Professional Documents

Culture Documents

MA Ninety User Manual E Rev 5.0

MA Ninety User Manual E Rev 5.0

Uploaded by

juanpgutierrezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MA Ninety User Manual E Rev 5.0

MA Ninety User Manual E Rev 5.0

Uploaded by

juanpgutierrezCopyright:

Available Formats

No.

18717-Z5e

Manual for initiation and maintenance

Novega Produktionssysteme GmbH

Gewerbepark 2 | 87477 Sulzberg (See) | Germany

Fon: +49/8376/92990-0 | Fax: +49/8376/92990-20

info@novega.de | www.novega-sea.com

Table of Contents:

1.0 Annotation of the number of this document....................................... 3

2.0 Symbols and Abbreviations ................................................................. 3

3.0 Table of Figures .................................................................................... 4

4.0 Revision History .................................................................................... 5

5.0 Introduction ........................................................................................... 6

6.0 General ................................................................................................... 6

6.1 Technical characteristics .................................................................... 6

6.2 Annotation of the part- and serial number system .............................. 7

6.3 Type plate example ............................................................................ 7

6.4 Original battery inserted ..................................................................... 8

6.5 Signal ................................................................................................. 8

6.6 Specification ....................................................................................... 9

6.7 Mounting ............................................................................................ 9

6.8 Spare parts and tools ......................................................................... 9

7.0 Installation ........................................................................................... 10

7.1 Installation criteria ............................................................................ 10

7.2 Site selection .................................................................................... 10

7.3 Appropriate usage ............................................................................ 10

8.0 Operational and Battery Test ............................................................. 11

8.1 General ............................................................................................ 11

8.2 Testing ............................................................................................. 11

8.3 Voltage serial number 18717-00-30001 to 18717-00-30335 ............ 12

8.4 Voltage starting from serial number 18717-00-30336 ...................... 12

9.0 Battery replacement ............................................................................ 13

9.1 Battery safety data sheet.................................................................. 13

10.0 Maintenance and cleaning.................................................................. 13

10.1 Cleaning ........................................................................................ 13

10.2 Long-term storage ......................................................................... 14

10.3 Avoiding corrosion ........................................................................ 14

11.0 Returns................................................................................................. 16

11.1 General ......................................................................................... 16

11.2 Reshipment for factory overhaul ................................................... 16

11.3 ULD return – defective .................................................................. 16

11.4 ULD return – no defect .................................................................. 17

11.5 Return ULD – out of warranty ....................................................... 17

12.0 Warranty............................................................................................... 17

13.0 Declaration of Conformity .................................................................. 17

14.0 Disclaimer and copyright ................................................................... 17

Manual for initiation and maintenance 2 of 17

No.18717-Z5e of 20- January -2015

1.0 Annotation of the number of this document

Manual for initiation and maintenance:

18717 - Z X e

Part Document Revision Language

number sequence number

number

2.0 Symbols and Abbreviations

ULD Underwater Locating Device

BSH Bundesamt für Seeschifffahrt und Hydrographie

FRM Final Recording Medium

VDR Voyage Data Recorder

°C Grad Celsius

°F Grad Fahrenheit

kg Kilogram

m Meter

ft Foot

mm Millimeter

min Minute

h Hour

s Second

ms Millisecond

dB Decibel

kHz Kilohertz

µPa Micro Pascal

MPa Mega Pascal

Manual for initiation and maintenance 3 of 17

No.18717-Z5e of 20- January -2015

3.0 Table of Figures

FIGURE 1: WATER SENSITIVE SWITCH ...................................................... 6

FIGURE 2: TYPE PLATE EXAMPLE .............................................................. 7

FIGURE 3: ORIGINAL ..................................................................................... 8

FIGURE 4: START THE SERVICE OPERATION MODE ............................. 11

FIGURE 5: BATTERY VOLTAGE MEASUREMENT..................................... 12

FIGURE 6: BATTERY VOLTAGE MEASUREMENT..................................... 12

FIGURE 7: ULD BRACKET ........................................................................... 14

FIGURE 8: SMALL DAMAGES ..................................................................... 15

Manual for initiation and maintenance 4 of 17

No.18717-Z5e of 20- January -2015

4.0 Revision History

Rev. Date Details of Modifications Modified by

1 01.04.2014 external form / arrangement Michael Zettler

2 16.06.2014 enable serial number assignment Michael Zettler

3 01.08.2014 external form / arrangement Michael Zettler

4 05.11.2014 Expl. original battery inserted Michael Zettler

5 20.01.2015 Type plate / original battery Michael Zettler

inserted

Manual for initiation and maintenance 5 of 17

No.18717-Z5e of 20- January -2015

5.0 Introduction

This manual contains the description, as well as the installation and

maintenance directions for the PT9 NINETY Underwater Locating Device.

