Professional Documents

Culture Documents

Electroplating: Lab Report ME-223 Adv Workshop Practice

Electroplating: Lab Report ME-223 Adv Workshop Practice

Uploaded by

Taha HassanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electroplating: Lab Report ME-223 Adv Workshop Practice

Electroplating: Lab Report ME-223 Adv Workshop Practice

Uploaded by

Taha HassanCopyright:

Available Formats

Lab Report

ME-223 Adv Workshop Practice

Student Name: Ahmed Bilal Reg No: 334972 Date: 07-10-2021

School: SMME Dept: Mechanical Section:ME-12 C

Title of Lab Conducted: ELECTROPLATING

Description of Practical:

Electroplating refers to a process that adds a surface layer of metal to another type of metal. There are

many types of it like zinc, tin, nickel, chrome, aluminum coating etc. The metal sample of appropriate

size was selected, and surface was smoothed using wire gauge and then it was cleaned with acidic and

basic bath. Later it was neutralized. After this the sample along with cathode and anode with electrolyte

was selected and then amperage and voltage were given accordingly. Time was set and then after the

process was completed inspection took place. Surface treatment has applications in protecting parts

against environmental exposure and it gives a cosmetic look.

Tanks:

To carry out the electroplating process

Electrolytic Tank

(Coating the anodic metal on the cathode )

To submerge the workpiece in acidic solution

Acidic Tank

To submerge the workpiece in acidic solution

Basic Tank

Soap cleaning tank To carry out anodic and cathodic cleaning

Water Tank/Supply To clean the workpiece

Equipment and Parts with Purpose:

Coverall, Helmet,

As PPE (Personal Protection Equipment)

Shoes, Googles, Gloves

Tool used with Purpose:

Grinding Machine To smooth the metal piece

Wire gauge To clean the surface

Steel wire To suspend the workpiece

Learning Objective:

Students to learn and understand the basic aspects of surface treatment including preparation, process, and

post treatment and how electroplating is done.

Student Signature

You might also like

- Special Process Presentation NewDocument23 pagesSpecial Process Presentation Newvivek nuthiNo ratings yet

- Electroplating Anodizing Metal PDFDocument53 pagesElectroplating Anodizing Metal PDFCrystian Kobee EmpeynadoNo ratings yet

- Surface TreatmentDocument34 pagesSurface TreatmentnagarajNo ratings yet

- Corrosion Prevention and Control Corrosion FundamentalsDocument9 pagesCorrosion Prevention and Control Corrosion FundamentalsbrodyNo ratings yet

- International Paint - Corrossion Knowledge Sharing - Rizal PDFDocument87 pagesInternational Paint - Corrossion Knowledge Sharing - Rizal PDFIndra100% (1)

- ElectroplatingDocument26 pagesElectroplatingYakshit Goel80% (10)

- EDCfinal Copy1Document69 pagesEDCfinal Copy1Andrei OleaNo ratings yet

- 439 PDFDocument5 pages439 PDFSNo ratings yet

- Electrochemical Machining (ECM)Document36 pagesElectrochemical Machining (ECM)Abhishek KumarNo ratings yet

- Electrochemistry Prelab 2Document2 pagesElectrochemistry Prelab 2Alexis ChicaizaNo ratings yet

- A Review Paper On (EDM) Electrical Discharge MachiningDocument3 pagesA Review Paper On (EDM) Electrical Discharge MachiningVishal Kumar JaiswalNo ratings yet

- Ucmp - Assignment 15P31A0383Document5 pagesUcmp - Assignment 15P31A0383Sài TejaNo ratings yet

- Review On Types and Methods of Electroplating On Metals: April 2021Document9 pagesReview On Types and Methods of Electroplating On Metals: April 2021ssv sai suryaNo ratings yet

- Materi Training Coating - 16.05.2019Document91 pagesMateri Training Coating - 16.05.2019yogiikfernandoNo ratings yet

- Seminar On Electrochemical and Chemical Metal Removal ProcessDocument9 pagesSeminar On Electrochemical and Chemical Metal Removal ProcessAbishek DhunganaNo ratings yet

- Assignment 2 (Praful Rawat 160970104033)Document5 pagesAssignment 2 (Praful Rawat 160970104033)as hgfNo ratings yet

- AME - M3 Ktunotes - inDocument54 pagesAME - M3 Ktunotes - inUttam MajiNo ratings yet

- Niir Electroplating Anodizing Metal Treatment Hand BookDocument7 pagesNiir Electroplating Anodizing Metal Treatment Hand BookYASH PARABNo ratings yet

