Professional Documents

Culture Documents

High-Pressure Vapor-Liquid Equilibria For Carbon Dioxide Linalool

High-Pressure Vapor-Liquid Equilibria For Carbon Dioxide Linalool

Uploaded by

Riski Agung NataOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

High-Pressure Vapor-Liquid Equilibria For Carbon Dioxide Linalool

High-Pressure Vapor-Liquid Equilibria For Carbon Dioxide Linalool

Uploaded by

Riski Agung NataCopyright:

Available Formats

900 J . Chem. Eng.

Data 1994,39, 900-902

High-pressure Vapor-Liquid Equilibria for Carbon Dioxide +

Linalool

Yoshio Iwai,*Noriaki Hosotani, Tatsuo Morotomi, Yoshio Koga, and Yasuhiko Arai

Department of Chemical Engineering, Faculty of Engineering, Kyushu University, Fukuoka 812, Japan

A circulation-type apparatus was constructed to measure high-pressure vapor-liquid equilibria. The

+

vapor-liquid equilibria for carbon dioxide linalool a t 313.2 K from 4.00 to 7.99 MPa, at 323.2 K from

4.00 to 9.78 MPa, and a t 333.2 K from 5.00 to 10.96 MPa were measured. The results were correlated

by the Peng-Robinson equation of state using conventional mixing rules with two interaction parameters.

Introduction OH

I ,CH3

Citrus oil is widely used as a raw material of flavor. H& =CH - C - CH2 - CH2- CH = C,

Steam distillation or solvent extraction is usually applied I

CH3

CH3

to refine citrus oil. However, the drawbacks of these

processes are considered to be low yields, formation of Figure 1. Structure of linalool (3,7-dimethyl-3-hydroxy-176-

molecular weight 154.3,boiling point 198 "C).

octadiene) (C10H180,

degradation products under a high operating temperature,

and solvent residue. Supercritical fluid extraction is found

to be an alternative process for refining citrus oil because vacuum pump

of its advantages of a low operating temperature and no 7

solvent residue. The high-pressure vapor-liquid equilibria I

+

I

I

for C02 citrus oil are required for rational equipment I

I I

I

design. However, few measurements on that system were heavy j I

I

available. comp. f

I

I

I

The main purpose of this work is to provide comprehen- *-!- I

I

sive measurements for the vapor-liquid equilibria of C02 I

.c02

-. -*&

I

+

I

I

citrus oil. For this purpose, a circulation-type apparatus I t

I

was designed and constructed. The vapor-liquid equilibria I

+

for C02 decane were measured in order to ascertain the I

I

I

I

I

I

reliability of the apparatus and experimental procedure. I I

+

Then, those for C02 linalool were measured at 313.2,

I

I

I

I

I

I

323.2, and 333.2 K up to the critical region of the mixture. I

I

I

I

Linalool is one of the most important flavor fractions in I -

I

I

I

I

citrus oil. The structure of linalool is shown in Figure 1. I

I

The results obtained were correlated by the Peng-Robin- 21

I 1 9 L-YJ

I

I

son equation of state using conventional mixing rules with l _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ I

22

two interaction parameters.

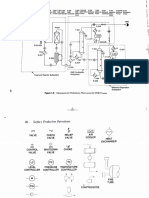

Figure 2. Circulation-type apparatus to measure the high-

pressure vapor-liquid equilibria: (1)pump; (2)equilibrium cell;

Experimental Section (3)impeller; (4)precision pressure gauge; (5,8) magnetic pumps;

Equipment and Procedure. A circulation-type ap- (6, 9) six-way valves; (7,10) sampling loops; (11, 16) three-way

valves; (12,17)line heaters; (13,18) expansion valves; (14,19)

paratus was constructed to measure high-pressure vapor-

cold traps; (15, 20)dry test meters; (21)bypass line; (22)water

liquid equilibria. The schematic diagram of the apparatus bath; (23,24)solvent lines.

is shown in Figure 2. The equilibrium cell 2 was evacuated.

