Professional Documents

Culture Documents

CB2-M-ZEN-21-20003-P&ID - Symbol & Legend (3of3) - Rev.B

Uploaded by

ari wibowoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CB2-M-ZEN-21-20003-P&ID - Symbol & Legend (3of3) - Rev.B

Uploaded by

ari wibowoCopyright:

Available Formats

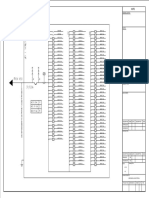

A B C D E F G H I J K L M N O P Q

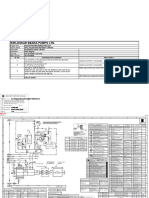

CB2-M-ZEN-21-20003

DWG NO.

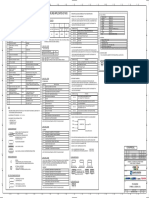

18. CODE LETTER FOR MEASURING POINTS 19. STRUCTURE AND APPLICATION OF KKS ※ SPECIFIRC RULES AND EXAMPLES OF PLANT IDENTIFICATION

(1) CLASS / RATING

ACC. TO DIN-19227 PART1 1. PIPINGS, DUCTS, CHUTES NUMBERING. A 2500# OVER ASME B16.34

1 PIPINGS, DUCTS, CHUTES ARE IDENTIFIED IN ACCORDANCE WITH PROCESS-RELATED B 2500# ASME B16.34 1

I. PROCESS-RELATED IDENTIFICATION IDENTIFICATION, AND ARE CODED WITH "BR" OF KKS LEVEL 2 AS EQUIPMENT CODE. C 1500# ASME B16.34

FIRST LETTER SUCCEEDING LETTERS D 900# ASME B16.34

THE FOLLOWING THREE NUMERIC DIGITS ARE ALLOCATED TO DISTINGUISH THE E 600# ASME B16.34

MEASURED OR INITIATING VARIABLE MODIFIER DISPLAY OR OUTPUT FUNCTIONS SERIAL NUMBER OF

0 1 2 3 FUNCTION OF THE PIPING, DUCT AND CHUTE. F 400# NOT USED

BREAKDOWN LEVEL

A ANALYSIS ALARM LIMIT VALUE G 300# ASME B16.34

DESIGNATION

EQUIPMENT COMPONENT NUMERIC CODE FUNCTION H 150# ASME B16.34 / AWWA C207 CL.D

DISPLAY OF STATE UNIT CODE SYSTEM CODE

B CODE CODE I NOT USED

(FOR EXAMPLE,MOTOR RUNING) 001 - 299 NORMAL PIPE EXCL. ITEMS AS SPECIFIED BELOW

J 125# ASME B16.1

C CONTROLLING, CLOSED LOOP CONTROL TYPE OF DATA 301 - 399 INSTRUMENTATION LEAD PIPE M MANUFACTURER'S RATING

2 AN AAANN AANNN AANN 2

CHARACTER

D DENSITY DIFFERENCE 701 - 799 PIPE FOR SAFETY/RELIEF VALVE

801 - 899 DRAIN PIPE (2) MATERIALS

E ALL ELECTRICAL VARIABLES SENSING ELEMENT

WHERE, A - ALPHA CHARACTERS (ROMAN LETTERS EXCEPT I AND O, AND SPECIAL SYMBOLS) A LOW, INTERMEDIATE AND HIGH ALLOY STEEL (CR-MO)

F FLOW RATE RATIO 901 - 999 VENT PIPE

N - NUMERICAL CHARACTERS (ARABIC NUMERALS) B CARBON STEEL

G POSITION OR LENGTH GAUGING 4, 5 AND 6 SERIES (RESERVED) C AUSTENITIC STAINLESS STEEL

HIGH D HIGH DENSITY POLY ETHYLENE (HDPE)

H HAND (MANUALLY INITIATED) A : KKS LEVEL 0 CODES F FIBERGLASS (GLASS-FIBER-REINFORCED THERMOSETTING-RESIN, GRP)

OPERATED 2. VALVE AND DAMPER NUMBERING.

