Professional Documents

Culture Documents

Repair Pro - Dr. Fixit Polymer Mortar HB

Uploaded by

AdityaVikramVermaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Repair Pro - Dr. Fixit Polymer Mortar HB

Uploaded by

AdityaVikramVermaCopyright:

Available Formats

Repair Pro – Dr.

Fixit Polymer Mortar HB

BUILDING REPAIRS

H I G H S T R E N G T H , H I G H B U I L D , D U A L S H R I N K A G E C O M P E N S AT E D

R E PA I R M O R TA R C O N F O R M I N G T O E N 1 5 0 4 -3 C L A S S R 4

Description

Dr. Fixit Polymer Mortar HB is a ready-to-use dimensionally stable cementitious fibre reinforced structural grade

repair mortar. It produces a dense, high strength repair mortar, with excellent bond characteristics to steel and

concrete.

226 Repair Pro Dr. Fixit Polymer Mortar HB

Typical Application

Used commonly for general repairs in industry, infrastructure, residential and commercial segment.

}}Repairs to reinforced or pre-stressed slabs, beams or columns.

}}Repair of structural members subjected to repetitive loading.

}}Overhead and vertical applications to restore concrete cover.

}}For renovating and resurfacing concrete structures such as tunnels, bridges, overpasses, retaining walls, beams

columns , building facades, ceilings, balconies and more.

Features

}}Pre- packaged material requiring mixing with clean water on-site to give an easily trowellable mortar.

}}Complies to the requirements for the performance characteristics of class R4 mortar of EN 1504-part 3.

}}Excellent adhesion to both old concrete (≥ 2 MPa) in accordance to EN1504 - 3.

}}Can be applied in a single layer between up to 30 mm thick.

}}Repair work on deteriorated concrete beams, pillars, buffer walls, cornices, edges of balconies and structural

members and elements that require the use of mortar with high mechanical performance characteristics.

}}Repairs and structural strengthening of concrete.

}}Repairing precast concrete members and elements.

}}Repairs to concrete damaged by rusty reinforcing bars due to carbonation.

Application thickness

}}Minimum applied thickness : 10 mm

}}Overhead : 40 mm in two layers

}}Vertical : 30 mm in single layer

Packaging

25 kg

Method of Application

1 S U R FAC E P R E PA R AT I O N

}}All damaged concrete should be removed.

}}Ensure that substrates are structurally sound, stable and solid & all damaged concrete should be removed.

}}Thoroughly clean the surface of substances that could affect bond strength of Dr. Fixit Polymer Mortar HB,

including dirt, paint, wax, oil, grease, form release agents, laitance, loose toppings, foreign substances.

}}Mechanically profile and prepare concrete surfaces by abrasive blasting, waterjetting or other engineer-

approved methods.

73

RPP Mortar HB-31/05/21

BUILDING REPAIRS

}}Ensure that the concrete substrate and ambient temperatures are between (10°C and 35°C) before application.

}}Before application of Dr. Fixit Polymer mortar HB, saturate surface-dry (SSD) and scrubcoat to ensure a secure

bond. Use reinforcement bars for added strength as needed.

2 P R E- W E T T I N G T H E S U B S T R AT E

226 Repair Pro Dr. Fixit Polymer Mortar HB

}}The Prepared substrate should be pre-soaked, preferably for 24 hours, but at least 2 hours before application of

Dr. Fixit Polymer Mortar HB.

}}The surface must be saturated surface dry, but without standing water.

}}Corroded steel/ Rebars to be exposed around its circumference completely.

}}Saw/disc cut edges of repair to 5 mm depth.

}}Replace totally corroded rebars.

}}Surface should be prepared thoroughly to provide heavy profile key.

3 M I X I N G

}}Dr. Fixit Polymer Mortar HB must be mixed mechanically. For this, heavy-duty slow speed drill with spiral mixing

paddle or forced action mixer can be used.

}}Add 4.25 litres of water into the mixer. Start the mixer and add the Polymer Mortar HB powder rapidly and

continuously. Mix for 3 to 5 minutes until mortar is homogeneous and lump free along with it.

