Professional Documents

Culture Documents

MODEL 210 SERIES (1977 - 1984) : Inspection Time Limits - Structure 1. Scope

Uploaded by

sandyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MODEL 210 SERIES (1977 - 1984) : Inspection Time Limits - Structure 1. Scope

Uploaded by

sandyCopyright:

Available Formats

CESSNA AIRCRAFT COMPANY

MODEL 210 SERIES (1977 - 1984)

SERVICE MANUAL

INSPECTION TIME LIMITS - STRUCTURE

1. Scope

A. This provides the mandatory times and inspection time intervals for components and airplane

structures. This section also gives the required details to monitor them using scheduled inspections.

This section applies to items such as fatigue components and structures, which are part of the

certification procedures. Refer to the description paragraph below for detailed information concerning

each of these sections.

NOTE: The time limits and maintenance checks listed in this section are the minimum

requirements for airplanes operated under normal conditions. For airplanes operated in

areas where adverse operating conditions may be encountered, such as high salt coastal

environments, areas of high heat and humidity, areas where industrial or other airborne

pollutants are present, extreme cold, unimproved surfaces, etc., the time limits should be

modified accordingly.

NOTE: The inspection guidelines contained in this section are not intended to be all-inclusive,

for no such charts can replace the good judgment of certified airframe and power plant

mechanics in performance of their duties. As the one primarily responsible for the

airworthiness of the airplane, the owner or operator should select only qualified personnel

to maintain the airplane.

2. Inspection Requirements

A. Two types of inspection requirements are available based on operating usage and two additional types

of inspections are available based on operating environment.

(1) Operating Usage

(a) Severe Usage Environment

1 If the average flight length is less than 30 minutes, then you must use the SEVERE

inspection time limits.

2 If the airplane has been engaged in operations at low altitudes such as pipeline

patrol, fish or game spotting, aerial applications, police patrol, sightseeing, livestock

management, etc. more than 30% of its life you must use the SEVERE inspection

time limits.

(b) Typical Usage Environment

1 If neither 2(A)(1)(a)(1) or 2(A)(1)(a)(2) above applies, the TYPICAL usage

environment applies.

(2) Operating Environment

(a) Severe Corrosion Environment

1 If the airplane is operating more than 30% of the time in a zone shown as severe on

the corrosion severity maps in Section 2A-30-01, then the SEVERE CORROSION

environment time limits apply.

(b) Mild or Moderate Corrosion Environment

1 If 2(A)(2)(a)(1) does not apply, then the MILD/MODERATE CORROSION

environment time limits apply.

B. After the operating usage and the operating environment are determined, make a logbook entry that

states which inspection schedules (TYPICAL or SEVERE operating usage and MILD/MODERATE or

SEVERE operating environment) are being used.

3. Description

NOTE: Listed below is a detailed description and intended purpose of the following sections.

A. Section 2A-10-00, Time Limits/Maintenance Checks - General. This section provides a description

and purpose of the inspection time intervals.

D2057-3-13 Temporary Revision Number 13 - Mar 15/2014 2A-10-00 Page 1

© Cessna Aircraft Company Mar 1/1996

CESSNA AIRCRAFT COMPANY

MODEL 210 SERIES (1977 - 1984)

SERVICE MANUAL

B. Section 2A-10-01, Inspection Time Limits.

(1) This section lists, in chart format, all inspection requirements which must be performed. Each

page contains the following five columns:

(a) Revision Status provides the date that a given item was added, deleted, or revised. A blank

entry in this column indicates no change since the reissue of this manual.

(b) Inspection Requirements provide a short description of the maintenance item.

(c) Inspection Interval indicates the frequency of the item.

(d) Applicable Operation(s) indicates the applicable inspection operation currently containing

the inspection item. The frequencies corresponding to each operation are listed in

Inspection Interval Requirements in this section.

(e) Applicable Zone refers to the physical location(s) in the airplane affected by the item.

(2) Primary purpose of the Inspection Time Limits section is to provide a complete listing of all

inspection items in an order that allows easy access for the information listed previously. This

section is not intended to be utilized as a guideline for inspection of the airplane.