Carbon dioxide was supplied from a gas cylinder, liquefied and that of the liquid sampling loop 10 was 3 cm3. After

through a cooling unit, compressed, and directed to the circulation for 30 min, the six-way valves 6 and 9 were

equilibrium cell. The heavy component (decane or linalool) switched in order to isolate the sampling loops from the

was fed into the equilibrium cell by a charging pump. An equilibrium cell. The samples in the loops were decom-

impeller 3 was used to promote the equilibrium condition. pressed through expansion valves 13 and 18, and then

The equilibrium cell had a dual glass window, and the introduced into glass tubes 14 and 19, in which COS and

vapor-liquid interface was controlled to be a t the center the heavy component were separated. The glass tubes

of the window. The inner diameter and volume of the cell were cooled under -40 "C, and the tubes contained ethanol

are 69 mm and 500 cm3, respectively. In order to maintain or hexane to trap the heavy component. Ethanol and

the desired temperature, the cell and its immediate aux- hexane were used to trap decane and linalool, respectively,

iliaries were placed in a constant-temperature water bath and had already been saturated with CO2 by using a bypass

which was controlled within f O . l K. M e r equilibrium line 21 before the sampling operation to avoid dissolution

(about 1 h after), stirring by the impeller was stopped and of COa in the sampling loops into ethanol or hexane. The

circulation of the vapor and liquid phases was started by amount of C02 was measured by dry test meters 15 and

magnetic pumps 5 and 8. A small amount of each phase 20. A small amount of heavy component remaining in the

was introduced into sampling loops 7 and 10, respectively. tubing and the expansion valve was removed and trapped

The volume of the vapor sampling loop 7 was about 15 cm3 by using supercritical C02 through the bypass line and

0021-9568/94/1739-0900$04.50/00 1994 American Chemical Society

Journal of Chemical and Engineering Data, Vol. 39, No. 4, 1994 901

Table 1. Vapor-Liquid Equilibria for COz + Decane and for COa + Linalool

C02 (1) + Decane (2)

T = 311.0 K T = 344.3 K

plMPa x1 Y1 plMPa x1 Y1

4.55 0.4461 0.9994 5.51 0.3834 0.9975

6.86 0.7466 0.9988 8.55 0.5936 0.9968

11.85 0.8058 0.9877

C02 (1)+ Linalool (2)

T = 313.2 K T = 323.2 K T = 333.2 K

pNPa x1 Y1 plMPa Xl Yl plMPa x1 Y1

4.00 0.3965 4.00 0.3449 0.9997 5.00 0.3864 0.9995

6.00 0.5933 0.9997 6.00 0.5167 0.9996 6.99 0.5351 0.9993

6.99 0.7122 0.9995 7.99 0.6906 0.9991 9.00 0.6799 0.9987

7.49 0.7852 0.9992 9.00 0.8062 0.9980 9.99 0.7431 0.9974

7.99 0.9103 0.9985 9.78 0.9420 0.9921 10.96 0.8294 0.9932

Xi Yl

1

0 9 8 099

0

I

41

Figure 3. Vapor-liquid equilibria for C02 (1)+ decane (2): ( A ,

0) present data at 311.0 and 344.3 K (A,0 ) data of Reamer and

Sage (1)at 311.0 and 344.3 K (a)data of Chou et al. (2)at 344.3

K, (-) smoothed line.

0 0.5

xi

1 0.999 1 0.995

Yl

Figure 4. Vapor-liquid equilibria for COZ(1)+ linalool (2): (A,

0, 0)present data at 313.2, 323.2, and 333.2 K, (A,0 ) data of

Suzuki et al. (3) at 313.2 and 333.2 K (-) calculated results by

the Peng-Robinson equation of state.

