Professional Documents

Culture Documents

Utd 1000 Series Laboratory Oven Range: User Manual

Utd 1000 Series Laboratory Oven Range: User Manual

Uploaded by

Costel FloreaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Utd 1000 Series Laboratory Oven Range: User Manual

Utd 1000 Series Laboratory Oven Range: User Manual

Uploaded by

Costel FloreaCopyright:

Available Formats

LABORATORY OVENS REVISION 4 1

USER MANUAL 18 09 2015

Mod. UTD 1295, 1300, 1305, 1310, 1315

UTD 1000 SERIES LABORATORY OVEN RANGE

UTD 1315 UTD 1300

USER MANUAL

UTEST MATERIAL TESTING EQUIPMENT

www.utest.com.tr

LABORATORY OVENS REVISION 4 2

USER MANUAL 18 09 2015

Mod. UTD 1295, 1300, 1305, 1310, 1315

NO INDEX PAGE

1 INTRODUCTION 3

2 WARNINGS and SAFETY DEVICES 4

3 GENERAL DESCRIPTION 5

4 TECHNICAL CHARACTERISTICS 5

5 IDENTIFICATION 6

6 SET UP 6

7 SAFETY RULES 7

8 USAGE INSTRUCTIONS 7

9 DOCUMENTS 12

10 TECHNICAL SPECIFICATION 22

11 CUSTOMER SUPPORT - Warranty 24

12 NOTES 25

NOTE: In order to increase product quality, the device technical specifications may be changed without informing beforehand. The

photographs in the user manual are representative ones. So, they may not be as completely the same as your device.

UTEST MATERIAL TESTING EQUIPMENT

www.utest.com.tr

LABORATORY OVENS REVISION 4 3

USER MANUAL 18 09 2015

Mod. UTD 1295, 1300, 1305, 1310, 1315

1. INTRODUCTION

The following symbols are used in this manual

This symbol recalls attention warning or procedure which assures operator safety or good functioning of

apparatus.

This symbol recalls attention useful information about test procedure and about easy use of the machine

and suggestions.

It is important to install device correctly, to maintain it regularly and to use as described manner.

The guarantee period of the machine you have bought is 1 year and the product end-of-life is 10 years. Product end-of-

life is the time in which all parts of the machine has to be kept in the stock of the company.

PS: Do not use the machine without reading this instruction manual. This manual will help you to use the machine

easily and safely. Specific test procedures are not mentioned in this instruction manual. It is recommended to read

related standards for further information.

This machine is manufactured without damaging the environment and animals.

UTEST MATERIAL TESTING EQUIPMENT

www.utest.com.tr

LABORATORY OVENS REVISION 4 4

USER MANUAL 18 09 2015

Mod. UTD 1295, 1300, 1305, 1310, 1315

2. WARNINGS and SAFETY DEVICES

Please read and follow the procedure below. There may be injuries, performance decrease of the machine or physical

damage. In such a case, every guarantee and reliability undertakings will be invalid.

WARNINGS

The device is designed to be used in the laboratory conditions. Do not set it in a dusty, humid or hot medium.

Set the machine correctly, use it as described manner and do maintenance regularly.

Contact with the technical service department in case the power cable or electrical cable is broken down.

Some problems may cause due to electrical equipment of the building. So the machine must be set into an

electrically suitable medium. It is very important to ground the machine and that the earth of the electrical

supply is in good condition. In the case of inefficient and non-existent earth, there is a potential danger to

operator, machine and the working performance of the Control Unit.

Do not change electric circuit of the machine.

While the power cable is plugged into the mains or while the machine is running, do not remove any parts of

the machine.

Only qualified person should perform the related repairs.

Do not change the calibration settings of the machine.

If the instructions given in troubleshooting cannot help to solve your problem, plug out the power cable and call

UTEST technical service.

The machine must only be used with samples and apparatus given in the instruction manual. Do not use

samples which has inappropriate hardness for the platens of the machine.

Keep this manual for future reference

Do not forget other general warning rules which are not given in this manual.

PS: The warnings are dedicated for all related UTEST Machine Park. Therefore, some of them may not be applicable to this

particular device.

SAFETY DEVICES:

UTEST UTD 1300 Series Lab. Ovens are fitted with:

Over temperature protection via an analogue over-temperature protection thermostat.