(3) The Inspection Time Limits Table shows the recommended intervals at which items are to be

inspected, based on usage and environmental conditions. The operator’s inspection intervals

shall not deviate from the inspection time limits shown in this table except as provided below:

(a) Each inspection interval can be exceeded by 10 hours (if time-controlled), or by 30 days

(if date-controlled) or can be performed early at any time prior to the regular interval as

provided below:

1 In the event of late compliance of any operation scheduled, the next operation

in sequence retains a due point from the time the late operation was originally

scheduled.

2 In the event of early compliance of any operation scheduled, that occurs 10 hours or

less ahead of schedule, the next operation due point may remain where originally set.

3 In the event of early compliance of any operation scheduled, that occurs more than

10 hours ahead of schedule, the next operation due point must be rescheduled to

establish a new due point from the time of early accomplishment.

C. Section 2A-20-01, Expanded Maintenance. This section provides additional information on some

maintenance/inspection procedures. It describes where the component/item is located, what to

inspect for, how to inspect it, etc. Detailed requirements, such as functional checks, operational

checks, etc., are listed in the appropriate section of the Model 210 Service Manual. Refer to the

appropriate section for complete detailed information.

D. Section 2A-30-00, Corrosion Prevention and Control Program (CPCP). This section gives the

guidelines and applications of the CPCP. This is a program used to control the corrosion in the

airplane's primary structure. The objective of the CPCP is to help to prevent or to control the

corrosion so that it does not cause a risk to the continued airworthiness of the airplane.

4. Inspection Time Limits

A. A complete airplane inspection includes all inspection items as required by 14 CFR Part 43, Appendix

D, Scope and Detail of annual/100-hour inspections. Refer to Section 2 of the Model 210 Service

Manual.

B. The intervals shown are recommended intervals at which items are to be inspected.

(1) The 14 CFR Part 91 operator's inspection intervals shall not deviate from the inspection time

limits shown in this manual except as provided below: (Refer to 14 CFR 91.409)

(a) The airplane can only exceed its inspection point up to 10 hours, if the airplane is en route

to a facility to have the inspection completed.

(b) In the event of late compliance of any operation scheduled, the next operation in sequence

retains a due point from the time the late operation was originally scheduled.

(c) In the event of early compliance of any operation scheduled, that occurs 10 hours or less

ahead of schedule, the next phase due point may remain where originally set.

(d) In the event of early compliance of any operation scheduled, that occurs more than 10

hours ahead of schedule, the next operation due point must be rescheduled to establish a

new due point from the time of early accomplishment.

D2057-3-13 Temporary Revision Number 13 - Mar 15/2014 2A-10-00 Page 2

© Cessna Aircraft Company Mar 1/1996

CESSNA AIRCRAFT COMPANY

MODEL 210 SERIES (1977 - 1984)

SERVICE MANUAL

5. Inspection Time Limits Legend

A. Each page of the inspection listed in Inspection Time Limits, Section 2A-10-01, contains the following

five columns:

(1) REVISION STATUS - This column provides the date that a given item was added, deleted, or

revised. A blank entry in this column indicates no change since the reissue of this manual.

(2) TASK - This column provides a short description of the inspection and/or servicing procedures.

Where a more detailed description of the procedure is required, a reference will be made to

either another selection located within the Model 210 Service Manual or a specific reference to

a supplier publication.

(3) INTERVAL - This column lists the frequency of the inspection.

(4) OPERATION - All of the inspections included in one operation are grouped together in the 2A-

12-XX documents (XX equals the operation number).

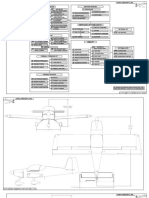

(5) ZONE - This column locates the components within a specific zone. For a breakdown of how

the airplane is zoned, refer to 2A-30-00, Figure 1, Airplane Zones.

6. Inspection Interval Requirements

Operation Details

1 - Every 100 hours of operation or 12 months, whichever occurs first.

2 - Corrosion Prevention and Control Program Inspections (Baseline Program)

items that are to be examined every 12 months. Refer to Section 2A-30-00,

Corrosion Prevention and Control Program, for additional information

concerning repeat Corrosion Program Inspection intervals.

3 - Corrosion Prevention and Control Program Inspections (Baseline Program)

items that are to be examined every 24 months. Refer to Section 2A-30-00,

Corrosion Prevention and Control Program for additional information

concerning repeat Corrosion Program Inspection intervals.

