Professional Documents

Culture Documents

Short-Term Mechanical Properties of High-Strength

Uploaded by

Deybi TtCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Short-Term Mechanical Properties of High-Strength

Uploaded by

Deybi TtCopyright:

Available Formats

ACI MATERIALS JOURNAL TECHNICAL PAPER

Title no. 106-M46

Short-Term Mechanical Properties of High-Strength

Concrete

by Andrew Logan, Wonchang Choi, Amir Mirmiran, Sami Rizkalla, and Paul Zia

A comprehensive experimental program was undertaken to determine high-performance concrete (HPC), with some specimens

the short-term mechanical properties of high-strength concrete referred to as “very high strength,” with 28-day compressive

(HSC). Modulus of rupture beams and two different sizes of strengths ranging from 8 to 13.4 ksi (55 to 92 MPa).6 The

concrete cylinders with three different target compressive strengths study found that the ratio of the compressive strength of the

ranging from 10 to 18 ksi (69 to 124 MPa) were subjected to three

6 x 12 in. (150 x 300 mm) cylinders to that of the 4 x 8 in.

different curing methods and durations. Test results were combined

with data from the literature to improve predictive equations for (100 x 200 mm) cylinders ranged from 0.91 to 0.98,

the elastic modulus and modulus of rupture of HSC. Of the three depending on the type of coarse aggregates used.6 The study

different curing methods, cylinders moist-cured for 7 days exhibited also determined that the proposed equation of Carrasquillo et

the highest compressive strengths at ages of 28 and 56 days. In al.4 (and ACI 363R-925) underestimated the elastic modulus

contrast, 1-day heat curing generally resulted in the lowest of HSC. With regards to the modulus of rupture, the study

compressive strength. The study shows that a Poisson’s ratio of 0.2 showed that at the design age, the ratio of the observed value

can be adequately used for HSC. to that predicted by ACI 318-053 was 1.06 for concrete made

with fly ash and 1.15 for concrete made with silica fume.

Keywords: compressive strength; elastic modulus; high-strength concrete; Comparing the measured values to those predicted by

modulus of rupture; Poisson’s ratio.

Carrasquillo et al.4 (and ACI 363R-92 5), the ratio was as

low as 0.686.

INTRODUCTION

The development of high-strength concrete (HSC) has led Mokhtarzadeh and French7 studied 142 concrete mixtures

to more efficient design of buildings and bridges, with shallower with 28-day compressive strengths ranging from 8 to 18.6 ksi

members and longer spans. Although some design specifications (55 to 128 MPa). Their data showed the ACI 318-053 equation

have addressed the use of HSC, many have implicitly or to overestimate the elastic modulus of HSC, whereas the

explicitly placed restrictions on its use, primarily because ACI 363R-925 equation was found more favorable. Also, the

of limited research data.1 For example, the American Association ACI 363R-925 equation for the modulus of rupture was

of Highway and Transportation Officials (AASHTO) LRFD found acceptable for the moist-cured specimens, whereas the

Bridge Design Specifications2 limits its applicability to modulus of rupture of the heat-cured specimens fell in

concrete compressive strength of 10 ksi (69 MPa) unless between the values predicted by the ACI 363R-925 and

physical tests are conducted. Furthermore, many design ACI 318-053 equations. The study proposed a new modulus

provisions in both ACI 318-053 and AASHTO-LRFD2 are of rupture equation with a coefficient of 9.3 to be used

based on test data obtained from specimens with compressive instead of the 7.5 in the ACI 318-053 equation.

strengths up to 6 ksi (41 MPa) and, therefore, do not accurately Légeron and Paultre8 reported that curing conditions

reflect the mechanical properties of HSC. significantly affected the measured value of the modulus of

In the late 1970s, Carrasquillo et al.4 tested specimens rupture. They also compiled data from the literature and

from three concrete mixtures with 53-day compressive proposed predictive equations for the minimum, average,

strengths ranging from 4.6 to 11.1 ksi (31.7 to 76.5 MPa). and maximum values of the modulus of rupture. They

Some of the specimens were moist-cured for 7 days and were suggested that the minimum values be used for service limit

then allowed to dry until tested at an age of 28 days. Others states to control deflections and cracking, whereas the

were moist-cured for 28 days and then allowed to dry until maximum values should be used for the ultimate limit state

tested at an age of 95 days. The control group was moist- to ensure ductility of flexural members. Burg and Ost9 found

cured until 2 hours prior to testing. The data suggested that that the ratio of the moduli of rupture of moist-cured specimens

drying of HSC cylinders resulted in a lower compressive to air-cured specimens ranged from 1.54 to 2.02.

strength and modulus of rupture, in contrast to the normal- In the last few years, the AASHTO has addressed the need

strength concrete (NSC). The reduction in the modulus of to expand the applicability of its LRFD Specifications2 to HSC

rupture was more significant than that of the compressive with a number of research projects conducted through the

strength. The study also revealed that the compressive National Cooperative Highway Research Program (NCHRP).

strength of 6 x 12 in. (150 x 300 mm) cylinders was, on This paper reports on one of these projects (NCHRP 12-64),

average, approximately 90% of that of the 4 x 8 in. (100 x which focused on flexure and compression design provisions

200 mm) cylinders, irrespective of the compressive strength

or the age at testing. Carrasquillo et al.4 then proposed equations

for both modulus of elasticity and modulus of rupture of HSC, ACI Materials Journal, V. 106, No. 5, September-October 2009.

which were later included in the ACI 363R-92 report.5 MS No. M-2008-005 received January 3, 2008, and reviewed under Institute publication

policies. Copyright © 2009, American Concrete Institute. All rights reserved, including the

The Strategic Highway Research Program (SHRP) of the making of copies unless permission is obtained from the copyright proprietors. Pertinent

discussion including authors’ closure, if any, will be published in the July-August 2010

early 1990s also focused on the mechanical properties of ACI Materials Journal if the discussion is received by April 1, 2010.