UTEST MATERIAL TESTING EQUIPMENT

www.utest.com.tr

LABORATORY OVENS REVISION 4 5

USER MANUAL 18 09 2015

Mod. UTD 1295, 1300, 1305, 1310, 1315

3. GENERAL DESCRIPTION

UTD 1000 Series Laboratory Ovens consist of 5 different capacities (50, 120, 250, 500 and 750 LT capacity versions

are available). They have been designed for drying asphalt, soil, rock, concrete, aggregate or similar materials. From

ambient to 250 ˚C temperature range with less than ±5 ˚C precision.

The interior is manufactured from stainless steel and the exterior is robustly constructed from sheet steel finished in

powder coated paint. The oven is also insulated with thick fiber-glass material.

All models are fan circulated (forced convection), fitted with the same direct reading digital control unit and equipped

with an analogue over-temperature protection thermostat. Laboratory Ovens are supplied with 2, 3, 4 or 5 shelves

according to the capacity.

The following standards such as;

ASTM C127-C136-D558-D559-D560-D698-D1557-D1559

EN 932-5 / 1097-5

BS 1377:1 / 1924:11

UNE 103300

in terms of technical properties.

4. TECHNICAL CHARACTERISTICS

Maximum Temperature: 250 °C for all models

Accuracy: Better than ±5°C (Class IB to ASTM E145)

Temperature Sensor: PT100 positioned inside the drying chamber, half way up on the left hand side.

Ambient Working Temperature: Between 5 and 40 °C

UTEST MATERIAL TESTING EQUIPMENT

www.utest.com.tr

LABORATORY OVENS REVISION 4 6

USER MANUAL 18 09 2015

Mod. UTD 1295, 1300, 1305, 1310, 1315

Heating Elements:

UTD 1295 … 1 Heating Elements

UTD 1300 … 2 Heating Elements

UTD 1305 … 4 Heating Elements

UTD 1310 … 6 Heating Elements

UTD 1315 … 8 Heating Elements

Digital Thermo-regulator: Closed loop PID control

5. IDENTIFICATION

The serial number and electrical characteristics of the oven are shown on the label attached to the unit. It is

recommend that this label is not removed or damaged. Always quote the model number and serial number when

ordering spare parts.

6. SET UP

The working environment must be sufficiently aired and must not contain dust. The temperature of the indoor

location has to be kept within the limit. The oven cannot work with an ambient temperature below 0°C.The oven

must not be used in explosive or corrosive environments. The oven is not designed to be used out doors and must

be protected against atmospheric elements. Place the oven on a stable base before connecting the mains. Ensure

that the mains supply corresponds to which of the oven.

UTEST MATERIAL TESTING EQUIPMENT

www.utest.com.tr

LABORATORY OVENS REVISION 4 7

USER MANUAL 18 09 2015

Mod. UTD 1295, 1300, 1305, 1310, 1315

7. SAFETY RULES

Use a suitable thermo-magnetic switch breaker on the mains supply line. The oven has to be earthed as per local

regulations.

The external surfaces of the oven may reach high temperatures during functioning. Use proper protective means

(e.g. gloves) while operating with the equipment.

8. USAGE INSTRUCTIONS

START-UP PROCESS:

□When the oven is ready for usage, turn on the oven using the main ON/OFF switch.

□ As soon as the main switch is on, below mentioned functions are activated.

The thermo-regulator

The heating elements

The fan/fans mounted on the panel of the oven

The control unit

□Front fascia (picture 1) consists of DT104 control unit, on/off switch and alarm led. Power cable and short circuit

breakers are located (picture 2) at rear section.

□ Control panel values are preset at UTEST so that there is nothing to get adjusted by the customer, but OFFSET

value for user calibration. When the oven temperature is calibrated by the customer via a reference thermometer, the

difference between the temperature values (if any) of control panel and reference thermometer can be compensated

via this submenu, please check Picture 4 for the related illustration. All the submenus of the control panel can be

observed from Picture 3.