}}Under no circumstances should excess water be added. Little extra water may be required in hot climatic

conditions.

}}The quantity water required will generally be between 4.25 litres and 4.50 litres per 25 kg bag of Dr. Fixit

Polymer mortar HB

}}If ambient temperature is more than 30 degree C, use chilled water for mixing and store unused product in

shed. For better results maintain the mixed temperature of product at 35 degree C. Mix only as much material

as can be applied within 45 minutes.

4 A P P L I C AT I O N

}}Clean any exposed steel reinforcement and coat with Dr. Fixit Zinc Rich Primer to protect against corrosion.

}}After mixing, Dr. Fixit Polymer Mortar HB can be applied by trowel on vertical and overhead surfaces.

}}When applying by hand Dr. Fixit Polymer Mortar HB must be forced tightly into the substrate to ensure complete

contact with the pre-wetted substrate. In situations where reinforcement steel is countered, the mixed material

should be placed behind the bars tightly and then subsequent thickness should be built up in layers, each layer

being upto 20 mm thick (wet on dry method).

}}A thin scrape coat or contact layer before building up to the required thickness, wet on wet, will improve

adhesion especially in case of hand application. If the concrete is pours apply one coat of Dr. Fixit Pidicrete MPB

in the ratio of 1:1 (MPB:Cement) as a bond coat .

}}Apply Dr. Fixit Polymer Mortar HB to the desired layer thickness of 20 to max 40 mm (wet on dry method) and

level using a screeding bar, trowel or wooden board. Can be applied in thicker layers in smaller patches or where

additional reinforcement is present. Smoothing with a trowel or finishing by float or sponge can be done as soon

as the mortar has begun to stiffen.

5 C U R I N G

}}During curing, protect Dr. Fixit Polymer Mortar HB from excessive heat and draft conditions.

}}Mist-spray the surface with water during the first 24 hours of wet curing. Alternatively, use damp burlap, or a

suitable ASTM C309 water- based curing compound. Do not use a solvent-based curing compound.

Precautions & Limitations

}} Strictly follow water-powder ratio as specified .

}}Ensure full circumference exposure of reinforced steel.

74

BUILDING REPAIRS

Consult structural engineer if the diameter of rebar is reduced by more than 20% of the original diameter.

}}

Replacement or provision of additional steel shall be done in consultation with structural consultant.

}}

The product during application should not be exposed to running water or prior to final setting.

}}

Curing is not advised by means of waterponding.

}}

226 Repair Pro Dr. Fixit Polymer Mortar HB

Remove curring compound completely after 28 days before the subsequent finish.

}}

Technical Information

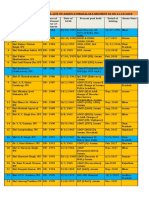

PROPERTIES SPECIFICATION RESULTS

Appearance Free flowing Powder

Colour Grey

Water : Product ratio by weight 0.17 – 0.18

Fresh Wet density. kg / m 3

2200 ± 100

Compressive strength @ 30 deg C, 1 day - N/mm 2

BS : 6319 : part 2 15 N/mm2 (Min.)

3 days - N/mm2 BS : 6319 : part 2 25 N/mm2 (Min.)

7 days - N/mm2 BS : 6319 : part 2 35 N/mm2 (Min.)

28 day - N/mm2 BS : 6319 : part 2 45 N/mm2 (Min.)

Flexural strength, 28 days - N/mm2 BS : 6319 : part 3 8 N/mm2 (Min.)

Tensile strength, 28 days – N/mm2 BS : 6319 : part 7 4.5 N/mm2 (Min.)