ACI Materials Journal/September-October 2009 1

Table 1—Concrete mixture proportions

Andrew Logan works for a civil engineering firm in Leesburg, FL. He received his

BS and MS in civil engineering from the University of Florida, Gainesville, FL, and Target compressive strengths

North Carolina State University, Raleigh, NC, respectively. His research interests 10 ksi 14 ksi 18 ksi

include short-term mechanical properties of high-strength concrete. Materials (69 MPa) (97 MPa) (124 MPa)

Wonchang Choi received his PhD from North Carolina State University, and his BS Cement (Type I/II), lb/yd3 (kg/m3) 703 (417) 703 (417) 935 (555)

and MS in civil engineering from Hongik University, Seoul, Korea. His research interests 3 3

include the flexural behavior of prestressed girders using high-strength concrete. Densified microsilica fume, lb/yd (kg/m ) 75 (44) 75 (44) 75 (44)

Fly ash, lb/yd3 (kg/m3) 192 (114) 192 (114) 50 (30)

Amir Mirmiran, FACI, is Professor and Interim Dean of the College of Engineering

and Computing at Florida International University, Miami, FL. He is a member of Sand, lb/yd3 (kg/m3) 1055 (625) 1315 (780) 1240 (736)

ACI Committees 440, Fiber Reinforced Polymer Reinforcement, and E803, Faculty

1830 1830 1830

Network Coordinating Committee, and Joint ACI-ASCE Committee 343, Concrete Rock (diabase 78M), lb/yd3 (kg/m3) (1085) (1085) (1085)

Bridge Design. His research interests include high-strength concrete and advanced

composite materials for bridge applications. Water, lb/yd3 (kg/m3) 292 (173) 250 (148) 267 (158)

Sami Rizkalla, FACI, is Distinguished Professor of Civil Engineering and Construction at High-range water-reducing admixture

17 (1110) 24 (1565) 36 (2345)

North Carolina State University. He serves as Director of the Constructed Facilities (HRWRA), oz/100 lb (mL/100 kg)*

Laboratory as well as the NSF I/UCR Center on Repair of Structures and Bridges at

NC State. He is a member of ACI Committees 440, Fiber Reinforced Polymer Reinforcement, Retarding agent, oz/100 lb (mL/100 kg)* 3 (195) 3 (195) 3 (195)

and E803, Faculty Network Coordinating Committee, and Joint ASI-ASCE Committees w/cm 0.30 0.26 0.25

423, Prestressed Concrete, and 550, Precast Concrete Structures.

Average 28-day compressive strength of 11.45 14.37 17.09

ACI Honorary Member Paul Zia is a Distinguished University Professor Emeritus at laboratory batch, ksi (MPa) (78.9) (99.1) (117.8)

NC State University. He is an ACI Past President and is currently a member of the *

Ounces per 100 lb of cementitious materials (mL per 100 kg cementitious materials).

Concrete Research Council, ACI Committee 363, High-Strength Concrete; Concrete

Research Council; and Joint ACI-ASCE Committees 423, Prestressed Concrete; and

445, Shear and Torsion.

the trial batches and the selected mixture proportions can be

found elsewhere.11

for HSC.10 As part of this project, an effort was made to

characterize the short-term mechanical properties of HSC. Specimen preparation and curing procedures

Concrete was batched in a ready mixed concrete plant

RESEARCH SIGNIFICANCE AND OBJECTIVES using commercial production procedures. The 4 x 8 in.

The main objective of this study was to improve predictive (100 x 200 mm) and 6 x 12 in. (150 x 300 mm) cylinders

equations for short-term mechanical properties of HSC, were used for the compressive strength and elastic modulus

including its elastic modulus, modulus of rupture, and of concrete, and 6 x 6 x 20 in. (150 x 150 x 510 mm) beams

Poisson’s ratio. The significance of this research is not only were used for the modulus of rupture. Cylinders were cast in

to improve the predictive equations, but also to enhance the plastic molds, and the beams were cast in steel molds. The spec-

test database for HSC with three different target compressive imens were made according to AASHTO T23 (ASTM C31)

strengths, different specimen sizes, and different curing (ACI 363.2R-9812). Table 2 shows the test matrix. Testing ages

conditions. The database is especially significant because it were 1, 7, 14, 28, and 56 days. On each testing day, two of the

is based on ready mixed concrete delivered from batch 4 x 8 in. (100 x 200 mm) cylinders were used to determine the

plants, and not laboratory-scale mixtures. Although not elastic modulus before being tested to failure.

directly the focus of this paper, it is also important to note

The specimens were subjected to one of the three

that the specimens for short-term mechanical properties

following curing conditions: 1) 7-day moist curing to represent

were made and tested side-by-side and as part of a larger test

typical curing procedures for reinforced concrete members;

matrix, which included reinforced concrete columns and

2) 1-day heat curing similar to that used in precast concrete

beams and prestressed girders.

plants for prestressed structural members; and 3) continual

moist curing until the day of testing according to the ASTM

EXPERIMENTAL PROGRAM standards used for the purposes of quality control and certifying

Materials and mixture design

Three different concrete mixtures with target compressive the compressive strength of concrete in the industry.12 The heat-

strengths of 10, 14, and 18 ksi (69, 97, and 124 MPa) were cured specimens were placed in a chamber with a heating

prepared using ready mixed concrete delivered from a batch regime ramping up to a constant temperature of 150 to 160° F

plant. The mixture proportions were selected from a large (66 to 71°C), and back to room temperature in 24 hours.

number of trial laboratory batches and are shown in Table 1.