4 - Corrosion Prevention and Control Program Inspections (Baseline Program)

items that are to be examined every 36 months. Refer to Section 2A-30-00,

Corrosion Prevention and Control Program for additional information

concerning repeat Corrosion Program Inspection intervals.

5 - Corrosion Prevention and Control Program Inspections (Baseline Program)

items that are to be examined every 48 months. Refer to Section 2A-30-00,

Corrosion Prevention and Control Program for additional information

concerning repeat Corrosion Program Inspection intervals.

6 - Corrosion Prevention and Control Program Inspections (Baseline Program)

items that are to be examined every 60 months. Refer to Section 2A-30-00,

Corrosion Prevention and Control Program for additional information

concerning repeat Corrosion Program Inspection intervals.

7 - Supplemental Inspection Document items that are to be examined after the

first 1,000 hours of operation. The inspection is to be repeated every 1,000

hours after the initial inspection has been accomplished.

8 - Inspection items that are to be examined after the first 100 hours of operation.

The inspection is to be repeated every 600 hours of operation or 12 months,

whichever occurs first, after the initial inspection has been accomplished.

9 - Supplemental Inspection Document items that are to be examined after the first

10,000 hours of operation or 20 years, whichever occurs first. The inspection

is to be repeated every 3,000 hours of operation or 5 years, whichever occurs

first, after the initial inspection has been accomplished.

D2057-3-13 Temporary Revision Number 13 - Mar 15/2014 2A-10-00 Page 3

© Cessna Aircraft Company Mar 1/1996

CESSNA AIRCRAFT COMPANY

MODEL 210 SERIES (1977 - 1984)

SERVICE MANUAL

Operation Details

10 - Supplemental Inspection Document items that are to be examined after the

first 3,000 hours of operation or 5 years, whichever occurs first. The inspection

is to be repeated every 3,000 hours of operation or 5 years, whichever occurs

first, after the initial inspection has been accomplished.

11 - Supplemental Inspection Document items that are to be examined after the

first 10 years. The inspection is to be repeated every 5 years after the initial

inspection has been accomplished.

12 - Supplemental Inspection Document items that are to be examined after the first

2,000 hours of operation or 10 years, whichever occurs first. The inspection is

to be repeated every 100 hours of operation or 1 year, whichever occurs first,

after the initial inspection has been accomplished.

13 - Supplemental Inspection Document items that are to be examined after the first

12,000 hours of operation or 20 years, whichever occurs first. The inspection

is to be repeated every 3,000 hours of operation or 5 years, whichever occurs

first, after the initial inspection has been accomplished.

14 - Supplemental Inspection Document items that are to be examined after the first

3,000 hours of operation or 10 years, whichever occurs first. The inspection is

to be repeated every 500 hours of operation or 5 years, whichever occurs first,

after the initial inspection has been accomplished.

15 - Supplemental Inspection Document items that are to be examined after the

first 20 years. The inspection is to be repeated every 10 years after the

initial inspection has been accomplished, for airplanes operating in a mild

or moderate corrosion environment.

16 - Supplemental Inspection Document items that are to be examined after

the first 20 years. The inspection is to be repeated every 5 years after the

initial inspection has been accomplished, for airplanes operating in a mild

or moderate corrosion environment.

17 - Supplemental Inspection Document items that are to be examined after

the first 10 years. The inspection is to be repeated every 5 years after the

initial inspection has been accomplished, for airplanes operating in a mild

or moderate corrosion environment.

18 - Supplemental Inspection Document items that are to be examined after

the first 5 years. The inspection is to be repeated every 5 years after the

initial inspection has been accomplished, for airplanes operating in a mild

or moderate corrosion environment.

19 - Supplemental Inspection Document items that are to be examined after

the first 10 years. The inspection is to be repeated every 5 years after the

initial inspection has been accomplished, for airplanes operating in a severe

corrosion environment.

20 - Supplemental Inspection Document items that are to be examined after

the first 10 years. The inspection is to be repeated every 3 years after the

initial inspection has been accomplished, for airplanes operating in a severe

corrosion environment.

