Professional Documents

Culture Documents

Brochure Claas 890-492 Buyers Guide

Uploaded by

husan shahCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Brochure Claas 890-492 Buyers Guide

Uploaded by

husan shahCopyright:

Available Formats

Buyer’s guide: Type 492 Claas Jaguar 890

If you are looking to take silage-making back in-house, then a secondhand self-propelled

forager looks an attractive buy. Though there could be some high running costs attached.

Matt Temple-Fry of Claas Western guides Geoff Ashcroft around a popular type 492 Claas

Jaguar 890.

In 14 years of production over 10,000 type 492 Jaguars were sold worldwide.

Claas’ type 492 self-propelled forager series was first introduced in 2000 and ran up until

2014. In that time, the German maker supplied over 10,000 models to a worldwide market,

making it one of the firm’s most popular types.

Changes were minimal throughout its lifecycle, with the firm’s proven four-feed roller

intake, Classic-spec chopping cylinder and crop accelerator remaining largely unchanged

across the range. More automation and convenience was added to the options list on later

models.

www.globalequipmentllc.us - 3764 US 75 Ave. Sioux Center | Iowa 51250 | USA

Jaguar 890 Specifications

Model: Claas Jaguar 890, type 492

Engine: Mercedes V8 twin turbo

Maximum power: 507hp @ 1,800rpm

Maximum torque: 762Nm @ 1,500rpm

Transmissions: SpeedStar 40kph two-range hydrostatic

Chopping cylinder: Classic drum, 20 or 24-knife

Crop intake: Four feed rollers, mechanical drive to top pair

There were five models, badged 830, 850, 870, 890 and 900. Six-cylinder engines featured

in the 830 to 870 models, with 870 (from 2006), 890 and 900 models getting V8 power.

Peak power spanned 345hp to 623hp across the range.

In 2005, the rear-end gained rounded styling and better airflow through the engine bay,

and Claas introduced the SpeedStar 40kph transmission above the 30kph ProfiStar spec.

‘Green eye’ models saw a change of joystick controller.

Despite their attractive purchase price as a secondhand buy, you can be sure a used self-

propelled forager will have been worked hard, so go in with your eyes wide open. Be

prepared to budget for hefty running costs.

Crop Intake

Crop presentation is essential if performance, productivity and consistent chop length are

to be maintained, says Claas.

With the header removed, take a good look at the four feed rollers. The top pair is driven

by a gearbox, which is shaft driven over the top of the upper rollers, from the left-hand

side. Give the shaft and yoke a good tug to feel for free play in the input shaft.

www.globalequipmentllc.us - 3764 US 75 Ave. Sioux Center | Iowa 51250 | USA

Bearings in the gearbox can

wear, as can the seals letting

oil out. A semi-fluid grease was

a common replacement for oil,

so check for content. A series

of springs provide crop

compression, along with a

damper - if the latter has lost

its mojo, the gearbox can

bounce, and springs break. Check feed roller condition; the smooth roller’s scraper can

wear away causing grass to build up and impede crop flow. If any of the rollers need

attention, be warned, says Mr Temple-Fry, the lower front roller contains the metal

detector, so avoid welding anywhere in here without taking advice on magnetism.

Knife sharpening and metal detection

Where later 494 models gained swing-out

feed rollers to access the chopping cylinder,

type 492 models used a bolt-clamp

mechanism. It is possible to detach the

feed rollers with the header, for simple

removal. Once removed, check chopping

cylinder drum bearings for end-float and

movement. You will need a big pry bar, and

inspect blades too for damage and excess

wear. Steel grease pipes for the autolube

system can also crack which means less

lube where it is needed.

Inspect the shearbar too, and the amount of material left on the sharpening stone. The

stone should be replaced when its rubber retaining rings are visible. This model features

optional auto-shear bar setting, allowing adjustments to be done from the cab - though

knives have to be sharpened before the shearbar can be auto-adjusted.

www.globalequipmentllc.us - 3764 US 75 Ave. Sioux Center | Iowa 51250 | USA

Cab

A tough cab interior can easily hide the Jaguar’s

overall condition and hours done. Other than

checking all the controls, there is little to worry

about in the cab, but it is worth checking the air

conditioning works properly - all that glass

means you will be sat in a mobile greenhouse

when it goes wrong.

Claas’ information system offers a host of

machine information and is where you will find

engine hours and drum hours.

Crop Flow

Check all aspects of the crop channel including

chopping cylinder concave, grass box and

accelerator. Removing the grass box lets you slot

in the corn cracker for maize or whole crop. Later

models used a modular corn cracker with bolt-on

pulleys, simplifying changes for different forage

and cracking performance.