The mixtures for the 10 and 14 ksi (69 and 97 MPa) Testing procedures and instrumentations

compressive strengths were proportioned to exceed their The cylinders were ground at both ends before testing to

target values by 10 to 20%, assuming that there would be a remove any surface irregularity and to also ensure that the

strength reduction due to the large batch size and the ends would be perpendicular to the sides of the specimen.

increased difficulty in maintaining quality control in truck- Compression tests were performed using a Universal testing

mixed batches. In both cases, however, as will be discussed machine for both the 4 x 8 in. (100 x 200 mm) and the 6 x 12 in.

later, the compressive strengths of the truck-mixed batches were (150 x 300 mm) cylinders. Tests followed ASHTO T22

approximately the same as those of the laboratory batches. (ASTM C39) at a loading rate of approximately 0.04 ksi/s

The coarse aggregates were crushed stone quarried in (0.28 MPa/s). The loading rate was selected at the higher end

Butner, NC, with a nominal maximum size of 3/8 in. (9.5 mm). of the standard range to avoid prolonged loading, which could

Manufactured sand made from the same type of rock was used possibly cause extensive microcracking in concrete cylinders.

as fine aggregates because the lab mixtures had clearly The elastic modulus was determined using the 4 x 8 in.

shown that it would increase the compressive strength of (100 x 200 mm) concrete cylinders and in accordance with

concrete. The cement was Type I/II. Additional details on ASTM C469. Deflections were measured using potentiometers

2 ACI Materials Journal/September-October 2009

Table 2—Description of test specimens for each target strength

Testing age (days)

Specimen Test type Curing method 1 7 14 28 56 Total

7-day moist curing 3 3 3 3 3 15

4 x 8 in. (100 x 200 mm) cylinders Axial compression 1-day heat curing 3 3 3 3 3 15

Continual moist curing 3 3 6

Total number of 4 x 8 in. (100 x 200 mm) cylinders 36

7-day moist curing 3 3 6

6 x 12 in. (150 x 300 mm) cylinders Axial compression 1-day heat curing 3 3 6

Continual moist curing 3 3 6

Total number of 6 x 12 in. (150 x 300 mm) cylinders 18

7-day moist curing 3 3 3 3 3 15

6 x 6 x 20 in. (150 x 150 x 510 mm) beams Modulus of rupture 1-day heat curing 3 3 3 3 3 15

Continual moist curing 3 3

Total number of 6 x 6 x 12 in. (150 x 150 x 510 mm) beams 33

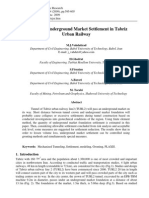

Fig. 1—Fully instrumented 4 x 8 in. (100 x 200 mm)

cylindrical specimen.

Fig. 3—Compressive strength of 4 x 8 in. (100 x 200 mm)

cylinders at 28 days.

TEST RESULTS AND DISCUSSIONS

Compressive strength

The compressive strengths for the first two concrete

mixtures exceeded their target values, whereas the third

batch failed to reach its target value (Table 1). The tests,

however, still provided useful information for expanding and

Fig. 2—Modulus of rupture test setup. adding to the knowledge base on mechanical properties of HSC.

The effects of curing procedures on the compressive

strength measured from the 4 x 8 in. (100 x 200 mm) cylinders

attached to two fixed rings (Fig. 1). Four vertical potentiometers

at 28 days are illustrated in Fig. 3. The 7-day moist-cured

measured axial deflections, while two horizontal potentiometers

specimens showed the highest compressive strengths at 28 days

attached at midheight measured lateral dilation of concrete.

in each of the three batches. The 1-day heat curing increased

The apparatus consisted of two aluminum rings with screws

strength gain at an early age, but weakened it at later ages. This

for attachment to the specimen. Prior to attaching the apparatus behavior was attributed to rapid hydration, which causes the

to the specimen, the rings were joined by three aluminum bars. structure of the cement paste to be more porous than when

The spacing between the screws on the top ring and the cement paste hydrates slowly. The higher porosity, in turn,

screws on the bottom ring when the aluminum bars were leads to decreased strength. Although the majority of the

attached was 5 in. (127 mm), which served as a gauge length strength gain in heat-cured specimens occurred within the

for calculating axial strains from the measured deformations. first few days, their strength continued to increase until 56 days,

The modulus of rupture beams were placed in the testing albeit at a slow rate. The average 28-day strength of the 7-day

frame, oriented in such a way that the specimen was turned moist-cured specimens were 1.17, 1.10, and 1.16 times those

on its side with respect to its molded position, as specified in of the heat-cured specimens for the 10, 14, and 18 ksi

ASTM C78 (Fig. 2). The load was applied using a hand (69, 97, and 124 MPa) target strengths, respectively. The

pump. The loading rate was controlled such that the stress at continually moist-cured specimens exhibited a slightly

the extreme bottom fiber of the beam would increase at a rate lower strength, with failure closer to the surface, primarily

of 0.15 ksi/s (1.03 MPa/s). because of the remaining moisture in the capillary pores.

ACI Materials Journal/September-October 2009 3

Fig. 4—Strength gain over time expressed as percentage

of 28-day strength. Fig. 6—Predictions of over 4400 data points using proposed

equation.

Fig. 5—Elastic modulus versus compressive strength. (Data Fig. 7—Statistical comparisons for modulus of elasticity.

from References 4 and 13 to 18).

Figure 5 shows test results from this research project as

The strength gain of concrete over time is depicted in Fig. 4. compared to the ACI 318-053 (AASHTO-LRFD2) and the

For the 10 and 14 ksi (69 and 97 MPa) target strengths, the heat- ACI 363R-925 equations. In the same figure, data by

cured specimens reached approximately 90% of their 28-day others4,13-18 are also shown for comparison. The measured

strength during the first day of curing. The specimens made values are generally in agreement with the predicted values

from the 18 ksi (124 MPa) target strength concrete also calculated using the ACI 363R-925 equation, regardless of

gained the majority of their 28-day strength in the first day, the curing method. The data also support the statement in

but at a lower rate. This was attributed to: 1) higher heat of ACI 363R-925 that the ACI 318-053 (AASHTO-LRFD2) equa-

hydration resulting from the larger cement content in the tion consistently overestimates the elastic modulus for HSC.

