Professional Documents

Culture Documents

LPS Design Kaushi Electrical

Uploaded by

Yazhisai SelviCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LPS Design Kaushi Electrical

Uploaded by

Yazhisai SelviCopyright:

Available Formats

LIGHTNING PROTECTION SYSTEM DESIGN

REPORT

Client : KAUSI TECHNICAL SERVICES PVT LTD

: M/s. CIKIT Electricals and Technologies

Prepared By

India Pvt. Ltd.

LIGHTNING PROTECTION SYSTEM (LPS)

The main and most effective measure for protection of structures against physical damage is

considered to be the lightning protection system (LPS). It usually consists of both external and

internal lightning protection system. An external Lightning Protection System is intended to

1) Intercept a lightning flash to a structure. (Air terminal system)

2) Conduct the lightning current safely towards the earth. (Down conductor system)

3) Disperse the lightning current into the earth. (Earthing system)

In most cases, the external LPS may be attached to the structure to be protected. An isolated LPS is

preferred for areas at risk of explosion and fire.

Air termination system:

The probability of structure penetration by a lightning current is reduced by the presence of

properly designed air termination system. It can be composed of any combination of the following

elements.

1) Rods

2) Catenary wires

3) Meshed conductors.

The individual air termination rods should be connected at roof level to ensure current division.

Radioactive materials should not be used as air terminals. The following methods are used to

determine the position of air termination system.

1) Protection Angle Method

2) Rolling Sphere Method and

3) Mesh Method

Protection angle method is suitable for simple shaped buildings. It also has limitations on the height

of the air terminal. The mesh method is suitable where plane surfaces are to be protected. Whereas

rolling sphere method can be used in all the cases.

Rolling Sphere Method:

The positioning of air termination system using rolling sphere method is adequate if no point of the

structure to be protected comes into contact with a sphere of radius r (depending on class of

protection), rolling around and on top of the structure in all possible directions. In this way, the

sphere only touches the air termination system.

The radius of the rolling sphere for different classes of LPS are as follows,

Rolling sphere

S.No Class of LPS

radius, r (m)

1 I 20

2 II 30

3 III 45

4 IV 60

#3, D.A.Swamy Avenue, Thirumullavoil Road, Korattur, Chennai 600 080

www.cikit.in | enquiry@cikit.in | +91 95000 35752

The sphere of radius r, is rolled around and over all the structure until it meets the ground plane or

object in contact with the ground plane which is capable of acting as a conductor of lightning. A

striking point could occur where the rolling sphere touches the structure and at such points

protection by an air-termination conductor is required.

Penetration distance:

The distance between the two air terminals should be chosen in such a way that, the protection is

provided for all the objects placed on the surface to be protected. The protection of the objects

placed on the surface can be ensured by calculating the penetration distance of the rolling sphere.

The distance between the level of air terminals and the least point of sphere in the space between

the air terminals is called penetration distance.

Let us consider an object of height ‘h’ placed on the surface to be protected. Let ‘ht’ be the height of

the air terminal, ‘p’ be the penetration distance and ‘d’ be the distance between the two terminals.

#3, D.A.Swamy Avenue, Thirumullavoil Road, Korattur, Chennai 600 080

www.cikit.in | enquiry@cikit.in | +91 95000 35752

In this case, the penetration distance should be less than the difference between the height of air

terminal and height of the object to be protected.

𝑝 < (ℎ𝑡 − ℎ)

Distance between air terminals:

The penetration distance of the rolling sphere below the level of conductors in the space between

the conductors can be calculated by using the below formula (IS 62305-3).

2

𝑝 = 𝑟 − √[𝑟 2 − (𝑑⁄2) ]

Where,

p – penetration distance

r – radius of rolling sphere

d – distance between the air terminals

For attaining a particular penetration distance, we can derive the required distance between the air

terminals from the above equation.

𝑑 = 2 ∗ √[2 ∗ 𝑝 ∗ 𝑟 − (𝑝)2 ]

If there are no objects protruding from the structure to be protected, then the penetration distance

can be increased up to the height of the air terminal to provide maximum protection. At this

condition, the distance can be calculated by substituting the value of height of air terminal (ht) in

place of penetration distance (p).