~ Y P iY= 4iLPxi

1 0.99 1

(1)

ethanol or hexane through lines 23 and 24. The amount

of heavy component was determined by means of a gas

chromatograph. The pressure was measured by a Bourdon where p is the equilibrium pressure and xi and yi are the

gauge 4, of which the accuracy was f0.15% in full scale. mole fractions of component i in the liquid phase and vapor

The equilibrium temperature was measured by a chromel- phase, respectively. In order to evaluate &, the Peng-

alumel thermocouple within *O. 1 K. Robinson equation of state (4) was used

Materials. Decane (supplied by Tokyo Kasei Kogyo Co.

Ltd.) and linalool (Wako Pure Chemical Industries, Ltd.) RT a

were used without further purification. The purities of v-b - u(u + b ) + b(u - b ) (2)

decane and linalool are more than 99% by gas chromato-

graphic area analysis. High-purity COz (more than 99.9 and conventional mixing rules for the constants a and b

vol % purity, Sumitomo Seika Co.) was used as received. were used

Result and Discussion

In order to ascertain the reliability of the apparatus and

procedure, the vapor-liquid equilibria for COz decane + i j

a t 311.0 and 344.3 K were measured. The experimental

data are shown in Table 1. The values listed in Table 1

were obtained from an arithmetic average of several

measurements at each pressure. The standard deviation

is less than 8.2 x The values are in good agreement where k, and lv are interaction parameters between unlike

with those of Reamer and Sage (1)and those of Chou et molecules i and j . When eqs 2-4 are used, the fugacity

al. ( 2 )as shown in Figure 3. coefficient c$i can be thermodynamically derived. The

The high-pressure vapor-liquid equilibria for COz + vapor-liquid equilibria were calculated by using the

linalool at 313.2, 323.2, and 333.2 K were measured. The properties of pure components listed in Table 2. The

results are listed in Table 1. The values in the vapor phase properties of linalool were not available in the literature,

are in good agreement with those of Suzuki et al. ( 3 ) as so these were estimated by the method of Lydersen and

shown in Figure 4. Edmister (51, which is group contribution method. The

interaction parameters kv and l i are treated as fitting

Correlation parameters. The parameter estimation was performed a t

The following fundamental equation can be used to each temperature by minimizing the following objective

calculate the vapor-liquid equilibrium: function:

902 Journal of Chemical and Engineering Data, Vol. 39, No. 4, 1994

Table 2. Critical Constants and Acentric Factor respectively. The calculated interaction parameters are

substance TJK p,lMPa w +

listed in Table 3. The correlation results for COz linalool

coz 304.2Q 7.37a 0.225a

are shown in Figure 4. The present data were well

linalool 630.5b 2.42b 0.748c correlated with the Peng-Robinson equation of state.

a Reference 5. Estimated by the Lydersen method ( 5 ) . Esti-

mated by the Edmister method (5). Literature Cited

Table 3. Interaction Parameters for COz (1) + Linalool Reamer, H. H.; Sage, B. H. J . Chem. Eng. Data 1963,8, 508.

(2) Chou, G. F.; Forbert, R. R.; Prausnitz, J . M. J . Chem. Eng. Data

1990,35,26.

T/K ktj I,. AAD(x)= AAD(r)b Suzuki. J.: Omata. Y.: Yonei. Y.: Shizematsu. H. Proceeding o f

313.2 0.053 -0.035 0.0131 0.0001 the 22nd Autumn Meeting of ’the’Soci& of Chemical Engineers’,

323.2 0.046 -0.038 0.0151 0.0005 Japan, Tokyo, 1989; p 420.

333.2 0.051 -0.027 0.0039 0.0006 Peng, D. Y.; Robinson, D. B. Ind. Eng. Chem. Fundam. 1976,15,

6C-l

I-.

Reid, R. C.; Prausnitz, J. M.; Sherwood, T. K. The Properties of

A A D ( x ) = (l/N,)Elxl(calc) - x11, where N, is the number of Gases and Liquids, 3rd ed.; McGraw-Hill: New York, 1977.

data for the liquid phase. AAD(y) = (l/N,)Zlyl(calc) - yil, where

Ny is the number of data for the vapor phase.