Bond Strength, 28 days – N/mm2 ASTM C 882 11 N/ mm2 (Min )

Water absorption 28 days BS 1882 : Part 122 < 2%

Length Change 28 days wet cured ASTM C 157 +0.02%

Performance requirements for Cementitious Structural Repair Mortar Dr. Fixit Polymer Mortar HB -

Conforming to EN 1504-3 Class R4 and following results were obtained at water : powder ratio of 0.18

Performance characteristics Test method Structural Repair Class R4

Requirement in Test Results for

(EN 1504, part 3) Polymer Mortar

HB

Compressive Strength, Mpa (At 28 days) EN 12190-1998 ≥45 46.29

Chloride content, % by mass EN 1504-3: 2005 ≥ 0.05 % 0.01 %

Adhesive Bond Test, Mpa EN 1542 ≥2 Without 2.44

primer

Shrinkage/Expansion Dry Condition Adhesive EN 12617 -4 ≥2 2.22

Bond test, Mpa

Shrinkage/Expansion Wet Condition Adhesive EN 12617- 4 ≥2 2.22

Bond test, Mpa

Thermal Compatibility Adhesive Bond test, Mpa EN 13687- 4 ≥2 2.23

Coefficient of Linear Thermal Expansion, EN 1770-1998 - 2.68x10-5

mm/mm0c

Capillary Absorption, kg/m2h1/2 EN 13057 ≤0.5 ≤0.31

75

BUILDING REPAIRS

Theoretical Coverage

}}1.4 m2 per 25 Kg pack at 10 mm thickness

}}Yield - 14 ltrs. at W/P ratio of 0.18

Shelf Life

226 Repair Pro Dr. Fixit Polymer Mortar HB

}}Shelf life is 6 months from date of manufacturing in unopen condition.

}}Store at cool and dry place away from moisture.

Health & Safety

This products contains cement. And contact with skin may cause irritation. It should not be inhaled and a quality

certified PPE should be used whilst handling, pouring and mixing the powder. Avoid contact with the product by

working carefully, using a barrier cream. If any contact does occur, wash thoroughly with soap and water. Avoid

contact with eyes, if such contact occurs flush of water irrigate with water for 20 minutes and seek medical advice.

If swalloed seek medical advise immediately- do not induce vomiting. See MSDS for further information..

Other Products Categories available

Dr. Fixit brings you the widest range of Construction Chemicals

Pidilite Industries Limited DISCLAIMER The product information & application details given by the company

Construction Chemicals Division & its agents has been provided in good faith & meant to serve only as a general

Ramkrishna Mandir Road, Post Box No. 17411 guideline during usage. Users are advised to carry out tests & take trials to ensure on

the suitability of products meeting their requirement prior to full scale usage of our

Andheri (E) Mumbai 400059 INDIA

products. Since the correct identification of the problems, quality of other materials

Tel +91-22-2835 7000 • Fax +91-22-2835 7008

used and the on-site workmanship are factors beyond our control, there are no

www.drfixit.co.in • info@drfixit.co.in expressed or implied guarantee / warranty as to the results obtained. The company

Dr. Fixit Advice Centre (Toll Free No.) 1800 209 5504 does not assume any liability or consequential damage for unsatisfactory results,

arising from the use of our products.

76

You might also like

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- 226 Dr. Fixit Repair Polymer MortarDocument3 pages226 Dr. Fixit Repair Polymer MortarNav Nirman Con SpecialitiesNo ratings yet

- DR Fixit Pidicrete MPB 71 1Document3 pagesDR Fixit Pidicrete MPB 71 1amandeepsuperanNo ratings yet

- 233 DR Fixit Pidicrete WPDocument3 pages233 DR Fixit Pidicrete WPreshmitapallaNo ratings yet

- Fosroc Renderoc HB45 1111Document4 pagesFosroc Renderoc HB45 1111Nikola ArsovskiNo ratings yet

- Polycrete STDocument2 pagesPolycrete STjovindhaNo ratings yet

- 302 DR Fixit Super LatexDocument3 pages302 DR Fixit Super LatexKathir Pandyan0% (1)

- Nitomortar HBDocument4 pagesNitomortar HBBalasubramanian AnanthNo ratings yet

- Renderoc TGDocument4 pagesRenderoc TGBalasubramanian Ananth100% (1)