21 - Supplemental Inspection Document items that are to be examined after

the first 5 years. The inspection is to be repeated every 2 years after the

initial inspection has been accomplished, for airplanes operating in a severe

corrosion environment.

D2057-3-13 Temporary Revision Number 13 - Mar 15/2014 2A-10-00 Page 4

© Cessna Aircraft Company Mar 1/1996

CESSNA AIRCRAFT COMPANY

MODEL 210 SERIES (1977 - 1984)

SERVICE MANUAL

Operation Details

22 - Supplemental Inspection Document items that are to be examined after

the first 3 years. The inspection is to be repeated every 3 years after the

initial inspection has been accomplished, for airplanes operating in a severe

corrosion environment.

23 - Supplemental Inspection Document items that are to be examined after the

first 10,000 hours or 20 years, whichever occurs first. The inspection is to be

repeated at engine overhaul.

24 - Supplemental Inspection Document items that are to be examined after 12,000

hours or 20 years, whichever occurs first. The inspection is to be repeated

every 1,000 hours or 3 years, whichever occurs first, after the initial inspection

has been accomplished, for airplanes operating in a typical usage environment.

25 - Supplemental Inspection Document items that are to be examined after 12,000

hours or 20 years, whichever occurs first. The inspection is to be repeated

every 3,000 hours or 10 years, whichever occurs first, after the initial inspection

has been accomplished, for airplanes operating in a typical usage environment.

26 - Supplemental Inspection Document items that are to be examined after the

first 5 years. The inspection is to be repeated every 5 years after the initial

inspection has been accomplished.

27 - Supplemental Inspection Document items that are to be examined after the

first 6,000 hours of operation or 3 years, whichever occurs first. The inspection

is to be repeated every 500 hours of operation or 1 year, whichever occurs first,

after the initial inspection has been accomplished, for airplanes operating in a

severe usage environment.

28 - Supplemental Inspection Document items that are to be examined after the first

6,000 hours of operation or 10 years, whichever occurs first. The inspection is

to be repeated every 1,000 hours of operation or 3 years, whichever occurs

first, after the initial inspection has been accomplished, for airplanes operating

in a severe usage environment.

29 - Supplemental Inspection Document items that are to be examined after the first

8000 hours of operation. The inspection is to be repeated every 2000 hours

of operation after the initial inspection has been accomplished, for airplanes

operating in a typical usage environment.

30 - Supplemental Inspection Document items that are to be examined after the

first 3500 hours of operation. The inspection is to be repeated every 500 hours

of operation after the initial inspection has been accomplished, for airplanes

operating in a severe usage environment.

D2057-3-13 Temporary Revision Number 13 - Mar 15/2014 2A-10-00 Page 5

© Cessna Aircraft Company Mar 1/1996

You might also like

- INSP. TIME LIMIT - STRUCDocument5 pagesINSP. TIME LIMIT - STRUCjesus francoNo ratings yet

- CPCP, Sid S Cessna Model 188 SeriesDocument155 pagesCPCP, Sid S Cessna Model 188 Seriesvilladazafabian713100% (1)

- Ssid Doc For 180Document60 pagesSsid Doc For 180Pankaj SharmaNo ratings yet

- Manual Title Manual Number - Paper Copy Temporary Revision NumberDocument54 pagesManual Title Manual Number - Paper Copy Temporary Revision NumberRay MillsNo ratings yet

- Temp Rev 5 - 152 Service ManualDocument200 pagesTemp Rev 5 - 152 Service ManualKamal Jit DhimanNo ratings yet

- Model FR172 Reims Rocket 1968 Thru 1976 Service Manual DEC 2011Document226 pagesModel FR172 Reims Rocket 1968 Thru 1976 Service Manual DEC 2011Paul100% (1)

- C172 Inspection Time IntervalsDocument6 pagesC172 Inspection Time IntervalsAndy WiyonoNo ratings yet

- ML C Ser c206hmm15Document3 pagesML C Ser c206hmm15Juan TapiaNo ratings yet

- Time Limits/Maintenance Checks 1. Time Limits/Maintenance Checks - GeneralDocument2 pagesTime Limits/Maintenance Checks 1. Time Limits/Maintenance Checks - GeneralRizqi PerdanaNo ratings yet