3 TOTAL PLANT CODE (3) SEQUENCE NUMBER 3

I CURRENT INDICATION VALVES AND DAMPERS ARE IDENTIFIED IN ACCORDANCE WITH PROCESS-RELATED

TYPE OF DATA CHARACTER AN IDENTIFICATION, AND ARE CODED WITH "AA" OF KKS LEVEL 2 AS THE EQUIPMENT CODE. A SEQUENTIAL NUMBER FOR THE PIPING MATERIAL CLASSIFICATION

J SCAN

DESIGNATION OF DATA CHARACTER U1 U2 IV. PIPING INSULATION THICKNESS

K TIME OR TIME PROGRAMME THE FOLLOWING THREE NUMERIC DIGITS ARE ALLOCATED TO DISTINGUISH THE

FUNCTION OF THE VALVE AND/OR DAMPER. (1) PURPOSE

L LEVEL LOW IH : INSULATION FOR HEAT CONSERVATION

U1 P SINCE "P1" IS APPLIED FOR CIREBON 1, (1) (2)

M MOISTURE OR HUMIDITY, MOTOR "P2" IS APPLIED FOR UNIT CODE OF CIREBON 2 PROJECT NUMERIC CODE FUNCTION IP : INSULATION FOR PERSONAL PROTECTION

U2 2

(2) THICKNESS

N OPTICAL VARIABLE PROCESS COMPUTER 001 - 299 NORMAL VALVE/DAMPER EXCI. ITEMS AS SPECIFIED BELOW

4 O RESTRICTION ORIFICE, OPTICAL SIGNAL 301 - 399 INSTRUMENT ROOT VALVE 4

P PRESSURE OR VACUUM TEST-POINT CONNECTION 701 - 799 SAFETY/RELIEF VALVE

Q QUALITY / ANALYSIS INTEGRATE OR INTEGRATING OR SUMMATING 801 - 899 DRAIN VALVE

EXCEPT D,M,V TOTALIZE

901 - 999 VENT VALVE

R RADIATION VARIABLE REGISTRATION, SELF-REGULATING

4, 5 AND 6 SERIES (RESERVED)

S VELOCITY, SPEED OR FREQUENCY SWITCHING, RELIEF OR SAFETY,

SOLENOID OPEN LOOP CONTROL

5 T TEMPERATURE TRANSMITTING B : KKS LEVEL 1 CODES 3. INSTRUMENT NUMBERING. 5

U MULTIVARIABLE MULTIFUNCTION UNIT SYSTEMS GROUPS INSTRUMENTS ARE IDENTIFIED IN ACCORDANCE WITH PROCESS-RELATED

V VISCOSITY VALVE, DAMPER, LOUVRE, ACTUATING IDENTIFICATION, AND ARE CODED WITH CODE ELEMENT : C (MEASURING CIRCUITS),

ELEMENT, UNSPECIFIED CORRECTING UNIT CODE IDENTIFICATION D (CLOSED LOOP CONTROL CIRCUITS) OR F (INDIRECT MEASURING CIRCUITS) OF KKS

W WEIGHT OR FORCE, MASS, GRAVITY WELL LEVEL 2 AS THE EQUIPMENT CODE.

A GRID AND DISTRIBUTION SYSTEMS

X UNCLASSIFIED VARIABLES X AXIS UNCLASSIFIED PROCESSING FUNCTION B POWER TRANSMISSION AND AUXILIARY POWER SUPPLY THE FOLLOWING THREE NUMERIC DIGITS ARE ALLOCATED TO DISTINGUISH THE

OTHER DIMENSIONS FUNCTION OF INSTRUMENTS.

Y VIBRATION, EXPANSION, Y AXIS COMPUTING RELAY, RELAY, C INSTRUMENTATION AND CONTROL EQUIPMENT

6 ECCENTRICITY, SHAFT POSITION ARITHMETIC FUNCTION E FUEL SUPPLY AND RESIDUES DISPOSAL NUMERIC CODE FUNCTION 6

Z Z AXIS EMERGENCY OR SAFETY ACTING, TRIP G WATER SUPPLY AND DISPOSAL ANALOG REMOTE MEASUREMENT CIRCUITS

001 - 299

+ MAX. LIMIT VALUE (E.G. TRANSMITTER, THERMOCOUPLE)