mixture; and 2) the larger dose of high-range water-reducing A total of 4388 test data for elastic modulus, with concrete

admixture in the mixture. strengths between 3.7 to 24 ksi and unit weight between

90 to 176 lbf, were collected from the literature19 (see

Elastic modulus Reference 20 for details). Based on the collected data, the

The current code equation in ACI 318-053 and the following equation for the elastic modulus of concrete with

AASHTO-LRFD2 for estimating the elastic modulus of compressive strength up to 18 ksi (124 MPa) is proposed20

concrete is as follows

1.5 Ec (ksi) = 310,000K1[wc(kip/ft3)]2.5 × [fc (ksi)]0.33

E c = 33w c f c psi

(1) Ec (MPa) = 0.000035K1[wc(kg/m3)]2.5 × [fc (MPa)]0.33 (3)

1.5

E c = 0.043w c f c MPa

where K1 is the correction factor to account for the source of

where w is the unit weight of concrete, and fc is the 28-day aggregates, which may be taken as 1.0 unless determined by

compressive strength. ACI 363R-925 suggests the following physical tests. The collected data, including results from this

alternative equation study, are compared with the proposed equation in Fig. 6.

The figure indicates that the collected data are still scattered,

Ec = (40,000(fc )0.5 + 106)(wc /145)1.5 (psi) however, with an improved R2 = 0.76. Figure 7 shows the

probability distribution of the modulus of elasticity data as a

Ec = (3320( fc )0.5 + 6900)(wc /2320)1.5 (MPa) (2) function of the predicted over the measured value for the

4 ACI Materials Journal/September-October 2009

Fig. 8—Poisson’s ratio for various concrete strengths.

three different equations using statistical analysis. The

figure shows that the ACI 318-053 (AASHTO-LRFD2)

equation overestimates the elastic modulus. Although

the ACI 363R-92 5 equation has the lowest standard deviation

among the three predictions, its predictions are slightly

conservative. The proposed equation, on the other hand,

has the best normal distribution, although its standard deviation

is slightly higher than that of the ACI 363R-925 equation.

Poisson’s ratio

Following ASTM C469,12 Poisson’s ratio was determined

using the measured lateral and axial strains of the cylinders

tested in compression, based on two points on the stress-

strain curve. The lower point was defined by an axial strain

value of 0.00005, while the upper point was defined by an

axial stress value of 40% of the peak stress. The measured

Poisson’s ratios for concrete had large variations, as shown

in Fig. 8. Test results do not show an apparent correlation

between the Poisson’s ratio and the measured compressive

strength. In addition, it was observed that curing procedures

and age of concrete had little or no effect on the Poisson’s

ratio. The average Poisson’s ratio for all tested cylinders is

0.17 with a standard deviation of 0.07. The generally

accepted range for the Poisson’s ratio of NSC is between

0.15 and 0.25, while it is generally assumed to be 0.2 for

analysis.21 Test data from this project suggest that it is

reasonable to use 0.2 as Poisson’s ratio for HSC up to

compressive strength of 18 ksi (124 MPa).

Modulus of rupture

Effect of curing methods on the modulus of rupture for the

three different target strengths are shown in Fig. 9. Test

results suggest that the modulus of rupture is significantly

affected by curing conditions for all target strengths. The Fig. 9—Effect of curing process on modulus of rupture for

trend indicates that removal of the beam specimen after 7 days concrete compressive strength: modulus of rupture versus

from the curing tank causes a significant reduction of the time for (a) 19 ksi (69 MPa) target strength; (b) 14 ksi (97 MPa

modulus of rupture. Similarly, the 1-day heat-cured beams target strength; and (c) 18 ksi (124 MPa) target strength.

showed low values of the modulus of rupture due to the cannot evaporate as quickly as the surface moisture. This

dryness after removal from the molds, which had prevented

relative shrinkage difference causes microcracking of

moisture loss during the first day of curing. In both cases, the

reduced modulus of rupture is attributed to the microcracks concrete. Therefore, the specimens that were moist-cured up

initiated by drying shrinkage. The low permeability of the to the day of testing showed much higher modulus of rupture

HSC is expected to cause differential shrinkage strains than those cured differently.

across the depth of the specimen due to the fact that the Figure 10 shows test data from material study tested in

moisture trapped in the interior part of the specimens this program along with the data collected from the litera-

ACI Materials Journal/September-October 2009 5

(124 MPa).

• The modulus of rupture was reduced significantly for

specimens removed from their sealed or moist environments

and allowed to dry. The continuously moist-cured

specimens developed modulus of rupture values, in

some cases twice as much as those obtained from the

7-day moist-cured specimens.

• The upper bound equation specified by the AASHTO-

LRFD2 provided a good estimate of the modulus of

rupture for the continuously moist-cured specimens,

but overestimated the modulus of rupture for the 1-day

heat-cured and 7-day moist-cured specimens. The

lower bound equation specified by the AASHTO-

LRFD2 overestimated the measured modulus of rupture

for 1-day heat-cured and 7-day moist-cured specimens.

Based on the test results, a better predictive equation,

Fig. 10—Modulus of rupture versus compressive strength. lower bound of the test data, was proposed for HSC up

to 18 ksi (124 MPa).

ture.1,7,13,16,19 Two equations for modulus of rupture given

in Section 5.4.2.6 of the current AASHTO-LRFD2 are also ACKNOWLEDGMENTS

shown in the figure. Some of the tests results correspond This study was sponsored by the American Association of State Highway

better to the current upper bound of the AASHTO-LRFD.2 and Transportation Officials in cooperation with the Federal Highway

This is mainly due to the curing condition and moisture Administration, and was conducted as part of the National Cooperative

content of the specimens. Test results suggest that the Highway Research Program Project 12-64, which is administered by the

Transportation Research Board of the National Research Council, Senior

current lower bound of the AASHTO-LRFD2 overestimates Program Officer D. Beal. The experiments were carried out at the

the modulus of rupture for HSC. A better predictive equation, Constructed Facilities Laboratory at North Carolina State University. The

which is the lower bound of the test data, fr = 0.19 f c ksi (fr contributions of consultants—H. Russell of Henry Russell, Inc. and R. Mast

= 0.5 f c MPa ), is proposed for HSC up to 18 ksi (124 MPa). of Berger/ABAM Engineers, Inc.—are greatly acknowledged. The assistance of

Ready Mixed Concrete, Boral Material Technologies, Degussa Admixtures,

Roanoke Cement, Carolina SunRock , and Elkem are also greatly appreciated.

