Professional Documents

Culture Documents

General ISO Geometrical Tolerances Per

Uploaded by

Dwi ApOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General ISO Geometrical Tolerances Per

Uploaded by

Dwi ApCopyright:

Available Formats

General ISO Geometrical Tolerances Per.

ISO 2768

Mechanical Tolerance Standards Menu

The following are general geometrical tolerances per. ISO 2768 for the following:

Linear Dimensions

External Radius and Chamfer Heights

Straightness and Flatness

Perpendicularity

Symmetry

Runout

Related Mechanical Tolerance Design Data

Preferred Tolerance Grade Zones ISO 286

ISO 286 Table Shaft Tolerances Calculator

ISO 286 Table Hole Tolerances Calculator

International Tolerance Grades

Variations on dimensions without tolerance values are according to " ISO 2768".

All tolerance limits are given in mm.

ISO 2768 and derivative geometrical tolerance standards are intened to simplify

drawing specifications for mechanical tolerances. ISO 2768 is mainly for parts that

are manufactured by way of machniing or removeal of materials.

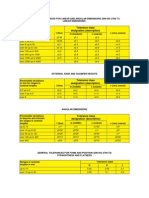

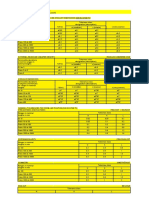

Linear Dimensions: Straightness and Flatness

Tolerance class designation Tolerance class

Permissible deviations in mm f (description) v (very Ranges in nominal lengths in mm

for ranges in nominal lengths (fine) coarse) H K L

m (medium) c (coarse)

up to 10 0.02 0.05 0.1

0.5 up to 3 ±0.05 ±0.1 ±0.2 -

over 10 up to 30 0.05 0.1 0.2

over 3 up to 6 ±0.05 ±0.1 ±0.3 ±0.5

over 30 up to 100 0.1 0.2 0.4

over 6 up to 30 ±0.1 ±0.2 ±0.5 ±1.0

over 100 up to 300 0.2 0.4 0.8

over 30 up to 120 ±0.15 ±0.3 ±0.8 ±1.5

over 300 up to 1000 0.3 0.6 1.2

over 120 up to 400 ±0.2 ±0.5 ±1.2 ±2.5

over 1000 up to 3000 0.4 0.8 1.6

over 400 up to 1000 ±0.3 ±0.8 ±2.0 ±4.0

over 1000 up to 2000 ±0.5 ±1.2 ±3.0 ±6.0 Perpendicularity

over 2000 up to 4000 - ±2.0 ±4.0 ±8.0

Tolerance class

Ranges in nominal lengths in mm

External Radius and Chamfer Heights H K L

up to 100 0.2 0.4 0.6

Tolerance class designation

Permissible deviations in mm f (description) v (very over 100 up to 300 0.3 0.6 1

for ranges in nominal lengths (fine) coarse) over 300 up to 1000 0.4 0.8 1.5

m (middle) c (coarse)

0.5 up to 3 ±0.2 ±0.2 ±0.4 ±0.4 over 1000 up to 3000 0.5 0.8 2

over 3 up to 6 ±0.5 ±0.5 ±1.0 ±1.0

over 6 ±1.0 ±1.0 ±2.0 ±2.0 Symmetry (Position for ISO G&T Standard not-ASME

or ANSI GD&T)

Angular Dimensions Tolerance class

Ranges in nominal lengths in mm

H K L

Permissible deviations in degrees Tolerance class

f designation (description) v (very up to 100 0.5 0.6 0.6

and minutes for ranges in

(fine) coarse) over 100 up to 300 0.5 0.6 1

nominal lengths m (middle) c (coarse)

over 300 up to 1000 0.5 0.8 1.5

up to 10 ±1º ±1º ±1º30' ±3º

over 1000 up to 3000 0.5 1 2

over 10 up to 50 ±0º30' ±0º30' ±1º ±2º

over 50 up to 120 ±0º20' ±0º20' ±0º30' ±1º

Run-Out

over 120 up to 400 ±0º10' ±0º10' ±0º15' ±0º30'

over 400 ±0º5' ±0º5' ±0º10' ±0º20' Tolerance class

H K L

0.1 0.2 0.5

You might also like

- ISO 2768 - General Geometrical Tolerances and Technical Drawings - Plianced Inc.Document8 pagesISO 2768 - General Geometrical Tolerances and Technical Drawings - Plianced Inc.dglpssenthilkumar497No ratings yet