These Underwater Locating Devices (ULD) have been type-examination

tested by the BSH (Federal Office for maritime navigation and hydrography),

and meet or exceed all requirements of SAE AS8045A.

Advice: This manual must be read to its full extent prior to any initiation or

operation, testing or maintenance of the Underwater Locating Device PT9

NINETY.

6.0 General

6.1 Technical characteristics

The PT9 NINETY Underwater Locating Device is battery-powered and

primarily consists of an electronic module and a signal transmitter. Protected

by a cylindrical, water- and weatherproof housing, the PT9 NINETY

withstands extreme environmental conditions, high G-impact shock and deep

sea - pressure up to 6096 m. The PT9 NINETY is activated by immersion into

fresh- or salt-water. The activation effects the emission of a defined ultrasonic

signal. The battery capacity is dimensioned in such a way that the

PT9 NINETY is able to send this ultrasonic signal with constant signal

intensity for the duration of at least 90 days.

Water switch (-)

Battery side

(3 bore holes)

Water switch (+)

Electronic side

Figure 1: Water sensitive switch

Manual for initiation and maintenance 6 of 17

No.18717-Z5e of 20- January -2015

6.2 Annotation of the part- and serial number system

18717 - 00 - XXXXX

Part Modification Serial

number index number

6.3 Type plate example

Original

battery install

date / date of

manufacture

month / year

perforated battery voltage

(see 6.4)

Battery

replaced

(vide 9.0)

Data matrix code

containing serial

number and

original battery

install date

Figure 2: Type plate example serial number

Manual for initiation and maintenance 7 of 17

No.18717-Z5e of 20- January -2015

6.4 Original battery inserted

The inspection sticker for the original battery records the

install date of the original battery. The marked inspection

sticker is positioned, so that the arrow points to the month in

which the original battery has been inserted.

Meaning of Original Battery Install Date: The month in which

the original battery was inserted into the PT9 (see Figure 3:

Original battery inserted).

Figure 3: Original

battery inserted

Advice: The battery is inserted just in time before the delivery to achieve

maximum battery lifetime for our clients. Relevant for the evaluation of the

beacon is in any case the “Original battery inserted” date only.

6.5 Signal

The ULB is certified to emit an ultrasonic signal of 37.5 kHz (+/- 1kHz) for a

regulatory transmission time of at least 90 days.

Manual for initiation and maintenance 8 of 17

No.18717-Z5e of 20- January -2015

6.6 Specification

Operating frequency: 37.5 kHz +/- 1kHz

Operating depth: 6096 m (~ 20.000 ft)

Pulse permanence: 9 ms (Minimum)

Pulse repetition rate: 0.9 pulses/s

Operating life: 90 days (Minimum)

Battery durability: 3 years (after insertion of the battery)

Life cycle ULD: 6 years (after installation)

Acoustic output, initial: 106 N/m² rms pressure @ 1m (160.5 dB)

Acoustic output after 90 days: 70 N/m² rms pressure @ 1m (157.0 dB)

Operating temperature range: -2°C (28°F) to +38°C (100°F)

Storage temperature range: 18°C ±5°C (65°F± 10°F)

Transport temperature: -55°C (-67°F) to +71°C (160°F)

Activation: Fresh- or Saltwater

Radiation pattern: 80% of a sphere

Length: 100 mm (3.92 inches)

Diameter: 33 mm (1.3 inches)

Weight: 187g (6.6 ounces)

6.7 Mounting

The ULD is to be mounted to a Final Recording Medium (FRM) by means of a

suitable mounting kit.

6.8 Spare parts and tools

• Battery replacement kit Order No.: 20297

• TAG 2550 Tester Order No.: 17610

• Torque 3.0 Order No.: Torque_3.0

• Pressure dispense clamp Order No.: 17359

Manual for initiation and maintenance 9 of 17

No.18717-Z5e of 20- January -2015

7.0 Installation

This section describes the methodical installation and mounting of the

Underwater Locating Device to the FRM.

7.1 Installation criteria

The installation of the Underwater Locating Device is to be completed in

accordance with the FRM or VDR manufacturers’ approved procedures and

his hardware.

7.2 Site selection

The position of the FRM and subsequently of the ULD is to be selected

according to the regulations of the standard IEC 61996.

In case of an incident, the possibility of demolition of the unit by crash is to be

minimized. The environment, selected for mounting the ULD, has to exclude

the possibility that the ULD can be struck by loosening, heavy weight

components.

Advice: Honeycomb structures, tarpaulins and persennings, clothes, cargo,

etc. are to be considered as sound absorbing materials. Do not surround the

ULD with those materials.

Upon observing all mandatory aspects above mentioned, the mounting

position of the FRM and subsequently of the ULD is to be selected thus, that

there is enough space for maintenance works and a comfortable access to

the ULD, same as the required space for demounting the ULD.

7.3 Appropriate usage

7.3.1 General

The PT9 NINETY ULD must not be disassembled, crushed, penetrated,

incinerated or exposed to temperatures above 75°C (167°F).