𝑑 = 2 ∗ √[2 ∗ ℎ𝑡 ∗ 𝑟 − (ℎ𝑡 )2 ]

#3, D.A.Swamy Avenue, Thirumullavoil Road, Korattur, Chennai 600 080

www.cikit.in | enquiry@cikit.in | +91 95000 35752

The distance between the air terminals(d) in rolling sphere method depends on two factors.

1) Height of the air terminal and

2) Radius of the rolling sphere

Among these two factors, the radius of rolling sphere is a constant value which depends on the class

of LPS as specified by IS/IEC 62305-3. Hence for particular class of LPS, the distance between the

air terminals purely depends on the height of air terminal.

Down Conductor system:

The function of a down conductor system is to conduct the lightning impulse from air-termination

system to the earthing system. The down conductor system should be installed in such a way that

the following points are ensured.

1) Several parallel current paths exist

2) Length of current path is kept to minimum.

3) Equipotential bonding to conducting parts is performed.

For each non-isolated LPS, the number of down conductors shall be not less than two and should be

distributed around the perimeter of the structure to be protected. An equal spacing of the down

conductors is preferred around the perimeter. The typical values of the distance between the

conductors are shown below.

Distance between

Class of LPS

conductors, m

I 10

II 10

III 15

IV 20

A down conductor should be installed at each exposed corner of the structure and as far as

practicable, they form a direct continuation of the air-termination conductors. Down conductors

are installed in such a way that they provide the shortest and most direct path to earth.

Down conductors, even if covered in insulating material, shall not be installed in gutters or water

spouts. The effects of moisture in the gutters lead to intensive corrosion of the down conductor.

Earth Termination system:

Earth termination system is a sub system of Lightning protection system which is intended to

conduct and disperse the lightning current into the earth. In general, a low earthing resistance

value of less than 10 ohms is recommended for lightning protection system.

There are 2 types of earth arrangements for lightning protection and the details are as follows.

i) Type A arrangement

ii) Type B arrangement

#3, D.A.Swamy Avenue, Thirumullavoil Road, Korattur, Chennai 600 080

www.cikit.in | enquiry@cikit.in | +91 95000 35752

Type – A arrangement:

This type of arrangement comprises horizontal or vertical earth electrodes connected to each down

conductor. The total number of earth electrodes in Type A arrangement shall not be less than two.

Type – B arrangement:

Type B arrangement It comprises of ring conductor external to the structure to be protected or the

foundation earth electrode forming a closed loop. In case of ring earth assembly, at least 80% of

total length of conductor should be in contact with the soil. The ring earth electrodes shall be

buried at a depth of at least 0.5m and at a distance of about 1m away from the external walls.

Designing:

Site Details:

Type of Structure : Shed

Roof : Metal sheet

Height of shed at centre : 17.5 m

Height of shed at corner : 16 m

Length of shed : 165 m

Width of shed : 60 m

Design Considerations:

Standard : IS/IEC 62305

Level of Protection / Class of LPS : IV

Air terminal Position Method : Rolling Sphere Method

Radius of sphere : 60 m

Height of air terminal (ht) : 1.6 m

Height of ventilator/ panel (h) :1m

Penetration distance (p) : 0.5 m

Ventilators and Solar panels are mounted on the metal roof sheets. To provide protection for them,

a penetration distance of 0.5m is considered for the designing. The penetration distance should be

less than the difference between the height of air terminal and height of the object to be protected.

𝒑 < (𝒉𝒕 − 𝒉)

0.5 < (1.6-1)

Note: Penetration distance of 0.5m is considered based on the instruction which we received “panel

height will be lesser than 1m.” (Height of terminal = 1.6m; height of panel = 1m; p=0.5m)

#3, D.A.Swamy Avenue, Thirumullavoil Road, Korattur, Chennai 600 080

www.cikit.in | enquiry@cikit.in | +91 95000 35752

Distance between the Air Terminals:

For attaining a particular penetration distance, we can find the required distance between the air

terminals using the formula.

𝒅 = 𝟐 ∗ √[𝟐 ∗ 𝒑 ∗ 𝒓 − (𝒑)𝟐 ] 𝒎

Here,

r = 60 m for LPL IV and

p = 0.5 m

𝒅 = 𝟐 ∗ √[𝟐 ∗ 𝟎. 𝟓 ∗ 𝟔𝟎 − (𝟎. 𝟓)𝟐 ]

𝒅 = 𝟏𝟓. 𝟓 𝒎

Hence, for obtaining a penetration distance of 0.5m at Class IV LPS, the distance between the two

adjacent air terminals shall not be greater than 15m.

