Professional Documents

Culture Documents

VDCHRD Is RPT Acu 00001

Uploaded by

Neeskens D'melloOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VDCHRD Is RPT Acu 00001

Uploaded by

Neeskens D'melloCopyright:

Available Formats

Volume 6 | S P E C I A L I S T DESIGNS

Table of contents

6.10.1 INTRODUCTION ................................................................................................................................................................................................................................................................................................ 5

6.10.2 PROJECT DESCRIPTION .................................................................................................................................................................................................................................................................................. 5

6.10.3 DESIGN METHODOLOGY ................................................................................................................................................................................................................................................................................. 5

6.10.4 STANDARD & DESIGN GUIDELINES ............................................................................................................................................................................................................................................................... 7

6.10.5 ENVIRONMENTAL NOISE SIMULATIONS ....................................................................................................................................................................................................................................................... 8

6.10.6 DESIGN CRITERIA -ARCHITECTURAL, MEP AND ID ..................................................................................................................................................................................................................................... 9

6.10.7 CONSTRUCTION ELEMENTS ......................................................................................................................................................................................................................................................................... 16

6.10.8 CONCLUSION.................................................................................................................................................................................................................................................................................................. 17

KEY ISSUES FOR COORDINATION: .................................................................................................................................................................................................................................................................................. 17

Appendix A: HVAC Guidelines ......................................................................................................................................................................................................................................................................................... 18

Appendix B: Construction Elements ............................................................................................................................................................................................................................................................................... 22

Appendix C: Acoustic Glossary ....................................................................................................................................................................................................................................................................................... 24

VIDA HOTEL RETAIL DISTRICT Concept Design Report | May 2017

Volume 6 | S P E C I A L I S T DESIGNS

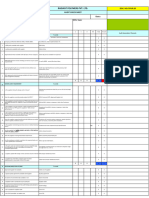

Location/Floor Name Activities

6.10.1 Introduction Basement Level-03 Parking Area & MEP Rooms

This is a Concept design document outlining the requirements, standards, strategies and methodologies to meet the design

Basement Level-02 Parking Area & MEP Rooms

criteria for VIDA DCH RD Project. The design principles and parameters discussed in this report are to be the established

Office Areas, Kitchen Area, Stores, MEP Rooms Parking

parameter of acoustic design for this project. This document is to serve as set of guidelines and reference for the other design Basement Level-01

Area

teams and the client.

Retails, Terrace, Restaurants, Kitchen Area, Stores, Office

Ground Floor

Areas, Prayer Rooms,

6.10.2 Project Description Level-01

Retail, Show Kitchen re-function, Multipurpose Rooms,

Board Room, Training Room, Office Areas

The VIDA DCH RD is a 55-story tower comprising 4 star Vida hotel and serviced apartments. The first 14 floors are the hotel part

Level-02 Retail, Prayer Rooms, House Keeping & Guest Rooms

and the remaining 15 to 55 floors are of Vida serviced apartments. The hotel is directly attached to nearby mall with a walking

bridge connecting at level 1. Level-03 Retail, House Keeping & Guest Rooms

The Hotel offers guests/residents access to all-day dining restaurants, retails as well as to the nearby mall. It also provides board Level-04 MEP Floor

rooms, multipurpose halls and pre-function Gym, Studio, Toilets, Humidor, BOH Kitchen, Cellar,

Level-05

areas. The 242 keys for hotel floors has a Pantry & Guest Rooms

diverse room mix ranging from Deluxe one bed Hotel Rooms

Room, Executive 2 bedrooms, kind Leisure Level-06-10 Floors Hotel Layout-1(Typical-5

Housekeeping & Guest Rooms

rooms Floors)

Level-11-13 Floors Hotel Layout-2 (Typical-3

The 310 keys serviced residential apartments Housekeeping & Guest Rooms

Floors)

has room mix ranging from one bedroom to four

Apartments

bedrooms on various levels from 15 to 55

Level-14-49 Floors Apartment Layout-1(Typical -36

Floors Apartments

Floors)

The Vida DCH RD comprises of the following. Level-50-52 Floors Apartment Layout-2(Typical -2

Apartments

Floors)

• 242 keys of Hotel Guestrooms

• 310 keys of Serviced Residential

apartments

• Gym

• Swimming pool 6.10.3 Design Methodology

• Food and Beverage outlets

• Board Facilities The design methodology for a 4-star hotel project would constitute of the following design elements:

Airborne Sound Isolation:

Airborne sound isolation would be considered critical in any building because of the nature of human hearing. The sound

travelling through the air has greater significance to the human ears than structure borne vibrations in-terms of perception.

Any building element that surrounds the listener should have sufficient airborne sound isolation to allow for a comfortable living

environment. Specifically, in a residential building the elements that we would be looking at from a design stance would be the

walls, the glazing, doors, floor and ceiling assemblies. The further spaced out two different spaces are the lower the sound being

transmitted.

VIDA HOTEL RETAIL DISTRICT Concept Design Report | May 2017

Volume 6 | S P E C I A L I S T DESIGNS

Any noise entering a space from an external source is defined as intrusion noise. The amount of intrusion noise within a space We would recommend that there be a impact isolation layer below the screed in the Guest rooms and the hotel apartments. This

can be controlled by altering the sound isolation of the building elements. would serve as a cushioning layer reducing the impact velocity of footfall and objects falling from the floor above. The other ways

of increasing the impact isolation would be to provide thicker slabs where the sound transmission would be reduced due to the

In buildings intrusion noise is primarily from external noise sources like traffic, noise from adjacent properties and tenants. Traffic

slabs sound isolation properties. Since increasing the slab thickness would result in complications with the structural design it is

noise is primarily mitigated by increasing the sound isolation of the facade wall and the facade glazing. The noise from adjacent

mostly preferred to include a resilient layer between the slab and the screed. Alternatively, to increasing the impact isolation of a

properties and tenancies is reduced by increasing the sound isolation of the partition wall between the properties or tenancies.

floor assembly carpets with resilient or spongy underlay can be used to the same effect. The impacts would be absorbed by the

underlay and thus the amount of sound transmitted through

the floor slab would be negligible.

Flanking Transmission:

Flanking transmissions are a result of sound travelling

through the structure of the building re-entering the rooms

as airborne sound. The partitions can be the primary source

of flanking transmissions. Other sources include shared

ductwork between two spaces. Occasionally flanking

transmission also happens through the facade wall or

glazing. the image below gives typical flanking

transmissions.

The above sections went into treating the architectural

Impact Sound Isolation:

elements of a building hence it is called architectural

Impact sounds would primarily arise from people walking on the floor above that doesn't have any treatment for impact isolation. acoustics. The following section details the mechanical

Occasionally there can be massive impact noises as a result of something heavy being dropped on the floor above. Both these noise isolation methodology that is to be used in this project.

cases are considered highly annoying and would warrant an impact isolation treatment.

Mechanical, Electrical and plumbing noise:

The mechanical, electric and plumbing equipment in any building would create constant noises that would be an annoyance to

the occupants. The nature of mechanical and electrical noise is constant tones with equal amplitude. The exceptions for this

case being generators or any other equipment that run at varying speeds depending on the loading.