- Renderoc HB25: Constructive SolutionsDocument4 pagesRenderoc HB25: Constructive SolutionsDoby YuniardiNo ratings yet

- Pidicrete CF 204Document3 pagesPidicrete CF 204Casey BallNo ratings yet

- Renderoc HB40 NewDocument5 pagesRenderoc HB40 NewJayvee G. DignosNo ratings yet

- Dr. Fixit Dampguard 145 1 PDFDocument3 pagesDr. Fixit Dampguard 145 1 PDFvbadsNo ratings yet

- Flo-Grout BP800Document26 pagesFlo-Grout BP800qasim078100% (1)

- Fosroc Renderoc HBS Mar 10Document4 pagesFosroc Renderoc HBS Mar 10Nikola ArsovskiNo ratings yet

- Polyrepair ST 50: High Strength Cementitious Repair MortarDocument2 pagesPolyrepair ST 50: High Strength Cementitious Repair MortarVaittianathan MahavapillaiNo ratings yet

- DR Fixit Polyplus CPDocument4 pagesDR Fixit Polyplus CPLalith KumarNo ratings yet

- DR Fixit Floor Repair Mortar 66 1Document3 pagesDR Fixit Floor Repair Mortar 66 1Suzaikumar R SanglikarNo ratings yet

- 301 Dr. Fixit Pidicrete URPDocument4 pages301 Dr. Fixit Pidicrete URPAlpesh ShahNo ratings yet

- Fosroc Conbextra EP40: Free Flowing, Epoxy Resin GroutDocument2 pagesFosroc Conbextra EP40: Free Flowing, Epoxy Resin GroutVincent JavateNo ratings yet

- DR Fixit Piditop 444 106 1Document3 pagesDR Fixit Piditop 444 106 1Mohammed Abdul BaseerNo ratings yet

- DR Fixit Pidicrete MPB 71 1Document3 pagesDR Fixit Pidicrete MPB 71 1vishutayalNo ratings yet

- Rheomix 131: Page 1 of 2Document2 pagesRheomix 131: Page 1 of 2Ankita Baban Gavade100% (1)

- Cipoxy 17Document2 pagesCipoxy 17KishoreNo ratings yet

- Nitobond - SBR FosrocDocument6 pagesNitobond - SBR FosrocVedachalam ManiNo ratings yet

- DR Fixit Epoxy Floor Screed 90 1Document4 pagesDR Fixit Epoxy Floor Screed 90 1amit sharmaNo ratings yet

- Abe Construction Chemicals Duraflex DatasheetDocument2 pagesAbe Construction Chemicals Duraflex DatasheetEthanNo ratings yet

- DR Fixit Pidifin 2k PDFDocument3 pagesDR Fixit Pidifin 2k PDFram ganeshNo ratings yet

- Conbextra STDDocument2 pagesConbextra STDPritha DasNo ratings yet

- Conbextra PDocument4 pagesConbextra Pm.elsanee.cubicNo ratings yet

- DR Fixit Pidipoxy MI EP Jan 2020Document3 pagesDR Fixit Pidipoxy MI EP Jan 2020rakeshNo ratings yet

- Renderoc HB40: High-Technology Medium Weight Concrete Reinstatement Mortar Uses Design CriteriaDocument4 pagesRenderoc HB40: High-Technology Medium Weight Concrete Reinstatement Mortar Uses Design CriteriasammyNo ratings yet

- 302 Dr. Fixit Super LatexDocument3 pages302 Dr. Fixit Super Latexmcg100% (1)

- 60 Piditop 444Document3 pages60 Piditop 444Jay RajNo ratings yet

- CONBEXTRA GP - JordanDocument4 pagesCONBEXTRA GP - JordanShabbir HussainNo ratings yet

- 6 2 3 6 3 Polybond Ac PDFDocument2 pages6 2 3 6 3 Polybond Ac PDFHtun ZarniNo ratings yet

- CHRYSO Beton Cire Finishing - DsDocument4 pagesCHRYSO Beton Cire Finishing - Dsjeffkarthick1No ratings yet

