Professional Documents

Culture Documents

Construction Materials and Testing Reviewer

Uploaded by

Erika TolentinoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Construction Materials and Testing Reviewer

Uploaded by

Erika TolentinoCopyright:

Available Formats

Highlight Colors

CMT REVIEWER Yellow- terms

Green- formulas

Soil- is a commonly used construction materials like cement, steel wood or concrete.

Red- notes

MAJOR DIVISION OF SOIL

Coarse Grained Soil- granular are those whose particle are visible.

Fine Grained Soil- particles are not visible to naked eye.

Organic Soil- those which contains amount of decayed plants and animals matter.

IDENTIFICATION OF SOILS BY VISUAL AND TEXTURE

Gravel- rounded and water loose

Sand- gritty and loose

Silt- fine and bravely visible

Clay- cohesive when wet

Organic Soil- gray to black in color

GROUPING OF SOILS ACCORDING TO PARTICLE SIZE

Clay- 0.001mm to 0.005mm

Silt- 0.005mm to 0.05mm > 0.074mm

Sand- 0.05mm > 0.074mm to 2.00mm

Gravel- 2.00mm to 76.2mm (3”)

Cobbles- 76.2mm to 203mm (8”)

Boulders- above 203mm

Colloids- smaller than 0.001mm

Sieve Analysis Test- it is consist of shaking the soil sample through the set of sieves.

Sieve- are made up of wire mesh with square openings.

Coarser Sieve- 3” to 1/4” (75mm to 6.3mm)

Finer Sieve- designated from their number of openings.

Sieve Analysis- for particles larger than 0.074mm in diameter.

Hydrometer Analysis- for particle size smaller than 0.074mm in diameter.

SIEVE SIZES

COARSE AGGREGATES FINE AGGREGATES

INCHES MM INCHES MM

3 75 #4 4.75

2½ 63 #8 2.36

2 50 #10 2.00

1½ 37.5 #16 1.18

1 25 #30 0.600

¾ 19 #40 0.425

½ 12.5 #50 0.300

3/8 9.5 #60 0.250

1/4 6.30 #100 0.150

#200 0.075

Consistency- most important index properties of finding soils in the natural state, it refers to the degree of adhesion

between soil particles

Liquid Limit (L.L) - the minimum H2O content at which soils is at liquid consistency.

Plastic Limit (P.L)- plastic state to semi solid state

Liquidity Index (L.I)-

Plastic Index (P.I)- larger P.I indicates a soil of very low permeability

Shrinkage Limit (S.L)- semi solid to solid state, smallest H2O content

Shrinkage Index (S.I)- indicate the amount of S.I= P.L-S.L reduction volume of S.I indicates a high volume change

TWO METHOD OF DECLINING THE GROUP INDEX

A. USED OF THE GI CHART

GI- sum the vertical readings on a vertical scale of chart I and II

Chart I- relation between P.I and the percentage passing the #200 sieve.

Chart II- relation between L.L and the percentage passing the #200 sieve.

FORMULA: P.I= L.L-P.L

B. USING EMPERICAL FORMULA

FORMULA: GI= 0.2(a) + 0.005ac + 0.01bd

a. Portion percentage passing #200 > 35 but not exceeding 75 (0 to 40)

b. Percentage passing from #200 > 15 but not exceeding 55 (0 to 40)

c. L.L > 40 > 60 (0.20)

d. P.I > 10 > 30 (0 to 20)

PROCEDURE IN USING THE SOIL CLASSIFICATION TABLE (AASHTO SOIL CLASSIFICATION SYSTEM)

a. Percentage passing through #200 – General Classification

b. Percentage passing through #200 – Group Classification

c. L.L -

d. P.I -

e. G.I – Group Index

Soil Classification Format: usual types of significant constituent materials, G.I (G.I Amount), General rating