An access panel also lets you assess accelerator

paddle condition and internal wear plates. All are

replaceable. Look for smooth surfaces - any

rippling to wear plates will cause crop to stumble

and roll, impacting crop flow. An external spout liner is bolted in place. Other pieces are

bolted internally. There is no liner on the hydraulically adjustable end flap, though it can

be plated when it wears through. Check the base of the spout for wear - excess movement

can be taken up with shims.

www.globalequipmentllc.us - 3764 US 75 Ave. Sioux Center | Iowa 51250 | USA

Powertrain and hydraulics

Mercedes V8 power

in this 890 model

uses two

turbochargers,

which should be

inspected for

excessive wear on

high hour machines.

Keeping the engine

bay clean is key to

prevent hot spots or a fire. The shaft-driven engine cooling fan has a 90-degree gearbox - if

it loses its oil and fails, it will be costly.

The main power drive belt runs forward along the left-hand side of the forager. It is

tensioned mechanically, so inspect the belt for signs of pending failure. It is also where you

will find most electro-hydraulic control valves. Check pipes, hoses and wires for chaffing

and general condition, to avoid a costly repair.

If four-wheel drive is fitted, make sure it is complete and operational - diff failure is not

uncommon, so take a look at diff oil and planetary hub oil levels too. There is a chance that

parts might have been removed completely, awaiting a later repair, so work can continue -

albeit in two-wheel drive.

www.globalequipmentllc.us - 3764 US 75 Ave. Sioux Center | Iowa 51250 | USA

You might also like

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorFrom EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNo ratings yet

- Ford Tractor Conversions: The Story of County, DOE, Chaseside, Northrop, Muir-Hill, Matbro & BrayFrom EverandFord Tractor Conversions: The Story of County, DOE, Chaseside, Northrop, Muir-Hill, Matbro & BrayNo ratings yet

- Sugar Cane Blade TypeDocument11 pagesSugar Cane Blade TypeselvenNo ratings yet

- CWS Forestry Power GrappleDocument2 pagesCWS Forestry Power GrappleCWS Industries0% (1)

- Dolmar 116si 120si ServiceDocument20 pagesDolmar 116si 120si ServiceslickattitudewiNo ratings yet

- Axial Piston Variable Pump A10V (S) O Series 31 AmericasDocument56 pagesAxial Piston Variable Pump A10V (S) O Series 31 AmericasFawzi AlzubairyNo ratings yet

- Problem Solution ManualsDocument12 pagesProblem Solution ManualsYOsefBeLOved0% (1)

- Nordic Tractor, The: The History and Heritage of Volvo, Valmet and ValtraFrom EverandNordic Tractor, The: The History and Heritage of Volvo, Valmet and ValtraNo ratings yet

- Quality Transmission Gears and Components from WATO KoreaDocument28 pagesQuality Transmission Gears and Components from WATO KoreaЕкатерина Калашникова100% (1)

- Radial Drill Safety GuideDocument86 pagesRadial Drill Safety GuideAnonymous HPlNDhM6ejNo ratings yet

- John Deere 3036EN Tractor Commercial Test ReportDocument30 pagesJohn Deere 3036EN Tractor Commercial Test ReportChoudhary Vikrant GurjarNo ratings yet

- Kat TT 2021 Zde180000041en 0921Document196 pagesKat TT 2021 Zde180000041en 0921Piotr ZiąbkowskiNo ratings yet

- LEXION After Sales PartsDocument48 pagesLEXION After Sales Parts孙维华100% (1)

- 4600 Series Operator S ManualDocument82 pages4600 Series Operator S ManualtangocharliepdxNo ratings yet

- Water Radiator - Spare PartsDocument32 pagesWater Radiator - Spare Partsnivaman03No ratings yet

- ZF OilsDocument21 pagesZF OilschrideerNo ratings yet

- AG150 250 Part 3Document6 pagesAG150 250 Part 3aritmeticsNo ratings yet

- Catalogo SKF PDFDocument438 pagesCatalogo SKF PDFJoseCorreaNo ratings yet

- JS 2013-02Document8 pagesJS 2013-02jandsproductsNo ratings yet

- Tractors Prices 2Document3 pagesTractors Prices 2arie_sppNo ratings yet

- Swaraj 855 Fe Xtra Tractor - T - 852-1362-2012Document12 pagesSwaraj 855 Fe Xtra Tractor - T - 852-1362-2012Surajit SarkarNo ratings yet

- Claas Tucano 480 470Document57 pagesClaas Tucano 480 470Zsolt Szabadi100% (2)