H BOILER

/ INTERMEDIATE VALUE L STEAM AND WATER CYCLE 301 - 399 BINARY REMOTE MEASUREMENT CIRUITS (E.G. SWITCH)

- MIN. LIMIT VALUE M MAIN MACHINE SETS 501 - 599 LOCAL MEASUREMENTS

P COOLING WATER SYSTEMS MEASUREMENT CIRCUITS FOR ACCEPTANCE AND TEST

NOTE 601 - 699

MEASUREMENT/TEST TAP

7

Q AUXILIARY SYSTEMS 7

1. MEASURING VARIABLE IDENTIFICATION FOR QUALITY ANALYSER MAY BE SHOWN ON LOWER RIGHT OF S ANCILLARY SYSTEMS 801 - 899 CALCULATED VALVE (NORMALLY NOT INDICATED IN P&ID)

THE INSTRUMENT IDENTIFICATION BALOON. U STRUCTURES 2, 4, 7 AND 9 SERIES (RESERVED)

2. SUCCEEDING LETTER SEQUENCE : I, R, C, T, Q, S Z, A X HEAVY MACHINERY (NOT MAIN MACHINES SETS)

EXAMPLE 1 PRESSURE AND TEMPERATURE CORRECTED FLOW MEASUREMENT.

3. SUPPLEMENTS FOR SUCCEEDING LETTERS Z WORKSHOP AND OFFICE EQUIPMENT

+ UPPER LIMIT VALUE (NOTE) FOR DETAILED INFORMATION, RETER TO "CB2-G-ZEN-05-32000" CF001

/ INTERMEDIATE VALUE

8 - LOWER LIMIT VALUE CT001 CORRECTION FF801 8

C : KKS LEVEL 2 CODES

CP003

LOCATION IDENTIFICATION

EQUIPMENT

(MEASURED VALVE) (CALCULATED VALVE)

GENERAL SYMBOL FOR MEASURING POINT : A MECHANICAL EQUIPMENT (ACTIVE EQUIPMENT)

PIC CODE LETTERS FOR M&C B MECHANICAL EQUIPMENT (PASSIVE EQUIPMENT)

21LAB10CP101 KKS-DESIGNATION OF MEASURING POINT

C DIRECT MEASURING CIRCUITS

REPRESENTATION OF THE OUTPUT 4. FIELD JUNCTION BOX (MARSHALLING BOX) AND LOCAL CONTROL CUBICLE NUMBERING

9 AND OPERATING POINT : D CLOSED LOOP CONTROL CIRCUITS 9

JUNCTION BOXES (MARSHALLING BOXES) AND LOCAL CONTROL CUBICLES ARE

- E ANALOG AND BINARY SIGNAL CONDITIONING

- FIELD MOUNTED INSTRUMENT IDENTIFIED IN ACCORDANCE WITH PROCESS-RELATED IDENTIFICATION, AND ARE CODED

F INDIRECT MEASURING CIRCUITS WITH "GH" OF KKS LEVEL 2 AS EQUIPMENT CODE.

- G ELECTRICAL EQUIPMENT EXAMPLE 9-2 UNIT 1 COMPRESSED AIR SYSTEM

LOCAL CONTROL SYSTEM

-

H SUBASSEMBLY OF MAIN AND HEAVY MACHINES FOR APPROVAL

UNIT 1 AIR COMPRESSOR CONTROL PANEL : 10QEA70 GH001

-

- PLANT CONTROL SYSTEM (DCS : DISTRIBUTED CONTROL SYSTEM) UNIT 1 COMPRESSED AIR SYSTEM MARSHALLING BOX-1 : 10QEA70 CH002

(NOTE) FOR DETAILED INFORMATION, RETER TO "CB2-G-ZEN-05-32000"

10 10

B '17.06.22 ISSUED FOR APPROVAL S.W.HONG S.S.KWUN J.M.SEO

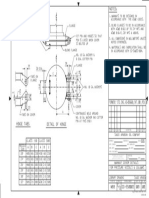

INTERLOCK IDENTIFICATION II. PIPING IDENTIFICATION A '17.01.20 ISSUED FOR APPROVAL S.W.HONG S.S.KWUN J.M.SEO

D : KKS LEVEL 3 CODES REV DATE DESCRIPTION DSGN CHKD APPD

GENERAL THIS LEVEL WILL GENERALLY NOT BE USED FOR MECHANICAL AND CIVIL ENGINEERING PROJECT:

I -INTERCONNECTING LOGIC OR SEQUENCE CONTROL DRAWINGS AND DOCUMENTS. THIS LEVEL WILL BE USED IF ANY SPECIAL CASE IS CIREBON 2, 1X1000MW COAL FIRED POWER

NORMALLY USED FOR LOCAL AUXILIARY CONTROL SYSTEM NECESSARY. ELECTRICAL AND I&C PROCESS ENGINEERING NEED THE 3RD LEVEL PROJECT, INDONESIA

ALWAYS : E.G.FOR CABLE/SIGNAL DESIGNATION.

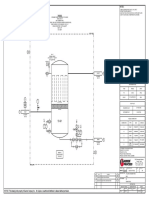

NOT NOMALLY ACCESSIBLE DIRECTION OF FLOW DIRECTION OF FLOW DIRECTION OF FLOW

OWNER:

I -DIGITAL LOGIC CONTROLS COMPONENT 11

11 INTERGRAL TO THE PROCESS CONTROL SYSTEM K MECHANICAL COMPONENTS OF EQUIPMENT UNITS 12LBA50 SYSTEM CODE 12LBA50 12LBA50

CONSULTANT:

M MECHANICAL COMPONENTS OF STATIC EQUIPMENT BR001 EQUIPMENT UNIT CODE BR001 BR001

Q MECHANICAL COMPONENTS FOR INSTRUMENTATION AND CONTROL DN 100 NOMINAL DIAMETER DN 100 DN 100

PER. TEST INSTRUMENT IDENTIFICATION BA 01 PIPING MATERIAL CLASS BA 01 BA 01 CONTRACTOR:

X SIGNAL ORIGINS (INPUT SIGNALS)

- PERFORMANCE TEST POINT Y SIGNAL APPLICATIONS (OUTPUT SIGNALS)

- (ACCEPTANCE TEST)

Z GATED SIGNALS (LOGIC RESULTANT SIGNALS) III. PIPING MATERIAL CLASS TITLE:

12

12 - PERFORMANCE CALCULATION - ELECTRICAL COMPONENTS P&I DIAGRAM

POINT (COMMERCIAL OPERATION)

-

(NOTE) FOR DETAILED INFORMATION, RETER TO "CB2-G-ZEN-05-32000"

(1) (2) (3) SYMBOL & LEGEND (3/3)

SCALE DRAWING NUMBER SHEET NO. REV. NO.

CB2-M-ZEN-21-20003 3/3 B

A B C D E F G H I J K L M N O P Q

You might also like

- Pressure Vessel Asme Strength Calculation ManualDocument38 pagesPressure Vessel Asme Strength Calculation ManualEsapermana Riyan80% (5)

- Cable Tray CatalogDocument152 pagesCable Tray CatalogJohn Bihag100% (1)

- 586 Calc Pro Mtbe FCV TK1102Document9 pages586 Calc Pro Mtbe FCV TK1102Muhammad Adil KhanNo ratings yet

- Design & Construction of Piping SystemsDocument115 pagesDesign & Construction of Piping SystemsSuresh Babu100% (13)

- Transformer Foundation 5Document1 pageTransformer Foundation 5A.K.M Shafiq MondolNo ratings yet

- Flange Calculation ASMEVIII-Custom WNRF (Alternate Check)Document11 pagesFlange Calculation ASMEVIII-Custom WNRF (Alternate Check)Kashif Kazi100% (1)

- Balanced Bellows Type Pressure Relief Valve NumbersDocument17 pagesBalanced Bellows Type Pressure Relief Valve NumbersswatkoolNo ratings yet

- 122002Document39 pages122002wdavid81No ratings yet

- Pressure Vessel - Asme - Strength - Calculation - ManualDocument38 pagesPressure Vessel - Asme - Strength - Calculation - ManualEsapermana Riyan100% (3)

