Professional Documents

Culture Documents

Part Names and Functions .7-: Vds 2E

Part Names and Functions .7-: Vds 2E

Uploaded by

chao wang0 ratings0% found this document useful (0 votes)

7 views1 pageOriginal Title

Img 0010016

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views1 pagePart Names and Functions .7-: Vds 2E

Part Names and Functions .7-: Vds 2E

Uploaded by

chao wangCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

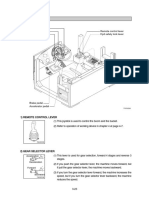

VDS 2E 2. Part Names and Functions .

7-

(1) Depth stop.

When the machine is placed on the pilot the depth stop rests on top of the pilot.

The depth stop is adjustable to set up the machine in proper position for cutting.

The depth stop (1) is held in the adjusted position by the locking screw (1.1).

(2) Downfee'd screw.

The desired depth of cut is set by tuning the down feed screw counterclockwise.

One graduation of the down feed scale (2.1) corresponds to 0,025 mm down feed.

(3) Driving motor assembly.

(4) Push button switch.

The machine is switched on as long as the push button switch is kept pressed.

(5) Feed actuator,

The automatic tram.sverse travel of the tool slide (8.1) is actuated by halting the feed actuator.

The pivoted lever (5.1) can be inserted into a groove provided in the feed actuator (5) to halt

the feed actuator.

(6) Rapid tool adjuster.

The tool slide (8.1) carrying the cutting tool (C) can be moved to the required position by

turning the rapid tool adjuster (6).

(7) Feed gear unit.

(8) Seat refacing head.

The seat refacing head is exchangeably attached to the feed gear unit and includes the tool

slide (8.1) which is guided under an angle corresponding to the valve seat angle as indicated

at the seat refacing head head.

The cutting tool (C) is clamped to the tool slide (8.1).

(9) Power supply unit.

The power supply unit is provided with a switch (9.1) for selecting the output voltage of

32VDC for low speed and 42VDC for high speed.

You might also like

- Engine Valve Lash ADJUST C27 C32Document5 pagesEngine Valve Lash ADJUST C27 C32manu luvunga100% (1)

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- Pragati - BTP Turret ManualDocument31 pagesPragati - BTP Turret Manualchidambaram kasi100% (17)

- Caterpillar Cat 329DL EXCAVATOR (Prefix WLT) Service Repair Manual (WLT00001 and Up) PDFDocument22 pagesCaterpillar Cat 329DL EXCAVATOR (Prefix WLT) Service Repair Manual (WLT00001 and Up) PDFfkdmmaNo ratings yet

- Cummins QSK38 Engine Spare Parts CatalogDocument21 pagesCummins QSK38 Engine Spare Parts CatalogChen Caroline100% (1)

- JUKI HZL-G Series Service ManualDocument34 pagesJUKI HZL-G Series Service Manualneotoxin100% (1)

- Caterpillar Cat 320d2 Excavator Prefix Zcs Service Repair Manual Zcs00001 and Up 1588418836Document23 pagesCaterpillar Cat 320d2 Excavator Prefix Zcs Service Repair Manual Zcs00001 and Up 1588418836rayendra100% (2)

- Electronic Unit Injector - AdjustDocument4 pagesElectronic Unit Injector - Adjustalonso100% (1)

- Machine Zero Point Setting BW209Document6 pagesMachine Zero Point Setting BW209Luis Angel Thirion PerezNo ratings yet

- Calibracion InyectoresDocument4 pagesCalibracion InyectoresWladimir AmaguañaNo ratings yet

- M19 LatheDocument36 pagesM19 LatheVinay Kumar Neelam100% (1)

- Operating Instructions: Gas Engine 12 V 4000 Lx4 16 V 4000 Lx4Document199 pagesOperating Instructions: Gas Engine 12 V 4000 Lx4 16 V 4000 Lx4chao wangNo ratings yet

- Partes Del Motor CAT 3512BDocument2 pagesPartes Del Motor CAT 3512BLuis Cacsire100% (2)

- Flywheel Housing & AlternatorsDocument9 pagesFlywheel Housing & AlternatorsLukman ChairkiandraNo ratings yet

- Testing and Adjusting TRANSMISION 966CDocument15 pagesTesting and Adjusting TRANSMISION 966Cdanavero76100% (2)

- c25 33 Propulsion Engines 06 01 2017Document143 pagesc25 33 Propulsion Engines 06 01 2017chao wang100% (1)

- Flight ControlsDocument28 pagesFlight ControlsmosesisdumbNo ratings yet

- TCP FanucDocument51 pagesTCP FanucAnonymous PJP78mSx33% (3)