UTEST MATERIAL TESTING EQUIPMENT

www.utest.com.tr

LABORATORY OVENS REVISION 4 8

USER MANUAL 18 09 2015

Mod. UTD 1295, 1300, 1305, 1310, 1315

Picture 1: The Front Fascia of the Control Box Picture 2: The Rear Section of the Control Box

UTEST MATERIAL TESTING EQUIPMENT

www.utest.com.tr

LABORATORY OVENS REVISION 4 9

USER MANUAL 18 09 2015

Mod. UTD 1295, 1300, 1305, 1310, 1315

Picture 3: Menu System of the Control Unit

UTEST MATERIAL TESTING EQUIPMENT

www.utest.com.tr

LABORATORY OVENS REVISION 4 10

USER MANUAL 18 09 2015

Mod. UTD 1295, 1300, 1305, 1310, 1315

Hold UP / SET buttons together approx. 3 seconds to reach the code screen. Then by using UP/DOWN buttons, enter 162. Use

set button in order to roll down the submenus. When you enter OFFSET submenu, which it is coded as oFFS, place the desired

temperature difference by using UP/DOWN buttons.

Picture 4: Adjusting Requested Offset Temperature

□ The oven is fitted with a forced ventilation system which causes an air flow in the oven from the bottom to the top

and ensures temperature uniformity at various points in the oven chamber (maximum variation less than ±5°C).

□ The vent duct allows:

- Faster cooling when the heating elements are switched off.

- Insertion of an additional temperature probe for checking/calibration of oven temperature.

UTEST MATERIAL TESTING EQUIPMENT

www.utest.com.tr

LABORATORY OVENS REVISION 4 11

USER MANUAL 18 09 2015

Mod. UTD 1295, 1300, 1305, 1310, 1315

Before opening the oven door, ensure that the chamber temperature has dropped to the safe level.

TEMPERTURE ADJUSTMENT:

Set Temperature Adjustment:

Picture 5: Actual and Set Temperature Values

In order to change the set temperature (set point, in YELLOW colour), hold SET button for 2-3

seconds and adjust the requested set temperature via arrow buttons.

The direction keys increase/decrease the value by one digit at a time, but if the buttons kept

pressed, the related set temperature value continuously and rapidly changes to allow quick

setting of the desired value.

Exit from the input mode is made automatically if no key is pressed for 2 seconds and the new set point is saved

and used.