- Office of The Director General of Civil AviationDocument4 pagesOffice of The Director General of Civil Aviationconfirm@No ratings yet

- 05 00 00 inDocument4 pages05 00 00 inMarco Antonio PrietoNo ratings yet

- CORROSION PREVENTION AND CONTROL PROGRAMDocument21 pagesCORROSION PREVENTION AND CONTROL PROGRAMjesus francoNo ratings yet

- 5 Hard Time and Maintenance ChecksDocument3 pages5 Hard Time and Maintenance ChecksWilly Gr100% (1)

- Cessna 152-TR10Document26 pagesCessna 152-TR10Muhammad Subhan100% (1)

- 2a-30-00 Corrosion Prevention and Control Program (CPCP)Document22 pages2a-30-00 Corrosion Prevention and Control Program (CPCP)Antonio Bedoya100% (1)

- 05-00-00time Limits Maintenance ChecksDocument3 pages05-00-00time Limits Maintenance ChecksShaurya AeronauticsNo ratings yet

- Operaciones de Mantenimiento c172Document5 pagesOperaciones de Mantenimiento c172Juan G Correa100% (1)

- 13 Biennial Scheduled Inspection ProgramDocument4 pages13 Biennial Scheduled Inspection ProgramWilly GrNo ratings yet

- 7 Scheduled Inspection Program Lj1073 and AfterDocument5 pages7 Scheduled Inspection Program Lj1073 and AfterWilly GrNo ratings yet

- Office of The Director General of Civil AviationDocument18 pagesOffice of The Director General of Civil AviationRoshith KrishnanNo ratings yet

- Amm 05-10-00 Time Limits and Maintenance ChecksDocument21 pagesAmm 05-10-00 Time Limits and Maintenance ChecksLUCIENE ORECCHIO VIEIRANo ratings yet

- Service Manual CE-172 - 1969 - 1976Document13 pagesService Manual CE-172 - 1969 - 1976Kyle BrandonNo ratings yet

- Etops Advisory CircularDocument13 pagesEtops Advisory CircularAhmed NaseerNo ratings yet

- PiperSeneca PA34 220T MaintenanceManual 100hrinspectionDocument18 pagesPiperSeneca PA34 220T MaintenanceManual 100hrinspectionR. Demmin100% (1)

- Time Limits / Maintenance Checks A. GeneralDocument6 pagesTime Limits / Maintenance Checks A. GeneralAlexis CabreraNo ratings yet

- 05 20 00 inDocument24 pages05 20 00 inWalter AsanzaNo ratings yet

- Chapter5 - General InspectionDocument2 pagesChapter5 - General InspectionElmer VillegasNo ratings yet

- 05 20 00 SchedchkDocument27 pages05 20 00 SchedchkSaid AdingniNo ratings yet

- D2B B1 PDFDocument5 pagesD2B B1 PDFHemanthNo ratings yet

- CHAPTER 5 - TIME LIMITS and MAINTENANCE CHECKSDocument39 pagesCHAPTER 5 - TIME LIMITS and MAINTENANCE CHECKSAlvaro Lemos100% (1)

- MEL DATA For A320Document5 pagesMEL DATA For A320amitNo ratings yet

- Emm Task 05 20 00 95 210 801 G100372359 - 1641564260467Document7 pagesEmm Task 05 20 00 95 210 801 G100372359 - 1641564260467marioNo ratings yet

- AAC No. 2 of 2023 outlines privileges and limitations of line maintenanceDocument6 pagesAAC No. 2 of 2023 outlines privileges and limitations of line maintenanceSawan KumarNo ratings yet

- Aeronautical Engineering-51-75Document25 pagesAeronautical Engineering-51-75Natural RawshortNo ratings yet

- 05 20 00 SchedchkDocument31 pages05 20 00 SchedchkSaid AdingniNo ratings yet

- MccauleyDocument14 pagesMccauleyjose luis rocha marquezNo ratings yet

- SM Cessna 152 Temporary Rev 9Document30 pagesSM Cessna 152 Temporary Rev 9technicmerpatipilotschoolNo ratings yet

- CAR Section II MEL ApprovalDocument5 pagesCAR Section II MEL ApprovalSheik AbdullahNo ratings yet

- Service Bulletin: TitleDocument13 pagesService Bulletin: TitleLuis EnriqueNo ratings yet