Air terminals:

The entire air terminal assembly shall be divided into two parts for designing purpose.

i) Along the width of shed

ii) Along the length of shed

Along the width of Shed:

Width of the shed = 60m.

Max. allowable distance between two air terminals = 15m.

Hence, five numbers of air terminals at an equal interval of 15m can be placed along the width of

the shed to provide protection for the entire 60m of the shed.

#3, D.A.Swamy Avenue, Thirumullavoil Road, Korattur, Chennai 600 080

www.cikit.in | enquiry@cikit.in | +91 95000 35752

Along the length of shed:

Length of the shed = 165 m.

Max. allowable distance between two air terminals = 15 m.

Hence, twelve numbers of air terminals at an equal interval of 15 m can be placed along the width

of the shed to provide protection for the entire 165m of the shed.

Total number of air terminals = no. of air terminals along length * no. of air terminals along width

= 12*5

Total number of air terminals = 60 terminals

Down Conductor:

The total down conductor used for the LPS can be calculated by dividing the system into two parts.

1. Conductor for Interlinking the air terminals.

2. Conductors for connecting the air terminal network to ground.

Conductor for interlinking air terminals:

Length of conductors runs along the length of shed = 3*170 = 510 m

Length of conductors runs along the width of shed = 9*65 = 585 m

Total length = 1095 m

#3, D.A.Swamy Avenue, Thirumullavoil Road, Korattur, Chennai 600 080

www.cikit.in | enquiry@cikit.in | +91 95000 35752

Conductors for connecting the air terminal network to ground:

The typical values of the distance between the conductors are shown below.

Distance between

Class of LPS

conductors, m

I 10

II 10

III 15

IV 20

Hence, for LPS of class IV, the distance between the down conductors (DC) shall be 20m.

Length of the shed = 165 m

Number of DC in one side of shed along the length= 9

Number of DC in two sides of shed along the length = 18

Number of DC along the width = 2

Total no. of DC = No. of DC along length + No. of DC along width

= 18+2

Total no. of DC = 20

Total length of DC connecting to earth = (No. of DC along length*18) + (No. of DC along width*20)

= (18*18) + (2*20)

= 324 + 40

Total length of DC connecting to earth = 364 m

Overall Down Conductors = 1095 + 364 = 1459 m

Earthing System:

Horizontal or vertical earth electrodes installed outside the structure to be protected should be

connected to each down-conductor. Hence, one of earth electrode can be installed for each down

conductor and all the earth electrodes shall be interconnected to form a grid. The earth electrodes

should be installed at a distance of 1m from the wall.

No. of down conductors = 20

No of earth pits = 20

Conductors needed for interconnection = (2*170) + (2*65)

= 470 m

#3, D.A.Swamy Avenue, Thirumullavoil Road, Korattur, Chennai 600 080

www.cikit.in | enquiry@cikit.in | +91 95000 35752

Conclusion:

Based on the inputs received, we have performed calculations and designed lightning protection

system using Rolling Sphere Method as per IS/IEC 62305. The summary of the design is as follows.

S.No Item Quantity

1 Air terminal (Height 1.6m) 60 Nos

Conductor: (DC + Interlinking)

2 ➔ Down Conductor – 1459 m 1929 m

➔ Earth pit inter connection – 470 m

3 Test Link 20 Nos

4 Earth Pit 20 Sets

5 Earth pit chamber 20 Sets

#3, D.A.Swamy Avenue, Thirumullavoil Road, Korattur, Chennai 600 080

www.cikit.in | enquiry@cikit.in | +91 95000 35752

You might also like

- The Four Common Types of Parenting StylesDocument11 pagesThe Four Common Types of Parenting StylesIka_Dyah_Purwa_1972100% (3)

- Preserving Food Drying Fruits and VegetablesDocument12 pagesPreserving Food Drying Fruits and Vegetablespdxpharris100% (1)

- Study On Current TranformersDocument9 pagesStudy On Current TranformersRoshan AkaravitaNo ratings yet

- Vrs PresentationDocument24 pagesVrs PresentationshrutipalkarNo ratings yet

- Electrical Grounding, Earthing & Earthing System ExplainedDocument11 pagesElectrical Grounding, Earthing & Earthing System ExplainedMuhammed MekkiNo ratings yet