N, NV Received for review April 21, 1994. Accepted July 11, 1994.@ The

authors gratefully acknowledge the financial support provided by

the Grant-in-Aid for Scientific Research on Priority Areas (Super-

critical Fluid 224,1992,042381061, The Ministry of Education,

Science and Culture, Japan, and the Kurata Research Grant (1993).

where calc means calculated results and N,and Ny are the

number of data for the liquid phase and vapor phase, Abstract published in Advance ACS Abstracts, September 1, 1994.

You might also like

- GD & T - Training Material Note PagesDocument252 pagesGD & T - Training Material Note Pageslokelooks92% (26)

- Material Selection HandbookDocument127 pagesMaterial Selection HandbookAdi SutardiNo ratings yet

- Holugt HL 110-120 Series Portable Breathing Air CompressorDocument12 pagesHolugt HL 110-120 Series Portable Breathing Air CompressorNicanor AliagaNo ratings yet

- CCUS Chap - 9 030521Document38 pagesCCUS Chap - 9 030521Ali AltowilibNo ratings yet

- Box Design 6x6Document79 pagesBox Design 6x6SM ConsultantsNo ratings yet

- Manual Hydrovane 837 PUASDocument73 pagesManual Hydrovane 837 PUASremier100% (3)

- Zap-Lok System For Pipeline Installation January 2019 PDFDocument35 pagesZap-Lok System For Pipeline Installation January 2019 PDFmutadiNo ratings yet

- Chieftain TankDocument28 pagesChieftain TankTateNo ratings yet

- CIAC - 3 - Operation & MaintenanceDocument15 pagesCIAC - 3 - Operation & Maintenanceleonardoacastro9886No ratings yet

- Uhde Brochure Ammonia SCR PDFDocument28 pagesUhde Brochure Ammonia SCR PDFBaher ElsheikhNo ratings yet

- Nitric Acid: A True All-Rounder!Document20 pagesNitric Acid: A True All-Rounder!mariatiNo ratings yet

- Double Disruptive Technology - Don Bari, IHS MarkitDocument27 pagesDouble Disruptive Technology - Don Bari, IHS MarkitAMANo ratings yet

- Basic - Cleaning in Place (Cip)Document46 pagesBasic - Cleaning in Place (Cip)Thu Anh Nguyễn100% (1)

- Mould Theory PDFDocument35 pagesMould Theory PDFArunava Bala75% (4)

- Atlas Dolog SystemsDocument49 pagesAtlas Dolog Systemslos hermanos ValiNo ratings yet

- Clsi GP28 ADocument60 pagesClsi GP28 ACristian Gutiérrez VeraNo ratings yet

- A New Advanced Power-Generation System Using Chemical-Looping CombustionDocument8 pagesA New Advanced Power-Generation System Using Chemical-Looping CombustionAga Sanity SainsNo ratings yet

- HDA ProcessDocument2 pagesHDA ProcessCluisantony Jayco Dize0% (1)

- Letter 2Document1 pageLetter 2Suresh BeelaNo ratings yet

- Brosur EFB - Compressed PDFDocument2 pagesBrosur EFB - Compressed PDFSun ChenNo ratings yet

- EPA EPA EPA's To: Title 40 Code (CFR)Document10 pagesEPA EPA EPA's To: Title 40 Code (CFR)Kevin PiocNo ratings yet

- Astm C 191Document8 pagesAstm C 191Deyla SoegionoNo ratings yet

- UHDEbrochure Hydrogen SCRDocument16 pagesUHDEbrochure Hydrogen SCRsaymondosmemesNo ratings yet

- Using Genetic Algorithms For Dynamic Optimization An IndustrialDocument2 pagesUsing Genetic Algorithms For Dynamic Optimization An IndustrialAntonio SánchezNo ratings yet