Note: for A-7-5 P.I ≤ L.L – 30

for A-7-6 P.I > L.L – 30

CONCRETE TECHNOLOGY

1. Plain Concrete- without reinforcement

2. Reinforce Concrete- with reinforcement

2 KINDS OF CONCRETE MIXTURE

1. Designed Mix- contractor desired

2. Prescribed Mix- engineer responsible

COMPONENTS OF CONCRETE

1. Cement- 7-8%

2. Water (H2O) - 15-20%

3. Aggregates- 66-78%

DIFFERENT TYPES OF CEMENT

1. Ordinary Portland cement

2. Rapid Hardening Portland cement- high strength

3. Blast Furnace or Sulphate cement- use for structure to resist chemical attack

4. Low heat Portland cement- use to reduce heat

5. Portland Pozzolana cement- cheaper not strong

6. High Alumina cement- rapid hardening early, high strength it can withstand than temperature

MAIN COMPOSITION OF CEMENT

1. Sulfur Trioxide- 1-5%

2. Lime- 60-65%

3. Silica- 18-25%

4. Iron Oxide- 4-5%

5. Alumina- 2.5%

6. Magnesia- 3.8%

QUALITY OF AGGREGATES

a. CA- composed of crushed stone gravel with particles retained on a 5mm sieve (#4)

b. FA- crushed stone or natural sand passing #4 sieve dividing lime between gravel and sand.

Quality and Quantity of H2O- free from impurities

Curing Condition- 72 hours minimum of 5 days, 2 days extension, 14 days light vehicles, 21-28 days heavy vehicles

Age- the strength of concrete increase with age

Time of Mixing-

Failure to follow specifications-

Construction Method are not consistent-

Lack of steel reinforcement-

PHYSICAL PROPERTIES OF CONCRETE

Workability- freshly mix concrete mix can be moved without segregation into final position

Degree of Workability- depends on the type of construction.

Strength-

Durability- withstand deformation due to weathering action

Impermeability- does not allow the passage of sewage of water, essential requirements to concrete

Economy- the concrete should be economically produce

CONCRETE PROPORTION AND CONCRETE MIXURE RATIO AND STRENGTH

CLASS RATIO STRENGTH

AA 1:2.5:3 4000 psi

A 1:2:4 3500 psi

B 1:2.5:5 2500 psi

C 1:3:6 2000 psi

RECOMMENDED RANGES OF SLUMP

MAX SIZE OF

TYPES OF CONSTRUCTION MAX. MIN. COARSE

AGGREGATES

1. Slab beams, reinforce walls 150(6) 45(3) 1”

2. Building columns 150(6) 75(3) 1”

3. Reinforced foundation wall

125(5) 50(2) 1 ½”

and footing

4. Plain footings, caissons and

100(4) 25(1) 2”

structure wall

5. Pavements 75(3) 50(2) 2”

6. Heavy mass construction 75(3) 25(1) 3”-6”

FORMULA: FINE AGGREGATES

wt .∈air of saturated surface dry −wt .∈air of oven dried sample

Absorbtion=

wt .∈air of oven dried sample

B− A

Absorbtion= × 100

A

wt .∈air of SSD Sample

Specific Gravity=

( wt .∈air of ssd sample ) + ( wt .∈air of pynometer + H 2O )− ( pynometer + H 2 O+ sample )

B

SG ( Bulk , SSD ) =

B−C

CLASSES AND USES OF CONCRETE

CLASS A

Superstructure and heavy reinforced structures for:

Slabs

Beams

Girders

Columns

Ribs box

Culverts

Reinforced abutment

Retaining walls

Reinforced footings

Precast piles

Cribbing

CLASS B

Footings

Pedestrals

Massive pod shafts

Pop bedding and gravity walls

Unreinforced or with only small amount of reinforcement

CLASS C

The reinforced sections

Railings

Fillers in grid floor

CLASS D

Pre-stress concrete structure and members.

Seal- concrete deposit in H2O

MAX H2O CEMENT CONSISTENCY RANGE

CLASS

RATIO (KG/KG) IN SLUMP MM(IN)

A 0.53 50-100 (2-4)

B 0.58 50-100 (2-4)

C 0.55 50-100 (2-4)

D 0.49 100 max (4)

Seal 0.58 100-200 (4-8)

You might also like

- ACI Method of Concrete Mix DesignDocument7 pagesACI Method of Concrete Mix DesignMuhammad Ave SenaNo ratings yet

- Civil Engineers GuideDocument46 pagesCivil Engineers GuideSrinivasan Reddy88% (17)

- Farmhouse Dog Bowl Stand: RB NADocument5 pagesFarmhouse Dog Bowl Stand: RB NAO'Neil JonesNo ratings yet