7.3.2 Shelf life

The ULD is a battery-powered device. Store the ULD in a cool (18°C ± 5°;

65°F ± 10°), dry place. The shelf life can be affected by higher or lower

temperatures, as well as by moisture. If a long-term storage of the ULD is

required, please follow the instructions in paragraph 10.2.

7.3.3 Water switch pin cleaning

Even though the ULD is equipped with a protection against unintentional

activation, both of the pins are to be kept clean and impurities are to be

removed. Clean water switch pins allow the moisture to collect into droplets

and so run off the switch (see 10.1).

Manual for initiation and maintenance 10 of 17

No.18717-Z5e of 20- January -2015

8.0 Operational and Battery Test

8.1 General

After its installation into the beacon retainer bracket of the VDR or S-VDR

Data Capsule, the PT9 NINETY shall be tested. At least once a year the PT9

NINETY is to be cleaned and tested by a qualified service technician.

Performance testing and replacement of the battery shall be done by a

qualified technician only.

8.2 Testing

Test equipment:

• For battery voltage measurement, use a high impedance multimeter

(impedance 10MΩ).

Advice: Instructions for use of the multimeter are contained in the

multimeter’s manual and are not further specified in this manual.

• For functional testing use the tester TAG 2550 (No. 17610). The

acoustic function is given when the yellow LED “Pulse” illuminates.

Advice: Specified information is to be taken from the TAG 2550 user

manual. TAG2550 User manual

Battery voltage measurement:

Please ensure that both water switch pins are clean and dry before starting

the test (see 10.1).

Advice: The PT9 NINETY comes with a patent pending, intelligent activation,

which avoids an unintentional activation, e.g. by rain, spray, ice or snow,

whereby the durability of the battery could be impaired. On this account,

observe the following procedure to set the PT9 NINETY into the service

operation mode.

Starting the service operation mode (Activation):

Use a wire jumper and connect both of the water switch pins for approx.

3 seconds to the left and the right of the ULD, which puts the PT9 NINETY

into the service operation mode.

Figure 4: Start the service operation mode

Manual for initiation and maintenance 11 of 17

No.18717-Z5e of 20- January -2015

8.3 Voltage serial number 18717-00-30001 to 18717-00-30335

The PT9 NINETY is now in the service operation mode for 60 seconds. At this

point, the battery voltage is circulating to the water switch pins. After

expiration of 60 seconds, the PT9 NINETY drops back into the sleep mode.

For battery voltage measurement, use a high impedance voltmeter

(impedance 10MΩ) and adjust the multimeter into a range of 20 V DC (direct

current). During the 60 seconds, press both of the multimeter test prods on

the ULD water switch pins to the left and the right, and read off the battery

voltage.

Figure 5: Battery voltage measurement

The water switch pin at the battery cap (3 bore holes side) is the negative

pole. The indication of the multimeter might balance in the decimal range.

This is normal and shows, that the ULD is pulsing the ultrasonic signal, which

causes a minor fall of voltage. The minimum read-out voltage value must not

fall below 2.5 V. If minimum value is undercut, the battery is to be replaced.

Use only the original replacement battery (No. 18725). The device can be

damaged and the licence expires, if batteries, other than the original

replacement battery, are used.

8.4 Voltage starting from serial number 18717-00-30336

The PT9 NINETY is now in the service operation mode for 60 seconds. At this

point, the battery voltage is circulating to the water switch pins. After

expiration of 60 seconds, the PT9 NINETY drops back into the sleep mode.

For battery voltage measurement, use a high impedance voltmeter

(impedance 10MΩ) and adjust the multimeter into a range of 20 V DC (direct

current). During the 60 seconds, press both of the multimeter test prods on

the ULD water switch pins to the left and the right, and read off the battery

voltage.

Figure 6: Battery voltage measurement

Manual for initiation and maintenance 12 of 17

No.18717-Z5e of 20- January -2015

The water switch pin at the battery cap (3 bore holes side) is the negative

pole. The indication of the multimeter might balance in the decimal range.

This is normal and shows, that the ULD is pulsing the ultrasonic signal, which

causes a minor fall of voltage. The minimum read-out voltage value must not

fall below 3.2 V. If minimum value is undercut, the battery is to be replaced.

Use only the original replacement battery (No. 18725). The device can be

damaged and the licence expires, if batteries, other than the original

replacement battery, are used.

9.0 Battery replacement

Warning: An incorrect installation of the battery might cause damage to the

ULD´s electronics!

Specified information is to be taken from PT9 Ninety Battery Replacement

9.1 Battery safety data sheet

PT9 Ninety Serial Number: 18717-00-30001 to 31200

Battery type: 18725-WHITE

PT9 Ninety Serial Number: starting from 18717-00-31201

Battery type: 18725-BLACK (non-restricted for transport)

Further information is to be taken from the relevant MSDS Data Sheet on our

website.