- General Tolerances DIN ISO 2768Document4 pagesGeneral Tolerances DIN ISO 2768NaveenRajNo ratings yet

- Guide To General Tolerance - ISO 2768 1&2 StandardDocument6 pagesGuide To General Tolerance - ISO 2768 1&2 StandardQuality controller100% (1)

- General Tolerances DIN ISO 2768Document4 pagesGeneral Tolerances DIN ISO 2768Ecaterina RusuNo ratings yet

- General Tolerances - DIN - IsO - 2768Document2 pagesGeneral Tolerances - DIN - IsO - 2768Pasca GheorgheNo ratings yet

- ISO 2768 TolerancesDocument2 pagesISO 2768 TolerancesJan Van de Velde100% (2)

- Maryland Metrics Technical Data Chart TolerancesDocument1 pageMaryland Metrics Technical Data Chart TolerancesMerimNo ratings yet

- Maryland Metrics Technical Data Chart: General Tolerances To DIN ISO 2768 T1 and T2Document3 pagesMaryland Metrics Technical Data Chart: General Tolerances To DIN ISO 2768 T1 and T2Nandha KumarNo ratings yet

- General Tolerances DIN ISO 2768Document2 pagesGeneral Tolerances DIN ISO 2768Ta CuongNo ratings yet

- Maryland Metrics Chart: General Tolerances DIN ISO 2768 T1 T2Document2 pagesMaryland Metrics Chart: General Tolerances DIN ISO 2768 T1 T2MerimNo ratings yet

- General Tolerances To DIN ISO 2768Document2 pagesGeneral Tolerances To DIN ISO 2768Ziyang XieNo ratings yet

- General Tolerances - DIN - ISO - 2768 PDFDocument2 pagesGeneral Tolerances - DIN - ISO - 2768 PDFHenrique MarquesNo ratings yet

- General Tolerances - DIN - IsO - 2768Document2 pagesGeneral Tolerances - DIN - IsO - 2768xuanquyvtNo ratings yet

- General tolerances for DIN ISO 2768Document2 pagesGeneral tolerances for DIN ISO 2768jaby100% (1)

- General Tolerances - DIN - IsO - 2768Document2 pagesGeneral Tolerances - DIN - IsO - 2768Brijith ShenoiNo ratings yet

- General Tolerances - DIN - IsO - 2768Document2 pagesGeneral Tolerances - DIN - IsO - 2768muamer1No ratings yet

- General Tolerances For Linear and Angular Dimensions (Din Iso 2768 T1)Document45 pagesGeneral Tolerances For Linear and Angular Dimensions (Din Iso 2768 T1)Apostol Vlad-AlexandruNo ratings yet

- General Tolerances DIN ISO 2768Document4 pagesGeneral Tolerances DIN ISO 2768La Hong LeNo ratings yet

- Iso 2768Document5 pagesIso 2768thanhhai130No ratings yet

- DIN ISO 2768.pdfDocument2 pagesDIN ISO 2768.pdfPankajMakwanaNo ratings yet

- General Tolerances For Linear and Angular Dimnsions (Din Iso 2768 t1)Document1 pageGeneral Tolerances For Linear and Angular Dimnsions (Din Iso 2768 t1)VIVEK UPADHYAYNo ratings yet

- Fundamentals of Limits, Fits & TolerancesDocument24 pagesFundamentals of Limits, Fits & TolerancesrajeshNo ratings yet

- Din Iso 2768Document3 pagesDin Iso 2768alberto.galloNo ratings yet

- JIS Technical Dimensional Tolerances for Formed Metal PartsDocument1 pageJIS Technical Dimensional Tolerances for Formed Metal Partsmr.nguyenkNo ratings yet