CONCLUSIONS AND RECOMMENDATIONS Z. Wu, S. Kim, and H. C. Mertol provided significant assistance during all

A total of thirty-six 4 x 8 in. (100 x 200 mm) cylinders, aspects of this research program. The findings and opinions expressed in

eighteen 6 x 12 in. (150 x 300 mm) cylinders, and thirty- this paper, however, are those of the authors alone and not necessarily the

views of the sponsoring agency.

three 6 x 6 x 20 in. (150 x 150 x 510 mm) beams were

prepared with three different target compressive strengths of

REFERENCES

10, 14, and 18 ksi (69, 97, and 124 MPa) using ready mixed 1. Paultre, P., and Mitchell, D., “Code Provisions for High-Strength

concrete delivered from a batch plant. Three different curing Concrete—An International Perspective,” Concrete International, V. 25,

regimes were used; 1-day heat curing, 7-day moist curing, No. 5, May 2003, pp. 76-90.

and continuous moist curing until the day of testing. The 2. AASHTO-LRFD, “LRFD Bridge Design Specifications,” third

specimens were tested to determine short-term mechanical edition, including 2005 and 2006 Interim Revisions, Washington, DC, 2004.

3. ACI Committee 318, “Building Code Requirements for Structural

properties of HSC. Based on the test data from this research Concrete (ACI 318-05) and Commentary (318R-05),” American Concrete

combined with those from the literature, the following Institute, Farmington Hills, MI, 2005, 430 pp.

conclusions can be drawn: 4. Carrasquillo, R. L.; Nilson, A. H.; and Slate, F. O., “Properties of

• Of the three different curing methods, cylinders with 7-day High-Strength Concrete Subject to Short-Term Loads,” ACI JOURNAL,

Proceedings V. 78, No. 3, Mar. 1981, pp. 171-178.

moist curing exhibited the highest compressive strengths at 5. ACI Committee 363, “Report on High-Strength Concrete (ACI 363R-92),”

ages of 28 and 56 days. In contrast, 1-day heat curing American Concrete Institute, Farmington Hills, MI, 56 pp.

generally resulted in the lowest strength. Cylinders 6. Zia, P.; Ahmad, S.; and Leming, M., “High Performance Concretes: A

moist-cured up to the day of testing resulted in strengths State-of-Art Report (1989-1994),” FHWA-RD-97-030, U.S. Department of

slightly lower strengths than their counterparts with 7-day Transportation, 1997.

7. Mokhtarzadeh, A., and French, C., “Mechanical Properties of High-

moist-curing. The reduction in the strength may be Strength Concrete with Consideration for Precast Applications,” ACI Materials

attributed to the differences in the internal moisture Journal, V. 97, No. 2, Mar.-Apr. 2000, pp. 136-147.

conditions of the concrete at the time of testing. 8. Légeron, F., and Paultre, P., “Prediction of Modulus of Rupture of

• Comparisons of the strength gain under various curing Concrete,” ACI Materials Journal, V. 97, No. 2, Mar.-Apr. 2000, pp. 193-200.

regimes showed that moist curing of HSC beyond 7 days 9. Burg, R. G., and Ost, B. W., “Engineering Properties of Commercially

Available High-Strength Concretes,” PCA Research and Development

would not result in any significant increase in strength. Bulletin RD104T, Portland Cement Association, Skokie, IL, 1992.

This is believed to be due to the low permeability of HSC 10. Rizkalla, S.; Mirmiran, A.; Zia, P.; Russell, H.; Mast, R.; Mertol, H. C.;

and the short time required for the capillary pores of HSC Wu, Z.; Choi, W.; Kim, S.; and Logan, A., “Application of the LRFD Bridge

to be blocked. Design Specifications to High-Strength Concrete: Flexure and Compression

Provisions,” NCHRP Report 12-64, National Cooperative Highway Research

• The equation specified by the AASHTO-LRFD2 overesti- Program (NCHRP), Transportation Research Board, Washington, DC, 2007.

mated the elastic modulus for all specimens. Based on the 11. Logan, A. T., “Short-Term Material Properties of High-Strength

tests’ results and the collected data in the literature, a new Concrete,” MS thesis, Department of Civil, Construction and Environmental

equation for the elastic modulus of concrete with compres- Engineering, North Carolina State University, Raleigh, NC, 2005, 116 pp.

sive strength up to 18 ksi (124 MPa) was proposed. 12. ACI Committee 363, “Guide to Quality Control and Testing of High-

Strength Concrete (ACI 363.2R-98),” American Concrete Institute,

• A Poisson’s ratio of 0.2 specified by the AASHTO- Farmington Hills, MI, 1998, 18 pp.

LRFD2 can adequately be used for HSC up to 18 ksi 13. Le Roy, R., “Instantaneous and Time Dependant Strains of High-

6 ACI Materials Journal/September-October 2009

Strength Concrete,” Laboratoire Central des Ponts et Chaussées, Paris, 18. Cusson, D., and Paultre, P., “High-Strength Concrete Columns

France, 1996, 376 pp. Confined by Rectangular Ties,” Journal of Structural Engineering, ASCE,

14. Dong, Z., and Keru, W., “Fracture Properties of High-Strength V. 120, No. 3, 1994, pp. 783-804.

Concrete,” Journal of Materials in Civil Engineering, V. 13, No. 1, 2001,

pp. 86-88. 19. Noguchi Laboratory Data, Department of Architecture, University of

15. Chin, M. S.; Mansur, M. A.; and Wee, T. H., “Effect of Shape, Size, and Tokyo, Japan, (http://bme.t.u tokyo.ac.jp/index_e.html).