- Review of State of Art and Process Parameter Influence in EDM TechnologyDocument9 pagesReview of State of Art and Process Parameter Influence in EDM TechnologyNguyễn Hữu PhấnNo ratings yet

- Process of Fabricating Nano-Surface Coating and Methods of Testing Their PropertiesDocument36 pagesProcess of Fabricating Nano-Surface Coating and Methods of Testing Their PropertiesMd Raza (B.Arch-2019)No ratings yet

- Process of Fabricating Nano-Surface Coating and Methods of Testing Their PropertiesDocument36 pagesProcess of Fabricating Nano-Surface Coating and Methods of Testing Their PropertiesMd Raza (B.Arch-2019)No ratings yet

- The Complete Technology Book On Electroplating, Phosphating, Powder Coating and Metal Finishing (2nd Revised Edition) - 546289Document119 pagesThe Complete Technology Book On Electroplating, Phosphating, Powder Coating and Metal Finishing (2nd Revised Edition) - 546289Laboratorio Recife FlateckNo ratings yet

- International Paint - Corrossion Knowledge Sharing - RizalDocument87 pagesInternational Paint - Corrossion Knowledge Sharing - RizalMikiRoniWijaya100% (1)

- The Optimum Condition Selection of Electrochemical PolishingDocument7 pagesThe Optimum Condition Selection of Electrochemical Polishingmohammadreza hajialiNo ratings yet

- Turning-Form Electrode in Ultrasonic-Aided Electrochemical FinishingDocument4 pagesTurning-Form Electrode in Ultrasonic-Aided Electrochemical FinishingffazlaliNo ratings yet

- Q (1) With Full Group Details Discuss The Theory and Principles of Different Techniques of Non-Traditional Manufacture ProcessDocument11 pagesQ (1) With Full Group Details Discuss The Theory and Principles of Different Techniques of Non-Traditional Manufacture Processsofyan samNo ratings yet

- Study of Electro-Chemical Machining Process For Drilling HoleDocument6 pagesStudy of Electro-Chemical Machining Process For Drilling Holekaushalshah28598No ratings yet

- MME 1061 Workshop PracticeDocument111 pagesMME 1061 Workshop Practicekaleem zargarNo ratings yet

- Influence of EDM Process Parameters in Deep Hole Drilling of Inconel 718Document11 pagesInfluence of EDM Process Parameters in Deep Hole Drilling of Inconel 718Pranes RainaNo ratings yet

- BTI1133 Ch34Document42 pagesBTI1133 Ch34ACC SHNo ratings yet

- ECmDocument32 pagesECmAmit BedareNo ratings yet

- The Influence of Mass Transfer On The Mechanism of Electropolishing of Nickel in Aqueous Sulphuric AcidDocument23 pagesThe Influence of Mass Transfer On The Mechanism of Electropolishing of Nickel in Aqueous Sulphuric Acidqnk7No ratings yet

- Electrochemical Stripping: Dr. Rudolf Keller and Brian J. BarcaDocument5 pagesElectrochemical Stripping: Dr. Rudolf Keller and Brian J. BarcaRinush Fedrikdo Bushido OdaNo ratings yet

- Cách Kiểm Tra Lớp Xi MạDocument3 pagesCách Kiểm Tra Lớp Xi Mạzenotv2No ratings yet

- Edm ResearchDocument2 pagesEdm Researchapi-637609979No ratings yet

- Study of Electro Chemical Machining Etching Effect On Surface Roughness and Variation With Chemical Etching ProcessDocument5 pagesStudy of Electro Chemical Machining Etching Effect On Surface Roughness and Variation With Chemical Etching ProcessSwan Saung TharNo ratings yet

- Chem For Eng 1Document123 pagesChem For Eng 1Am AsdfghjklNo ratings yet

- Unconventional MachinesDocument10 pagesUnconventional MachinesPethurajNo ratings yet

- Unit 3Document40 pagesUnit 3Dare DevilNo ratings yet

- Usm, Ecm, EdmDocument24 pagesUsm, Ecm, EdmFRANCIS THOMASNo ratings yet

- Surface Finishing and Electroless Nickel Plating of AdditivelyDocument4 pagesSurface Finishing and Electroless Nickel Plating of Additively王重睿No ratings yet

- Electrochemical Deburring: Definition, Parts or Construction, Working Principle, Application, Advantages, and Disadvantages (Notes & PDF)Document6 pagesElectrochemical Deburring: Definition, Parts or Construction, Working Principle, Application, Advantages, and Disadvantages (Notes & PDF)ShubhamNo ratings yet