- Iso 2768-1 TolerancesDocument2 pagesIso 2768-1 TolerancesTang Bv100% (2)

- According To DIN ISO 2768-1: Branco Engineering BureauDocument1 pageAccording To DIN ISO 2768-1: Branco Engineering BureauPHUONGNo ratings yet

- DIN 7168 general dimension and angle tolerance chartDocument2 pagesDIN 7168 general dimension and angle tolerance chartMiroslav MyšičkaNo ratings yet

- According To DIN ISO 2768-1Document2 pagesAccording To DIN ISO 2768-1Joe JoeNo ratings yet

- DIN ISO 2768 General Tolerances T1 T2Document2 pagesDIN ISO 2768 General Tolerances T1 T2manageieNo ratings yet

- General Tolerances DIN ISO 2768Document2 pagesGeneral Tolerances DIN ISO 2768Vasil Gospodinov79% (24)

- UNI EN 22768 - 1 Standard tolerancesDocument1 pageUNI EN 22768 - 1 Standard tolerancesBlashko Gjorgjiev100% (1)

- Is 2102 24 - Annexure 3Document1 pageIs 2102 24 - Annexure 3Ashish MehtaNo ratings yet

- NT0371 enDocument3 pagesNT0371 enrodrigoNo ratings yet

- Tolerance Class Designation (Description)Document2 pagesTolerance Class Designation (Description)Cristian PopescuNo ratings yet

- High-Performance Gradient Elution: The Practical Application of the Linear-Solvent-Strength ModelFrom EverandHigh-Performance Gradient Elution: The Practical Application of the Linear-Solvent-Strength ModelNo ratings yet

- Design and Modelling of a Pelton Wheel BucketDocument3 pagesDesign and Modelling of a Pelton Wheel BucketDwi ApNo ratings yet

- How To Phone Verify Your YouTube AccountDocument5 pagesHow To Phone Verify Your YouTube AccountDwi ApNo ratings yet

- Reversible Impactors: When Versatility, Reliability, and Long Service Life Matter!Document2 pagesReversible Impactors: When Versatility, Reliability, and Long Service Life Matter!Dwi ApNo ratings yet

- Book 1 Updraft Gasifier 2012Document102 pagesBook 1 Updraft Gasifier 2012Dwi ApNo ratings yet

- Pipe Chart PDFDocument2 pagesPipe Chart PDFCarlos Rivera0% (1)

- Inventor AddINDocument27 pagesInventor AddINgwyderNo ratings yet

- Fastener HandoutDocument32 pagesFastener HandoutRaifan RaizerNo ratings yet

- Integrated Conceptual Design Environment For Centrifugal Compressors Flow Path DesignDocument11 pagesIntegrated Conceptual Design Environment For Centrifugal Compressors Flow Path DesignDwi ApNo ratings yet

- Alloy 310 Spec Sheet: Multi-Purpose Austenitic Heat Resistant Stainless SteelDocument2 pagesAlloy 310 Spec Sheet: Multi-Purpose Austenitic Heat Resistant Stainless SteelManoj PaneriNo ratings yet

- Design of Impeller Blade by Varying Blades and Type of Blades Using Analytical PDFDocument11 pagesDesign of Impeller Blade by Varying Blades and Type of Blades Using Analytical PDFasrikalyanNo ratings yet

- A Hand Book For The Mechanical Designer Ventilation Duct FanDocument107 pagesA Hand Book For The Mechanical Designer Ventilation Duct Fanrawneeh100% (6)

- Engineering Drawing Abbreviations and SymbolsDocument21 pagesEngineering Drawing Abbreviations and Symbolsshivajitagi100% (2)

- GE LOGIQ E9 Ultrasound Machine BrochureDocument7 pagesGE LOGIQ E9 Ultrasound Machine BrochureПётр Трашкун100% (1)

- Jongka:the Traditional Korean Family: Exploring Jongka Food in The Context of Korean Food CategoriesDocument14 pagesJongka:the Traditional Korean Family: Exploring Jongka Food in The Context of Korean Food CategoriesSözen BayraktarNo ratings yet