Mechanical equipment can be considered as being two different types of noise sources. They can vibrate producing structure

borne noise and they can also produce airborne noise. These noise components are of significance because of noise exposure

to the occupants and secondly the noise pollution regulations of Dubai.

VIDA HOTEL RETAIL DISTRICT Concept Design Report | May 2017

Volume 6 | S P E C I A L I S T DESIGNS

Noise Pollution:

Noise pollution is a concerning area in the UAE as there are multiple developments that are coming up on a regular basis. The

Typical treatment to isolate this equipment for structure borne noise and vibration would be to mount them on springs or resilient noise pollution from these properties has been regulated and controlled by the various governing bodies. In Dubai, the Dubai

material which would absorb the vibrations. Concrete inertia bases, spring mounts, neoprene pads, floating floors are some of Municipality has issued guidelines and rules to adhere to specific noise levels from different types of developments.

the typical treatment that are used.

As for the airborne noise the partitions and the floor ceiling assemblies around the mechanical equipment can be made to isolate

most of the sound energy. Typically, thick walls of up to 300mm are used around mechanical areas to isolate the sound from

6.10.4 Standard & Design Guidelines

equipment like generators, AHUs, chillers, etc. Like any other discipline acoustics has its own set of international standards and design guidelines. The adherence to these

standards and guidelines would be considered crucial to achieving a good acoustic environment.

Room Acoustics:

The following section provides a list of key standards or guidelines referred in the current report.

Room acoustics involves treating the room internally to make it comfortable for occupants to have conversations. The primary

issue when it comes to enclosed spaces made out of hard materials is that the hard surfaces reflect the sound energy. These a. BS 8233:2014 Guidance on Sound insulation and noise reduction for buildings

reflections affect the occupants’ ability to recognize the speech. This would be an annoyance in public spaces. b. Emaar standards, Volume 2, Residential developments, Rev 1, Aug 2016.

c. Emaar standards, Volume 3, Hospitality developments, Rev 1, Aug 2016

To mitigate the effects of these reflections sound absorption panels, namely acoustic wall panels and ceiling panels can be used. d. Emaar standards, Volume 2, Retail developments, Rev 1, Aug 2016

The acoustic panels absorb the sound energy such that the reflections loose most of their energy and thereby becoming e. Federal Environmental Agency, UAE – Noise Regulations

inaudible. f. Al Safat /Dubai Municipality Green Building Regulations

g. Dubai Municipality Technical Guideline -10

h. 2015 ASHRAE Handbook - HVAC Systems and Applications, Chapter 48 Noise and Vibration Control.

i. CIBSE B5: 2002 HVAC Design Guidelines

j. BS EN ISO 10140-4 Measurement of sound insulation in buildings and of building elements – Part 4 Field

measurement of airborne sound insulation of building elements.

k. BS EN ISO 10140-5 Measurement of sound insulation in buildings and of building elements – Part 5 Field

measurement of airborne sound insulation of façade elements and facades.

VIDA HOTEL RETAIL DISTRICT Concept Design Report | May 2017

Volume 6 | S P E C I A L I S T DESIGNS

l. BS EN ISO 10140-7 Measurement of sound insulation in buildings and of building elements – Part 7 Field from the air traffic is not anticipated to be continuous and disturbing.

measurements of impact sound insulation of floors.

m. BS EN ISO 717-1: 2013 Acoustics - Rating of sound insulation in buildings and of building elements –

Airborne sound insulation.

n. BS EN ISO 717-2: 2013 Acoustics - Rating of sound insulation in buildings and of building elements – Part 2

Impact sound insulation.

o. BS EN ISO 3382:2009 Part2 Acoustics – Measurement of the reverberation time in ordinary rooms.

6.10.5 Environmental Noise Simulations

The site is located within the creek harbour, Dubai. The roads surrounding the site are fairly busy during the rush hours of the

day.

The minimum distance from building to the centre of the road is about 40 meters. Assuming traffic levels given below calculations

are made to determine the noise incident on the building and the glazing required.

Type of vehicle Heavy Vehicles Light motor vehicles Motorcycles

Avg. Speed 80 100 60

No. per Hour 15 300 60

A daytime average sound level (Leq) of 82dB for the road noise generated, the average sound level near the building can be

anticipated to be about 71dB at the ground floor. Given the internal sound level to be achieved (NC 30), the building façade

needs to provide about 40dB of attenuation.

The Hotel Tower will have the impact of traffic noise from nearby roads and the proposed metro line which is only 50 mts away We would recommend the use of glazing with Rw of 40 to the front of the building facing towards the Metro and road lines. This

from the property wherein it would be a noisy area. Since there is no major airport within a 5km radius of the plot, noise impact would be implemented from the ground floor to the 26th floor to achieve a background noise level less than NC of 30. We would

also recommend the backside facade glazing with an RW of 37. The thickness of the glazing elements would be about 35 - 40

mm depending on the glass preferred.

We would recommend that the exterior wall itself have a sound isolation of Rw 55. This can be achieved by using the proposed

250mm thermally insulated blockwork. The density of this blockwork would have to be higher than 1400 kg/m3.

VIDA HOTEL RETAIL DISTRICT Concept Design Report | May 2017

Volume 6 | S P E C I A L I S T DESIGNS

Source/path 63 Hz 125 Hz 250 Hz 500 Hz 1 kHz 2 kHz 4 kHz 8 kHz • Reverberation Time (RT)

Metro Train noise @94dBA- 1m from Track 116.2 110.1 102.6 97.2 94 92.8 93 94.1 The reverberation time is defined as the time taken for the sound to decay by 60dB after the source has stopped generating

sound.

Metro rail noise barrier loss ( -10dB) 106.2 100.1 92.6 87.2 84 82.8 83 84.1

Noise level @2m 103.2 97.1 89.6 84.2 81 79.8 80 81.1 • Impact sound Isolation (IIC)

Noise level @4m 100.2 94.1 86.6 81.2 78 76.8 77 78.1

Impact sound insulation is the ability of a material to dampen sound. This is commonly determined by measuring the sound

Noise level @8m 97.2 91.1 83.6 78.2 75 73.8 74 75.1

pressure level (in dB) on the receiver side of the material being excited by a sound source on the source side. Impact sound

Noise level @16m 94.2 88.1 80.6 75.2 72 70.8 71 72.1

insulation can be measured using the procedures set out in BS EN ISO 140-5 and BS EN ISO 140-7.

Noise level @32m 91.2 85.1 77.6 72.2 69 67.8 68 69.1

Road Noise @82dBA -Centre of the road 90 85 87 85 80 76 68 61 Sound Isolation – General

The recommended Rw of partitions between two different spaces are as given below.

Noise level @2m 87 82 84 82 77 73 65 58

Noise level @4m 84 79 81 79 74 70 62 55

Noise level @8m 81 76 78 76 71 67 59 52 Guestroom,

Noise level @16m 78 73 75 73 68 64 56 49 Corridor, Lobby, Apartments, Gymn BOH Restaur Kitchen, Mechanical

Noise level @32m 75 70 72 70 65 61 53 46

lounge, Reception Board room, asium, offices ant Retails rooms

Background noise from adjacent Prayer room

74 69 71 68 64 58 50 43

developments @ 65dBA

Cumulative average 91 85 79 75 71 68 68 69

Corridor, Lobby,

NC target @ 30 57 48 41 35 31 29 28 27 lounge, 50 55 60 50 60 55 60

Glazing Required 34 37 38 40 40 39 40 42 Reception

Guestroom,

Apartments

55 55 55 55 50 60 60

6.10.6 Design Criteria -Architectural, MEP and ID Board Room,

Prayer room

Following are the criteria required to be met to achieve the desired acoustical environment.