- PE2000-5154 Rev XA (X00E50205094)Document1 pagePE2000-5154 Rev XA (X00E50205094)chao wang100% (1)

- Autogard Series 820 Torque Limiter: Installation and Maintenance InstructionsDocument16 pagesAutogard Series 820 Torque Limiter: Installation and Maintenance InstructionsIvana Z. OgnjanovićNo ratings yet

- Harmonic Hdi Infinit Indexer CatalogDocument6 pagesHarmonic Hdi Infinit Indexer CatalogElectromateNo ratings yet

- EPM Sec II 143 MM ThrowDocument11 pagesEPM Sec II 143 MM ThrowDondapati SaipradeepchowdaryNo ratings yet

- Control Device: Steering Wheel Remote Control Lever Hyd Safety Lock Lever Steering Wheel LeverDocument2 pagesControl Device: Steering Wheel Remote Control Lever Hyd Safety Lock Lever Steering Wheel LeverJuNo ratings yet

- HM-32B Manual.Document23 pagesHM-32B Manual.cheufelNo ratings yet

- C-15 Electronic Unit Injector - AdjustDocument4 pagesC-15 Electronic Unit Injector - AdjustCEVegaONo ratings yet

- Azipod CZ1400 Product IntroductionDocument20 pagesAzipod CZ1400 Product Introductionbill baileyNo ratings yet

- Pistons and Connecting Rods - InstallDocument5 pagesPistons and Connecting Rods - Installeshopmanual limaNo ratings yet

- Chapter 2. Operator Control and Instruments Section 1. Operator ControlsDocument34 pagesChapter 2. Operator Control and Instruments Section 1. Operator ControlsPeetNo ratings yet

- Antes Da Operação D9T Ing.Document7 pagesAntes Da Operação D9T Ing.Jardel Fernandes de MoraesNo ratings yet

- Operating InstructionsDocument34 pagesOperating InstructionsCarlos IntriagoNo ratings yet

- Recoil Spring - Disassemble: Disassembly and AssemblyDocument6 pagesRecoil Spring - Disassemble: Disassembly and Assemblyeshopmanual limaNo ratings yet

- 4 Automatic Tool ChangersDocument40 pages4 Automatic Tool ChangersRogerNo ratings yet

- Ser 200 IMDocument5 pagesSer 200 IMshadialameddinNo ratings yet

- CF1711 - Trocador AtcDocument24 pagesCF1711 - Trocador Atcmec04162No ratings yet

- 3 8 PDFDocument2 pages3 8 PDFYeny CatzinNo ratings yet

- MRDocument15 pagesMRSuresh UmadiNo ratings yet

- Manual de Serviço Dual 1219Document43 pagesManual de Serviço Dual 1219rogerioNo ratings yet

- Vds 2E 1. Technical Details: Capacity: 35 - 90mm 20° and 3ooDocument1 pageVds 2E 1. Technical Details: Capacity: 35 - 90mm 20° and 3oochao wangNo ratings yet

- Manual of The Universal Milling Machine X6432Document23 pagesManual of The Universal Milling Machine X6432Kauã NovaesNo ratings yet

- Calibracion de InyectoresDocument1 pageCalibracion de InyectoresJose FavaNo ratings yet

- Connecting Rod Bearings - Install - Connecting Rods in PositionDocument4 pagesConnecting Rod Bearings - Install - Connecting Rods in PositionTatiano BrolloNo ratings yet

- Piston Cooling Jets - Remove and InstallDocument4 pagesPiston Cooling Jets - Remove and Installeshopmanual limaNo ratings yet

- Tugas Bahasa Inggris Artikel Mesin Kelas ME 1 C: Jurusan Teknik Mesin Politeknik Negeri Semarang 2010Document11 pagesTugas Bahasa Inggris Artikel Mesin Kelas ME 1 C: Jurusan Teknik Mesin Politeknik Negeri Semarang 2010Ryand Adhi PNo ratings yet

- Gear Group (Front) - Install - Idler Gear Only: Desmontagem e MontagemDocument6 pagesGear Group (Front) - Install - Idler Gear Only: Desmontagem e MontagemJose nildo lobato Mendes MendesNo ratings yet

- Gearless Variable Speed Reducer'Document9 pagesGearless Variable Speed Reducer'nik_dixitNo ratings yet

- Type 1051 and 1052 Diaphragm Rotary Actuators: Bulletin 61.1:1051Document12 pagesType 1051 and 1052 Diaphragm Rotary Actuators: Bulletin 61.1:1051Datt NguyenNo ratings yet