- Source Changeover SystemsDocument112 pagesSource Changeover SystemsLucianno NmNo ratings yet

- A Study To Assess The Knowledge of Antenatal Mothers Regarding Selected Minor Disorders Affecting PregnancyDocument4 pagesA Study To Assess The Knowledge of Antenatal Mothers Regarding Selected Minor Disorders Affecting PregnancyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Rele Micon Schneider Vamp-11F PDFDocument538 pagesRele Micon Schneider Vamp-11F PDFDivanil Marins100% (1)

- GTP For Panther ConductorDocument2 pagesGTP For Panther ConductorPritam SinghNo ratings yet

- Measuring Earth ResistanceDocument13 pagesMeasuring Earth Resistancemadhava_srinivasan174No ratings yet

- 373 - Offer For C.M.V. Marriage Hall - 45kVA - RKDocument6 pages373 - Offer For C.M.V. Marriage Hall - 45kVA - RKHarish S KiranNo ratings yet

- Technical Specification For Sandwiched BusductDocument12 pagesTechnical Specification For Sandwiched BusductJishnu M PillaiNo ratings yet

- Jsa-0002 - CCTV Pipe Inspection RapidDocument8 pagesJsa-0002 - CCTV Pipe Inspection RapidMohamad AfifNo ratings yet

- Abb Lightning Portection SystemDocument52 pagesAbb Lightning Portection SystemMuddassir NiazNo ratings yet

- Design Calculations of Lightning Protection Systems - Part SixDocument17 pagesDesign Calculations of Lightning Protection Systems - Part SixHansika RajapakshaNo ratings yet

- Swing and Deflection CalculationsDocument28 pagesSwing and Deflection CalculationsanandpurushothamanNo ratings yet

- EHV HV Cable Sheath EarthingDocument20 pagesEHV HV Cable Sheath EarthingSachinNo ratings yet

- 1500kVA-3 Phase LSA 50.2 L8 - 440V - 60HzDocument2 pages1500kVA-3 Phase LSA 50.2 L8 - 440V - 60HzsupermannonNo ratings yet

- Silver Rain Svetlana Perevalova PDFDocument9 pagesSilver Rain Svetlana Perevalova PDFAndrea Koumarian100% (1)

- Grounding & Earth ResistanceDocument11 pagesGrounding & Earth ResistanceDhammike100% (1)

- 2240 162 Pve U 004 SHT 3 3 01Document13 pages2240 162 Pve U 004 SHT 3 3 01Anagha DebNo ratings yet

- Earthing Calculation - Grid (Exm)Document33 pagesEarthing Calculation - Grid (Exm)balaeee123No ratings yet

- Earthing Calculation - V - 0.2Document18 pagesEarthing Calculation - V - 0.2Ravishankar.AzadNo ratings yet

- Swe-Spp-001-P-Dc-061 - DC String Cable Sizing - R3Document9 pagesSwe-Spp-001-P-Dc-061 - DC String Cable Sizing - R3Vishnu Kumar VyasNo ratings yet

- Substation Lightning Protection and Earthing PDFDocument8 pagesSubstation Lightning Protection and Earthing PDFPritam100% (1)

- IEEE CTs and PTs 6 10Document99 pagesIEEE CTs and PTs 6 10brianwg2100% (1)

- Power-Transformers-Installation-Manual (Torques)Document33 pagesPower-Transformers-Installation-Manual (Torques)Cesar Andrés Prada Vega100% (1)

- Gu 363Document45 pagesGu 363adriancovalciuc4863No ratings yet

- Protection Structure Against LightningDocument147 pagesProtection Structure Against LightningApichartj Jusuay100% (2)

- Lightning Protection Risk Management: Date: 4/12/2020 Project No.: 12/008Document15 pagesLightning Protection Risk Management: Date: 4/12/2020 Project No.: 12/008Tan Yu HennNo ratings yet

- Rolling Sphere MethodDocument17 pagesRolling Sphere Methodarieldimacali100% (1)

- Surge Protection Over Voltage DevicesDocument24 pagesSurge Protection Over Voltage Devicesnooruddinkhan1No ratings yet

- Plastering Techniques and MethodsDocument6 pagesPlastering Techniques and MethodsYazhisai SelviNo ratings yet

- Plastering Techniques and MethodsDocument6 pagesPlastering Techniques and MethodsYazhisai SelviNo ratings yet