UTEST MATERIAL TESTING EQUIPMENT

www.utest.com.tr

LABORATORY OVENS REVISION 4 12

USER MANUAL 18 09 2015

Mod. UTD 1295, 1300, 1305, 1310, 1315

9. DOCUMENTS

UTEST MATERIAL TESTING EQUIPMENT

www.utest.com.tr

LABORATORY OVENS REVISION 4 13

USER MANUAL 18 09 2015

Mod. UTD 1295, 1300, 1305, 1310, 1315

UTEST MATERIAL TESTING EQUIPMENT

www.utest.com.tr

LABORATORY OVENS REVISION 4 14

USER MANUAL 18 09 2015

Mod. UTD 1295, 1300, 1305, 1310, 1315

UTEST MATERIAL TESTING EQUIPMENT

www.utest.com.tr

LABORATORY OVENS REVISION 4 15

USER MANUAL 18 09 2015

Mod. UTD 1295, 1300, 1305, 1310, 1315

UTEST MATERIAL TESTING EQUIPMENT

www.utest.com.tr

LABORATORY OVENS REVISION 4 16

USER MANUAL 18 09 2015

Mod. UTD 1295, 1300, 1305, 1310, 1315

UTEST MATERIAL TESTING EQUIPMENT

www.utest.com.tr

LABORATORY OVENS REVISION 4 17

USER MANUAL 18 09 2015

Mod. UTD 1295, 1300, 1305, 1310, 1315

Picture 6: Electric Diagram of UTD-1295

UTEST MATERIAL TESTING EQUIPMENT

www.utest.com.tr

LABORATORY OVENS REVISION 4 18

USER MANUAL 18 09 2015

Mod. UTD 1295, 1300, 1305, 1310, 1315

Picture 7: Electric Diagram of UTD-1300

UTEST MATERIAL TESTING EQUIPMENT

www.utest.com.tr

LABORATORY OVENS REVISION 4 19

USER MANUAL 18 09 2015

Mod. UTD 1295, 1300, 1305, 1310, 1315

Picture 8: Electric Diagram of UTD-1305

UTEST MATERIAL TESTING EQUIPMENT

www.utest.com.tr

LABORATORY OVENS REVISION 4 20

USER MANUAL 18 09 2015

Mod. UTD 1295, 1300, 1305, 1310, 1315

Picture 9: Electric Diagram of UTD-1310

UTEST MATERIAL TESTING EQUIPMENT

www.utest.com.tr

LABORATORY OVENS REVISION 4 21

USER MANUAL 18 09 2015

Mod. UTD 1295, 1300, 1305, 1310, 1315

Picture 10: Electric Diagram of UTD-1315

UTEST MATERIAL TESTING EQUIPMENT

www.utest.com.tr

LABORATORY OVENS REVISION 4

USER MANUAL 18 09 2015

22

Mod. UTD 1295, 1300, 1305, 1310, 1315

10. TECHNICAL SPECIFICATION

MODEL … UTD-1295

Drying Chamber Capacity, LT 50

Internal Dia., mm 380x380x380

External Dia., mm 580x550x510

Working Ambient Temp. Range, °C 5-40

Max. Temp. , 250

Better than ± 5 (Class IB to ASTM E145)

Accuracy, °C

Weight ( Approx.), kg 50

Power Parameters 220 V ± 10 %, 10 A, 50 Hz, 1 Phase

MODEL … UTD-1300

Drying Chamber Capacity, LT 120

Internal Dia., mm 470x450x600

External Dia., mm 800x500x720

Working Ambient Temp. Range, °C 5-40

Max. Temp. , 250

Better than ± 5 (Class IB to ASTM E145)

Accuracy, °C

Weight ( Approx.), kg 60

Power Parameters 220 V ± 10 %, 10 A, 50 Hz, 1 Phase

UTEST MATERIAL TESTING EQUIPMENT

www.utest.com.tr

LABORATORY OVENS REVISION 4

USER MANUAL 18 09 2015

23

Mod. UTD 1295, 1300, 1305, 1310, 1315

MODEL … UTD-1305

Drying Chamber Capacity, LT 250

Internal Dia., mm 600x570x800

External Dia., mm 850x790x980

Working Ambient Temp. Range, °C 5-40

Max. Temp. , 250

Better than ± 5 (Class IB to ASTM E145)

Accuracy, °C

Weight ( Approx.), kg 95

Power Parameters 220 V ± 10 %, 10 A, 50 Hz, 1 Phase

MODEL … UTD-1310

Drying Chamber Capacity, LT 500

Internal Dia., mm 800x570x1100

External Dia., mm 920x650x1440

Working Ambient Temp. Range, °C 5-40

Max. Temp. , 250

Better than ± 5 (Class IB to ASTM E145)

Accuracy, °C

Weight ( Approx.), kg 127

Power Parameters 380 V ± 10 %, 50-60 Hz, 3 Ph

UTEST MATERIAL TESTING EQUIPMENT

www.utest.com.tr

LABORATORY OVENS REVISION 4

USER MANUAL 18 09 2015

24

Mod. UTD 1295, 1300, 1305, 1310, 1315

MODEL … UTD-1315

Drying Chamber Capacity, LT 700

Internal Dia., mm 900x570x1400

External Dia., mm 1100x800x1600

Working Ambient Temp. Range, °C 5-40

Max. Temp. , 250

Better than ± 5 (Class IB to ASTM E145)

Accuracy, °C

Weight ( Approx.), kg 185

Power Parameters 380 V ± 10 %, 50-60 Hz, 3 Ph

11. CUSTOMER SUPPORT-Warranty

UTEST technical services group is available for your technical questions. The technical service engineers are well-trained and

experienced on UTEST material testing equipment and should be able to answer your questions. It is recommended to reread the

related test standard such as EN, ASTM etc. if your questions are related with test procedures.

The guarantee period of the machine is 1 year and the product end-of-life is 10 years. Product end-of-life is the time in which all spare

parts of the machine has to be kept in the stock of the company. Also the pictures used in this user manual are just for showing

purpose. So that they may not be completely the identical to your apparatus.

Failing to perform the recommended maintenance actions or maintenance performed by unauthorized people can void the warranty.

UTEST will not be responsible for maintenance and service actions performed by unauthorized people.