- CB2-M-ZEN-21-20003-P&ID - Symbol & Legend (3of3) - Rev.DDocument1 pageCB2-M-ZEN-21-20003-P&ID - Symbol & Legend (3of3) - Rev.Dari wibowoNo ratings yet

- 2007 ASME Boiler & Pressure Vessel CodeDocument6 pages2007 ASME Boiler & Pressure Vessel Codeibson045001256No ratings yet

- Reinforcement Pad CalculationDocument5 pagesReinforcement Pad Calculationsada siva100% (1)

- Conventional Type Pressure Relief Valve NumbersDocument18 pagesConventional Type Pressure Relief Valve NumbersswatkoolNo ratings yet

- 15 TPH FBC Boiler ManualDocument348 pages15 TPH FBC Boiler ManualMuttappa T JainapurNo ratings yet

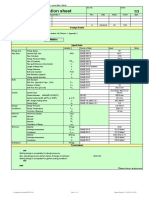

- Equipment Data Sheet: Type: Doc No: Mds-Pv-01Document3 pagesEquipment Data Sheet: Type: Doc No: Mds-Pv-01Waqas WaqasNo ratings yet

- Datasheets For Bucket Type StrainerDocument2 pagesDatasheets For Bucket Type StrainerbecpavanNo ratings yet

- DX SplitDocument29 pagesDX Splitsiva_nagesh_2No ratings yet

- Notes:: TAG# SV-01Document1 pageNotes:: TAG# SV-01omarNo ratings yet

- Flare Scrubber DSDocument8 pagesFlare Scrubber DSsudjonoNo ratings yet

- CB2-M-ZEN-21-20003-P&ID - Symbol & Legend (33) - Rev.1Document1 pageCB2-M-ZEN-21-20003-P&ID - Symbol & Legend (33) - Rev.1ari wibowoNo ratings yet

- CB2-M-ZEN-21-20003-P&ID - Symbol & Legend (3of3) - Rev.CDocument1 pageCB2-M-ZEN-21-20003-P&ID - Symbol & Legend (3of3) - Rev.Cari wibowoNo ratings yet

- 8in Gas Lift Lines - Rev 1Document27 pages8in Gas Lift Lines - Rev 1babuNo ratings yet

- r5t4z4 SpecDocument1 pager5t4z4 Specmike00No ratings yet

- Toaz - Info Lifting Lug Calculation On Dish End PRDocument156 pagesToaz - Info Lifting Lug Calculation On Dish End PRandry4jcNo ratings yet

- Dibujos Válvulas-Bola Top Entry y CompuertaDocument4 pagesDibujos Válvulas-Bola Top Entry y CompuertaJUAN ANTONIO HERNANDEZ SOSANo ratings yet

- DrenajeDocument1 pageDrenajeSleyda MunozNo ratings yet

- Fit-Up Piping B192-5ADocument54 pagesFit-Up Piping B192-5APrathamesh OmtechNo ratings yet

- C29732-01-Pid-02.0 - P&id Scrubber TT-006Document1 pageC29732-01-Pid-02.0 - P&id Scrubber TT-006omarNo ratings yet

- Design Drawing: Baladna Farm 2 Tse Polishing PlantDocument12 pagesDesign Drawing: Baladna Farm 2 Tse Polishing PlantWasim OfficialNo ratings yet

- Ipromsa Ltda: FILE: EMAG240-IBMPEDM-0001-Rev.1Document5 pagesIpromsa Ltda: FILE: EMAG240-IBMPEDM-0001-Rev.1Cristobal Leal ArandaNo ratings yet

- Sampel 1Document1 pageSampel 1Muhammad KurniawanNo ratings yet

- EFD-015 - General Valve List - 200731Document3 pagesEFD-015 - General Valve List - 200731cmc261185No ratings yet

- Tube Bundle Detail Drawing 1200-E-4006: Document TitleDocument2 pagesTube Bundle Detail Drawing 1200-E-4006: Document TitleAnwar SadatNo ratings yet

- J&P Projects Quality Control Plan: ? ? 0 ? Equipment & Workpack InformationDocument16 pagesJ&P Projects Quality Control Plan: ? ? 0 ? Equipment & Workpack InformationEnrico BishopNo ratings yet