10.0 Maintenance and cleaning

This paragraph contains instructions for the cleaning of the ULD as well as its

long-term storage. Initially, the ULDs shall be tested with every installation

and battery replacement, according to paragraph 8.0. When the ULD has

been mounted on a Voyage Data Recorder and the Recorder has been

installed in compliance with the manufacturer´s specifications, the recurrent

period for cleaning and testing of the ULD is 12 months. Otherwise the

required maintenance period is 6 months. The battery replacement is to be

performed within an interval of 3 years after the original battery was inserted

(see 9.0) or if the battery voltage is not within its limits (see 8.2).

Replace the PT9 NINETY 6 years after the first installation and dispose it in

accordance with all local, state and federal regulations. Please do not hesitate

to contact us for assistance.

10.1 Cleaning

Clean the water switch pins and the housing with a soft cloth and a mild

detergent, and then dry them carefully with a clean cloth. Clean the white

insulations around the water switch pin as well, to reach an optimum dripping

performance of wetting fluids. The water switch pins are to be cleaned

whenever dirt or dust accumulate.

Manual for initiation and maintenance 13 of 17

No.18717-Z5e of 20- January -2015

10.2 Long-term storage

When long-term storage of the ULD is required, the ULD should be stored in

the original shipping container or adequate packaging. Ensure that the ULD is

stored in a cool, dry environment. The ULD must be stored closed, but

without battery. The maximum storage time for Underwater Locating Devices,

with extracted battery, is 10 years. Please contact us for further instructions.

10.3 Avoiding corrosion

For assembly of the PT9 NINETY do not use sharp-edged tools or tools which

apply a force on the device! These could damage the surface coating, and

consequently will cause corrosions!

10.3.1 Corrosion safety measures when mounting

• The packaging of the PT9 NINETY can be opened by turning the box

cases counterclockwise. On no account open the packaging by using a

knife or other sharp objects, as the surface coating could become

scratched or damaged.

• Before removing the PT9 NINETY from the packaging, ensure that the

contact surfaces of the ULD bracket (see Figure 7: ULD Bracket) are free

of impurities and rust. The ULD bracket must not have any blank or sharp-

edged areas, as these could damage the surface coating of the PT9

NINETY and thus cause corrosions. If applicable, repair the affected spots

by abrasion and varnishing.

• Always be sure to do the mounting of the device on an adequate and level

surface to avoid accidental dropping of the ULD. As a result, small pieces

of the coating could chip off the edges of the PT9 NINETY and corrosion

could be the consequence of those coating defects.

• Pay attention not to cant or deform the PT9 NINETY while mounting it into

the ULD bracket.

Figure 7: ULD Bracket

Manual for initiation and maintenance 14 of 17

No.18717-Z5e of 20- January -2015

10.3.2 Damaged ULD coating

If there are visible damages on the surface coating (see Figure 8: Small

damages), they are to be repaired immediately, because they could cause

corrosions at the damaged spot. This will have negative effects on the

durability of PT9 NINETY.

Figure 8: Small damages

10.3.3 Repair of small damages

The PT9 NINETY is provided with an extremely resistant surface coating. It is

subject to a quality inspection and is only delivered without damages.

Possible small damages, caused by transport or handling on site, can be

corrected by applying a protective paint. For this purpose, use the paint as

listed in paragraph 10.3.4. Apply it, after having degreased the surface at and

around the damaged area with an adequate detergent (Please see the

varnish producers’ manual, concerning specified information: e.g. the curing

time).

10.3.4 Varnish information

These small damages can be repaired with a protective coating. For this, we

recommend a “Single-coat lacquer”. Apply it after having degreased the

surface at and around the damaged area with an adequate detergent.

Coating repair kit order number: 20543

10.3.5 Procedure in case of major damages

In case of doubt, or if the PT9 NINETY should show major damages, please

contact us.

Manual for initiation and maintenance 15 of 17

No.18717-Z5e of 20- January -2015

11.0 Returns

11.1 General

Please contact us for clearing the details and planning before returning the

Beacon.

Assure yourself of the use of a clean protective packaging for the ULD, i.e.

protection against unintended crash, scratches or abrasion.

Required Documentation:

• Reason for reshipment

• Serial number of the Acoustic Beacon

• Order (if required) for replacement of the Acoustic Beacon

Service address:

Novega Produktionssysteme GmbH

Gewerbepark 2 | 87477 Sulzberg (See) | Germany

Fon: (+49) 8376-92990-0

Fax: (+49) 8376-92990-20

E-Mail: info@novega.de

www.novega-sea.com

11.2 Reshipment for factory overhaul

The Acoustic Beacon can be returned to Novega for battery replacement and

for a factory overhaul at or close to the specific date for battery replacement.