- ACI Method of Concrete Mix Design-C211Document6 pagesACI Method of Concrete Mix Design-C211ah ay100% (2)

- DEsign, Cons and Maintenance RP) PDFDocument215 pagesDEsign, Cons and Maintenance RP) PDFShiba Shankar Satapathy100% (1)

- Construction and Quality Control For Concrete Structures by D.v.bhavanna RaoDocument150 pagesConstruction and Quality Control For Concrete Structures by D.v.bhavanna Raoapncrmptpqa100% (2)

- Asphalt Concrete Ingredient, Design, Production and LayingDocument17 pagesAsphalt Concrete Ingredient, Design, Production and LayingKali Bahadur ShahiNo ratings yet

- Concrete NotesDocument37 pagesConcrete Notesကိုနေဝင်းNo ratings yet

- Concrete Practice B&FDocument259 pagesConcrete Practice B&Fvijay100% (1)

- Table A1.6.3.1 - Recommended Slumps For Various Types of Construction (SI) Slump, MM Types of ConstructionDocument6 pagesTable A1.6.3.1 - Recommended Slumps For Various Types of Construction (SI) Slump, MM Types of Constructiongreat_triskelionNo ratings yet

- Concrete LabDocument97 pagesConcrete LabSiva NatNo ratings yet

- Porus Asphalt DetailsDocument11 pagesPorus Asphalt DetailsPrasad NbNo ratings yet

- Concrete Mix SpecsDocument5 pagesConcrete Mix SpecsKent XyrellNo ratings yet

- Acids and Alkalis WorksheetsDocument42 pagesAcids and Alkalis WorksheetsAFuentesCaballero100% (1)

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Dep 30.48.40.31-Gen-Feb-2019 Thermally Sprayed Aluminium CoatingsDocument21 pagesDep 30.48.40.31-Gen-Feb-2019 Thermally Sprayed Aluminium CoatingsDevam RajNo ratings yet

- Shaban Booklet 19-11-2016 - 162 Pages NewDocument162 pagesShaban Booklet 19-11-2016 - 162 Pages NewMahmood DlzarNo ratings yet

- Experiment N0. 09 Preparing A Concrete Mix and Casting Various Samples Required For Different TestsDocument5 pagesExperiment N0. 09 Preparing A Concrete Mix and Casting Various Samples Required For Different TestsAli HaiderNo ratings yet

- CONCRETEDocument13 pagesCONCRETEbereket gNo ratings yet

- Day OneDocument141 pagesDay OneChina AlemayehouNo ratings yet

- Mix Design 8 2Document6 pagesMix Design 8 2Eulogio JameroNo ratings yet

- ACI Mix-Design-8-2Document6 pagesACI Mix-Design-8-2Aboalmaail AlaminNo ratings yet

- Lecture 1 - Aggregates by MjcmonderondoDocument55 pagesLecture 1 - Aggregates by Mjcmonderondoisidro ylananNo ratings yet

- Spring 2018/2019 Homework # 2Document5 pagesSpring 2018/2019 Homework # 2Abdallah AlhasanNo ratings yet

- AgreggatesDocument33 pagesAgreggateszinaNo ratings yet

- Concrete Pavement-MoRTH MoRD 14.02.19Document47 pagesConcrete Pavement-MoRTH MoRD 14.02.19ShivajiNo ratings yet

- Hot Dip Galvanizing and Corrosion Categories: Rev 4 October 2017Document3 pagesHot Dip Galvanizing and Corrosion Categories: Rev 4 October 2017Gaurav SharmaNo ratings yet

- AggregatesDocument48 pagesAggregatesMuhammad HamadNo ratings yet

- Basic SpecificationDocument5 pagesBasic SpecificationArunpandiyanNo ratings yet

- Aci Method of Proportioning Concrete Mixes: Step 1. Choice of SlumpDocument6 pagesAci Method of Proportioning Concrete Mixes: Step 1. Choice of SlumpEulogio JameroNo ratings yet

- Day 2 S2 BNBC 2020Document38 pagesDay 2 S2 BNBC 2020November RainNo ratings yet

- Aggregates: CE 201 Engineering MaterialsDocument17 pagesAggregates: CE 201 Engineering MaterialsMahadi HasanNo ratings yet