Casting Direction of Specimens on Stress-Strain Curves of High-Strength 20. Choi, W. C., “Flexural Behavior of Prestressed Girder with High

Concrete,” ACI Materials Journal, V. 94, No. 3, May-June 1997, pp. 209-219. Strength Concrete,” PhD thesis, Department of Civil, Construction, and

16. Khan, A. A.; Cook, W. D.; and Mitchell, D., “Early Age Compressive Environmental Engineering, North Carolina State University, Raleigh, NC,

Stress-Strain Properties of Low, Medium and High-Strength Concretes,” ACI

Materials Journal, V. 92, No. 6, Nov.-Dec. 1995, pp. 617-624. 2006, 167 pp.

17. Iravani, S., “Mechanical Properties of High-Performance Concrete,” 21. Neville, A. M., Properties of Concrete, fourth edition, John Wiley

ACI Materials Journal, V. 93, No. 5, Sept.-Oct. 1996, pp. 416-426. and Sons, Inc., New York, 844 pp.

ACI Materials Journal/September-October 2009 7

You might also like

- Strain GaugeDocument8 pagesStrain GaugeLegendaryNNo ratings yet

- A Review of "3D Concrete Printing" Materials and Process Characterization, Economic Considerations and Environmental SustainabilityDocument32 pagesA Review of "3D Concrete Printing" Materials and Process Characterization, Economic Considerations and Environmental Sustainabilityhamed sadaghianNo ratings yet

- Compressive Strength and Elastic Moduli of Intact Rock Core Specimens Under Varying States of Stress and TemperaturesDocument9 pagesCompressive Strength and Elastic Moduli of Intact Rock Core Specimens Under Varying States of Stress and Temperaturesodo18100% (1)

- Torsion of High-Strength Reinforced Concrete Beams and Minimum Reinforcement RequirementDocument8 pagesTorsion of High-Strength Reinforced Concrete Beams and Minimum Reinforcement RequirementSuhas Natu100% (1)

- Confined Concrete Columns With StubsDocument19 pagesConfined Concrete Columns With StubsKaren Perez LievanaNo ratings yet

- Properties of High Strenght Concrete Subjet To Short Terms LoadsDocument7 pagesProperties of High Strenght Concrete Subjet To Short Terms LoadsBegoña Ignacia Aguirre BejaranoNo ratings yet

- Influence of Adding Short Carbon Fibers On The Flexural Behavior of Textile-Reinforced Concrete One-Way SlabDocument18 pagesInfluence of Adding Short Carbon Fibers On The Flexural Behavior of Textile-Reinforced Concrete One-Way SlabShaker QaidiNo ratings yet

- ICC_Fiber_Acceptance_CriteriaDocument17 pagesICC_Fiber_Acceptance_CriteriaDiego TorresNo ratings yet

- Vol_44_43-54Document12 pagesVol_44_43-54Qasim MasoodNo ratings yet

- Optimizing The Mix Design of Cold Bitumen Emulsion Mixtures Using Response Surface MethodologyDocument15 pagesOptimizing The Mix Design of Cold Bitumen Emulsion Mixtures Using Response Surface MethodologyKiplgat ChelelgoNo ratings yet

- Effect of Matrix Self-Healing On The Bond-Slip Behavior of Micro Steel Fibers in Ultra High-Performance ConcreteDocument23 pagesEffect of Matrix Self-Healing On The Bond-Slip Behavior of Micro Steel Fibers in Ultra High-Performance ConcreteNguyen Ngoc Tri HuynhNo ratings yet

- Weiss 2017Document21 pagesWeiss 2017Girard Immanuel SorianoNo ratings yet

- Using Theoretical and Experimental Particle Packing For AggregateDocument109 pagesUsing Theoretical and Experimental Particle Packing For AggregateMayur MaskeNo ratings yet

- PHD DissertationDocument227 pagesPHD DissertationGuilherme HoffmanNo ratings yet

- Compressive Characteristics of Damaged Circular Hollow Section (CHS) Steel Columns Repaired by CFRP or Grout JacketingDocument11 pagesCompressive Characteristics of Damaged Circular Hollow Section (CHS) Steel Columns Repaired by CFRP or Grout Jacketingnomigamer99No ratings yet

- A Probability Characteristic of Crack Intersecting With Embedded Microcapsules in Capsule-Based Self-Healing MaterialsDocument13 pagesA Probability Characteristic of Crack Intersecting With Embedded Microcapsules in Capsule-Based Self-Healing MaterialsNguyen Ngoc Tri HuynhNo ratings yet

- 1-s2.0-S2214785322053779-mainDocument4 pages1-s2.0-S2214785322053779-mainalassane wadeNo ratings yet

- Properties of ultra-high-performance self-compacting fiber-reinforced concrete modified with nanomaterialsDocument31 pagesProperties of ultra-high-performance self-compacting fiber-reinforced concrete modified with nanomaterialsMohamed ArbiliNo ratings yet

- 10-Flexural Strength Recycled AggregateDocument9 pages10-Flexural Strength Recycled Aggregateshna jabarNo ratings yet

- The Technology of Building DefectsDocument373 pagesThe Technology of Building DefectsCatalina CristeaNo ratings yet

- 1-s2.0-S0950061819328272-mainDocument14 pages1-s2.0-S0950061819328272-mainPraveen DevarajanNo ratings yet

- 109-05-Aci Materials Journal Sept.-Oct. 2012 CompleteDocument90 pages109-05-Aci Materials Journal Sept.-Oct. 2012 CompleteKhin Aung ShweNo ratings yet

- 29-3-2024Document133 pages29-3-2024Dr. Satish MahadikNo ratings yet

- 2 ND ConferenceDocument404 pages2 ND ConferenceAntonio Tomas Gonzalez LosaNo ratings yet