• Performance of all functional tests for controlling the power of the Acoustic

Beacon according to its specifications (SAE AS 8045A)

• Battery- and O-ring replacement

• Guarantee extension for two years

Every consignment of overhauled Acoustic Beacons includes the required

documentation to prove, that the returned product complies with its known

specifications.

11.3 ULD return – defective

• In case of a failure, which is determined to be within the warranty terms (see

12.0), the ULD will be replaced free of charge by Novega.

• Upon return after a warranty service, the customer will receive a new original

guarantee.

Manual for initiation and maintenance 16 of 17

No.18717-Z5e of 20- January -2015

11.4 ULD return – no defect

If an acoustic ULD is returned to Novega and it is found to be functional, the

ULD will be returned to the customer, corresponding shipment costs will

charged. In addition, the customer will be informed that an analysis fee is

required. Please note that differences of the housing and the cover in terms of

colour are production process specific and do not demonstrate damage.

11.5 Return ULD – out of warranty

If the ULD is returned to Novega out of warranty, the customer will receive an

estimate of costs of repair.

12.0 Warranty

The warranty period of the PT9 NINETY is 3 years from the date of delivery

from Novega.

Specified information is to be taken from PT9 Warranty

13.0 Declaration of Conformity

Specified information is to be taken from PT9 Ninety Declaration of

Conformity

14.0 Disclaimer and copyright

This manual is developed and published by Novega Produktionssysteme

GmbH. Novega Produktionssysteme GmbH reserves the right not to be

responsible for the topicality, correctness, completeness or quality of the

information provided. Liability claims regarding damage caused by the use of

any information provided, including any kind of information which is

incomplete or incorrect, will therefore be rejected.

Novega Produktionssysteme GmbH intended not to use any copyrighted

material for the publication or, if not possible, to indicate the copyright of the

respective object. The copyright for any material created by the Novega

Produktionssysteme GmbH is reserved. Any duplication or use of such

diagrams, sounds or texts in other electronic or printed publications is not

permitted without the author's agreement.

Manual for initiation and maintenance 17 of 17

No.18717-Z5e of 20- January -2015

You might also like

- H732Sanny Parts ManualDocument732 pagesH732Sanny Parts ManualThuong Hoang0% (1)

- SAM Service Software User Manual 72.145.300Document33 pagesSAM Service Software User Manual 72.145.300bzkxt100% (1)

- Human FactorsDocument127 pagesHuman FactorsChristina Gray100% (1)

- Mustang Iv: SMPS + AMP Schematic Diagram 1/3Document12 pagesMustang Iv: SMPS + AMP Schematic Diagram 1/3Valentin NichiforNo ratings yet

- DSAE0028998 f7nm80Document17 pagesDSAE0028998 f7nm80Especialista DexterNo ratings yet

- Raf 917 10 36 P217 - Ret670 - F871 - CompDocument17 pagesRaf 917 10 36 P217 - Ret670 - F871 - CompSARAVANAN ANo ratings yet

- Ga11, Cai709981Document108 pagesGa11, Cai709981mh.xperiaplayNo ratings yet

- Sanyo - ds24424 Service ManualDocument30 pagesSanyo - ds24424 Service Manualrafa martinezNo ratings yet

- 7ND70en 0297Document20 pages7ND70en 0297howard bitasNo ratings yet

- IC-ON-LINE - CN p75nf75 71035Document16 pagesIC-ON-LINE - CN p75nf75 71035Daniel David PeñaNo ratings yet

- DS20424sanyo PDFDocument26 pagesDS20424sanyo PDFdwi aryantoNo ratings yet

- Infineon FP100R12N3T7 DataSheet v00 - 21 ENDocument21 pagesInfineon FP100R12N3T7 DataSheet v00 - 21 ENrajat tiwariNo ratings yet

- P 4 NK 80 ZDocument18 pagesP 4 NK 80 ZMalik Farhan ShabirNo ratings yet

- Marquette Cardioserv V4 - Service Manual PDFDocument113 pagesMarquette Cardioserv V4 - Service Manual PDFPablo Millaquén GNo ratings yet

- Marquette Cardioserv V4 - Service Manual PDFDocument113 pagesMarquette Cardioserv V4 - Service Manual PDFbruno barbosaNo ratings yet

- SM RSJ 200 380Document47 pagesSM RSJ 200 380elshan_asgarovNo ratings yet

- Spec - Dappro 16Mb SRAM - 5V - QFP68Document23 pagesSpec - Dappro 16Mb SRAM - 5V - QFP68Deepa DevarajNo ratings yet

- Cold Planer Parts Book English SEBP6250-02Document149 pagesCold Planer Parts Book English SEBP6250-02potenzaengenhariaNo ratings yet

- Valve Controller: Series ND800Document20 pagesValve Controller: Series ND800Nano SujaniNo ratings yet

- DatasheetDocument80 pagesDatasheetselocaNo ratings yet

- LHF 630 & 800 File 0740 800 028Document34 pagesLHF 630 & 800 File 0740 800 028Madalina Lazar100% (1)