- Off 1 B3 6Document1 pageOff 1 B3 6Don Roseller DumayaNo ratings yet

- 81-03-0074-00 General Assembly, X400-2D With FlangeDocument1 page81-03-0074-00 General Assembly, X400-2D With FlangeMuthukumar RadhakrishnanNo ratings yet

- Catalogo Bridas BrivamexDocument91 pagesCatalogo Bridas BrivamexGabriel Humberto Salinas CoyocNo ratings yet

- Line Sizing MainDocument10 pagesLine Sizing MainNitin KurupNo ratings yet

- Hydrant PillarDocument1 pageHydrant PillarsobariNo ratings yet

- Aa1a32 02Document3 pagesAa1a32 02MramirezNo ratings yet

- BG6944 6 PDFDocument1 pageBG6944 6 PDFArmando De la TorreNo ratings yet

- Steel Structure Drawing XAT10 20X10Document9 pagesSteel Structure Drawing XAT10 20X10Casio AutomaNo ratings yet

- ESLCS150-01 Pipe ScheduleDocument3 pagesESLCS150-01 Pipe Schedulethomas.jaggerNo ratings yet

- SealDocument3 pagesSealshashwatchaurasia83No ratings yet

- Notes: C: CLASS 150 A B C A B C CLASS 300Document1 pageNotes: C: CLASS 150 A B C A B C CLASS 300Honesto BautistaNo ratings yet

- Spectacle Blind 8-600 FFDocument2 pagesSpectacle Blind 8-600 FFJovianto PrisilaNo ratings yet

- Extruded Outlet HeaderDocument2 pagesExtruded Outlet Headermario salazarNo ratings yet

- SymbolsDocument1 pageSymbolsSolongo SoLoNo ratings yet

- Stud Bolts 2hex Nuts Weight Imperial SizesDocument12 pagesStud Bolts 2hex Nuts Weight Imperial SizesBryan Mauricio Diaz Avila100% (1)

- 25571-DRG-2020Jan Fusion T2 StandardDocument5 pages25571-DRG-2020Jan Fusion T2 StandardKevin KuanNo ratings yet

- 23ho-139me-D-01 - Rev.a1 - Tube Bundle General ArrangementDocument1 page23ho-139me-D-01 - Rev.a1 - Tube Bundle General ArrangementIkatan Alumni GumuruhNo ratings yet

- Chapter-5 Technical Specification For Spiral Wound Metallic GasketDocument3 pagesChapter-5 Technical Specification For Spiral Wound Metallic GasketSomeshNo ratings yet

- Parking AreaDocument4 pagesParking AreabintangNo ratings yet

- Pro Board TCDocument1 pagePro Board TCMuhammad AfifuddinNo ratings yet

- Check Sheet Inspection: Pt. DffiDocument2 pagesCheck Sheet Inspection: Pt. DffiJovianto PrisilaNo ratings yet

- Planetary CarrierDocument1 pagePlanetary Carrierapi-439358555No ratings yet

- r5t2z4 SpecDocument1 pager5t2z4 Specmike00No ratings yet

- Ag Group: Item No. Part Number Description Qty. 1 AG-0002-B Ring Assembly 1 2 AG-0003-B Roller 29Document1 pageAg Group: Item No. Part Number Description Qty. 1 AG-0002-B Ring Assembly 1 2 AG-0003-B Roller 29Anonymous IQD4PqB876No ratings yet

- Key Plan: CoordinationDocument1 pageKey Plan: CoordinationMOHAMED AHMED ShabanNo ratings yet

- Ag Group: Unless Otherwise Specified: JSL 03-10-04Document1 pageAg Group: Unless Otherwise Specified: JSL 03-10-04Anonymous IQD4PqB876No ratings yet

- 3.tech Spec & Paint Spec-Valve PKG For Namrup-2022-09-29-05 53 44 PDFDocument61 pages3.tech Spec & Paint Spec-Valve PKG For Namrup-2022-09-29-05 53 44 PDFSravan DasariNo ratings yet

- Aph Idf FDF PafDocument44 pagesAph Idf FDF Pafari wibowoNo ratings yet

- Ok Hvac 44-Fa06781c-N-01-NeDocument31 pagesOk Hvac 44-Fa06781c-N-01-Neari wibowoNo ratings yet