ASO 1. Organize Sanayi Bölgesi Ural Cad. No: 18 Sincan /Ankara / TURKEY

T. +90 312 394 3875

F. +90 312 394 3877

UTEST MATERIAL TESTING EQUIPMENT

www.utest.com.tr

LABORATORY OVENS REVISION 4

USER MANUAL 18 09 2015

25

Mod. UTD 1295, 1300, 1305, 1310, 1315

12. NOTES

UTEST MATERIAL TESTING EQUIPMENT

www.utest.com.tr

You might also like

- Study Electronic Road TollingDocument125 pagesStudy Electronic Road TollingSiska Riantini ArifNo ratings yet

- Adhesion Test SpecDocument3 pagesAdhesion Test SpecdcevipinNo ratings yet

- CDI Tester Circuit Electronic Circuit ProjectsDocument37 pagesCDI Tester Circuit Electronic Circuit Projectssahilsahni200% (1)

- Om E215B EN PDFDocument257 pagesOm E215B EN PDFKrunoslavNo ratings yet

- Viscosity Cup Astm d1200 Ford Vf2029 d44Document3 pagesViscosity Cup Astm d1200 Ford Vf2029 d44RodrigoNo ratings yet

- Arduino Controlled CNC Printing Circuit MachineDocument7 pagesArduino Controlled CNC Printing Circuit MachineEditor IJTSRDNo ratings yet

- Bugatti "La Voiture Noire" - A One-Off Car PDFDocument1 pageBugatti "La Voiture Noire" - A One-Off Car PDFrobrrtNo ratings yet

- Certificate IPT 501Document3 pagesCertificate IPT 501Guilherme DiasNo ratings yet

- Viscosity Standard n4000 5181005110Document1 pageViscosity Standard n4000 5181005110Rachel McArdleNo ratings yet

- SICE Company ProfileDocument37 pagesSICE Company ProfileJavierNo ratings yet

- Mikrobasic Pic and UsbDocument21 pagesMikrobasic Pic and UsbM Munir Qureshi Madni100% (1)

- Manual Omron E5csDocument108 pagesManual Omron E5csFernando Barragán LúaNo ratings yet

- Self Balancing VehicleDocument6 pagesSelf Balancing VehicleGRD JournalsNo ratings yet

- Ultrasonic Flowmeter and Hot Wire AnemometerDocument32 pagesUltrasonic Flowmeter and Hot Wire AnemometerManzari AnandNo ratings yet

- Agricultural Based DroneDocument47 pagesAgricultural Based DroneFasih ullahNo ratings yet

- 2020 ISASMELT Compendium of PapersDocument344 pages2020 ISASMELT Compendium of PapersVale IbujesNo ratings yet

- Calibration Defelsko Certified ShimsDocument6 pagesCalibration Defelsko Certified ShimsPubcrawlNo ratings yet

- Viscosity Cup PDFDocument16 pagesViscosity Cup PDFSaut Maruli Tua SamosirNo ratings yet

- Ea 10-08 PDFDocument16 pagesEa 10-08 PDFAna Safranec VasicNo ratings yet

- Product Catalogue: Gke Steri-RecordDocument22 pagesProduct Catalogue: Gke Steri-RecordTestNo ratings yet

- Toll Gate Collection Using Delphi7Document60 pagesToll Gate Collection Using Delphi7herveNo ratings yet

- CE Jan 2013Document68 pagesCE Jan 2013Jose PeñaNo ratings yet

- R PDFDocument16 pagesR PDFMoises Abraham Villalba RojasNo ratings yet

- Troubleshooting & Maintenance of Electronic Equipments: Central Board of Secondary EducationDocument99 pagesTroubleshooting & Maintenance of Electronic Equipments: Central Board of Secondary EducationSandeep BhardwajNo ratings yet

- Class D IR2110 SCHDocument1 pageClass D IR2110 SCHMr.Mongkhon J.No ratings yet

- Notes AtherosclerosisDocument1 pageNotes AtherosclerosisElizabeth de GuzmanNo ratings yet

- 07-Speed Trainer Magnetic PhotoDocument16 pages07-Speed Trainer Magnetic Photohydromec_indiaNo ratings yet

- Motorola gp900 PDFDocument6 pagesMotorola gp900 PDFnjesraNo ratings yet

- Ramsey Hobby 2 KDocument40 pagesRamsey Hobby 2 Kjsmith20No ratings yet

- EURAMET Cg-18 V 3.0 Non-Automatic Weighing Instruments 01Document84 pagesEURAMET Cg-18 V 3.0 Non-Automatic Weighing Instruments 01Dragana Srdic100% (1)

- Engineering Catalogue: Innovation in Engineering EducationDocument96 pagesEngineering Catalogue: Innovation in Engineering EducationJayadev S RNo ratings yet

- En002v1maintenance GuideDocument118 pagesEn002v1maintenance GuideAli HadiNo ratings yet

- An IP Enabled TETRA Radio NetworkDocument33 pagesAn IP Enabled TETRA Radio NetworkGerardo Nassir TelloNo ratings yet