- Jaa-Agm - S2 - L26 - (Jar-Ops - 1&3 - Aircraft - Maintenance - Programme - Frequences)Document4 pagesJaa-Agm - S2 - L26 - (Jar-Ops - 1&3 - Aircraft - Maintenance - Programme - Frequences)Salim Moghtased AzarNo ratings yet

- Chapter 04 - AWLDocument24 pagesChapter 04 - AWLreginaldo11No ratings yet

- Daily inspection checklist CH-47D helicopterDocument4 pagesDaily inspection checklist CH-47D helicopterMinsung ChoNo ratings yet

- Phase Inspections PDFDocument141 pagesPhase Inspections PDFHrishikesh Narasimhan100% (1)

- MODEL 182 SERIES (1977 - 1986) : Inspection Operation 11Document1 pageMODEL 182 SERIES (1977 - 1986) : Inspection Operation 11Gabriel vieiraNo ratings yet

- Time Limits and Maintenance Checks: 1. GeneralDocument12 pagesTime Limits and Maintenance Checks: 1. GeneralSergio LópezNo ratings yet

- Cabos de VooDocument2 pagesCabos de VooRebeca SerranoNo ratings yet

- Manual Title Manual Number - Paper Copy Temporary Revision NumberDocument35 pagesManual Title Manual Number - Paper Copy Temporary Revision NumberJean Mark SilvestreNo ratings yet

- 72.00.00 Engine - Inspection - CheckDocument83 pages72.00.00 Engine - Inspection - CheckTimoteo Molina RomeroNo ratings yet

- Inspection Operation 14: Item Code Number Task Zone Mech IN-SP RemarksDocument1 pageInspection Operation 14: Item Code Number Task Zone Mech IN-SP RemarksBrian NolascoNo ratings yet

- AC 121-1 Amdt. 0 - Standard Operations Specifications - Aircraft Maintenance HandbookDocument84 pagesAC 121-1 Amdt. 0 - Standard Operations Specifications - Aircraft Maintenance HandbookUjang SetiawanNo ratings yet

- Nepalese Civil Airworthiness Requirements Section D Approval ProceduresDocument4 pagesNepalese Civil Airworthiness Requirements Section D Approval ProceduresSantosh SahNo ratings yet

- Service Bulletin: TitleDocument12 pagesService Bulletin: TitleLuis EnriqueNo ratings yet

- Nepalese Civil Airworthiness Requirements: Section CDocument2 pagesNepalese Civil Airworthiness Requirements: Section CSantosh SahNo ratings yet

- Amm 5Document762 pagesAmm 5dsenpen100% (2)

- 05 00 00 inDocument8 pages05 00 00 inÜmit KazanNo ratings yet

- 05 - Scheduled - Unscheduled MaintenanceDocument14 pages05 - Scheduled - Unscheduled MaintenanceEsang AkanNo ratings yet

- 737 Performance Reference Handbook - EASA EditionFrom Everand737 Performance Reference Handbook - EASA EditionRating: 4.5 out of 5 stars4.5/5 (3)

- Multi-Engine Oral Exam Guide: The comprehensive guide to prepare you for the FAA checkrideFrom EverandMulti-Engine Oral Exam Guide: The comprehensive guide to prepare you for the FAA checkrideRating: 5 out of 5 stars5/5 (4)

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- Welcome To The New Piper M-Class: in This IssueDocument12 pagesWelcome To The New Piper M-Class: in This IssuesandyNo ratings yet

- Site Controller Iii Board Set Installation Instructions: Expansion Port Screws (Steps 3 and 6)Document1 pageSite Controller Iii Board Set Installation Instructions: Expansion Port Screws (Steps 3 and 6)sarge18No ratings yet

- Product Catalog: Cleveland Wheels & BrakesDocument296 pagesProduct Catalog: Cleveland Wheels & BrakesАлександр ГладкийNo ratings yet

- SB 1103BDocument5 pagesSB 1103BsandyNo ratings yet

- Piper's M600 Personal Turboprop: For The Pilots of Owner-Flown, Cabin-Class AircraftDocument36 pagesPiper's M600 Personal Turboprop: For The Pilots of Owner-Flown, Cabin-Class AircraftsandyNo ratings yet