- Boiler Tube FailuresDocument15 pagesBoiler Tube FailuresBIRANCHINo ratings yet

- Everything an Employee Experiences at WorkDocument1 pageEverything an Employee Experiences at WorkAnushka Seth BBA2021MCNo ratings yet

- Design Driven Data Science - MJV Technology & InnovationDocument180 pagesDesign Driven Data Science - MJV Technology & Innovationjefferson CamposNo ratings yet

- How To Write A VHDL Test BenchDocument4 pagesHow To Write A VHDL Test BenchEvliya ÜlkerNo ratings yet

- DISC-Test Test PDFDocument22 pagesDISC-Test Test PDFKazekamiXNo ratings yet

- Older People's Experiences of Falling and Perceived Risk of Falls in The CommunityDocument1 pageOlder People's Experiences of Falling and Perceived Risk of Falls in The Communitysabao kizuiteNo ratings yet

- Management Science Chapter 11Document42 pagesManagement Science Chapter 11Myuran SivarajahNo ratings yet

- Products Profile Unitech Ikkcomunitech Ikkcomsfspsfsp Profile 6 SFSPDocument46 pagesProducts Profile Unitech Ikkcomunitech Ikkcomsfspsfsp Profile 6 SFSPSaad AkramNo ratings yet

- Physical Preparation of The Modern Elite Football PlayerDocument8 pagesPhysical Preparation of The Modern Elite Football PlayerKamil SochaNo ratings yet

- Vision IAS CSP21T30S FLT6Document39 pagesVision IAS CSP21T30S FLT6AvanishNo ratings yet

- Croft LeafletDocument2 pagesCroft Leafletece142No ratings yet

- Everyday English Vocabulary PDFDocument2 pagesEveryday English Vocabulary PDFSamantha0% (1)

- 4 6023697383601211598 PDFDocument232 pages4 6023697383601211598 PDFmahshid kianiNo ratings yet

- (Atlas Copco) - Industrial Power Tools 2012Document332 pages(Atlas Copco) - Industrial Power Tools 2012mg_catana100% (1)

- DNV Otg - 02 Floating Liquefied Gas Terminals - tcm4-460301Document128 pagesDNV Otg - 02 Floating Liquefied Gas Terminals - tcm4-460301Jeril PhilipNo ratings yet

- CBC-Tailoring NC IIDocument66 pagesCBC-Tailoring NC IICharmaine Mae RetizaNo ratings yet

- Digital Scent TechnologyDocument13 pagesDigital Scent TechnologyRahul Maravi0% (1)

- Identify What Is Being Described in Each NumberDocument2 pagesIdentify What Is Being Described in Each NumberAeronn Jass SongaliaNo ratings yet

- SemblexTechManual2011 PDFDocument129 pagesSemblexTechManual2011 PDFAlex100% (1)

- SAIL Catalogue: DownloadDocument16 pagesSAIL Catalogue: Downloadmishra usNo ratings yet

- Conveyor Control System ProjectDocument15 pagesConveyor Control System ProjectzhackhieNo ratings yet

- Manual E7370Document12 pagesManual E7370Carlos Rodríguez MartínNo ratings yet

- The Ambiguity of Self and Identity in Pi PDFDocument6 pagesThe Ambiguity of Self and Identity in Pi PDFShweta kashyapNo ratings yet

- Effect of COVID-19 On Global Supply ChainDocument4 pagesEffect of COVID-19 On Global Supply ChainInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 2019 ACS101 Academic Skills Students MaterialDocument90 pages2019 ACS101 Academic Skills Students MaterialSONAM TSHERING100% (2)

- Time Management - Anthony RobbinsDocument55 pagesTime Management - Anthony RobbinsWind100% (24)

- The Validity of Beck Depression Inventory - Short Version in Depressed Patients Diagnosed According To ICD10Document11 pagesThe Validity of Beck Depression Inventory - Short Version in Depressed Patients Diagnosed According To ICD10sarhang talebaniNo ratings yet