- BatchReactor Simulation-3Document17 pagesBatchReactor Simulation-3earcem9264No ratings yet

- KL CKDocument3 pagesKL CKnaushadmnnitNo ratings yet

- DBT 4 2021 - 22Document1 pageDBT 4 2021 - 22omkar daveNo ratings yet

- DBT 4 2021 - 22Document1 pageDBT 4 2021 - 22omkar daveNo ratings yet

- DBT 4 2021 - 22Document1 pageDBT 4 2021 - 22omkar daveNo ratings yet

- Fractionation of Wood TarDocument10 pagesFractionation of Wood TarThomas JacobsenNo ratings yet

- Chemical Process Equipment - Selection and Design (Walas) .PDF (PDFDrive - Com) - 1-100Document11 pagesChemical Process Equipment - Selection and Design (Walas) .PDF (PDFDrive - Com) - 1-100Angelica Maria Barrientos ValerianoNo ratings yet

- Cape Biology 2005 U2 p1Document23 pagesCape Biology 2005 U2 p1BritneyDNo ratings yet

- Calculate Saturated-Gas Loads For Vacuum SystemsDocument137 pagesCalculate Saturated-Gas Loads For Vacuum SystemsDHAVALESH AMNo ratings yet

- BTEX in GDUDocument19 pagesBTEX in GDUAnonymous QSfDsVxjZNo ratings yet

- Safety Checklist For Outdoor EventsDocument2 pagesSafety Checklist For Outdoor EventsTodd AtwoodNo ratings yet

- 48 CHP 4 5 PDFDocument16 pages48 CHP 4 5 PDFHarish ChavlaNo ratings yet

- Design of Synthetic Egr and Simulation Study of The Effect of Simplified Formulations On The Ignition Delay of Isooctane and N-HeptaneDocument1 pageDesign of Synthetic Egr and Simulation Study of The Effect of Simplified Formulations On The Ignition Delay of Isooctane and N-HeptaneDarío López PintorNo ratings yet

- Chapter 3 Tanpa Jawaban QuizDocument58 pagesChapter 3 Tanpa Jawaban QuizSigit AryantoNo ratings yet

- The Star Process by Uhde: Industrial SolutionsDocument24 pagesThe Star Process by Uhde: Industrial SolutionsAjaykumarNo ratings yet

- Analysis of DME HCCI Combustion 20030236 - Ssato - Final - 030319Document10 pagesAnalysis of DME HCCI Combustion 20030236 - Ssato - Final - 030319Costin DanielNo ratings yet

- W8L2 - Review Concluding RemarksDocument8 pagesW8L2 - Review Concluding RemarksJay patelNo ratings yet

- Nitrates and Sulphate Fertilizers: Leading Fertilizer Know-HowDocument19 pagesNitrates and Sulphate Fertilizers: Leading Fertilizer Know-Howexergy 33No ratings yet

- Toyota Surf Maint SchedDocument2 pagesToyota Surf Maint SchedPaolo A. AguilaNo ratings yet

- CAPE Chemistry 2007 U1 P2Document11 pagesCAPE Chemistry 2007 U1 P2Lilian RegeNo ratings yet

- ' Methanol R-201 DME E-205: Subsystems For Preliminary Plan Layout For DME ProcessDocument4 pages' Methanol R-201 DME E-205: Subsystems For Preliminary Plan Layout For DME ProcessRodolfo Solano SilvaNo ratings yet

- PFD ISA Standard PDFDocument4 pagesPFD ISA Standard PDFRodolfo Solano SilvaNo ratings yet

- Head RD MDS 540Document2 pagesHead RD MDS 540claudioNo ratings yet

- All ProcesseesDocument11 pagesAll ProcesseesMd. Sifat RaihanNo ratings yet

- Carbon Compounds NotesDocument3 pagesCarbon Compounds Notesm-8885756No ratings yet