- Service Bulletin: Alternator Model ALU-6539-4 Installation of Missing SpacerDocument9 pagesService Bulletin: Alternator Model ALU-6539-4 Installation of Missing SpacersandyNo ratings yet

- M600 SLS Halo BrochureDocument2 pagesM600 SLS Halo BrochuresandyNo ratings yet

- Parts Manual: Topkat Fuel Management SystemDocument20 pagesParts Manual: Topkat Fuel Management SystemsandyNo ratings yet

- Current Online CatalogDocument376 pagesCurrent Online CatalogsandyNo ratings yet

- 20110610Document6 pages20110610sandyNo ratings yet

- Service Bulletin: Alternator Model ALU-6539-4 Installation of Missing SpacerDocument9 pagesService Bulletin: Alternator Model ALU-6539-4 Installation of Missing SpacersandyNo ratings yet

- Piper Seminole PA44-180 Checklist: Nice AirDocument4 pagesPiper Seminole PA44-180 Checklist: Nice AirDoĞuŞ SaracNo ratings yet

- PR46BT: 115838449 Rev. A 2016-05-02Document41 pagesPR46BT: 115838449 Rev. A 2016-05-02sandyNo ratings yet

- The New Standard in Aviation: Safety Standards That Exceed Your Highest StandardsDocument2 pagesThe New Standard in Aviation: Safety Standards That Exceed Your Highest StandardssandyNo ratings yet

- ATP CatalogDocument158 pagesATP Catalogsandy100% (1)

- 2019 Specification Book: Cabin Class - Single-Engine - Pressurized TurbopropDocument5 pages2019 Specification Book: Cabin Class - Single-Engine - Pressurized Turbopropsandy100% (1)

- Vans Aircraft Building InstructionDocument6 pagesVans Aircraft Building Instructionsandy100% (1)

- Airworthiness Bulletin: AWB Issue: Date: 1. ApplicabilityDocument2 pagesAirworthiness Bulletin: AWB Issue: Date: 1. ApplicabilitysandyNo ratings yet

- C130 HérculesDocument21 pagesC130 HérculesJesus Ocaña Calderón75% (4)

- Supplemental Type Aertificate: Bepartment of Transportation - Hederal Adiation AdministrationDocument26 pagesSupplemental Type Aertificate: Bepartment of Transportation - Hederal Adiation AdministrationsandyNo ratings yet

- KR 87 PDFDocument45 pagesKR 87 PDFFilip SkultetyNo ratings yet

- Service Letter: Single EngineDocument10 pagesService Letter: Single EnginesandyNo ratings yet

- Piper aircraft inspection reportDocument5 pagesPiper aircraft inspection reportsandyNo ratings yet

- 206L4 Spec Book 22013-WebDocument45 pages206L4 Spec Book 22013-WebSamuel LimaNo ratings yet

- Cessna ConquestDocument18 pagesCessna ConquestsandyNo ratings yet

- Chuck Guide Il 2 Cliffs of Dover He111Document91 pagesChuck Guide Il 2 Cliffs of Dover He111sandyNo ratings yet

- VANTAGE TruckALL and VanGO Series Operation and Service ManualDocument209 pagesVANTAGE TruckALL and VanGO Series Operation and Service ManualsandyNo ratings yet

- Inflight Guide CJ4-V2.0Document30 pagesInflight Guide CJ4-V2.0Phil Marsh100% (3)

- Current Revision Levels FOR Instructions For Continued Airworthiness (Ica), Flight Manual Supplements (FMS) and Sa52Document4 pagesCurrent Revision Levels FOR Instructions For Continued Airworthiness (Ica), Flight Manual Supplements (FMS) and Sa52sandyNo ratings yet

- KING KE1107/KEJ1107: Solid Fuel Catalytic StoveDocument60 pagesKING KE1107/KEJ1107: Solid Fuel Catalytic StovesandyNo ratings yet

- Sheet - PDF 3Document4 pagesSheet - PDF 3Nazar JabbarNo ratings yet

- 02 - Consumerism Then and NowDocument28 pages02 - Consumerism Then and NowGeorge TsangNo ratings yet