- 15-Rehabilitation and Strengthening of Concrete StructuresDocument8 pages15-Rehabilitation and Strengthening of Concrete StructuresHossam AtifNo ratings yet

- Situ Testing ConcreteDocument17 pagesSitu Testing Concreteran2315570No ratings yet

- Bio Remediation of Cracks A Novel Technique To Self Heal Cracks in The ConcreteDocument16 pagesBio Remediation of Cracks A Novel Technique To Self Heal Cracks in The Concreteac2686No ratings yet

- One For GeotechDocument317 pagesOne For GeotechLiti LatikaNo ratings yet

- Proceeding ICCE2021-Volume1Geo-Materials and EnvironmentDocument636 pagesProceeding ICCE2021-Volume1Geo-Materials and Environmentcsdfs.chimieNo ratings yet

- (Asce) CC 1943-5614 0001068Document15 pages(Asce) CC 1943-5614 0001068Arthur DahokloryNo ratings yet

- brussels silica cementDocument97 pagesbrussels silica cementwakefullmindNo ratings yet

- Achievements and Prospects of Advanced Pavement Materials TechnologiesDocument422 pagesAchievements and Prospects of Advanced Pavement Materials TechnologiesmahmoudalieNo ratings yet

- Barret, 2015, PHD Thesis-Internal-curingDocument531 pagesBarret, 2015, PHD Thesis-Internal-curingÁlvaro MendozaNo ratings yet

- CONSTRUCTION CONDITION ASSESSMENT – WHY AND HOW LupasteanuDocument12 pagesCONSTRUCTION CONDITION ASSESSMENT – WHY AND HOW LupasteanuSorin CretuNo ratings yet

- Proceedings VOL II Is GI Brussels 2012Document548 pagesProceedings VOL II Is GI Brussels 2012Gys AnamaliNo ratings yet

- Research On CDM, SustainabilityDocument20 pagesResearch On CDM, SustainabilitySakshi SinglaNo ratings yet

- Polymer Modified Mortar and Concrete Present Status a ReviewDocument12 pagesPolymer Modified Mortar and Concrete Present Status a ReviewAhsanul Kabir SumonNo ratings yet

- Quantitative study of cement hydrationDocument7 pagesQuantitative study of cement hydrationsabarinathmuruganNo ratings yet

- Bridge Maintenance Non-Structural ItemsDocument34 pagesBridge Maintenance Non-Structural Itemsjakka09100% (1)

- Assessment of Carbon Dioxide Emission and Its Impact on High-RiseDocument145 pagesAssessment of Carbon Dioxide Emission and Its Impact on High-RisewalaaeconNo ratings yet

- Statistical Modeling of Mechanical and Transport Properties of Concrete Incorporating Glass PowderDocument19 pagesStatistical Modeling of Mechanical and Transport Properties of Concrete Incorporating Glass PowderAly Hussein AbdallaNo ratings yet

- نسخة من 239R-18 Ultra-High-Performance Concrete An Emerging Technology ReportDocument28 pagesنسخة من 239R-18 Ultra-High-Performance Concrete An Emerging Technology ReportwalidkcNo ratings yet

- Concrete Construction Article PDF - Accelerated Concrete Curing - The BasicsDocument3 pagesConcrete Construction Article PDF - Accelerated Concrete Curing - The BasicsfahadNo ratings yet

- Compressive Strength and Water Absorption Rate For Concrete Mixture With Rice Husk Ash As Sand Replacement and Chicken Feathers As ReinforcementDocument75 pagesCompressive Strength and Water Absorption Rate For Concrete Mixture With Rice Husk Ash As Sand Replacement and Chicken Feathers As ReinforcementDeanielle Grace MarananNo ratings yet

- Rock Dynamics and Applications - State of The Art, 2013Document632 pagesRock Dynamics and Applications - State of The Art, 2013Adriano Cesar De Almeida GonçalvesNo ratings yet

- Denavit and Hajjar - Composite Members and Frames With Applications For Design - Report No. NSEL-034-UIUC 2014Document691 pagesDenavit and Hajjar - Composite Members and Frames With Applications For Design - Report No. NSEL-034-UIUC 2014mulualemNo ratings yet

- AN ANALYTICAL STUDY ON EFFECT OF WIND LOAD FOR TALL BUILDINGDocument15 pagesAN ANALYTICAL STUDY ON EFFECT OF WIND LOAD FOR TALL BUILDINGcumlicospuNo ratings yet

- Materials & Design: Jian-Xin Lu, Peiliang Shen, Hafiz Asad Ali, Chi Sun PoonDocument21 pagesMaterials & Design: Jian-Xin Lu, Peiliang Shen, Hafiz Asad Ali, Chi Sun PoonSOMNo ratings yet

- Article 3 - Applications and Properties of Fibre Reinforced ConcreteDocument9 pagesArticle 3 - Applications and Properties of Fibre Reinforced Concretesara.marrok17No ratings yet

- 12.basalt Fibers - ProjectDocument8 pages12.basalt Fibers - ProjectSahil GandhiNo ratings yet

- Annex NLDocument43 pagesAnnex NLnishnitrr100% (1)

- TVBM 3104Document257 pagesTVBM 3104Bianca CalderónNo ratings yet

- Ultra High Performance Fiber Reinforced Concrete Hydration and MicrostructureDocument3 pagesUltra High Performance Fiber Reinforced Concrete Hydration and MicrostructureShaker QaidiNo ratings yet

- Evaluation of EC2 rules for design of tension lap jointsDocument9 pagesEvaluation of EC2 rules for design of tension lap jointsMartin CibulkaNo ratings yet

- Evaluation of Ultra-High-Performance-Fiber Reinforced Concrete Binder Content Using The Response Surface MethodDocument9 pagesEvaluation of Ultra-High-Performance-Fiber Reinforced Concrete Binder Content Using The Response Surface MethodNuril IshakNo ratings yet

- Numerical analysis of reinforced concrete beamDocument118 pagesNumerical analysis of reinforced concrete beamHowo4DieNo ratings yet