- Manual de FPP TsDocument28 pagesManual de FPP TsAlexander CallaNo ratings yet

- LISY300AL: MEMS Inertial Sensor: Single-Axis 300°/s Analog Output Yaw Rate GyroscopeDocument13 pagesLISY300AL: MEMS Inertial Sensor: Single-Axis 300°/s Analog Output Yaw Rate GyroscopeAnsar AliNo ratings yet

- Tetrode Manual PDFDocument49 pagesTetrode Manual PDFYo Wahyono100% (1)

- Tetrode Manual PDFDocument49 pagesTetrode Manual PDFYo WahyonoNo ratings yet

- Csavarkompresszoros - SM GB0003 - r0 - 01-07-Service Manual RCUE AG2Document182 pagesCsavarkompresszoros - SM GB0003 - r0 - 01-07-Service Manual RCUE AG2TiborNo ratings yet

- Valve Controller: Installation, Maintenance and Operating Instructions 7 ND 70 en Issue 5/01Document32 pagesValve Controller: Installation, Maintenance and Operating Instructions 7 ND 70 en Issue 5/01Nano SujaniNo ratings yet

- TV LCD Sanyo CLT 2054Document43 pagesTV LCD Sanyo CLT 2054videosonNo ratings yet

- GA 7-15 VSD+ Spare Parts List en Antwerp 2930712799Document178 pagesGA 7-15 VSD+ Spare Parts List en Antwerp 2930712799raviNo ratings yet

- Epcdg0971cc0369 enDocument634 pagesEpcdg0971cc0369 enPhuong Ta VanNo ratings yet

- STB80NF55-08 STP80NF55-08 - STW80NF55-08Document15 pagesSTB80NF55-08 STP80NF55-08 - STW80NF55-08Carlos SoaresNo ratings yet

- 0914-0503 - I2 - 200804-Service ManualDocument66 pages0914-0503 - I2 - 200804-Service ManualinfoNo ratings yet

- MP3V5050V R3 - 2015Document12 pagesMP3V5050V R3 - 2015leonardoviolimNo ratings yet

- GHS 350-900 VSD Airpower (Antwerp) ASLDocument130 pagesGHS 350-900 VSD Airpower (Antwerp) ASLLeonardo Augusto Ramirez SaenzNo ratings yet

- Drive 21481044 - 200929Document84 pagesDrive 21481044 - 200929kevin kurnia marpaung100% (1)

- 7000 Series Deep Sea PLC Operators ManualDocument122 pages7000 Series Deep Sea PLC Operators ManualMaya MayoshkaNo ratings yet

- 95 8616 8.2 - GT3000Document26 pages95 8616 8.2 - GT3000sithulibra0% (1)

- MMC Manual MMC Flexi-Dip D-2401Document53 pagesMMC Manual MMC Flexi-Dip D-2401BigBaby Julian100% (1)

- GTFM4 ManualDocument26 pagesGTFM4 ManualRobert MeglicNo ratings yet

- Yamaha 2-Stroke 115C PartsDocument63 pagesYamaha 2-Stroke 115C PartsJohn DoNo ratings yet

- Service Manual Trucks: Circuit and Wiring Numbers VN, VHDDocument34 pagesService Manual Trucks: Circuit and Wiring Numbers VN, VHDАндрейNo ratings yet

- L1013684 - H1 060-068 Closed Circuit Axial Piston Pumps Parts ManualDocument112 pagesL1013684 - H1 060-068 Closed Circuit Axial Piston Pumps Parts ManualIanNo ratings yet

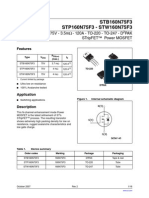

- Stb160N75F3 Stp160N75F3 - Stw160N75F3: N-Channel 75V - 3.5M - 120A - To-220 - To-247 - D Pak Stripfet™ Power MosfetDocument16 pagesStb160N75F3 Stp160N75F3 - Stw160N75F3: N-Channel 75V - 3.5M - 120A - To-220 - To-247 - D Pak Stripfet™ Power MosfetmoabdolyNo ratings yet

- Panasonic AC Servo Driver Technical ReferenceDocument121 pagesPanasonic AC Servo Driver Technical ReferenceHamdiNo ratings yet

- RAF-917-10-36-P220 RET670 F67 Comp SATDocument8 pagesRAF-917-10-36-P220 RET670 F67 Comp SATSARAVANAN ANo ratings yet

- Gas Gauge IC With Battery Charger Control For Handheld ApplicationsDocument35 pagesGas Gauge IC With Battery Charger Control For Handheld ApplicationsAlfonso BlancoNo ratings yet

- Intorq Bfk455: Setting The StandardDocument52 pagesIntorq Bfk455: Setting The StandardAlexNo ratings yet