- BE8256-Basic Mechanical Engineering Chemical Engineering 2018-2019Document5 pagesBE8256-Basic Mechanical Engineering Chemical Engineering 2018-2019dsathiyaNo ratings yet

- 0620 - s05 - QP - 2. Chemistry O LevelDocument16 pages0620 - s05 - QP - 2. Chemistry O LeveltiffaNo ratings yet

- Extraction of BTX Hydrocarbons From Saudi Arabian Refinery PlatformatesDocument14 pagesExtraction of BTX Hydrocarbons From Saudi Arabian Refinery PlatformatesaminoNo ratings yet

- Temperature Measurement and CalibrationDocument79 pagesTemperature Measurement and CalibrationCarlos A. Diaz NoboaNo ratings yet

- 4.76 - SOP For Utlisation of ETP Sludge As NPKDocument8 pages4.76 - SOP For Utlisation of ETP Sludge As NPKMukesh SoniNo ratings yet

- Moulinex 129 UsMan (EN)Document6 pagesMoulinex 129 UsMan (EN)Gisell ZapataNo ratings yet

- StartingDocument2 pagesStartingsfsdffdsdfsdfsdfNo ratings yet

- Introduction To Steam TurbinesDocument95 pagesIntroduction To Steam TurbinesAYMA CHAUPIS EDSON LEONARDONo ratings yet

- 2013 NGL CRYO-PLUS Brochure19 - 97595 - Linde PDFDocument12 pages2013 NGL CRYO-PLUS Brochure19 - 97595 - Linde PDFJaqueline MoraisNo ratings yet

- Next Generation Lubricants For The Textile IndustryDocument5 pagesNext Generation Lubricants For The Textile IndustrySergey MedvedevNo ratings yet

- Fuel Air Cycle: ChapterDocument6 pagesFuel Air Cycle: Chapterحسين كاظم ياسين100% (1)

- A Zero Emission Combustion Power Plant For Enhanced Oil RecoveryDocument6 pagesA Zero Emission Combustion Power Plant For Enhanced Oil RecoverySebastian LopezNo ratings yet

- 9 Stray Gassing of Refinery StreamsDocument4 pages9 Stray Gassing of Refinery StreamsalumnopitagorasNo ratings yet

- SOP-Pumping OperationDocument14 pagesSOP-Pumping OperationVoltonix InfratechNo ratings yet

- Chemistry ProjectDocument15 pagesChemistry ProjectAadarsh MouryaNo ratings yet

- Beda Glukosa Dan Isomernya - Fessenden 2nd EdDocument2 pagesBeda Glukosa Dan Isomernya - Fessenden 2nd EdRiski Agung NataNo ratings yet

- Isobaric Vapor-Liquid Equilibria For Binary System of Ethanol (1) + Eugenol (2) at 400 and 760 MMHGDocument5 pagesIsobaric Vapor-Liquid Equilibria For Binary System of Ethanol (1) + Eugenol (2) at 400 and 760 MMHGRiski Agung NataNo ratings yet

- J. Chem. Thermodynamics: Sandra M. García-Abarrio, Luisa Haya, Juan I. Pardo, José S. Urieta, Ana M. MainarDocument5 pagesJ. Chem. Thermodynamics: Sandra M. García-Abarrio, Luisa Haya, Juan I. Pardo, José S. Urieta, Ana M. MainarRiski Agung NataNo ratings yet

- Cheng 2000Document13 pagesCheng 2000Riski Agung NataNo ratings yet

- Isobaric (Vapour Þ Liquid) Equilibria of (Linalool Þ 1propanol) and (Linalool Þ 1butanol)Document7 pagesIsobaric (Vapour Þ Liquid) Equilibria of (Linalool Þ 1propanol) and (Linalool Þ 1butanol)Riski Agung NataNo ratings yet

- Digital Control Systems: Lecture NotesDocument61 pagesDigital Control Systems: Lecture NotesHari Pavan0391No ratings yet