- Metals: Corrosion Effects On Durability of RC StructuresDocument2 pagesMetals: Corrosion Effects On Durability of RC StructuresAvinash PrajapatiNo ratings yet

- Journal of Civil Engineering Vol 65 No 2Document48 pagesJournal of Civil Engineering Vol 65 No 2tevredeNo ratings yet

- MJ July 2018 V. 115 No. 4Document138 pagesMJ July 2018 V. 115 No. 4Carson BakerNo ratings yet

- Seismic Cone Enhances Site CharacterizationDocument24 pagesSeismic Cone Enhances Site CharacterizationSorabh GuptaNo ratings yet

- Probabilistic service life model of RC structures subjected to the combined effect of chloride-induced corrosion and cyclic loadingFrom EverandProbabilistic service life model of RC structures subjected to the combined effect of chloride-induced corrosion and cyclic loadingNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Outrigger Design For High-Rise BuildingsDocument0 pagesOutrigger Design For High-Rise Buildings1753989084533% (9)

- Slender-Concrete-Columns-Non-Sway-Frame-Moment-Magnification-ACI 318-19Document21 pagesSlender-Concrete-Columns-Non-Sway-Frame-Moment-Magnification-ACI 318-19Thadarth NaNo ratings yet

- Strain Limitsvs - Reinforcementratiolimits - AcollectionofDocument13 pagesStrain Limitsvs - Reinforcementratiolimits - AcollectionofDeybi TtNo ratings yet

- Short-Term Mechanical Properties of High-StrengthDocument7 pagesShort-Term Mechanical Properties of High-StrengthDeybi TtNo ratings yet

- Nonlinear Dynamic Analysis of RC Frames UsingDocument22 pagesNonlinear Dynamic Analysis of RC Frames UsingDeybi TtNo ratings yet

- EIM212 16 EIM212Nov2013Document6 pagesEIM212 16 EIM212Nov2013Priviledge MuzotaNo ratings yet

- BE Civil Degree Programme 18Document471 pagesBE Civil Degree Programme 18biopharmacyNo ratings yet

- The Elastic Properties of CarbonatesDocument4 pagesThe Elastic Properties of CarbonatesRodrigo SantosNo ratings yet

- Biomechanics Lecture NotesDocument16 pagesBiomechanics Lecture NotesscdubalNo ratings yet

- D 5449 - D 5449m - 93 r00 Rdu0ndkvrdu0ndlnDocument9 pagesD 5449 - D 5449m - 93 r00 Rdu0ndkvrdu0ndlnJuanNo ratings yet

- Hedayati2014 Article BirdStrikeAnalysisOnATypicalHeDocument12 pagesHedayati2014 Article BirdStrikeAnalysisOnATypicalHeSharan KharthikNo ratings yet

- Tunnel Face PressureDocument11 pagesTunnel Face PressureHarsha Gm100% (2)

- Chapter 2 Poisson's RatioDocument9 pagesChapter 2 Poisson's RatioMalik Umar KhakhNo ratings yet

- The Effective Elastic Moduli of Porous Granular Rocks: P. J. DigbyDocument6 pagesThe Effective Elastic Moduli of Porous Granular Rocks: P. J. DigbySohrab GheibiNo ratings yet

- Evaluation of Shallow Foundation PDFDocument433 pagesEvaluation of Shallow Foundation PDFkyleNo ratings yet

- Kinematics pairs and types of camsDocument40 pagesKinematics pairs and types of camsJohn Paul Coñge Ramos100% (1)

- EBPlateDocument8 pagesEBPlateLeonardo BalocchiNo ratings yet

- 6 - Design of Rigid Pavements - 2019Document106 pages6 - Design of Rigid Pavements - 2019Rakesh SigdelNo ratings yet

- Machine Design Chapter 20: Stress, Strain and Material PropertiesDocument6 pagesMachine Design Chapter 20: Stress, Strain and Material PropertiesSYBRELLE CRUZNo ratings yet

- Stress and StrainDocument24 pagesStress and Strainsatish448No ratings yet

- Laser Spallation of Rocks For Oil Well DrillingDocument6 pagesLaser Spallation of Rocks For Oil Well DrillingmiguelNo ratings yet

- Strain ProblemsDocument4 pagesStrain ProblemsBianca GuevarraNo ratings yet

- Mechanical and Electrical Properties of RocksDocument78 pagesMechanical and Electrical Properties of RocksEric FamacyNo ratings yet

- Analysis of Tent StructuresDocument65 pagesAnalysis of Tent Structuressri_amartNo ratings yet

- Calculating Ejection ForcesDocument5 pagesCalculating Ejection ForcesTrexa GyreueNo ratings yet

- 1974 Gibson1974 The Analytical Method in Soil MechanicsDocument26 pages1974 Gibson1974 The Analytical Method in Soil MechanicsyudhatebeNo ratings yet

- Design of Ground Supported Fiber Reinforced Slab Based On AciDocument12 pagesDesign of Ground Supported Fiber Reinforced Slab Based On AciJhon Guzman CALIDADNo ratings yet

- Unit 11Document20 pagesUnit 11Venkatesh Gangadhar100% (1)

- bfc20903 ch1Document55 pagesbfc20903 ch1nabilahasrulNo ratings yet

- 45662597562obj CivilEngineering 2006paper IDocument18 pages45662597562obj CivilEngineering 2006paper I94738183No ratings yet

- Design of Rigid Pavement CC Road With M30Document108 pagesDesign of Rigid Pavement CC Road With M30Ajay Singh100% (1)

- TR 09 07 Lab Stength Testing of DGR 2 To DGR 6 Core R0Document70 pagesTR 09 07 Lab Stength Testing of DGR 2 To DGR 6 Core R0Daniel MarínNo ratings yet

- 6applications of Theory of Elasticity in Rock MechanicsDocument26 pages6applications of Theory of Elasticity in Rock MechanicsSheshu BabuNo ratings yet