- Chinese Diesel Heater Workshop InstallDocument47 pagesChinese Diesel Heater Workshop InstallamacmanNo ratings yet

- 3975 Mint Chopper Paerts ManualDocument252 pages3975 Mint Chopper Paerts ManualRayNo ratings yet

- Allis-Chalmers Manufacturing Company Bulletin 1403Document16 pagesAllis-Chalmers Manufacturing Company Bulletin 1403Mr Thane100% (1)

- Dual Range 7 & 8 Speed Transmission - Gears & Related Parts - 5600, 6600, 7600, 5700, 6700, 7700Document8 pagesDual Range 7 & 8 Speed Transmission - Gears & Related Parts - 5600, 6600, 7600, 5700, 6700, 7700Cristian Ivan Grageda YocupicioNo ratings yet

- Mercedes Gearbox Catalogue PDFDocument6 pagesMercedes Gearbox Catalogue PDFcommorilNo ratings yet

- Brochure Tractor Case PDFDocument24 pagesBrochure Tractor Case PDFhmayda riadNo ratings yet

- Front Axle, Steering and Related Components: Sparex Replacement Spare Parts For Ford/New Holland (65 - )Document39 pagesFront Axle, Steering and Related Components: Sparex Replacement Spare Parts For Ford/New Holland (65 - )Selmirije2100% (1)

- Carraro 711-19 Axle Workshop ManualDocument0 pagesCarraro 711-19 Axle Workshop ManualSelmirije2100% (1)

- Engine Serial Number Plate: Specialty Engine Catalog For Sugar Cane Harvester (6081Ht801/Ht802)Document103 pagesEngine Serial Number Plate: Specialty Engine Catalog For Sugar Cane Harvester (6081Ht801/Ht802)marioNo ratings yet

- Pinto+doc Med+res PDFDocument20 pagesPinto+doc Med+res PDFfarish100% (1)

- G9wvkov4 Volvo AtfDocument6 pagesG9wvkov4 Volvo AtfRikrdoNo ratings yet

- User Guide: Connect GuardDraw to DatabaseDocument90 pagesUser Guide: Connect GuardDraw to DatabaseRuben CuevasNo ratings yet

- Hose Truck IntercoolerDocument25 pagesHose Truck IntercoolerCassie ZengNo ratings yet

- T25 2013 Catalogue 75dpi PDFDocument68 pagesT25 2013 Catalogue 75dpi PDFsinyoprimaNo ratings yet

- AE200 PartsDocument18 pagesAE200 PartsgggNo ratings yet

- Agopsm7131 m7151 m717101Document298 pagesAgopsm7131 m7151 m717101Alejandro Rodríguez GalvisNo ratings yet

- IMANTEΣ 6100-6900 serieDocument1 pageIMANTEΣ 6100-6900 serieinfo7879No ratings yet

- Kubota U10-3 HandleidingDocument132 pagesKubota U10-3 HandleidingPieter LecluyseNo ratings yet

- Professional Tool Set in Aluminum Case, 149 PCS.: Item # 15501Document10 pagesProfessional Tool Set in Aluminum Case, 149 PCS.: Item # 15501HERRAPRONo ratings yet

- Fiat&Ford&New HollandDocument193 pagesFiat&Ford&New Hollandsumit shresthaNo ratings yet

- Tractors SameDocument82 pagesTractors Sameomni_parts100% (1)

- 760 Turbo Road Test 1985Document3 pages760 Turbo Road Test 1985jbouzaNo ratings yet

- TP9238 Meritor® Driver-ControlledDocument6 pagesTP9238 Meritor® Driver-ControlledLeoNo ratings yet

- Agri FarmDocument26 pagesAgri FarmPercy Ramon Salazar SullcaNo ratings yet

- Mead Speedcat Newspaper AdDocument2 pagesMead Speedcat Newspaper Adkwayneolson6081100% (1)

- Operators Manual 500 SeriesDocument36 pagesOperators Manual 500 SeriesAutochthon GazetteNo ratings yet

- Spicer DanaDocument252 pagesSpicer DanaAndrew Hollady100% (1)

- Gates BeltsDocument448 pagesGates BeltsArgoparts100% (1)

- How To Tachofy Your MK 1 DieselDocument24 pagesHow To Tachofy Your MK 1 DieselheartofdixieNo ratings yet

- Cylinder Boring Machine ManualDocument8 pagesCylinder Boring Machine ManualJoseDavidSanchezYepesNo ratings yet

