Crane Inspection FormDocument3 pagesTruck Crane Inspection FormAdhy Darmawan100% (1)

- Consequence Management Sytem EsepplDocument1 pageConsequence Management Sytem Eseppluttam mishra100% (2)

- Roller Compactor Monthly ChecklistDocument2 pagesRoller Compactor Monthly ChecklistDAOUMY YOUNESSNo ratings yet

- Fire Fighting Equipment Monthly Inspection ReportDocument2 pagesFire Fighting Equipment Monthly Inspection Reportnadeem mallickNo ratings yet

- InspectionChecklist-CompressedGas 2016Document2 pagesInspectionChecklist-CompressedGas 2016austinraja50% (2)

- Telehandler Forklift Pre-Use Inspection ChecklistDocument1 pageTelehandler Forklift Pre-Use Inspection ChecklistMalika Baboo100% (1)

- Brush Cutter Pre Use ChecklistDocument1 pageBrush Cutter Pre Use ChecklistBruce Hove100% (2)

- Fire Water TankDocument1 pageFire Water TankAnonymous yCpjZF1rFNo ratings yet

- Main Progress for Lusail Stadium WorksDocument4 pagesMain Progress for Lusail Stadium Worksemmy100% (1)

- Vehicle Inspection SheetDocument1 pageVehicle Inspection Sheetcad curNo ratings yet

- 68 - Daily Inspection Checklist For Launching GirdersDocument13 pages68 - Daily Inspection Checklist For Launching GirdersankitNo ratings yet

- 14-Weekly Tower Crane Check ListDocument2 pages14-Weekly Tower Crane Check ListJigarNo ratings yet

- TF33674675Document13 pagesTF33674675Ulp BtuNo ratings yet

- Trencher Pre-Start ChecklistDocument1 pageTrencher Pre-Start ChecklistRabbanNo ratings yet

- Drilling Machine ChecklistDocument1 pageDrilling Machine ChecklistRabbanNo ratings yet

- Monthly Inspection Color CodeDocument1 pageMonthly Inspection Color CodeRabbanNo ratings yet

- Application - Patty CashDocument1 pageApplication - Patty CashRabbanNo ratings yet

- Part IV - 02 Marine OperationsDocument5 pagesPart IV - 02 Marine Operationssalah abddayemNo ratings yet

- Vehicle Maintenance PermitDocument2 pagesVehicle Maintenance PermitRabbanNo ratings yet

- Action plan correctionsDocument2 pagesAction plan correctionsRabbanNo ratings yet

- Hawiyah Unayzah Gas Reservoir Dust Control ScheduleDocument1 pageHawiyah Unayzah Gas Reservoir Dust Control ScheduleRabbanNo ratings yet

- Proximity Warning Alarm System - PWAS Daily Checklist: Hawiyah Unayzah Gas Reservoir Storage Project (HUGRS)Document1 pageProximity Warning Alarm System - PWAS Daily Checklist: Hawiyah Unayzah Gas Reservoir Storage Project (HUGRS)RabbanNo ratings yet

- List of TBT Agendas: S.# TBT Topic Reference NumberDocument31 pagesList of TBT Agendas: S.# TBT Topic Reference NumberRabban100% (1)

- Proximity Warning Alarm System - PWAS Daily Checklist: Hawiyah Unayzah Gas Reservoir Storage Project (HUGRS)Document1 pageProximity Warning Alarm System - PWAS Daily Checklist: Hawiyah Unayzah Gas Reservoir Storage Project (HUGRS)RabbanNo ratings yet

- Camp Compliance Checklist PMT (Saudi Aramco) COVID-19Document13 pagesCamp Compliance Checklist PMT (Saudi Aramco) COVID-19RabbanNo ratings yet

- Attendance Sheet: Date: Time: Location: SubjectDocument1 pageAttendance Sheet: Date: Time: Location: SubjectRabbanNo ratings yet

- Monthly Walk Aroung Fuel Tanker Inspection ChecklistDocument1 pageMonthly Walk Aroung Fuel Tanker Inspection ChecklistRabban100% (1)

- Fountain Gulf Gen Con Est Delivery Notes: SL No Date Receipt No Item LTR TotalDocument1 pageFountain Gulf Gen Con Est Delivery Notes: SL No Date Receipt No Item LTR TotalRabbanNo ratings yet

- Attendance Sheet: Date: Time: Location: SubjectDocument1 pageAttendance Sheet: Date: Time: Location: SubjectRabbanNo ratings yet