- Instruction Manual 862 Interface-Thermo-ElementDocument16 pagesInstruction Manual 862 Interface-Thermo-ElementAlvaro Chang100% (1)

- Resistron: Operating InstructionsDocument26 pagesResistron: Operating InstructionsTOPOTRONIKNo ratings yet

- Infct and Infct-Xxxb: Infinity C Programmable Digital Thermocouple MeterDocument56 pagesInfct and Infct-Xxxb: Infinity C Programmable Digital Thermocouple MeterenticoNo ratings yet

- H1 Axial Piston Pumps: Parts ManualDocument100 pagesH1 Axial Piston Pumps: Parts Manualjoliveira_387024No ratings yet

- CVT Re0f06aDocument120 pagesCVT Re0f06aFSR1407No ratings yet

- 997279ASLv00 Manual de PartesDocument77 pages997279ASLv00 Manual de PartesWillyas AsNo ratings yet

- SN 74 LVC 3 G 17Document27 pagesSN 74 LVC 3 G 17joaica5046No ratings yet

- Pioneer VSX 920 K SMDocument72 pagesPioneer VSX 920 K SMSyed Khawar MukhtarNo ratings yet

- Guia de Instalação Do SL7000-RTDocument53 pagesGuia de Instalação Do SL7000-RTandresNo ratings yet

- Rxfa14g ManualDocument116 pagesRxfa14g ManualJose Manuel SuárezNo ratings yet

- Infineon FF1200XTR17T2P5P 4Document17 pagesInfineon FF1200XTR17T2P5P 4maxmoron600No ratings yet

- Microprocessor Programming and Applications for Scientists and EngineersFrom EverandMicroprocessor Programming and Applications for Scientists and EngineersNo ratings yet

- Power Electronics Design: A Practitioner's GuideFrom EverandPower Electronics Design: A Practitioner's GuideRating: 4.5 out of 5 stars4.5/5 (3)

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to LSIFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to LSINo ratings yet

- Air Operations Annex IV (Part-CAT), Subpart D (Instruments, Data, Equipment)Document155 pagesAir Operations Annex IV (Part-CAT), Subpart D (Instruments, Data, Equipment)andreijataNo ratings yet

- Easy Access Rules For Airworthiness and Environmental Certification (Regulation (EU) No 7482012) (Revision From March 2021)Document565 pagesEasy Access Rules For Airworthiness and Environmental Certification (Regulation (EU) No 7482012) (Revision From March 2021)andreijataNo ratings yet

- List of Frequently Used EASA AbbreviationsDocument15 pagesList of Frequently Used EASA AbbreviationsandreijataNo ratings yet

- Airbus Aircraft Characteristics - A321 Ch.2Document103 pagesAirbus Aircraft Characteristics - A321 Ch.2andreijataNo ratings yet

- Airbus Aircraft Characteristics - A321 Ch.6Document44 pagesAirbus Aircraft Characteristics - A321 Ch.6andreijataNo ratings yet

- Airbus Aircraft Characteristics - A321 Ch.5Document71 pagesAirbus Aircraft Characteristics - A321 Ch.5andreijataNo ratings yet

- DEV - Cargo - in - Pax - Cabin - FOR CONSULTATION - Rev-1Document15 pagesDEV - Cargo - in - Pax - Cabin - FOR CONSULTATION - Rev-1andreijataNo ratings yet

- Airbus Aircraft Characteristics - A321 Ch.4Document33 pagesAirbus Aircraft Characteristics - A321 Ch.4andreijataNo ratings yet

- Airbus Aircraft Characteristics - A321 Ch.7Document71 pagesAirbus Aircraft Characteristics - A321 Ch.7andreijataNo ratings yet

- Airbus Airplanes - Overview of CompositesDocument43 pagesAirbus Airplanes - Overview of Compositesandreijata100% (1)

- Ryanair Successful Low Cost LeadershipDocument7 pagesRyanair Successful Low Cost LeadershipandreijataNo ratings yet

- TTS Notes 10.1 Regulatory FrameworkDocument32 pagesTTS Notes 10.1 Regulatory Frameworkandreijata0% (1)

- Vol 1 Electronic Fundametanls (Easa Part 66 Module 3) .Document317 pagesVol 1 Electronic Fundametanls (Easa Part 66 Module 3) .andreijata96% (25)

- Airbus Aircraft Characteristics - A321 Ch.3Document15 pagesAirbus Aircraft Characteristics - A321 Ch.3andreijataNo ratings yet

- 17.2 TTSDocument44 pages17.2 TTSandreijata100% (3)

- Elec - MachinesDocument30 pagesElec - Machinesspan98No ratings yet

- Fatigue in Aviation by John A CaldwellDocument12 pagesFatigue in Aviation by John A CaldwellandreijataNo ratings yet

- LM350 Adjustable Voltage RegulatorDocument10 pagesLM350 Adjustable Voltage Regulatorjeffreygovender5745No ratings yet