- Operation Parts Manual TMVDocument105 pagesOperation Parts Manual TMVtylerorourkerNo ratings yet

- Autopilot Computer - Maintenance PracticesDocument5 pagesAutopilot Computer - Maintenance PracticesEleazarNo ratings yet

- Engine Valve Lash - Inspect/Adjust: Shutdown SIS Previous ScreenDocument5 pagesEngine Valve Lash - Inspect/Adjust: Shutdown SIS Previous ScreenaliNo ratings yet

- 7K User ManualDocument17 pages7K User Manualandrea772No ratings yet

- HY400 HP500 Operation InstallationDocument37 pagesHY400 HP500 Operation Installationdavidsandu27No ratings yet

- Manual For Spindle MotorDocument11 pagesManual For Spindle MotorVictor MartinezNo ratings yet

- C32 - RSD00176 - Electronic Unit Injector - Adjust PDFDocument4 pagesC32 - RSD00176 - Electronic Unit Injector - Adjust PDFyakubNo ratings yet

- Switches: Systems OperationDocument5 pagesSwitches: Systems OperationEshop ManualNo ratings yet

- Finding Top Center Position For No. 1 PistonDocument3 pagesFinding Top Center Position For No. 1 Pistoneshopmanual limaNo ratings yet

- 541 Series 2 Teste Hélice - 083140Document6 pages541 Series 2 Teste Hélice - 083140Dário Martins da CunhaNo ratings yet

- Форсунки охлажденияDocument3 pagesФорсунки охлажденияВиталий ОрловNo ratings yet

- Engine Valve Lash - Inspect/Adjust: Shutdown SIS Previous ScreenDocument4 pagesEngine Valve Lash - Inspect/Adjust: Shutdown SIS Previous ScreenbejoythomasNo ratings yet

- Shift and Select MechanismDocument7 pagesShift and Select MechanismDwi UpariadiNo ratings yet

- Operating Manual SV 550Document14 pagesOperating Manual SV 550juan manuel sierra solisNo ratings yet

- MFT - II Lab ManualDocument33 pagesMFT - II Lab ManualMohan Prasad.M0% (1)

- Chevalier FSG-1224ADIIIDocument12 pagesChevalier FSG-1224ADIIIOsvaldo MarinNo ratings yet

- Documents - MX Pragati BTP Turret Manual - PDFDocument31 pagesDocuments - MX Pragati BTP Turret Manual - PDFPetar Petrovic100% (3)

- Bushealth Measurements: Addendum For 125BDocument12 pagesBushealth Measurements: Addendum For 125Bchao wangNo ratings yet

- O) N - N:Itf!:: :affae - Iyn Haoneds - Mv:Srttue:I:Goronb::Ct::Vent FFL FFLDocument1 pageO) N - N:Itf!:: :affae - Iyn Haoneds - Mv:Srttue:I:Goronb::Ct::Vent FFL FFLchao wangNo ratings yet

- Vds 2E 1. Technical Details: Capacity: 35 - 90mm 20° and 3ooDocument1 pageVds 2E 1. Technical Details: Capacity: 35 - 90mm 20° and 3oochao wangNo ratings yet

- Marine Transmissions List of Lubricants TE-ML 04Document15 pagesMarine Transmissions List of Lubricants TE-ML 04chao wangNo ratings yet

- Differential Pressure Switches For Gas, Air, Flue and Exhaust Gases GGW A4 GGW A4-U GGW A4/2 GGW A4-U/2Document6 pagesDifferential Pressure Switches For Gas, Air, Flue and Exhaust Gases GGW A4 GGW A4-U GGW A4/2 GGW A4-U/2chao wangNo ratings yet

- Operation Manual: TPS52-F31Document116 pagesOperation Manual: TPS52-F31chao wangNo ratings yet

- KW Per Cylinder: New B36:45V Gas Engine SeriesDocument3 pagesKW Per Cylinder: New B36:45V Gas Engine Serieschao wangNo ratings yet

- KW Per Cylinder: New B33:45V Liquid Fuel Engine SeriesDocument3 pagesKW Per Cylinder: New B33:45V Liquid Fuel Engine Serieschao wangNo ratings yet

- Sitop Psu8200 24 v20 ADocument108 pagesSitop Psu8200 24 v20 Achao wangNo ratings yet

- MOTORTECH Manual VariFuel2 01.50.001 EN 2020 09 WEB - 01Document50 pagesMOTORTECH Manual VariFuel2 01.50.001 EN 2020 09 WEB - 01chao wangNo ratings yet