- Main Components of Electrical Substation: Incoming LineDocument10 pagesMain Components of Electrical Substation: Incoming LineShiv Kumar Verma100% (1)

- P127 PDFDocument628 pagesP127 PDFmadhavan100% (1)

- Buku PUIL 2011 Edisi 2014Document3 pagesBuku PUIL 2011 Edisi 2014slamet_rNo ratings yet

- JE-2004 Building Risk Assessment Lightning Protection DesignDocument3 pagesJE-2004 Building Risk Assessment Lightning Protection Designblack_3289No ratings yet

- Lfaa en 0926Document8 pagesLfaa en 0926carlose_123No ratings yet

- Augmenting Lightning Protection at 110kV GIS SubstationDocument40 pagesAugmenting Lightning Protection at 110kV GIS SubstationGOKUL GNo ratings yet

- PCS-902 X Instruction Manual en Customized ECKF100721 R1.00 (En XLBH5102.0063.1101)Document251 pagesPCS-902 X Instruction Manual en Customized ECKF100721 R1.00 (En XLBH5102.0063.1101)TheaBinNo ratings yet

- Electrical HazardsDocument56 pagesElectrical HazardsZainorin AliNo ratings yet

- Advisory Boards 36A 37: Section 35Document48 pagesAdvisory Boards 36A 37: Section 35kittiey100% (6)

- Battery Room Design Review Checklist 2014Document3 pagesBattery Room Design Review Checklist 2014candratrikusuma100% (1)

- EasergyMiCOM BR NRJED116740EN 102018 PDFDocument24 pagesEasergyMiCOM BR NRJED116740EN 102018 PDFPushpendra Kumar SinghNo ratings yet

- 11kV Capacitor Technical SpecificationDocument35 pages11kV Capacitor Technical SpecificationJAY PARIKH100% (1)

- 7.0 Synchroscope ManualDocument3 pages7.0 Synchroscope ManualAyan MajiNo ratings yet

- Acsr Panther Conductor 10 PDFDocument14 pagesAcsr Panther Conductor 10 PDFSenthil ThanappanNo ratings yet

- Sepam 10 Seped307026en Int PDFDocument22 pagesSepam 10 Seped307026en Int PDFJeffrey Reynaldo RidwanNo ratings yet

- Determining Settings For Capacitor Bank Protection2columnDocument9 pagesDetermining Settings For Capacitor Bank Protection2columnvksharma13No ratings yet

- Review of Lighning ProtectionDocument4 pagesReview of Lighning ProtectionKarthik VNo ratings yet

- Area ClassificationDocument12 pagesArea ClassificationSandeep GuptaNo ratings yet

- General Specifications For Electrical Works - Part-Vi-Fire Alarm System 1988Document72 pagesGeneral Specifications For Electrical Works - Part-Vi-Fire Alarm System 1988Sabyasachi Naik (Zico)No ratings yet

- 7SJ66 Manual A7 Us PDFDocument658 pages7SJ66 Manual A7 Us PDFAnonymous PzbYdcEzNo ratings yet

- Switchgear Preventive MaintainanceDocument59 pagesSwitchgear Preventive MaintainancerkbcppNo ratings yet

- Caterpillar - Class of Insulation and Temprature Rise - Online CommunityDocument3 pagesCaterpillar - Class of Insulation and Temprature Rise - Online Communitylbk50No ratings yet

- PCS-985TE - X - Instruction Manual - EN - Overseas General - X - R1.00 PDFDocument380 pagesPCS-985TE - X - Instruction Manual - EN - Overseas General - X - R1.00 PDFjayofo8363No ratings yet

- Slip Ring Motor Liquid Resistor Soft Starting System (HV-LRS) PDFDocument4 pagesSlip Ring Motor Liquid Resistor Soft Starting System (HV-LRS) PDFLouie FernandezNo ratings yet

- R8005C MvawDocument20 pagesR8005C MvawRinda_RaynaNo ratings yet

- Distance Protection SchemeDocument8 pagesDistance Protection Schemesajjad ramezanzadehNo ratings yet

- Examples of Surge Protective Device SPD Applications in 230Document18 pagesExamples of Surge Protective Device SPD Applications in 230Gia BảoNo ratings yet

- Info Iec60038 (Ed6.2) en DDocument4 pagesInfo Iec60038 (Ed6.2) en DArief Muhammad LubisNo ratings yet