- Renderoc HSDocument2 pagesRenderoc HSMansoor AliNo ratings yet

- DR Fix It Micro ConcreteDocument3 pagesDR Fix It Micro ConcreteAjaykumar MistryNo ratings yet

- Polypoxy FC: Solvent Free Epoxy Resin CoatingDocument2 pagesPolypoxy FC: Solvent Free Epoxy Resin CoatingAlexi ALfred H. TagoNo ratings yet

- Nitoflor Hardtop PDFDocument4 pagesNitoflor Hardtop PDFVincent JavateNo ratings yet

- Nitobond SBR TDS PDFDocument3 pagesNitobond SBR TDS PDFJong Dollente Jr.No ratings yet

- Nitobond SBR PDFDocument4 pagesNitobond SBR PDFhelloitskalaiNo ratings yet

- MasterProtect 1891Document2 pagesMasterProtect 1891SHAIK ASIMUDDINNo ratings yet

- 112 DR Fixit Pidifin 2kDocument3 pages112 DR Fixit Pidifin 2kreshmitapallaNo ratings yet

- WIKA - Kijing Terminal Site Visit July 2019Document38 pagesWIKA - Kijing Terminal Site Visit July 2019virez jeloveNo ratings yet

- 202 Dr. Fixit Crack-X PowderDocument3 pages202 Dr. Fixit Crack-X Powderkkundan52No ratings yet

- DR Fixit PU Plain InjectionDocument3 pagesDR Fixit PU Plain InjectionMiscNo ratings yet

- DR Fixit CSL 4000 89 1Document4 pagesDR Fixit CSL 4000 89 1Harsh Kr. SharmaNo ratings yet

- Polybit Polypoxy FCDocument2 pagesPolybit Polypoxy FCrazeeth1212No ratings yet

- Cempatch HM PDFDocument2 pagesCempatch HM PDFharish14586No ratings yet

- Fosroc Conbextra BB80: Constructive SolutionsDocument4 pagesFosroc Conbextra BB80: Constructive SolutionsVincent JavateNo ratings yet

- Concrete Repair - Estopatch RSP - TDS - 111203Document2 pagesConcrete Repair - Estopatch RSP - TDS - 111203Elias Jaya PerkasaNo ratings yet

- Betocrete - C35: Technical Data SheetDocument2 pagesBetocrete - C35: Technical Data SheetFair MutasaNo ratings yet

- Nitomortar BDocument2 pagesNitomortar BtalatzahoorNo ratings yet

- DR Fixit Piditop 333 105 1Document3 pagesDR Fixit Piditop 333 105 1hunky11No ratings yet

- Conbextra EP40 UAEDocument2 pagesConbextra EP40 UAEjasonNo ratings yet

- 63db379fced6e DF Fastflex Brochure PDFDocument4 pages63db379fced6e DF Fastflex Brochure PDFEr Shashank SharmaNo ratings yet

- Polyrepair Lw35: Lightweight Concrete Repair MortarDocument2 pagesPolyrepair Lw35: Lightweight Concrete Repair MortarVaittianathan MahavapillaiNo ratings yet

- Fosroc Nitomortar FC: High Strength Trowel Grade, Epoxy Resin Fairing Coat, Repair Mortar, Bedding and AdhesiveDocument2 pagesFosroc Nitomortar FC: High Strength Trowel Grade, Epoxy Resin Fairing Coat, Repair Mortar, Bedding and AdhesiveVincent JavateNo ratings yet

- Concrete EngineersDocument2 pagesConcrete EngineersAdityaVikramVermaNo ratings yet

- DR Fixit Flexi Pu 270 I PDFDocument4 pagesDR Fixit Flexi Pu 270 I PDFDeepak KhannaNo ratings yet

- Dr. Fixit Samshield XL 1500/2100: Cross Laminated Sbs Self Adhesive WaterproofingDocument3 pagesDr. Fixit Samshield XL 1500/2100: Cross Laminated Sbs Self Adhesive WaterproofingAdityaVikramVermaNo ratings yet