Gymnasium 60 55 50 55 - 55 60

Metrics used:

The Acoustic design follows several guidelines provided by international agencies to achieve the best acoustical environment BOH offices 50 55 55 50 50 55 60

inside the building. As per the standards and norms, several criteria have been drawn for different parameters that define the

Restaurant 60 50 - 50 - 50 60

quality of acoustics in each space within the Maryland Hotel Development.

Kitchen, Retail 55 60 55 55 50 50 60

• Indoor Ambient Noise Levels (NC)

The indoor ambient noise level determines the allowable noise level considering the external noises and noises produced by the Mechanical

60 60 60 60 60 60 60

service machinery within the room.This helps in maintaining good speech clarity based on the activity of the room. rooms

• Weighted Sound Reduction Index (Rw) Table 1: Recommended Internal Wall Insulation for the building

A single-number quantity which characterizes the airborne sound insulation of a material or building element over a range of

frequencies.

VIDA HOTEL RETAIL DISTRICT Concept Design Report | May 2017

Volume 6 | S P E C I A L I S T DESIGNS

The recommended Door Rw for different rooms are given below– in accordance with BS8233:2014.

Doors Rw

Guestroom to Corridor 37

Apartments to Corridor 37

Gymnasium door 40

Main entry doors 37

Admin offices 30

Lounge 35

Restaurants 40

Prayer room 37

Board Room door 40

Table 2: Recommended Door Rw for the building i. Electrical Outlets shall not be back to back on a demising wall (electrical outlets to be staggered)

Impact Sound Isolation:

The floor slabs must have high IIC to prevent any sounds emanating on the upper floors from passing over to the lower floors.

Space Above

Space Below Guestroom, Gymnasium/ Mechanical

Apartments

Guestroom, Apartments 55 60 60

Gymnasium 55 - 60

Mechanical 55 55 -

ii. In case if there are any unavoidable conditions, having back to back Electrical Outlets then the follow detail has to be

Table 3: Recommended Floor IIC for the building strictly followed. However, this will not be as effective as a staggered Electrical Outlets details. There will be a drop in

the performance of the wall

Flanking Sound Transmission

Flanking transmission is the sound passes around, over the top or under the primary partition separating two spaces. Flanking

sound transmission is an issue between adjacent guestrooms. Since the Emaar brand comprises of multiple interconnecting

guestrooms it is critical to adhere to the following recommendations to reduce flanking noise.

VIDA HOTEL RETAIL DISTRICT Concept Design Report | May 2017

Volume 6 | S P E C I A L I S T DESIGNS

Noise criteria

Room

(NC)

Lobby 35

Corridor 35

Guestroom 30

Apartments

30

Gymnasium 30

Retail 40

Multipurpose Room 35

FOH / BOH Office 35

Public areas 35

iii. HVAC supply ducts shall be routed from the corridor and branched into each cabin. Common ducts to be avoided to All Day Dining 35

reduce flanking noise between the rooms.

Lounge 30

Board room 30

BOH areas 40

Kitchen 45-50

Table 4: Recommended sound levels for HVAC systems

NC level specifics:

The Design guidelines provide selection criteria for equipment selections they are as follows for the NC levels given above.

NC 30

Background Noise Levels Hertz 63 125 250 500 1000 2000 4000 8000

The indoor ambient noise level determines the allowable noise level considering the external noises and noises produced by

dB 57 47 41 35 31 29 28 27

the service machinery within the room. This helps in maintaining good speech clarity based on the activity of the room. - in

accordance with BS8233:2014.

Following are the NC criteria for the Hotel building.

VIDA HOTEL RETAIL DISTRICT Concept Design Report | May 2017

Volume 6 | S P E C I A L I S T DESIGNS

NC 35 Pumps

Hertz 63 125 250 500 1000 2000 4000 8000 1. It is preferred that an acoustic enclosure be constructed around the pumps to prevent the air-borne sound from

spreading. Otherwise, the walls and the ceiling around the pumps are preferred to be clad with acoustic absorbers to

dB 60 53 46 40 36 34 33 32

minimize the sound build up due to reflected sound waves.

NC 40 2. The pumps must be installed on pedestals with appropriate vibration isolators to prevent structure borne noise.

Hertz 63 125 250 500 1000 2000 4000 8000 3. The pipes must be lagged with foam/rubber jackets at places where they are in contact with the walls or ceiling slabs.

dB 64 57 51 45 41 39 38 38 4. Flexible connectors to be used between the pipes and the pumps.

5. The pipes and electrical conduits connecting the pump rooms must all be detached from the structure employing

appropriate rubber isolators along the entire running length at every 1000mm distance.

Basement levels and MEP areas

The Basements houses many machine rooms and provides space for parking. The noise from the machine rooms would be high

and may reach sound levels beyond 85dB. The vehicle movement would also be a good source of noise.

Given below are the recommendations to minimize the noise levels in the basement levels.

1. The boundary walls of any electrical or telephone rooms shall offer an Rw of 50 and the entry doors of these rooms

shall offer an Rw of 30. The boundary walls of all other MEP services rooms shall provide Rw of 60 and doors Rw of 45.

2. The walls of MEP shafts should provide an Rw of 55.

3. The noise from the machinery can be treated either with a sound attenuating enclosure that attenuates the sound to

55dB measured at 1m from the machine or by treating the walls and ceiling of the machine room with sound absorbing

panels in addition to the recommended wall types.

4. The cable trays carrying the cables and duct hangers in the machine rooms (AHU room/ pump rooms) should be fixed

to the ceiling only through a vibration isolator until at least the cable tray is brought 5m out from the concerned room.

This will reduce the noise that may be generated by vibration picked up by cable tray plates and ducts.

5. The machines that may be placed in MEP rooms induce low frequency vibrations into the building which would travel AHU & Ducting

as structure borne sounds. These have to be curtailed using appropriate vibration isolators for the mounts or pedestals The AHUs generate a continuous low-mid frequency sounds that are bothersome. The supply and return air ducts that originate

based on the machine dynamics. and terminate into the room are very good paths for sound to travel long distances. The machines generate a lot of noise that

will travel through these ducts.

6. The heavy machines must be mounted on platforms supported and isolated by spring isolators. The spring isolators

shall be selected by the machine load and vibrations. 1. The internal surfaces of the chiller room are lined with sound absorption in the lower and mid frequencies.

7. The air movement for the machine is forced through parallel baffle mufflers or acoustic louvers (where necessary) which 2. The ducts coming into the room will be through punctures in the walls with appropriate acoustic sealants between the

are designed based on the machine specifications, air requirement for breathing and cooling and back pressure wall and the ducts.

calculations. Fans would have to be used for air suction and exhaust.