- Technical Notes: Strength, Water Absorption and Porosity of Concrete Incorporating Natural and Crushed AggregateDocument11 pagesTechnical Notes: Strength, Water Absorption and Porosity of Concrete Incorporating Natural and Crushed AggregateSALIL GUPTANo ratings yet

- Quality Control Measures in Asphalt Pavement Constructio BetongDocument125 pagesQuality Control Measures in Asphalt Pavement Constructio BetongMark James MateoNo ratings yet

- Coarse and Fine AggregateDocument27 pagesCoarse and Fine Aggregatekunal humaneNo ratings yet

- Chapter 4 AggregatesDocument60 pagesChapter 4 AggregatesClasolNo ratings yet

- Revised Lecture by Sir JanggoDocument43 pagesRevised Lecture by Sir JanggoAriel Dela CruzNo ratings yet

- 08 Chapter 3Document11 pages08 Chapter 3proscokeNo ratings yet

- 05 Reinforced Concrete Constituents 02Document24 pages05 Reinforced Concrete Constituents 02S. M. ZAHIDUR RAHMAN 1301129No ratings yet

- Revised Lecture by Sir JanggoDocument62 pagesRevised Lecture by Sir JanggoHan SelNo ratings yet

- Item 200 - Aggregate Sub Base Course Sieve DesignationDocument20 pagesItem 200 - Aggregate Sub Base Course Sieve DesignationAeron Paul AntonioNo ratings yet

- Notes For Practical Construction Work (Civil) : Compiled By: Muhammad Imran ChaudharyDocument14 pagesNotes For Practical Construction Work (Civil) : Compiled By: Muhammad Imran ChaudharysarwarawNo ratings yet

- Lec 4 - Road MaterialsDocument51 pagesLec 4 - Road MaterialsRuel B. Ramos Jr.No ratings yet

- BCE - H2SO4 Tower InternalsDocument3 pagesBCE - H2SO4 Tower InternalsDũng LêNo ratings yet

- Use of Industrial Wastes in The Construction of Flexible PavementsDocument6 pagesUse of Industrial Wastes in The Construction of Flexible Pavementssai venkateshNo ratings yet

- Shaban Booklet 8-1-2016 - 156 Pages PDFDocument156 pagesShaban Booklet 8-1-2016 - 156 Pages PDFTolaz KoyiNo ratings yet

- Summary of Construction SpecificationDocument11 pagesSummary of Construction SpecificationShafiqullah GowharyNo ratings yet

- ITEM 300 (To Be Used)Document18 pagesITEM 300 (To Be Used)Mj RequillosNo ratings yet

- Hot Dip Galvanizing and Corrosion CategoriesDocument2 pagesHot Dip Galvanizing and Corrosion CategoriesLaxman DuggiralaNo ratings yet

- Item 311Document64 pagesItem 311Jansen WongNo ratings yet

- Standard Specification For Building MaterialsDocument18 pagesStandard Specification For Building Materialskidi mollaNo ratings yet

- 05 Jan 2015guidelines For Manufacturing Quality Fly Ash BricksDocument11 pages05 Jan 2015guidelines For Manufacturing Quality Fly Ash BricksJoy Prokash RoyNo ratings yet

- 1-Designing and Proportioning Normal Concrete MixturesDocument50 pages1-Designing and Proportioning Normal Concrete MixturesMa ThiNo ratings yet

- M 147-65 (2004) Materials For Aggregate Soil-Agg SB B & SCDocument3 pagesM 147-65 (2004) Materials For Aggregate Soil-Agg SB B & SCFranz Richard Sardinas MallcoNo ratings yet

- Advances in Ceramic Armor XIFrom EverandAdvances in Ceramic Armor XIJerry C. LaSalviaNo ratings yet

- Modern Glass CharacterizationFrom EverandModern Glass CharacterizationMario AffatigatoNo ratings yet

- Advances in Ceramic Armor XFrom EverandAdvances in Ceramic Armor XJerry C. LaSalviaNo ratings yet

- Advances in Solid Oxide Fuel Cells and Electronic Ceramics IIFrom EverandAdvances in Solid Oxide Fuel Cells and Electronic Ceramics IIMihails KusnezoffNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- A Level Chemistry Paper 2 Exam 22Document3 pagesA Level Chemistry Paper 2 Exam 22Anthony AndyNo ratings yet