- A4 Heat Press ManualDocument13 pagesA4 Heat Press ManualGabrielNo ratings yet

- Bulletin 13-3 en World Meteorological Association July 1964Document79 pagesBulletin 13-3 en World Meteorological Association July 1964Lin CornelisonNo ratings yet

- 1991 Intel 16-Bit Embedded Controller HandbookDocument624 pages1991 Intel 16-Bit Embedded Controller HandbookBayanaka TehnikNo ratings yet

- NCHRP RPT 375Document103 pagesNCHRP RPT 375Victor OlmedoNo ratings yet

- 40 MHZ Frequency MeterDocument5 pages40 MHZ Frequency MeterIvon Indra FerdiantoNo ratings yet

- R135 E04Document48 pagesR135 E04naranjocarlosNo ratings yet

- Electronics Mar Apr 2016 Ems PDFDocument52 pagesElectronics Mar Apr 2016 Ems PDFzhafranabdNo ratings yet

- ISO1524 2000 Paints, Varnishes and Printing Inks - Determination of Fineness of GrindDocument12 pagesISO1524 2000 Paints, Varnishes and Printing Inks - Determination of Fineness of GrindCemalOlgunÇağlayanNo ratings yet

- Best PracticesDocument328 pagesBest PracticesDIEGO TUNARROSANo ratings yet

- Thermomeer PDFDocument7 pagesThermomeer PDFbharatheeeyuduNo ratings yet

- 6-Doc-Microcontroller Based Patient Medicine Reminder SystemDocument59 pages6-Doc-Microcontroller Based Patient Medicine Reminder SystemAadhya Suman80% (5)

- Cenelec: Final Draft en 50174-2 Fpra1Document52 pagesCenelec: Final Draft en 50174-2 Fpra1Arvind SrivastavaNo ratings yet

- AVR: Which Microcontroller To Choose: PIC VsDocument17 pagesAVR: Which Microcontroller To Choose: PIC VsMuhammad Zawar100% (1)

- STD Bubble Visco MetersDocument6 pagesSTD Bubble Visco Metersmanox007No ratings yet

- The Technical Difference of Digital StandardDocument4 pagesThe Technical Difference of Digital StandardPrithish DevadigaNo ratings yet

- Precision Honing ToolsDocument14 pagesPrecision Honing ToolsMatija BušićNo ratings yet

- Elcometer Adhesion Tester Brochure PDFDocument11 pagesElcometer Adhesion Tester Brochure PDFPardhu YellaNo ratings yet

- Level Measurement DevicesDocument23 pagesLevel Measurement DevicesRahul JaiswalNo ratings yet

- DKD R 6 2 t3 eDocument10 pagesDKD R 6 2 t3 eAntmavrNo ratings yet

- Proact II WoodwardDocument67 pagesProact II WoodwardGabriel Paco LunaNo ratings yet

- Thermometer Liquid in Glass Calibrationvvs102Document10 pagesThermometer Liquid in Glass Calibrationvvs102juncar25100% (1)

- Amara SamiraDocument35 pagesAmara SamiraHassinaNo ratings yet

- Self Balancing RobotDocument10 pagesSelf Balancing RobotVasu RockstarNo ratings yet

- "Pressure Maintainer": Instruction ManualDocument10 pages"Pressure Maintainer": Instruction ManualJorge Armando Ysuiza RomeroNo ratings yet

- Final Manual A879 Steam SterilierDocument64 pagesFinal Manual A879 Steam SterilierSteven BrownNo ratings yet

- Acoples MecanicosDocument49 pagesAcoples MecanicosOmar BallezterosNo ratings yet

- Kioti Daedong PX1153PC-AU Tractor Service Manual 03-2019Document19 pagesKioti Daedong PX1153PC-AU Tractor Service Manual 03-2019LisakolyNo ratings yet

- HE800DIQ716CDocument8 pagesHE800DIQ716CRicardo NunesNo ratings yet

- PLANT INSPECTION AND MAINTENANCE SCHEDULE & SOP - 20 May 2020Document5 pagesPLANT INSPECTION AND MAINTENANCE SCHEDULE & SOP - 20 May 2020izarulhaqNo ratings yet

- Mr. Faisal (Mediporex PVT LTD)Document5 pagesMr. Faisal (Mediporex PVT LTD)AbdullahdodhyNo ratings yet