- Construction of The Protected Volume With Proper Application of Rolling Sphere MethodDocument5 pagesConstruction of The Protected Volume With Proper Application of Rolling Sphere MethodPLAKAR 2018100% (1)

- Procedure For First Charging Oh HT InstallationDocument7 pagesProcedure For First Charging Oh HT InstallationMadhu KrishnaNo ratings yet

- 2 LPS - Part 3 (Edited)Document35 pages2 LPS - Part 3 (Edited)Sky engineering consultancyNo ratings yet

- Lightning Protection TechnologyDocument48 pagesLightning Protection TechnologyNguyen Phu LocNo ratings yet

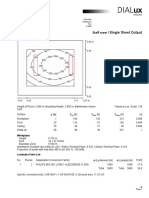

- NBCC-Staff Room - BF (Opt-1)Document1 pageNBCC-Staff Room - BF (Opt-1)Yazhisai SelviNo ratings yet

- Single Sheet Output: 3F-Doc ToiletDocument1 pageSingle Sheet Output: 3F-Doc ToiletYazhisai SelviNo ratings yet

- Single Sheet Output: BF-CorridorDocument1 pageSingle Sheet Output: BF-CorridorYazhisai SelviNo ratings yet

- NBCC-Staff Room - BF (Opt-2)Document1 pageNBCC-Staff Room - BF (Opt-2)Yazhisai SelviNo ratings yet

- Single Sheet Output: Corridor-GFDocument1 pageSingle Sheet Output: Corridor-GFYazhisai SelviNo ratings yet

- 09 Schedule B (Sola, Ahmedabad)Document223 pages09 Schedule B (Sola, Ahmedabad)Yazhisai SelviNo ratings yet

- WRD Sor 2021 - 2022Document60 pagesWRD Sor 2021 - 2022Yazhisai SelviNo ratings yet

- 16.04.2022 - Description of CSSDocument2 pages16.04.2022 - Description of CSSYazhisai SelviNo ratings yet

- 8 Catalogue - 2021 22Document152 pages8 Catalogue - 2021 22Yazhisai SelviNo ratings yet

- Tech Empower Ga Rev 00Document23 pagesTech Empower Ga Rev 00Yazhisai SelviNo ratings yet

- 9tech Spec 100 To 2500 KVA Dry Type Dist - Tranformer 1Document30 pages9tech Spec 100 To 2500 KVA Dry Type Dist - Tranformer 1Yazhisai SelviNo ratings yet

- City Side Station Building - First Floor PlanDocument1 pageCity Side Station Building - First Floor PlanYazhisai SelviNo ratings yet

- LDC LP No. 07 DTD 6th December 2021Document14 pagesLDC LP No. 07 DTD 6th December 2021Yazhisai SelviNo ratings yet

- 07 Schedule B (Gandhi Nagar, Ahmedabad) )Document215 pages07 Schedule B (Gandhi Nagar, Ahmedabad) )Yazhisai SelviNo ratings yet

- Acti9 SPD Catalog v1 enDocument76 pagesActi9 SPD Catalog v1 enYazhisai SelviNo ratings yet

- Sapthagiriyam Apartments SpecsDocument20 pagesSapthagiriyam Apartments SpecsYazhisai SelviNo ratings yet

- Sor 2021 2022 ApprovedDocument174 pagesSor 2021 2022 ApprovedRadhuGounderNo ratings yet

- Material Sibmittal For Fire Protection SystemDocument98 pagesMaterial Sibmittal For Fire Protection SystemYazhisai SelviNo ratings yet

- LDC LP No. 07 DTD 6th December 2021Document14 pagesLDC LP No. 07 DTD 6th December 2021Yazhisai SelviNo ratings yet

- Material Submittal For Compressed Air SystemDocument99 pagesMaterial Submittal For Compressed Air SystemYazhisai SelviNo ratings yet

- AP - HOBPAS CN - Author - UserManual - V 1.001Document93 pagesAP - HOBPAS CN - Author - UserManual - V 1.001Yazhisai SelviNo ratings yet

- Material Sibmittal For Fire Protection SystemDocument98 pagesMaterial Sibmittal For Fire Protection SystemYazhisai SelviNo ratings yet

- Cor 2Document113 pagesCor 2Yazhisai SelviNo ratings yet

- Submission of Material SubmittalDocument2 pagesSubmission of Material SubmittalYazhisai SelviNo ratings yet