8. The machine fresh air supply and exhaust lines must have mufflers installed.

9. Please refer Construction elements section for Rw details of walls.

VIDA HOTEL RETAIL DISTRICT Concept Design Report | May 2017

Volume 6 | S P E C I A L I S T DESIGNS

Figure showing wall punctures sealed around the duct

3. A typical sound attenuator should be provided between the HVAC machine and the duct origin.

Figure showing an Elbow Acoustical Lining

8. All the duct tapers up to 15m from the machine should be lined internally with sound absorbing materials.

Figure showing typical sound attenuator

4. At the duct joints, 5mm thick neoprene strips must be used between the flanges.

5. The duct supports and hangers must use neoprene washers between the plate and the suspender rods. The support

plate must be lined with 5mm neoprene rubber strips.

Figure showing a Tapers Acoustical Lining

9. The ducts are to be lined internally by sound absorbing material till 1m beyond the first bend.

10. In places where FCU are installed, the punctures in the false ceiling have to be minimized. Acoustical sealants are to

be used around the fittings. Acoustical pads to be used on the false ceiling below the FCU to absorb sounds of the

FCU. The FCUs must be wrapped using sound absorbing materials to reduce the noise at source.

Guestrooms & Apartments

Privacy inside the Guestrooms is a priority. Unwanted sounds inside a guestroom are a cause for irritation and stress and needs

to be eliminated. Sounds from various sources such as from the adjacent Guestrooms, from the corridor, AC vents, plumbing

shafts, plumbing lines, nearby machinery, etc., could spoil the comfort of the inhabitants.

Given below are the measures to be taken to ensure good acoustics inside a Guestroom.

Figure showing duct supports

1. Wall between two Guestrooms or between a Guestroom and corridor shall provide an Rw of 55.

6. The ducts should be acoustically lined with from inside using sound absorbing materials up to 15m from the machine

and the first bend. 2. Wall between Guestroom and MEP services room shall provide an Rw of 60

3. Internal partitions of the Guestroom should provide an Rw of 45.

7. All the elbow bends of the ducting layout up to 15m from the machine, specifically in high velocity air flow ducts, should

be lined internally with inside using sound absorbing materials . 4. The entry door to the Guestroom should provide an Rw of 35.

5. The floor slabs must provide IIC 55.

Given below are the measures to be taken to ensure good acoustics inside an Apartments.

1. Wall between two apartments or between an Apartment and corridor shall provide an Rw of 55.

VIDA HOTEL RETAIL DISTRICT Concept Design Report | May 2017

Volume 6 | S P E C I A L I S T DESIGNS

2. Wall between Apartment and MEP services room shall provide an Rw of 60 Entrance Lobbies, Corridors and stairwells

3. Internal partitions of the Apartment should provide an Rw of 45. These spaces act as sound paths and allow sound waves to travel greater distances due to short multiple reflections.

4. The entry door to the Apartment should provide an Rw of 35 and all internal doors to provide an Rw of 30. 1. Since the area of the main entrance lobby is large, it is recommended that this space has a sound absorptive false

ceiling for not less than 70% of the ceiling area.

5. The floor slabs must provide IIC 55.

2. It is also recommended that the corridor has a sound absorptive false ceiling. This minimizes multiple reflections of

Gym / Fitness sound in the corridor and thus the ambient noise levels.

This section includes the fitness areas indicated as the cardio area strength area etc. 3. The entry door to the stairwells should provide an Rw of 35.

1. The walls between the amenities should provide an Rw of 55.

4. The floor slabs must provide L’n,w of not more than 60.

2. The walls between toilets and amenities should provide an Rw of 50.

Generator and Transformer

3. The entry door to the amenities should provide an Rw of 35.

The generator room would be a prime source of noise pollution. To minimize the impact of the generator noise on adjacent

4. The floor slabs must provide IIC 60. properties and the building itself the following measures would have to be followed.

1. The walls of the generator room should have a sound isolation of Rw 60.

Function Halls (Board rooms & Ballrooms)

2. The walls of the transformer room should have a sound isolation of Rw 60.

Given below are the measures to be taken to ensure good acoustics inside the Function Halls.

3. The entry door to the generator and Transformer room should provide an Rw of 40.

1. The walls between board rooms and other spaces should provide an Rw of 55.

4. The generator room walls are to be lined with acoustic absorbers to reduce the sound build up within the room.

2. The walls between business centre and board room should provide an Rw of 55.

3. The entry door to the board room should provide an Rw of 40. 5. The transformer is to be mounted on vibration isolators on a floating floor.

4. The floor slabs must provide IIC 55.

Elevator Installation

5. The walls between the Ballroom and the pre-function should provide an Rw of 60.

Elevator shafts act as sound paths and carry the machine sound through them. It is important to take precautions in the

6. The walls between the Ballroom and other areas should provide an Rw of 60.

installation of the elevators so as to minimize noise generation.

7. The entry door to the Ballroom should provide an Rw of 45.

8. The floor slab in this level must provide IIC 55 1. At the basement and parking levels, it is advised to have a partition with door having Rw 35 between the elevator

entrances/lobbies and the open floor. This prevents unwanted noised entering the elevator shaft, which would act like

BOH Areas a barrier

This section includes building services areas.

2. Car rails to be installed by using resilient mounts

1. The walls between the BOH and Guestrooms should provide an Rw of 55.

3. The motor and winch are mounted on an inertia block which is mounted on vibration isolators.

2. The walls between BOH areas should provide an Rw of 50.

3. The walls between toilets and BOH areas should provide an Rw of 50.

4. The entry door to the BOH areas should provide an Rw of 35. Any internal door of the BOH areas should provide an Rw

of 30.

5. All external glazing for BOH areas should provide an RW of 30 except for areas advised otherwise.

6. The floor slabs must provide IIC 55.

VIDA HOTEL RETAIL DISTRICT Concept Design Report | May 2017

Volume 6 | S P E C I A L I S T DESIGNS

4. The elevator door shall provide an Rw of 35.

5. Openings between the elevators room and the shaft are minimized using cover plates.

6. The electrical control panels are to be mounted on vibration isolators.

Sketch showing treatment of a pipe penetration through a wall

7. The interior car noise levels shall not exceed 52 dBA when measured from 1m from the door.

3. It is also recommended that the main runners are lagged with acoustic lagging at the bends for 500mm on each side.

8. The machine room noise level shall not exceed 65dBA during a full cycle of operation.

9. The brake noise should not exceed 70dBA when measured at 1 m away from the brakes.

Plumbing Noise:

Noise is an unavoidable by-product of plumbing systems within a building. Noise generated by the operation of plumbing

systems is a critical factor in architectural and mechanical design. There could be many sources of noise in plumbing

system; Noise could be due to turbulence, cavitation, water splash, waste flow or water hammer. These noises can be

arising in piping runs, fixtures, appliances and pumps.

1. Piping runs must be completely avoided on common walls.

2. Around wall/ceiling penetrations, the plumbing lines will have to be wrapped with acoustic lagging (foil lined fibreglass

wool) and then the wall punctures should be filled with moisture resistant acoustic sealants

Sketch showing a Vibration isolation mount for pipes

4. The taps/faucets used should be so that it allows water to flow slowly and steadily. This will help reduce the flow noise.