- Tendernotice 1Document24 pagesTendernotice 1AdityaVikramVermaNo ratings yet

- C-23 FinalDocument3 pagesC-23 FinalAdityaVikramVermaNo ratings yet

- Dr. Fixit Flexi PU 270 (I) : Polyurethane Waterproofing MembraneDocument5 pagesDr. Fixit Flexi PU 270 (I) : Polyurethane Waterproofing MembraneAdityaVikramVermaNo ratings yet

- Dr. Fixit Foamshield: Spray Applied Polyurethane Foam SystemDocument4 pagesDr. Fixit Foamshield: Spray Applied Polyurethane Foam SystemAdityaVikramVermaNo ratings yet

- Department of Anaesthesiology, KGMU UP, Lucknow List of All ResidentsDocument5 pagesDepartment of Anaesthesiology, KGMU UP, Lucknow List of All ResidentsAdityaVikramVermaNo ratings yet

- Aditya Vikram Verma - CVDocument2 pagesAditya Vikram Verma - CVAdityaVikramVermaNo ratings yet

- Dr. Fixit Polyplus CP Admix: Integral Crystalline Waterproofing AdmixtureDocument3 pagesDr. Fixit Polyplus CP Admix: Integral Crystalline Waterproofing AdmixtureAdityaVikramVermaNo ratings yet

- Z 0 Uku 7 Appendix IFORM6Document1 pageZ 0 Uku 7 Appendix IFORM6AdityaVikramVermaNo ratings yet

- Architects HsiidcDocument16 pagesArchitects HsiidcankurNo ratings yet

- 6077d17c9db8e Dr. Fixit Superseal 4500 PuhDocument4 pages6077d17c9db8e Dr. Fixit Superseal 4500 PuhAdityaVikramVermaNo ratings yet

- Masterseal M 811 TdsDocument4 pagesMasterseal M 811 TdsAdityaVikramVermaNo ratings yet

- Fosroc Polyurea WH 200Document4 pagesFosroc Polyurea WH 200AdityaVikramVermaNo ratings yet

- Important Press Release-15.7.2021Document3 pagesImportant Press Release-15.7.2021AdityaVikramVermaNo ratings yet

- Ips Civil List - 2018 PDFDocument5 pagesIps Civil List - 2018 PDFVijay MisraNo ratings yet

- EC - Compliance - Report - June - 2019Document42 pagesEC - Compliance - Report - June - 2019AdityaVikramVermaNo ratings yet

- Public Notice For PG Counselling 2020Document1 pagePublic Notice For PG Counselling 2020AdityaVikramVermaNo ratings yet

- NIT PanchkulaDocument30 pagesNIT PanchkulaAdityaVikramVermaNo ratings yet

- VigyaptiAdvt2021WrittenExam 24.06.2021Document1 pageVigyaptiAdvt2021WrittenExam 24.06.2021AdityaVikramVermaNo ratings yet

- ODs July 2021 Airbus Commercial AircraftDocument42 pagesODs July 2021 Airbus Commercial AircraftAdityaVikramVermaNo ratings yet

- Approved - Syllabus VTH To VIII Sem AutomobileDocument37 pagesApproved - Syllabus VTH To VIII Sem AutomobileAdityaVikramVermaNo ratings yet

- IRCTC - Plan My TravelDocument2 pagesIRCTC - Plan My TravelAdityaVikramVermaNo ratings yet

- Strength of MaterialsDocument3 pagesStrength of Materialsvp0209198825% (4)

- Introduction-Phase DiagramDocument10 pagesIntroduction-Phase DiagramYassin Abd El AalNo ratings yet

- Ductile Iron Fittings, Dismantling Joints and XR Reducers - 0Document30 pagesDuctile Iron Fittings, Dismantling Joints and XR Reducers - 0Mahmoud AwadNo ratings yet

- Module 3 - Soil ClassificationDocument20 pagesModule 3 - Soil ClassificationCjoy De RoxasNo ratings yet

- Datasheet For Safety ShowerDocument2 pagesDatasheet For Safety ShowernhatvipNo ratings yet