- MF 7700 enDocument44 pagesMF 7700 enriad100% (1)

- KERN 440 Service ManualDocument12 pagesKERN 440 Service Manualمصطفى الكوتNo ratings yet

- Bus Differential System: Grid SolutionsDocument762 pagesBus Differential System: Grid SolutionsgabrielrezvNo ratings yet

- Hvac Ducting System - BoqDocument6 pagesHvac Ducting System - BoqBeò FhathastNo ratings yet

- B. 140 - 1253078 - 880457 - Hand-In - P2-Rapport-Vertical-Axis-Wind-Turbine-GeneratorDocument93 pagesB. 140 - 1253078 - 880457 - Hand-In - P2-Rapport-Vertical-Axis-Wind-Turbine-GeneratorChristianNo ratings yet

- 16xe1 Digital RadioDocument6 pages16xe1 Digital RadioJorge BalzaNo ratings yet

- A55F-M4 V1.0 - Manual PDFDocument72 pagesA55F-M4 V1.0 - Manual PDFcomando2009No ratings yet

- Lifting Equipment 04 11 2023Document22 pagesLifting Equipment 04 11 2023rome reyesNo ratings yet

- Chevrolet N300P Parts CatalogueDocument2 pagesChevrolet N300P Parts Cataloguecifer.xiongNo ratings yet

- Experiment: 5: Aim: TheoryDocument2 pagesExperiment: 5: Aim: TheorypiyushdalsaniaNo ratings yet

- XMT*308 digital temperature control instrument manualDocument4 pagesXMT*308 digital temperature control instrument manualzivko13No ratings yet

- Programmable Onoff Controller: Universal Input, 2 Setpoints, I/V Out VER 13.XXDocument2 pagesProgrammable Onoff Controller: Universal Input, 2 Setpoints, I/V Out VER 13.XXAndi RafianNo ratings yet

- Technical Data Sheet B43H5L 110-120V 60Hz 1 R134a: Compressor Model Voltage RefrigerantDocument4 pagesTechnical Data Sheet B43H5L 110-120V 60Hz 1 R134a: Compressor Model Voltage RefrigerantLuisinho PerdomoNo ratings yet

- 4 Gimatic Framing PDFDocument34 pages4 Gimatic Framing PDFGylman Soto SuarezNo ratings yet

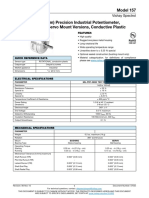

- Model 157: Vishay SpectrolDocument4 pagesModel 157: Vishay SpectrolJulio Vazquez MorenoNo ratings yet

- OSHA hand tool safety standardsDocument8 pagesOSHA hand tool safety standardsAlma Tomas-CafeNo ratings yet

- AVR sps-101Document1 pageAVR sps-101Sunil SangaNo ratings yet

- Smart Watch Phone User GuideDocument2 pagesSmart Watch Phone User GuideIRT ShopNo ratings yet

- Miller Toyota-Conversion-Kit Letter ENG WEBDocument4 pagesMiller Toyota-Conversion-Kit Letter ENG WEBskyduckNo ratings yet

- Electric Motor and GeneratorDocument6 pagesElectric Motor and GeneratorJesell JeanNo ratings yet

- Crompton Jet Pumps Single StageDocument2 pagesCrompton Jet Pumps Single StageAriol ZereNo ratings yet

- Global LCD Panel Exchange Center Datasheet ResourceDocument39 pagesGlobal LCD Panel Exchange Center Datasheet ResourceTono Agung NoviyantoNo ratings yet

- Prado - Merú SeDocument940 pagesPrado - Merú SeMauricio Montaño Rodriguez100% (3)

- 8-Bit PIC® Microcontrollers - Architecture - Microchip Technology IncDocument2 pages8-Bit PIC® Microcontrollers - Architecture - Microchip Technology IncSidharth MahotraNo ratings yet

- FA5i MR PDFDocument2 pagesFA5i MR PDFpramodh kumarNo ratings yet

- Hydrochlor TS: Salt Water Pool ChlorinatorDocument2 pagesHydrochlor TS: Salt Water Pool Chlorinatorethan8888No ratings yet

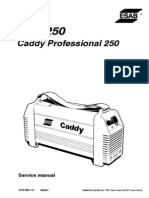

- Käyttöohje Generaattori Esab LHN 250 EngDocument34 pagesKäyttöohje Generaattori Esab LHN 250 EngmaciucapompaNo ratings yet