VIDA HOTEL RETAIL DISTRICT Concept Design Report | May 2017

Volume 6 | S P E C I A L I S T DESIGNS

Sketch showing treatment of a pipe with lagging penetration detail through a wall Sketch showing treatment of vertical pipe risers

5. Resilient material such as neoprene of at least 6mm thickness must be used as vibration isolators at every 10m distance

wherever the piping run passes through the structure.

6.10.7 Construction Elements

6. Larger pipe should be supported with a riser isolation system composed of guides, isolators and anchors as

engineered by a manufacturer. Floor slabs

In multi-storey buildings, flooring slabs must be acoustically strong to prevent noises from penetrating to the floors below. Impact

noises such as movement of personnel, material, furniture, etc. are clearly heard below.

IIC 55:

A 5mm resilient mat made of rubber substrate is used as an underlayment to the flooring tiles to achieve the required rating. It is

very important to extend the underlayment to the wall skirting (As shown in the figure below) to ensure good impact isolation.

VIDA HOTEL RETAIL DISTRICT Concept Design Report | May 2017

Volume 6 | S P E C I A L I S T DESIGNS

6.10.8 Conclusion

This document is a Concept design report dwelling on the importance of acoustics in the VIDA DCH RD hotel building. This

report identifies the acoustically critical areas and recommends measures to achieve criteria set forth by relevant standards.

Key Issues for Coordination:

1. Architecture to confirm wall thicknesses based on appendix B of this report

2. MEP team to confirm and coordinate NC levels and vibration isolation measures specified in this report.

3. Façade Glazing configuration and specifications to be coordinated based on section 5 of this report.

Alternatively carpeting with underlayment can be used within the guestrooms and corridors to eliminate the underlayment below 4. Recycled rubber underlayment required below screed to satisfy the impact isolation requirement. Architect to confirm

screed. the floor makeup with this addition.

GYM Flooring: 5. General coordination with the other disciplines after coordination of concept design.

Gymnasiums must have a floor additional treatment for good impact noise insulation. It is suggested to have soft flooring made

of resilient material to lessen the effect of impact noises apart from the measures taken for maintaining the recommended IIC .

The area of the gym where the equipment are installed and where free weights are used, it is recommended that a high resilient

material is used for the floor.

VIDA HOTEL RETAIL DISTRICT Concept Design Report | May 2017

Volume 6 | S P E C I A L I S T DESIGNS

Appendix A: HVAC Guidelines

Introduction 5.5 m/s (1085

NC30 6.5 m/s (1120 fpm) 3.0 m/s (590 fpm)

fpm)

The control of building services noise and vibration is an important aspect of system design,

particularly regarding low-noise-criteria spaces requiring NC30 or less. The location of plantrooms 6.0 m/s (1180

NC35 7.5 m/s (1475 fpm) 3.5 m/s (690 fpm)

and the routing of services will require special attention to minimize the impact on internal noise- fpm)

sensitive spaces, as well as to control noise emission from the site to surrounding areas.

Table 1: Limiting airflow velocities in ducts

For areas, which require a noise criterion of NC35 and higher, one would expect the engineer to

In-duct sound attenuators will be incorporated where required, and may need to be split and

adequately design the building services using guidelines published by CIBSE Guide B5 Noise and

located such that primary, secondary and even tertiary attenuators are provided. As a guide, the

vibration control for HVAC and ASHRAE. However, the services design to spaces with a noise

allowances for attenuator sizes are recommended in Table 2 below for Tender costing:

criterion of NC30 or less should be considered as deserving particular attention and the following

principles are to be applied to the design. Attenuator Length, m and ft Maximum

Acoustic

Noise Specification Airway

Criterion Primary Secondary

All equipment shall be selected with consideration for noise, and octave sound power levels, or Velocity, ms-1

sound pressure levels at a distance, shall be specified and substantiated by reliable test data.

NC25 2.7 m ( 9 ft) 1.2 m (4 ft) 7 m/s (fpm)

Selecting the quietest equipment available will reduce the treatment necessary. All air handling

NC30 2.1 m (7 ft) 1.2 m (4 ft) 9 m/s (fpm)

units shall have a double skin casing, low noise fans, optimized airflow through components,

flexible couplings on cable, ductwork and pipework connections and vibration isolation which may NC35 1.8 m (6 ft) 0.9 m (3 ft) 10 m/s (fpm)

require the main isolation between the casing and plantroom structure.

Table 2: Indicative duct attenuator sizing for sensitive spaces

Duct-borne Fan Noise

Note that when in-duct attenuators incorporate melinex or mylar film the static (with airflow)

Control of duct-borne fan noise to the conditioned spaces will require significant amounts of insertion loss performances are significantly lower than standard attenuators. The above lengths

attenuation, with large cross sectional areas. As a guide, the allowances for duct velocities are are likely to be increased by at least 0.6 m (2 ft) to provide similar performances.

recommended in Table 1 below:

Acoustic Duct Airway Velocity in m/s and fpm

Good aerodynamic arrangements are required at attenuator entries and exits with maximum

Criterion Main Duct Branch Duct Runout Duct separation between the attenuator and adjacent bends, branches etc. In some cases, where

space restrictions limit the length of attenuators that can be fitted, internal duct lining may be

NC25 5.0 m/s (850 fpm) 4.5 m/s (875 fpm) 2.5 m/s (490f pm)

needed on the supply and extract ducts systems to account for the shortfall in attenuator insertion

loss performance.

VIDA HOTEL RETAIL DISTRICT Concept Design Report | May 2017

Volume 6 | S P E C I A L I S T DESIGNS

Where large lined plenums are used, they will be beneficial in providing additional low frequency necessary. Any ductwork routed into the noise sensitive space shall use the branch velocity as a

attenuation of fan noise that will preclude the use of tertiary attenuators. maximum. The greater the quantity of distribution ductwork above a particular area the greater will

be the care and consideration necessary to avoid problems.

The geometry of the ductwork in section and layout can influence the attenuation of fan noise

through the system. Rectangular ductwork can be used to maximize the attenuation of duct-borne To reduce the use of volume control dampers the system shall be designed as much as possible

noise. Square bends provide greater fan noise attenuation than radius bends, but produce greater on a symmetrical basis so that the pressure drop on secondary runs shall be as close as possible

regenerated noise. Therefore, use rectangular bends near fans and radius bends near diffuser to the index run.

and grille outlets.

The avoidance of volume control dampers is preferred but it is accepted that some will be

The low frequency effect from end reflections at duct outlets can be optimized by providing a necessary and these shall be located on the plant side of the system attenuators.

number of smaller outlets rather than one large one.

Control dampers on the terminal side of the final attenuators shall be avoided where spaces require

Duct Breakout Noise NC30 or below.

Where control of break-out noise is required preference shall be given to circular spirally wound, or Control dampers shall not be located within 5 duct dimensions of any element other than a straight

straight seamed, ductwork as they have much better low frequency transmission losses. length of duct. Preference will be given to airfoil splitter dampers.

The routing of ductwork through noise sensitive spaces, and the location on the walls of noise All fire dampers shall be out of the airstream type.

sensitive spaces, shall be minimized. Acoustic lagging treatments may be necessary in ductwork

Noise is generated at supply and extract air grilles or diffusers. Positive action is needed to ensure

entering and leaving plant room structures.

that the generated levels are within the targets set. In the most sensitive situations consideration

Regenerated Noise will be given to developing simple slots and other quiet openings without terminal devices.