- RTI SpicesDocument226 pagesRTI SpicesvivebajajNo ratings yet

- Miri Datalogger FlyerDocument1 pageMiri Datalogger FlyerernestoveigaNo ratings yet

- SPC Company BrochureDocument22 pagesSPC Company BrochureDaivasigamaniNo ratings yet

- M7Ge-Iiib-1: Renante Tillo JosolDocument3 pagesM7Ge-Iiib-1: Renante Tillo JosolRenante T. JosolNo ratings yet

- Effect of pH extraction on properties of pigeon pea protein concentrateDocument11 pagesEffect of pH extraction on properties of pigeon pea protein concentrateRezaa RezNo ratings yet

- Prakhar Gupta Epics and Empires-Game of Thrones Make Up EssayDocument5 pagesPrakhar Gupta Epics and Empires-Game of Thrones Make Up EssayGat DanNo ratings yet

- Teacher Thought For InterviewDocument37 pagesTeacher Thought For InterviewMahaprasad JenaNo ratings yet

- A Christmas Memory. Lesson - AnthologyDocument24 pagesA Christmas Memory. Lesson - AnthologySherry CallisonNo ratings yet

- Prepare SCI for Service and Merchandising BusinessesDocument8 pagesPrepare SCI for Service and Merchandising BusinessesFunji BuhatNo ratings yet

- Uber+PM+Prioritisation+Assignment+Submission+File-Shashank KaranthDocument6 pagesUber+PM+Prioritisation+Assignment+Submission+File-Shashank KaranthShashank KaranthNo ratings yet

- The Promised Land PDFDocument12 pagesThe Promised Land PDFnazim2851No ratings yet

- Can We Define Ecosystems - On The Confusion Between Definition and Description of Ecological ConceptsDocument15 pagesCan We Define Ecosystems - On The Confusion Between Definition and Description of Ecological ConceptsKionara SarabellaNo ratings yet

- Ictracker Summary of Stocks With Outlook 'Strong Buy' in United StatesDocument12 pagesIctracker Summary of Stocks With Outlook 'Strong Buy' in United StatesBosZ AndersonNo ratings yet

- Papaer JournelDocument6 pagesPapaer JournelsonalisabirNo ratings yet

- HLTARO001 HLTAROO05 Student Assessment Booklet 1 1Document68 pagesHLTARO001 HLTAROO05 Student Assessment Booklet 1 1Amber PreetNo ratings yet

- Mens and Actus ReusDocument3 pagesMens and Actus ReusBrian Okuku OwinohNo ratings yet

- Boot Time Memory ManagementDocument22 pagesBoot Time Memory Managementblack jamNo ratings yet

- String instruction guide for data manipulationDocument11 pagesString instruction guide for data manipulationammerNo ratings yet

- UNIABROAD PitchdeckDocument21 pagesUNIABROAD PitchdeckVikas MurulidharaNo ratings yet

- Too Early! by Anton Pavlovich ChekhovDocument4 pagesToo Early! by Anton Pavlovich Chekhovapi-19787590No ratings yet

- AQA Power and Conflict GCSE Revision Guide LADocument49 pagesAQA Power and Conflict GCSE Revision Guide LAderaw11557No ratings yet

- Certified Vendors As of 6 17 22Document18 pagesCertified Vendors As of 6 17 22Harry ConnerNo ratings yet

- Intro To StarsDocument37 pagesIntro To StarsENo ratings yet

- Syeda Qirtas Zehra 14948 ObcDocument20 pagesSyeda Qirtas Zehra 14948 ObcSyeda ZehraNo ratings yet

- Impacts of Extracurricular Activities On The Academic Performance of Student AthletesDocument3 pagesImpacts of Extracurricular Activities On The Academic Performance of Student AthletesKarlo VillanuevaNo ratings yet

- 3286306Document5 pages3286306Sanjit OracleTrainingNo ratings yet

- Roy B. Kantuna, MPRM, CESE: (For Midterm) (Instructor)Document8 pagesRoy B. Kantuna, MPRM, CESE: (For Midterm) (Instructor)Athena Mae DitchonNo ratings yet

- Advanced Diploma in Cyber Defense Overview (ADCDDocument8 pagesAdvanced Diploma in Cyber Defense Overview (ADCDrahulmultivisionNo ratings yet