- Diesel Engines Fire Faghting Mark EvensDocument47 pagesDiesel Engines Fire Faghting Mark Evensblacx_rzkyNo ratings yet

- Dynapac CA-250-Workshop Electrico PDFDocument19 pagesDynapac CA-250-Workshop Electrico PDFedhuam100% (3)

- Tandem Asphalt RollersDocument12 pagesTandem Asphalt Rollershusan shahNo ratings yet

- New Hollamd f1c Rear Work Lights SchematicDocument1 pageNew Hollamd f1c Rear Work Lights Schematichusan shahNo ratings yet

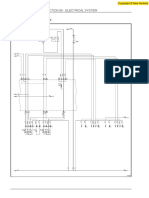

- 2.5 Electric System: F2 F1 S1 N1 PT1 PT2 PT4 LT1 C1 G1 G2Document2 pages2.5 Electric System: F2 F1 S1 N1 PT1 PT2 PT4 LT1 C1 G1 G2husan shahNo ratings yet

- Deutz EMR Panel Installation & InstructionsDocument24 pagesDeutz EMR Panel Installation & InstructionsJorge CorralesNo ratings yet

- Cat Electronic Technician 2019A v1.0 Product Status ReportDocument4 pagesCat Electronic Technician 2019A v1.0 Product Status Reporthusan shahNo ratings yet

- DSE7320 Installation Instructions PDFDocument2 pagesDSE7320 Installation Instructions PDFRafael Fernando100% (1)

- Newholland FeilkoderDocument19 pagesNewholland Feilkoderaliosha2k89% (9)

- 5-1 Technical DatasheetDocument10 pages5-1 Technical DatasheetJegadeshwaran RNo ratings yet

- t8. Fault CodesDocument33 pagest8. Fault CodesjuanNo ratings yet

- PV77620184635 MID128 Faultcode Guide 2007 Emissions VNVHD2 VTDocument54 pagesPV77620184635 MID128 Faultcode Guide 2007 Emissions VNVHD2 VTFA Ubc100% (4)

- Transmision HTE Volvo L120EDocument8 pagesTransmision HTE Volvo L120ECHARLES HUMBERTO100% (5)

- Error Tree IVECODocument118 pagesError Tree IVECOHHEF400187% (71)

- Hydraulic System Chapter 1 GuideDocument14 pagesHydraulic System Chapter 1 Guidehusan shahNo ratings yet

- d65-15 Errors PDFDocument5 pagesd65-15 Errors PDFjacklyn ade putra100% (1)

- 2010-07-25 113120 416-438 Series II Elec PDFDocument2 pages2010-07-25 113120 416-438 Series II Elec PDFmasakpNo ratings yet

- Flash Cable For Lcr/Lcr-Ii Cpu BoardDocument1 pageFlash Cable For Lcr/Lcr-Ii Cpu Boardhusan shahNo ratings yet

- d65-15 Errors PDFDocument5 pagesd65-15 Errors PDFjacklyn ade putra100% (1)

- Cat Electronic Technician 2019A v1.0 Product Status ReportDocument4 pagesCat Electronic Technician 2019A v1.0 Product Status Reporthusan shahNo ratings yet

- Caterpillar Fault Codes PDFDocument21 pagesCaterpillar Fault Codes PDFElhadi Enp84% (56)

- T5000 ManualDocument4 pagesT5000 Manualhusan shahNo ratings yet

- Manual Himoinsa Cem7 Control AdvancedDocument105 pagesManual Himoinsa Cem7 Control Advancedmss00667% (6)

- Troubleshooting 966H WL POWERTRAINDocument12 pagesTroubleshooting 966H WL POWERTRAINAhmet100% (1)

- Crane Market Courtesy DocumentDocument20 pagesCrane Market Courtesy Documenthusan shahNo ratings yet

- 82329Document26 pages82329Henry OviedoNo ratings yet

- Komtrax Terms of UseDocument10 pagesKomtrax Terms of Usehusan shahNo ratings yet

- Electronic Ticket Receipt, September 05 For MRS FAHMIDA BEGUMDocument3 pagesElectronic Ticket Receipt, September 05 For MRS FAHMIDA BEGUMhusan shahNo ratings yet

- Caterpillar Fault Codes PDFDocument21 pagesCaterpillar Fault Codes PDFElhadi Enp84% (56)

- EM100-11 - (LCRII Setup & Operation) - 0Document31 pagesEM100-11 - (LCRII Setup & Operation) - 0husan shahNo ratings yet

- Gears RE5R05A PDFDocument8 pagesGears RE5R05A PDFossoskiNo ratings yet

- Mopar Accessories Jeep RamDocument38 pagesMopar Accessories Jeep RamlinseysabrinaNo ratings yet