- Applications and Future Scope - Energy Harvesting ApplicationsDocument25 pagesApplications and Future Scope - Energy Harvesting Applicationssreenivasulu mudeNo ratings yet

- Ilovepdf MergedDocument13 pagesIlovepdf Mergednilesh sableNo ratings yet

- Download textbook Activity Coefficients In Electrolyte Solutions Second Edition Pitzer ebook all chapter pdfDocument53 pagesDownload textbook Activity Coefficients In Electrolyte Solutions Second Edition Pitzer ebook all chapter pdfbobbie.eastman650100% (17)

- Part I. Relativistic "Paradoxes": Ch. 1. Physics of The Relativistic Length Contraction and The Ehrenfest ParadoxDocument26 pagesPart I. Relativistic "Paradoxes": Ch. 1. Physics of The Relativistic Length Contraction and The Ehrenfest ParadoxYoni Ramirez RoblesNo ratings yet

- 8.4 Improper IntegralsDocument13 pages8.4 Improper IntegralsLindokuhle MkhizeNo ratings yet

- Confidence Intervals For A Single Sample: H.W. Kayondo C 1Document16 pagesConfidence Intervals For A Single Sample: H.W. Kayondo C 1shjahsjanshaNo ratings yet

- Periodical Test in Science 4 Q3Document7 pagesPeriodical Test in Science 4 Q3emmanuel catamponganNo ratings yet

- For Sthe, Heat Exchanger Design: Shell Side Tubes Side Petroleum FractionDocument3 pagesFor Sthe, Heat Exchanger Design: Shell Side Tubes Side Petroleum FractionWilmer MoralesNo ratings yet

- AtxDocument2 pagesAtxHatim AliNo ratings yet

- Dynamics Homework 2Document3 pagesDynamics Homework 2Ayrton Medina PanezNo ratings yet

- CBSE Class 9 Science Chapter 9 Force and Laws of Motion Revision NotesDocument14 pagesCBSE Class 9 Science Chapter 9 Force and Laws of Motion Revision NotesBriti DubeyNo ratings yet

- FS PLM 111 0008Document14 pagesFS PLM 111 0008Jako MishyNo ratings yet

- IAS Prelims General Studies Paper 1996 Part 4Document4 pagesIAS Prelims General Studies Paper 1996 Part 4ShrishtiNo ratings yet

- Creature of Unknown Kind FinalDocument240 pagesCreature of Unknown Kind Finalgamepaas001No ratings yet

- Vector AnalysisDocument24 pagesVector AnalysisHoàng Nguyễn ĐìnhNo ratings yet

- 02 - Basic Operations in Force SystemsDocument14 pages02 - Basic Operations in Force SystemsSophia Althea SaavedraNo ratings yet

- Ma724 - 36Document5 pagesMa724 - 36sumanNo ratings yet

- Phy Definitions For Dse Chapter 3Document4 pagesPhy Definitions For Dse Chapter 3Oscar TsangNo ratings yet

- Books For IJSO PreparationDocument1 pageBooks For IJSO PreparationSwayamNo ratings yet

- Cambridge IGCSEDocument20 pagesCambridge IGCSEVarvaraNo ratings yet

- Supercollider 2Document801 pagesSupercollider 2velarteNo ratings yet

- PID Feedback Control Method For Linear Resonant Actuator Using An Estimated External Load From The back-EMF As A Target VoltageDocument5 pagesPID Feedback Control Method For Linear Resonant Actuator Using An Estimated External Load From The back-EMF As A Target Voltagenour el imen mouaffekNo ratings yet

- Balancing Chemical Equations Using Reduced Row Echilon Form (RREF)Document7 pagesBalancing Chemical Equations Using Reduced Row Echilon Form (RREF)Pretzel Jade Rodil PadillaNo ratings yet

- BS en Iso 22827-1 - 2005Document16 pagesBS en Iso 22827-1 - 2005Anbarasan PerumalNo ratings yet