- Exam Preparation Chartered Member Past Paper 20220303Document17 pagesExam Preparation Chartered Member Past Paper 20220303SettuNo ratings yet

- What's New in ISO 14692-2017 EditionDocument3 pagesWhat's New in ISO 14692-2017 EditionAvik KunduNo ratings yet

- Sample DisturbanceDocument29 pagesSample DisturbanceTheo Philus50% (2)

- Ashbee Corporate BrochureDocument13 pagesAshbee Corporate Brochuregarych72No ratings yet

- Bonding Solutions For Assembly OperationsDocument11 pagesBonding Solutions For Assembly OperationsID ICVONo ratings yet

- Axial DeformationDocument19 pagesAxial DeformationVanessa AggabaoNo ratings yet

- Geotechnical LabDocument76 pagesGeotechnical LabJAZIRA BINTI JEFFRY -No ratings yet

- CT3 - Floating Floor Loading Calculation - R0 - 020320Document4 pagesCT3 - Floating Floor Loading Calculation - R0 - 020320MyureshwaranNo ratings yet

- Bamboo Usage Evaluation As Reinforcement of Highway Rigid PavementDocument12 pagesBamboo Usage Evaluation As Reinforcement of Highway Rigid PavementOcta IrawanNo ratings yet

- Crack Width As Per BS 8110Document1 pageCrack Width As Per BS 8110Pujan NeupaneNo ratings yet

- Remi Holdings LTD: LEED BD+C: New Construction (v2009)Document1 pageRemi Holdings LTD: LEED BD+C: New Construction (v2009)Zam ZamNo ratings yet

- 6001F Rev 07 Material, Fabrication and Installation StructureDocument83 pages6001F Rev 07 Material, Fabrication and Installation StructurePatrickioNo ratings yet

- Trampa de Vapor Tipo Boya Modelo FTEDocument4 pagesTrampa de Vapor Tipo Boya Modelo FTEMaicol CarrascoNo ratings yet

- Ductile Errors in StaadDocument2 pagesDuctile Errors in Staadsitaram gvNo ratings yet

- Pavement DeteriorationDocument4 pagesPavement DeteriorationMd Habibur RahmanNo ratings yet

- Creating A Balanced Mix Design For High-Strength Concrete: by Bryce SimonsDocument4 pagesCreating A Balanced Mix Design For High-Strength Concrete: by Bryce SimonsFrancis CayananNo ratings yet

- Properties of Building Materials and Their Importance in ConstructionDocument5 pagesProperties of Building Materials and Their Importance in ConstructionDaisy Jane LulabNo ratings yet

- SCPL Phe BoqDocument120 pagesSCPL Phe BoqSajeshKumarNo ratings yet

- Wood SteelDocument50 pagesWood SteelAnonymous 7lnR7QkssNo ratings yet

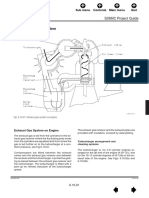

- MAN B&W Diesel A/S S26MC Project Guide: 6.10 Exhaust Gas SystemDocument10 pagesMAN B&W Diesel A/S S26MC Project Guide: 6.10 Exhaust Gas SystemMuhammad Ihsan KamilNo ratings yet

- Jhilke Khola Hydrology Aug 1 2021 20mx1Document15 pagesJhilke Khola Hydrology Aug 1 2021 20mx1Ranjit Kumar ShahNo ratings yet

- Internal PHE Works - BOQDocument2 pagesInternal PHE Works - BOQSenthilKumar RameshNo ratings yet

- Nova ABS Plastic Formwork by Sandeep NaikwadeDocument11 pagesNova ABS Plastic Formwork by Sandeep NaikwadeNovaFormworkNo ratings yet

- Shell Structures and Cable StructuresDocument33 pagesShell Structures and Cable StructuresSanika Kadam100% (1)

- Applications of Value EngineeringDocument6 pagesApplications of Value EngineeringJohn Ray CuevasNo ratings yet