Prevention of regenerated noise in ductwork generally depends upon maintaining an

aerodynamically efficient ductwork design and limiting the actual velocity of the air flow. Flow can

Crosstalk Noise

be faster with internally lined ducts, as the lining attenuates regenerated noise.

Where ducted systems supply or exhaust from adjacent rooms, such that there is a short route for

noise through the outlets and ductwork from one room to another, the possibility of cross-talk must

The geometry of branches, tees, transformations etc shall be as good as, or better than, be guarded against. Where separation between rooms is anything other than territorial, with

recommended by good practice and such documents as DW/144 Specification for Sheet Metal minimal sound insulation requirements, attenuation may be needed. Where the rooms have a low

Ductwork. It is essential to minimize turbulence and the separation between different fittings shall services noise criterion, additional noise control may be necessary.

be kept to a minimum of three to four duct dimensions. The maximum velocities to spaces

Services Penetrations of Structure

requiring NC30 and below shall be limited to those specified in Table 1 above.

Ductwork and pipework penetrations of structures must be sealed acoustically with a detail

The duct velocities are intended to represent maximum velocities, not average velocities, and if the

determined by the performance required. To facilitate this, sufficient separation shall be provided

recommendations for geometry and spacing are not followed then substantial reductions are

between services and between services and building surfaces to enable access for effective

VIDA HOTEL RETAIL DISTRICT Concept Design Report | May 2017

Volume 6 | S P E C I A L I S T DESIGNS

sealing, ie typically 25 mm (1”) clearance around the duct or pipe, pack void with mineral wool or acoustically sealed. Conduit and trunking is preferred as they are more effectively sealed than

fire stop and seal with non-hardening sealant, mastic or foam cable trays.

The number of penetrations into sensitive areas shall be minimized. Building Services Vibration

Ducted penetrations of building elements may reduce the sound insulation considerably and Vibration of the building services at audible frequencies shall not cause sound levels which exceed

particular consideration must be given to this for the acoustic envelope of sensitive spaces. a value 5 dB below the NC criteria specified in for each room. Vibration should not be perceptible

(feelable) in occupied spaces. The perceptibility threshold is taken as a surface vertical velocity

Plumbing Services

not greater than 0.1 mms-1rms on the surfaces of occupied areas (excluding plantrooms).

Rainwater pipes shall not pass through noise sensitive spaces, or be fixed to the building fabric of

Vibration due to building services, measured in the floors of plantrooms, shall not exceed a vertical

such spaces. Cast iron rainwater pipework is preferred to reduce the break-out of hydraulic noise.

velocity of 0.3 mms-1rms in any 1/3 octave band in the frequency range 8 to 80 Hz.

Toilets, showers etc must be located as far away as possible from noise sensitive spaces. Services

Vibration due to building services, measured on the floor, shall not exceed the Curves in each

to such areas shall not be routed through noise sensitive spaces, or fixed to the structure of such

horizontal or transverse direction as recommended and defined in BS 6472:1992 Guide to

spaces. Fittings shall be selected for low noise characteristics and to prevent water hammer.

evaluation of human exposure to vibration (1 Hz to 80 Hz), depending on the particular sensitivity of

For other piped services, such as symphonic systems, the general requirements for isolation, the space.

lagging and routing away from noise sensitive spaces shall apply.

Vibration Isolation System Performance

Electrical Services

Spring type anti-vibration mounts for fans and air-handling units shall be selected with a minimum

Lifts should not be located within 10 m (30’) of critical spaces (NC30 and below), or it will require isolation efficiency of 95%.

structural isolation of the lift shaft.

Spring type vibration isolators shall be unhoused and shall preferably be constructed from suitably

Motors, pumps, lift and counterweight guides, etc will need isolation and provision of resilient rollers treated and finished steel or steel alloys. They shall be manufactured with rubber, neoprene or

or sleeves where appropriate. glassfibre "acoustic pads" to prevent transmission of high frequencies. The material of the pad

Lift motor rooms should be constructed of concrete, brick or dense blockwork with specialist shall be selected to suit the location. Holes shall be provided for fixing both to the supported

acoustic doors where necessary. Lift shaft and motor room ventilation may need to be attenuated machine and the supporting structure.

to prevent break-out of noise or transfer of noise within the building. The criteria of spring stability under compression shall be that the ratio "lateral stiffness/vertical

The noise and vibration generated by lifts shall comply with the requirements given in CIBSE Guide stiffness" is at least 1.2 times the ratio "static deflection/working height".

D Transportation systems in buildings (see Appendix C of this report) Duct Hangers

As with other services, routing through sensitive spaces shall be avoided. Avoid penetration of Hangers used for vibration control shall consist of a mild steel welded cage containing a helical

electrical distribution between two adjacent sensitive spaces, the installation of back-to-back outlet spring, or neoprene/rubber/glass fibre isolator, (or both) and be suitable for suspension from drop

boxes, and recessed boxes in the envelope of sensitive spaces. All penetrations of walls must be

VIDA HOTEL RETAIL DISTRICT Concept Design Report | May 2017

Volume 6 | S P E C I A L I S T DESIGNS

rods. Where both types of isolating elements are used together, the spring shall be at the pipe or Prevention of overloading of vibration isolation systems

duct end of the hanger. The spring or active materials shall be used in compression.

Vibration isolation systems whose mountings can be overloaded by excessive deflections, shall be

Steel springs shall be stable at all loadings up to full compression and full compression shall not provided with "bottoming" or similar restraints. The restraints may be part of the mountings,

occur before 150% of the rated maximum loading. No permanent deformation shall be caused by machinery or bases.

full compression. The load shall be transmitted to the spring through a neoprene washer bushed

into the moving end to prevent metal to metal contact.

Neoprene/rubber/glass fibre isolators shall be protected from overloading by metal to metal

restraints or lateral containment. Acoustic Flexible Duct Connectors

The hanger cage shall be capable of carrying five times the maximum rated normal service load Acoustic flexible duct connectors are to be provided at the inlet and discharge of all fans, air

handling units, fan coil units and where indicated on the selection schedules or drawings. Duct

without permanent distortion. The drop rod arrangements shall allow 30 movement without metal

connections are to be formed from resilient sound barrier mat of minimum surface weight of 5 kgm-

to metal contact.

2

with a minimum 25 mm slack across a 100 mm gap to ensure effective isolation, installed to avoid

Asymmetrical loading of anti-vibration mounts

impeding air flow.

The vibration isolation system shall allow the deflection of each mounting to be adjusted to the

Electrical Connections

design value at the operating condition of the supported equipment.

Electrical connections between equipment mounted on vibration isolation bases and equipment

The maximum difference between resonant frequencies of any two mountings of a set when the

fixed to structures shall be made through flexible conduit which changes direction by at least 90

supported equipment is operating shall not differ by more than 15%.

in a minimum length of 25 conduit diameters.