- 2 X 100% Q 500 M3/H P 0.35 Mpa: From Ro Cleaning TankDocument2 pages2 X 100% Q 500 M3/H P 0.35 Mpa: From Ro Cleaning Tankari wibowoNo ratings yet

- Safety Data Sheet: Section-1. IdentificationDocument7 pagesSafety Data Sheet: Section-1. Identificationari wibowoNo ratings yet

- EDG Load CalculationDocument15 pagesEDG Load Calculationari wibowoNo ratings yet

- FCAW Process WeldingDocument130 pagesFCAW Process WeldingahmetNo ratings yet

- Dresser 10C25 Meter IOM Manual CompressedDocument74 pagesDresser 10C25 Meter IOM Manual Compressedangel017No ratings yet

- SPCC PTM P Ts 001 Rev BDocument27 pagesSPCC PTM P Ts 001 Rev BDan MorganNo ratings yet

- Review ProblemsDocument19 pagesReview ProblemsJohnson SambranoNo ratings yet

- Jamal Poles BrochureDocument16 pagesJamal Poles BrochureSana Nazir0% (1)

- VersaJet ManualDocument36 pagesVersaJet ManualJOSE LUIS HERNANDEZ CHAVEZNo ratings yet

- SPE-192878-MS Maximizing Pipeline Flexibility With Drag Reducing AgentsDocument9 pagesSPE-192878-MS Maximizing Pipeline Flexibility With Drag Reducing AgentsQaiser HafeezNo ratings yet

- Stripper Efficiency Calculationfor Ammonia CO2 Stripping ProcessDocument10 pagesStripper Efficiency Calculationfor Ammonia CO2 Stripping ProcessRaga BimaNo ratings yet

- Amse PiDocument5 pagesAmse PiNnamdi Celestine NnamdiNo ratings yet

- Tuberia Recubrimiento Interior ConpipeDocument145 pagesTuberia Recubrimiento Interior ConpipeYamil Diaz SantosNo ratings yet

- Salamander Grill (Tsig-3230)Document2 pagesSalamander Grill (Tsig-3230)sam turnoverNo ratings yet

- BUTTING Clad Pipes PDFDocument12 pagesBUTTING Clad Pipes PDFsiswoutNo ratings yet

- CMTP006Document8 pagesCMTP006mohantyomNo ratings yet

- Meistream Plus: Class C Bulkmeter For Cold Potable Water DN 40... 150 PN 16Document4 pagesMeistream Plus: Class C Bulkmeter For Cold Potable Water DN 40... 150 PN 16Raluca OlaruNo ratings yet

- Flow Measurement of Gases & Clear Liquids With Series 6001 & 6002Document8 pagesFlow Measurement of Gases & Clear Liquids With Series 6001 & 6002Jani WidodoNo ratings yet

- TechnicalCatalogueHELIROMA SDocument404 pagesTechnicalCatalogueHELIROMA SyotaNo ratings yet

- MSS SP 6-2017Document10 pagesMSS SP 6-2017elciolbezerraNo ratings yet

- 549-GB-11-01 ManualDocument40 pages549-GB-11-01 Manualmiguelfpinto100% (1)

- Waterboy RO Unit PamphletDocument7 pagesWaterboy RO Unit PamphletDhiren DayaNo ratings yet

- Technical Data Sheet: Reinforcekit 1D (R1D) DescriptionDocument2 pagesTechnical Data Sheet: Reinforcekit 1D (R1D) DescriptionThien NguyenNo ratings yet

- Buckling Pin Relief Technology: Catalog #77-1015Document12 pagesBuckling Pin Relief Technology: Catalog #77-1015Pham LanphuongNo ratings yet

- DG Fitting StandardDocument92 pagesDG Fitting StandardAnonymous B1AOOsmRMiNo ratings yet

- Curriculum Vitae: Kanti Desai Varma Pamu Professional ExperienceDocument3 pagesCurriculum Vitae: Kanti Desai Varma Pamu Professional ExperienceKiran KumarNo ratings yet

- IP &cal Home WorkDocument20 pagesIP &cal Home WorkAndri Nusantara PutraNo ratings yet