- Hindustan Shipyard Limited:: Visakhapatnam - 530 005: (A Government of India Undertaking)Document26 pagesHindustan Shipyard Limited:: Visakhapatnam - 530 005: (A Government of India Undertaking)M MaheshNo ratings yet

- Material Submittal For Compressed Air SystemDocument99 pagesMaterial Submittal For Compressed Air SystemYazhisai SelviNo ratings yet

- Submission of Material SubmittalDocument2 pagesSubmission of Material SubmittalYazhisai SelviNo ratings yet

- Risk Assessment Report - Skka TempleDocument20 pagesRisk Assessment Report - Skka TempleYazhisai SelviNo ratings yet

- Dupont Heir Sexually Abuses DaughterDocument3 pagesDupont Heir Sexually Abuses DaughterJuandelaCruzNo ratings yet

- Surgical Technologist Resume SampleDocument2 pagesSurgical Technologist Resume Sampleresume7.com100% (3)

- Designing Resistance Training Programmes To Enhance Muscular Fitness A Review of The Acute Programme VariablesDocument12 pagesDesigning Resistance Training Programmes To Enhance Muscular Fitness A Review of The Acute Programme VariablesSheilani MartinsNo ratings yet

- Sarah Fahy CV College PDFDocument4 pagesSarah Fahy CV College PDFapi-487352339No ratings yet

- Plano Grupo ElectrogenoDocument2 pagesPlano Grupo Electrogenoluis alberto rodriguezNo ratings yet

- SorghumDocument13 pagesSorghumMohaajanan AliNo ratings yet

- Performance Evaluation of Sewage Treatment Plants (STPS) in Multistoried BuildingsDocument6 pagesPerformance Evaluation of Sewage Treatment Plants (STPS) in Multistoried BuildingsAnonymous iTzCnMNo ratings yet

- Name: Sport: Movement PrepDocument24 pagesName: Sport: Movement PrepS HNo ratings yet

- Bab 06 PindahPanasDocument41 pagesBab 06 PindahPanasPurna Satria NugrahaNo ratings yet

- Complementary Therapies in Clinical Practice: Effect of Aromatherapy On Post-Partum Complications: A Systematic ReviewDocument7 pagesComplementary Therapies in Clinical Practice: Effect of Aromatherapy On Post-Partum Complications: A Systematic ReviewAras PinantiNo ratings yet

- 3023 History Cuisine WorksheetDocument6 pages3023 History Cuisine WorksheetFlor HenríquezNo ratings yet

- Uganda National Urban ProfileDocument74 pagesUganda National Urban ProfileUnited Nations Human Settlements Programme (UN-HABITAT)No ratings yet

- What Is A PronounDocument9 pagesWhat Is A PronounFanera JefferyNo ratings yet

- ZinkPower Batam - Company BrochureDocument6 pagesZinkPower Batam - Company BrochureansarALLAAHNo ratings yet

- NFPA 97 - 2003 Standard Glossary of Terms Relating To Chimneys, Vents, and Heat-Producing AppliancesDocument34 pagesNFPA 97 - 2003 Standard Glossary of Terms Relating To Chimneys, Vents, and Heat-Producing Appliancesonepunchman yaoNo ratings yet

- Personal LetterDocument4 pagesPersonal LetterAskme AzmyNo ratings yet

- Subway 2009Document12 pagesSubway 2009sparklers_mNo ratings yet

- Low Noise Pseudomorphic HEMT Technical DataDocument4 pagesLow Noise Pseudomorphic HEMT Technical Datahendpraz88No ratings yet

- "Fish" From Gourmet RhapsodyDocument4 pages"Fish" From Gourmet RhapsodySean MattioNo ratings yet

- Benign EntitiesDocument37 pagesBenign EntitiesleartaNo ratings yet

- 14 People V Manalo (Verba Legis)Document15 pages14 People V Manalo (Verba Legis)zeynNo ratings yet

- The Electrooculogram (EOG)Document34 pagesThe Electrooculogram (EOG)Prasidha PrabhuNo ratings yet

- Jear C PB 2018 PDFDocument174 pagesJear C PB 2018 PDFArasu RajendranNo ratings yet

- Humic Substances As Electron Acceptor For Microbial RespirationDocument4 pagesHumic Substances As Electron Acceptor For Microbial RespirationNed FlandersNo ratings yet