Static and dynamic forces due to fluid pressure at flexible connections to fans

Mineral insulated cables shall be taken through at least 360 at 75 mm radius or double the

Vibration isolation systems for fans shall allow for forces and movement due to pressure differences permissible minimum radius, whichever is the larger.

at flexible connections. Mountings shall be laid out and sized for their loadings at all operating

Air Gap Resonance

speeds. "Inertia" blocks and counterweights may be used to reduce the percentage variations in

mounting loads at varying speeds to the amount specified. The width of air gap between undersides of solid machine bases (supported on vibration isolation

mountings) and the floor shall be selected to avoid resonance of the air gap at the major vibrational

Where services are joined to equipment with flexible connectors, the first three service supports

or acoustic frequencies generated by the supported plant. Similarly, the distance between the

next to the equipment shall include vibration isolators giving 90% efficiency at the fundamental

panels of air-handling units and floors, walls, or soffits shall be chosen to avoid resonance of the

forcing frequency of the equipment. The supports shall be designed to prevent movement of the

panel and air gap at the fan or motor rotational and fan blade passing frequen

connected duct due to static or dynamic forces due to the fluid weight or velocity.

Isolated sway braces, buffers and similar devices may be used to prevent movement in directions

perpendicular to the vibration.

VIDA HOTEL RETAIL DISTRICT Concept Design Report | May 2017

Volume 6 | S P E C I A L I S T DESIGNS

2 * 12.5 mm Gypsum

plasterboards on either side +

Appendix B: Construction Elements 200 mm thick solid block wall

125mm stud (100mm 48 kg/m3

(>1400kg/m3) with 12mm plastering on

Fiberglass wool insulation +

R,w Masonry wall Drywall Partition either side200 mm thick solid block wall 25mm air gap)

(>1400kg/m3) with 12mm plastering on

300mm thick Solid block wall Staggered double stud wall either side

(>1500kg/m3) with 15mm plastering on

– 12mm fibre cement board

either side

+ 12.5mm thick

gypsum

plasterboard on

55

either side

+ 2 X 70mm studs

60

[50mm

48kg/m³ fibreglass

wool

insulation on either

side

+ 40mm air gap in

the

centre]

VIDA HOTEL RETAIL DISTRICT Concept Design Report | May 2017

Volume 6 | S P E C I A L I S T DESIGNS

150mm thick solid block wall(>1520kg/m3) with 1*12.5mm Gypsum + 1*10mm 100mm thick solid block wall (1800 kg/m3) + 2*12.5mm Gypsum Plasterboards

12mm plastering on either side Fibre cement board on either side 12mm plastering on either sid board on either

+ 100mm stud (2*50mm 48

side + 50mm stud (50mm 48

kg/m3 Fiberglass

kg/m3

wool insulation)

Fiberglass wool

insulation)

50 45

VIDA HOTEL RETAIL DISTRICT Concept Design Report | May 2017

Volume 6 | S P E C I A L I S T DESIGNS

IMPACT SOUND

Appendix C: Acoustic Glossary

Sound produced by a vibrating material or panel due to direct impact. The vibrating material or panel causes the air molecules to

vibrate which leads to an airborne sound wave being created. For example, footsteps on a floor can be classified as ‘impact’

sound.

AIRBORNE SOUND

IMPACT SOUND INSULATION

Sound in the air is generated by a material vibrating which in turn causes air molecules to vibrate and create a sound wave. For

example, sound produced by a loudspeaker in a room can be classified as ‘airborne’ sound. Impact sound insulation is the ability of a material to dampen sound. This is commonly determined by measuring the sound

pressure level (in dB) on the receiver side of the material being excited by a sound source on the source side. Impact sound

AIRBORNE SOUND INSULATION

insulation can be measured using the procedures set out in BS EN ISO 140-5 and BS EN ISO 140-7.

Airborne sound insulation is the ability of a material or room to contain sound within it, or exclude sound from it. This is commonly

measured in terms of sound reduction index (in dB) being the ratio of sound transmitted by the material to that incident upon it.

Airborne sound insulation can be measured using the procedures set out in BS EN ISO 140-3 and BS EN ISO 140-4. NOISE RATING CURVES (NC)

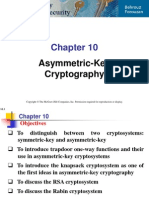

AMBIENT AND BACKGROUND NOISE LEVEL, LA90,T A method of expressing noise in a more meaningful way that the standard values in the form of curves as shown below.

The A-weighted sound pressure level of non-specific noise in decibels exceeded for 90% of the given time, T.

Noise Rating Curves

A - WEIGHTING dB(A)

100.0 100

80 100

The sound pressure level determined when using the frequency-weighting network A. The A-weighting network modifies the 90 100

electrical response of a sound level meter so that the sensitivity of the meter varies with frequency in approximately the same way 70

80

90

90.0 90

that the sensitivity of the human hearing system varies with frequency. 80

90

90

60 70 80

The human ear has a non-linear frequency response; it is less sensitive at low and high frequencies and most sensitive in the range 80.0 80

1 to 4 kHz. The A-weighting is applied to measured or calculated sound pressure levels so that these levels correspond more 70 80

80

50 60

closely to the response of the human ear. A-weighted sound levels are often denoted as dB(A). 70

70.0 70

60 70

40

50 70

60

SPL (dB)

60.0 60

30 50

40 60

60

DECIBEL 50

20

50.0 40 50

30

The ratio of sound pressures which we can hear is a ratio of 10 6:1 (one million: one). For convenience, therefore, a logarithmic 50

50

measurement scale is used. The resulting parameter is called the ‘sound pressure level’ (Lp) and the associated measurement unit 10 40

40.0 20 30 40

is the decibel (dB). As the decibel is 10times the logarithmic ratio, the laws of logarithmic addition and subtraction apply. 40

40

30

EQUIVALENT CONTINUOUS A-WEIGHTED SOUND PRESSURE LEVEL (LAeq) 10 20

30.0 30

30

Value of the A-weighted sound pressure level of a continuous, steady sound that, within a specified time interval T starting at t1 and 30

20

ending at t2 and measured in decibels, has the same mean square sound pressure as the sound under consideration whose level 20.0

10

20

63.0 125.0 250.0 500.0 1 k 2 k 4 k

varies with time.

Fr e que ncy (Hz)

FREQUENCY

The curves represent the human’s perception of noise. Less annoyance is caused by low frequency noise than by higher frequency

The rate of repetition of a sound wave. The subjective equivalent in music is pitch. The unit of frequency is the Hertz (Hz), which is

noise at the same sound pressure level. Hence higher levels may be tolerated for low frequency noise. Noise spectra, measured or

identical to cycles per second. A thousand hertz is often denoted kHz, eg 2 kHz = 2000 Hz. Human hearing generally ranges

specified, are often quoted as a NC value for ease of reference.

approximately from 20 Hz to 20 kHz.