- Sensors and Electrical Connectors: TroubleshootingDocument7 pagesSensors and Electrical Connectors: TroubleshootingManuel Ruiz CayunNo ratings yet

- Bus Safety ChecklistDocument2 pagesBus Safety ChecklistMohamed Kasim Mohamed Ibrahim0% (1)

- Treadmill BicycleDocument4 pagesTreadmill BicycleAnonymous kw8Yrp0R5rNo ratings yet

- MFI Control System 2 (HYUNDAI 1.6 DOHC)Document2 pagesMFI Control System 2 (HYUNDAI 1.6 DOHC)Jesús GINo ratings yet

- SSP 414 4MOTION With Four-Wheel Drive Coupling Generation IVDocument28 pagesSSP 414 4MOTION With Four-Wheel Drive Coupling Generation IVfrancois.garcia31100% (1)

- 2016 Toyota Hilux DPL en PDFDocument48 pages2016 Toyota Hilux DPL en PDFNguyễn Kim TùngNo ratings yet

- Locomotive - IntroductionDocument13 pagesLocomotive - IntroductionArpan MaheshwariNo ratings yet

- Deac13uk10mm Uk Thermal Ac-Compressor Leaflet WebDocument2 pagesDeac13uk10mm Uk Thermal Ac-Compressor Leaflet Webcatur yulianaNo ratings yet

- 1948 56 Truck Parts CatalogDocument139 pages1948 56 Truck Parts CatalogBrian-Marti Boatright100% (1)

- Engine Data Sheet: CFP83-F10, F20, F30 2218 G Drive 26110 Cummins Fire Power FR - 90242, 90243Document6 pagesEngine Data Sheet: CFP83-F10, F20, F30 2218 G Drive 26110 Cummins Fire Power FR - 90242, 90243Reynaldo MarianoNo ratings yet

- Modern Marine Internal Combustion Engines A Technical and Historical Overview 1st Ed 9783030497484 9783030497491 CompressDocument395 pagesModern Marine Internal Combustion Engines A Technical and Historical Overview 1st Ed 9783030497484 9783030497491 Compressilliashapshalov38No ratings yet

- Elise Trouble CodesDocument3 pagesElise Trouble Codesrigg61No ratings yet

- Nissan 240SXDocument7 pagesNissan 240SXPreetiNo ratings yet

- Jordan Driving School Practice TestDocument13 pagesJordan Driving School Practice TestJumana KamelNo ratings yet

- Emissions 17th EditionDocument204 pagesEmissions 17th EditionCarlos TorreNo ratings yet

- A6-Headlight Adjustment ProcedureDocument5 pagesA6-Headlight Adjustment ProcedureChris WilkieNo ratings yet

- Tansmisii CVT Pentru TractoareDocument35 pagesTansmisii CVT Pentru TractoareCochintu RaduNo ratings yet

- Teaching Aids Torque Converter - ModuleDocument16 pagesTeaching Aids Torque Converter - ModuleMohd HaikalNo ratings yet

- Agricultural Tractors Types and SelectionDocument10 pagesAgricultural Tractors Types and SelectionSunil DhankharNo ratings yet

- Industrial Diesel Generator Set: Standby Power RatingDocument6 pagesIndustrial Diesel Generator Set: Standby Power RatingDheeraj YadavNo ratings yet

- PWC Parts & Accessories CatalogDocument250 pagesPWC Parts & Accessories CatalogFernando CentenoNo ratings yet

- Motor Tracker Peugeot - 8-Valve Engine Description PDFDocument23 pagesMotor Tracker Peugeot - 8-Valve Engine Description PDFKISKACNo ratings yet

- Tata MotorsDocument15 pagesTata MotorsRosismita KashyapNo ratings yet

- JCB Parts CatalogueDocument629 pagesJCB Parts CatalogueRajan Mullappilly92% (26)

- Condor Body Installation ManualDocument154 pagesCondor Body Installation ManualProfessional TrustNo ratings yet

- Part Catalogue Yamaha YZF R25 2020 B4P1 MALAYSIADocument69 pagesPart Catalogue Yamaha YZF R25 2020 B4P1 MALAYSIAmhz myNo ratings yet

- Double Coin OTR Data BookDocument16 pagesDouble Coin OTR Data BookCrimzon18No ratings yet

- Benelli TNT 1130 - Service Manual - EN PDFDocument392 pagesBenelli TNT 1130 - Service Manual - EN PDFAlejandro Jose Malave Ramos100% (2)