- Nontraditional Manufacturing ProcessesDocument157 pagesNontraditional Manufacturing ProcessesProf. Arshad Noor Siddiqui (D/o Mechanical Engineering)No ratings yet

- Revised SOP For TinningDocument2 pagesRevised SOP For TinningAnkit GalaniNo ratings yet

- Assignment No 04 Electro Chemical MachiningDocument3 pagesAssignment No 04 Electro Chemical MachiningChirag BotkondleNo ratings yet

- EDM and ECM NotesDocument25 pagesEDM and ECM NotesFRANCIS THOMASNo ratings yet

- Dokumen - Tips Electropolishing-58620fe2d578eDocument9 pagesDokumen - Tips Electropolishing-58620fe2d578eSy Nguyen VietNo ratings yet

- Plat General InformationDocument32 pagesPlat General InformationjayNo ratings yet

- Experimental Investigation of Process Parameters On Inconel 925 For EDM Process by Using Taguchi MethodDocument6 pagesExperimental Investigation of Process Parameters On Inconel 925 For EDM Process by Using Taguchi MethodVishal Kumar JaiswalNo ratings yet

- Olasubomi Omowa's Alpha UnoDocument58 pagesOlasubomi Omowa's Alpha UnoOlasubomi OmowaNo ratings yet

- NCM Assignment 5Document13 pagesNCM Assignment 5dhanraj287308No ratings yet

- Exp 2Document5 pagesExp 2alexchong93No ratings yet

- Electroplating: Louie VillaverdeDocument19 pagesElectroplating: Louie VillaverdeAi Heart PinkNo ratings yet

- Improving Surface Roughness of The 3D Printed Part Using Electroless PlatingDocument1 pageImproving Surface Roughness of The 3D Printed Part Using Electroless PlatingDr. Avesh MohdNo ratings yet

- Magesh 2017A Review of Process Parameter of EDM Ijariie7176Document4 pagesMagesh 2017A Review of Process Parameter of EDM Ijariie7176vijayaragavanNo ratings yet

- Electropolishing of AISI 316L Effect On Surface CHDocument33 pagesElectropolishing of AISI 316L Effect On Surface CHphamcuongNo ratings yet

- Surface EngineeringDocument43 pagesSurface Engineering10rajNo ratings yet

- Electrochemical MachiningDocument12 pagesElectrochemical MachiningShubham PoteNo ratings yet

- Sadeghi 2021Document13 pagesSadeghi 2021KArenNo ratings yet

- Amorphous and Nano Alloys Electroless Depositions: Technology, Composition, Structure and TheoryFrom EverandAmorphous and Nano Alloys Electroless Depositions: Technology, Composition, Structure and TheoryNo ratings yet

- TIG WeldingDocument1 pageTIG WeldingTaha HassanNo ratings yet

- Chapter 9 TablesDocument5 pagesChapter 9 TablesTaha HassanNo ratings yet

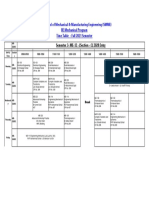

- NUST School of Mechanical & Manufacturing Engineering (SMME) BE Mechanical Program Time Table - Fall 2021 SemesterDocument1 pageNUST School of Mechanical & Manufacturing Engineering (SMME) BE Mechanical Program Time Table - Fall 2021 SemesterTaha HassanNo ratings yet

- NUST School of Mechanical & Manufacturing Engineering (SMME) BE Mechanical Engineering Programme Time Table - Spring 2021 SemesterDocument1 pageNUST School of Mechanical & Manufacturing Engineering (SMME) BE Mechanical Engineering Programme Time Table - Spring 2021 SemesterTaha HassanNo ratings yet

- NUST School of Mechanical & Manufacturing Engineering (SMME) BE Mechanical Engineering Programme Time Table - Spring 2021 SemesterDocument1 pageNUST School of Mechanical & Manufacturing Engineering (SMME) BE Mechanical Engineering Programme Time Table - Spring 2021 SemesterTaha HassanNo ratings yet

- Workshop PHOsDocument10 pagesWorkshop PHOsTaha HassanNo ratings yet

- TIG WELDING Processes: Lab Report ME-223 Adv Workshop PracticeDocument1 pageTIG WELDING Processes: Lab Report ME-223 Adv Workshop PracticeTaha HassanNo ratings yet

- Metal Casting Sand Mold: Sand Casting, Also Known As Sand Molded Casting, Is ADocument1 pageMetal Casting Sand Mold: Sand Casting, Also Known As Sand Molded Casting, Is ATaha HassanNo ratings yet