- ActivityDocument5 pagesActivityALDANA MARY GARCIANo ratings yet

- Testing & Adjusting of CRI System Testing & Adjusting of CRI SystemDocument9 pagesTesting & Adjusting of CRI System Testing & Adjusting of CRI SystemJemmy AnggaraNo ratings yet

- Motorola Mini Din AdapterDocument1 pageMotorola Mini Din AdapterAdmir BečićNo ratings yet

- AP1 MeasuringBox-Rev4Eng PDFDocument9 pagesAP1 MeasuringBox-Rev4Eng PDFGaby ZgubyutzaNo ratings yet

- Installation Use and Maintenance: Cooling-Only, Heat Pump and Free-Cooling VersionsDocument64 pagesInstallation Use and Maintenance: Cooling-Only, Heat Pump and Free-Cooling VersionsВасилий КонстантиновNo ratings yet

- Porsche 997.1 Wiper Motor RepairDocument8 pagesPorsche 997.1 Wiper Motor Repairwachu73No ratings yet

- YUKEN Hydraulic Equipment (PG 618)Document1 pageYUKEN Hydraulic Equipment (PG 618)yogi fransbeenNo ratings yet

- Emerging Trends in Mechanical Engineering (22652-)Document91 pagesEmerging Trends in Mechanical Engineering (22652-)Hiphop Op100% (1)

- Testing and Commissioning Procedure For Ventilation and General Exhaust FansDocument3 pagesTesting and Commissioning Procedure For Ventilation and General Exhaust FansDong Vanra100% (1)

- Brake System FunctionDocument6 pagesBrake System FunctionNguyen Vu BuiNo ratings yet

- Mini Dozer Info 1979Document6 pagesMini Dozer Info 1979Jim100% (3)

- SSM SSV Datasheet Wfds745Document2 pagesSSM SSV Datasheet Wfds745Welmi AfdalNo ratings yet

- Ниворегулатори и флусостатиDocument2 pagesНиворегулатори и флусостатиStudioWDFNo ratings yet

- Lecture-2 Lifeboat Case StudyDocument8 pagesLecture-2 Lifeboat Case Studykhan asifNo ratings yet

- Hydraulic Torque Wrenches Repairing Services Rent PDFDocument3 pagesHydraulic Torque Wrenches Repairing Services Rent PDFlasdy.razoNo ratings yet

- KHD Tube MillDocument2 pagesKHD Tube MillKeynes de SavaNo ratings yet

- InnoLIFT Retail Price SheetDocument1 pageInnoLIFT Retail Price SheetIsrael MerinoNo ratings yet

- 2019 Ecosport - B515 - BW WG INDDocument103 pages2019 Ecosport - B515 - BW WG INDShreyas TamhanNo ratings yet

- Robotic Gripper DesignDocument22 pagesRobotic Gripper DesignHaider-e-KararNo ratings yet

- Part List - 69NT40-541-200 To 299Document83 pagesPart List - 69NT40-541-200 To 299cloviskrellingNo ratings yet

- (Rev) Lab Activity 3Document6 pages(Rev) Lab Activity 3MitzOsorioNo ratings yet

- Corner Systems: Kitchen and Bath OrganizationDocument19 pagesCorner Systems: Kitchen and Bath Organizationآلاء ساميNo ratings yet

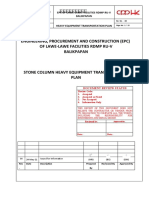

- 26076-110-V12-HEGS-00049 SC Heavy Equipment Transportation Plan (R3)Document20 pages26076-110-V12-HEGS-00049 SC Heavy Equipment Transportation Plan (R3)bangunNo ratings yet

- Okonite Instrument CableDocument2 pagesOkonite Instrument CableAnonymous Wu6FDjbNo ratings yet

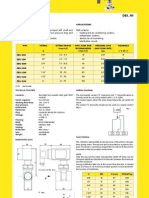

- Description Mechanical Dimensions: 1 Watt ZENER DIODES (3.3V To 100V)Document2 pagesDescription Mechanical Dimensions: 1 Watt ZENER DIODES (3.3V To 100V)Paul DamianNo ratings yet

- Pexlim P-Z LeafletDocument2 pagesPexlim P-Z LeafletchengkkNo ratings yet

- MX50 - 60 ATS Controllers Intro R1 - 1Document31 pagesMX50 - 60 ATS Controllers Intro R1 - 1gilizardoNo ratings yet