- A Feasibility Study of Wood-Plastic Composite Paver Block For Basic Rest AreasDocument15 pagesA Feasibility Study of Wood-Plastic Composite Paver Block For Basic Rest AreasJanaki RamNo ratings yet

- Connections 1 - Ch.3 Welds Notes (94-153)Document15 pagesConnections 1 - Ch.3 Welds Notes (94-153)travis8zimmermannNo ratings yet

- Corrosion Assessment Noor Energy 1 CT - PT R0 24.02.2022Document148 pagesCorrosion Assessment Noor Energy 1 CT - PT R0 24.02.2022Sanaulla Abdul SubhanNo ratings yet

- Pureit Classic Ro MF ManualDocument17 pagesPureit Classic Ro MF ManualShyam0% (1)

- Merck 2014-2015Document352 pagesMerck 2014-2015Chetan Joshi100% (1)

- Glycol Ethers For Aqueous Cleaners: Page 1 of 6 Trademark of The Dow Chemical Company Form No. 110-00632-0304Document6 pagesGlycol Ethers For Aqueous Cleaners: Page 1 of 6 Trademark of The Dow Chemical Company Form No. 110-00632-0304B4nt3nNo ratings yet

- 730AL - 264 Additives ProductguideDocument20 pages730AL - 264 Additives ProductguidemajidhajnasrNo ratings yet

- R-Value TableDocument3 pagesR-Value TableJitendra Gautam0% (1)

- L16-17 DA and DB BlendsDocument28 pagesL16-17 DA and DB BlendsDanial AhmedNo ratings yet

- Serene Lighting 2022 灯饰目录Document85 pagesSerene Lighting 2022 灯饰目录qq1691492197No ratings yet

- Joining Process Ghosh and MalikDocument8 pagesJoining Process Ghosh and MalikPKNo ratings yet

- Ceccato Filter PDFDocument4 pagesCeccato Filter PDFGodel KHolikNo ratings yet

- Electrolyser-Operating Manual PDFDocument6 pagesElectrolyser-Operating Manual PDFcderin20000% (1)

- Masterpren Masterpren Masterpren Masterpren 1000 1000 1000 1000Document2 pagesMasterpren Masterpren Masterpren Masterpren 1000 1000 1000 1000Lemark R.No ratings yet

- CHEM14.1 E5 ColloidsDocument5 pagesCHEM14.1 E5 ColloidsGlenn Vincent Tumimbang50% (2)

- A Kinetic Study of Copper Cementation With Zinc in Aqueous SolutionsDocument6 pagesA Kinetic Study of Copper Cementation With Zinc in Aqueous SolutionsIbrahim MücahitNo ratings yet

- Foc Data Sheet-U M CablesDocument4 pagesFoc Data Sheet-U M CablesKAVIYARASAN SNo ratings yet

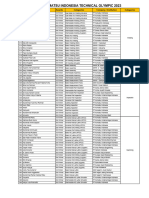

- 12th All Komatsu Indonesia Technical Olympic 2022 Official ResultDocument2 pages12th All Komatsu Indonesia Technical Olympic 2022 Official ResultMarchal KawengianNo ratings yet

- (2021) Microplastics in Dumping Site SoilsDocument10 pages(2021) Microplastics in Dumping Site SoilsVĩ PhùngNo ratings yet

- FormworkDocument12 pagesFormworkalomartaylorNo ratings yet

- Technical Information Surface Chemistry - Akzo NobelDocument15 pagesTechnical Information Surface Chemistry - Akzo NobelAlfredo MéndezNo ratings yet

- Oxidation and ReductionDocument2 pagesOxidation and ReductionClaudine VelascoNo ratings yet

- Aluminum Alloy Common Grade 6061 w/T4 TemperDocument7 pagesAluminum Alloy Common Grade 6061 w/T4 TemperPhyo ThuNo ratings yet

- Disability List Exemptions List 32 From 2012Document160 pagesDisability List Exemptions List 32 From 2012Vaishnavi JayakumarNo ratings yet

- Nitocote En901Document5 pagesNitocote En901ashishpearl100% (1)

- Nancar 1041: Polymer DescriptionDocument3 pagesNancar 1041: Polymer DescriptionThị Nga VũNo ratings yet