- TEM Bent Foil Treater 300Document224 pagesTEM Bent Foil Treater 300ravinder.singh800No ratings yet

- Designed For Heavy Duty Product DescriptionDocument2 pagesDesigned For Heavy Duty Product DescriptionSérgio AmorimNo ratings yet

- Fire Alarm Using NAND and OR Gate: Course: Digital Logic and Circuit Lab Section: C Group: 07Document6 pagesFire Alarm Using NAND and OR Gate: Course: Digital Logic and Circuit Lab Section: C Group: 07Nouroj AminNo ratings yet

- ICT In-Cylinder Transducers: SeriesDocument12 pagesICT In-Cylinder Transducers: SeriesMehmet CELİKNo ratings yet

- Es1107 Assignment-01Document6 pagesEs1107 Assignment-01K. BHANU PRAKASH REDDYNo ratings yet

- Trailer Mounted Pump Model Drive Cylinder Circuit Hydraulic ComponentsDocument18 pagesTrailer Mounted Pump Model Drive Cylinder Circuit Hydraulic ComponentsthuanNo ratings yet

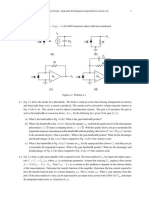

- Derive The Expressions For The Average DC Current, DC Load Voltage, Rectifier Efficiency, Ripple Factor, Piv Rating For The Bridge Rectifier CircuitDocument9 pagesDerive The Expressions For The Average DC Current, DC Load Voltage, Rectifier Efficiency, Ripple Factor, Piv Rating For The Bridge Rectifier CircuitS DispiserNo ratings yet

- MAX218Document8 pagesMAX218Edson HenriqueNo ratings yet

- كهرباء من الميش الى السوبر بوزشنDocument33 pagesكهرباء من الميش الى السوبر بوزشنljjb100% (1)

- Industrial Automation 1Document41 pagesIndustrial Automation 1Chandan Chandan100% (2)

- Dc-Da2000 - SM 2-2Document8 pagesDc-Da2000 - SM 2-2Poon Electronic Training CentreNo ratings yet

- Voltage Relay SUA145Document2 pagesVoltage Relay SUA145Txema GarciaNo ratings yet

- Mapping Civil Aviation Orders Casr Parts 91 119 135 Australian Air Transport Operations Smaller AeroplanesDocument32 pagesMapping Civil Aviation Orders Casr Parts 91 119 135 Australian Air Transport Operations Smaller Aeroplanesthao lêNo ratings yet

- Hspice MosfetDocument630 pagesHspice MosfetSarosij AdakNo ratings yet

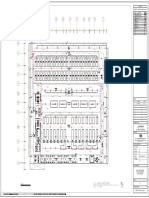

- DWG-050-FA-ONJ-I-23-003 Installation Fire Alarm System Area Lantai ProduksiDocument1 pageDWG-050-FA-ONJ-I-23-003 Installation Fire Alarm System Area Lantai ProduksiYosep HeryanaNo ratings yet

- Decon (Radial Thru-Hole) FR SeriesDocument1 pageDecon (Radial Thru-Hole) FR Serieszuigh899gNo ratings yet

- CA10230E - 14B Hookstick Operated SwitchesDocument28 pagesCA10230E - 14B Hookstick Operated SwitchesMelvin Enoc Chavarría ZelayaNo ratings yet

- ESP MicroProjectDocument10 pagesESP MicroProjectOmkar KhopadeNo ratings yet

- Metroamp 100 Watt Master Volume: Step-By-Step Instructions V 1.2 AUGUST 2009Document58 pagesMetroamp 100 Watt Master Volume: Step-By-Step Instructions V 1.2 AUGUST 2009Виталий ИвановNo ratings yet

- Thévenin and Norton Equivalent Circuits (Exercises & Answers)Document3 pagesThévenin and Norton Equivalent Circuits (Exercises & Answers)mahfuzahismail0% (1)

- Eflux Ax21000Document28 pagesEflux Ax21000Manuel “Mevch” vNo ratings yet

- IEEE STD C37.104-2002Document55 pagesIEEE STD C37.104-2002SAEL SOLAR100% (1)

- Peza PDFDocument14 pagesPeza PDFdexterbautistadecember161985No ratings yet

- Assignment 04Document3 pagesAssignment 04Anchal Debnath ee21b017No ratings yet

- Oilbath: Product SpecificationDocument3 pagesOilbath: Product SpecificationMalik KNo ratings yet

- Selective Coordination Requirements Inspection FormDocument1 pageSelective Coordination Requirements Inspection FormAbraham RodriguezNo ratings yet

- Chap 6 - High Voltage Testing of EquipmentDocument16 pagesChap 6 - High Voltage Testing of Equipmenthadrien100% (1)

- Emf Equation of Transformer 28.6.2020Document20 pagesEmf Equation of Transformer 28.6.2020Sunil GurubaxaniNo ratings yet