VIDA HOTEL RETAIL DISTRICT Concept Design Report | May 2017

Volume 6 | S P E C I A L I S T DESIGNS

OCTAVE BANDS AND OCTAVE BAND SOUND PRESSURE LEVEL Sound absorption can be measured using the procedures set out in BS EN 20354. Single figure descriptors include the practical

sound absorption coefficient (αp) and weighted sound absorption coefficient (αw) as defined in BS EN ISO 11654. Other commonly

The octave-band pressure level of a sound is the band pressure level for a frequency band corresponding to a specified octave.

used terms (in the USA) are NCC (Noise Reduction Coefficient) which is the arithmetic average of α at 250 Hz, 500 Hz, 1 kHz and

(The location of the octave-band pressure level on a frequency scale is usually denoted by the geometric mean of the upper and

2 kHz rounded to the nearest 5%.

lower frequencies of the octave.) The ISO standard octave centre frequencies are 31.5, 63, 125, 250, 500, 1k, 2k, 4k, 8k, 16k Hz

(etc.). For design purposes, the octave bands between 63 Hz to 8 kHz are generally used. SOUND POWER LEVEL (Lw)

PERCENTILE LEVEL (STATISTICAL SOUND LEVEL INDICES, LAN, LA90) The sound power level of a sound source, in decibels, is 10 times the logarithm to the base 10 of the ratio of sound power radiated

by the source to a reference power. The reference power is 1 picowatt (1 x 10 -12 watt).

LAN is the dB(A) level exceeded N% of the time measured on a sound level meter with Fast(F) time weighting, eg L A90 the dB(A) level

exceeded for 90% of the time, is commonly used to estimate background noise level. L A10, the dB(A) level exceeded for 10% of the The sound power level is the fundamental measure of the total sound energy radiated by a source per unit time.

time, is commonly used in the assessment of road traffic noise.

SOUND LEVEL DIFFERENCE (D)

REVERBERATION AND REVERBERATION TIME (RT60)

The sound insulation required between two spaces may be determined by the sound level difference (D) needed between them.

The time, in seconds, taken for a sound within a space to decay by 60 dB after the sound source has stopped. An important Single figure descriptors include the weighted sound level difference (Dw) and the normalized weighted sound level difference (DnTw)

indicator of the subjective acoustic within an auditorium. The symbol Tmf to represent the mid-frequency arithmetic average of the as defined in BS EN ISO 717-1.

reverberation time in the 500 Hz, 1 kHz and 2 kHz octave bands. Reverberation time can be measured using the procedures set

SOUND PRESSURE LEVEL (SPL)

out in BS EN ISO 3382. The symbols T20 and T30 are the reverberation times extrapolated from a 20 and 30 dB dynamic range,

starting at the -5 dB point, in order not to introduce errors due to irregularities in the early reflections The level of the pressure of the sound above the internationally accepted reference value of 20 μPa (2x10-5 N/m2), which corresponds

to the pressure of the quietest sound an average person can hear at the frequency of 1000 Hz. It is a quantity that can be measured,

SIGNAL-TO-NOISE RATIO (S/N)

thus the quantity of a sound can be derived from it.

This is the difference between the source noise level and the background (or ambient) noise level. The higher the difference, the

A value equal to 10 times the logarithm to the base 10 of the ratio of the root-mean-square pressure of a sound to a reference

better the speech intelligibility of the PA/VA system. For PA/VA system announcements, it is preferable to have an S/N ration of at

pressure, which is normally taken to be 2x10-5 N/m2.

least 15 dB(A) and preferably 25 dB(A) for the hearing impaired.

SOUND REDUCTION INDEX (R)

SOUND ABSORPTION AND SOUND ABSORPTION COEFFICIENT

The sound reduction index, R, (or transmission loss) of a building element is a measure of the loss of sound through the material,

When sound waves strike a material, some of the sound energy is absorbed and the remaining energy is reflected. The ability of a

ie its attenuation properties.

material to absorb sound is expressed in terms of sound absorption coefficient. The sound absorption coefficient (α) is the

percentage of sound absorbed by the material. If a material has α = 0.8 at 500 Hz it means that 80% of the sound is absorbed at

this frequency.

It is a property of the component, unlike the sound level difference which is affected by the common area between the rooms and VIBRATION DOSE VALUE (VDV)

the acoustic of the receiving room. The weighted sound reduction index, R w, is a single figure description of sound reduction index

A measure of the amount of vibration as experienced by a person. It is a dosage based on both the total exposure time and the

which is defined in BS EN ISO 717-1. The Rw is calculated from measurements in an acoustic laboratory. Sound insulation ratings

vibration acceleration level experienced. Only vibrations in the range of 1 Hz to 80 Hz are considered and these are weighted in

derived from site (which are invariably lower than the laboratory figures) are referred to as the R’ w ratings.

accordance with BS 6472.

SPEECH TRANSMISSION INDEX (STI)

WEIGHTED SOUND REDUCTION INDEX (Rw)

A physical quantity representing the transmission quality of speech with respect to intelligibility, ie the ability to understand the

The weighted sound reduction index, Rw, is a single figure description of sound reduction index which is defined in BS EN ISO 717-

spoken word.

1: 1997. The Rw is calculated from measurements in an acoustic laboratory to BS EN ISO 140-3 and rated to BS EN ISO 717-1.

VIBRATION LEVEL Sound insulation ratings derived from site (which are invariably lower than the laboratory figures) are referred to as the R’ w ratings

and measured to BS EN ISO 140-4.

Vibration is generally measured in terms of the velocity (in mm/s or m/s) or the acceleration (in mm/s 2 or m/s2) but can also be

measured in terms of amplitude (in mm or m). These values are often converted into dB values on a logarithmic scale.

VIDA HOTEL RETAIL DISTRICT Concept Design Report | May 2017

Volume 6 | S P E C I A L I S T DESIGNS

End of Report

VIDA HOTEL RETAIL DISTRICT Concept Design Report | May 2017

You might also like

- Noise and Vibration Control For Hvac Piping and EquipmentDocument15 pagesNoise and Vibration Control For Hvac Piping and EquipmentarjantinNo ratings yet

- Passive Noise Control in BuildingsDocument12 pagesPassive Noise Control in BuildingsANJUSREE B.S. MBT18CE025No ratings yet

- Introduction To Mechanical VibrationsDocument38 pagesIntroduction To Mechanical VibrationsrajeshNo ratings yet

- Entran: Noise AssessmentDocument28 pagesEntran: Noise AssessmentNaken FittaNo ratings yet

- Noise and Vibrations in HVAC SystemsDocument56 pagesNoise and Vibrations in HVAC SystemsBalasubramani vNo ratings yet

- Sheet Steel Facts 16Document4 pagesSheet Steel Facts 16Giordano VieiraNo ratings yet

- Request 15 NoiseDocument28 pagesRequest 15 NoiseHannibal1969No ratings yet

- C008 - Quiet Revolution Noise Statement 20100803v1Document15 pagesC008 - Quiet Revolution Noise Statement 20100803v1Roland PetersNo ratings yet

- Tetra Tech Sound Vibration Analysis 201704Document86 pagesTetra Tech Sound Vibration Analysis 201704OpgcNo ratings yet

- Acoustic GuideDocument17 pagesAcoustic GuideMohamad ShabeerNo ratings yet

- Genset Noise Outdoor Environment Sound SilencerDocument18 pagesGenset Noise Outdoor Environment Sound SilencerTrần Quang ToánNo ratings yet

- Transformers Are Never SilentDocument4 pagesTransformers Are Never SilentEngr. AbdullahNo ratings yet

- HVAC SYSTEM DESIGNDocument19 pagesHVAC SYSTEM DESIGNmostafa HusseinNo ratings yet

- Kenneth Kaliski Slides 6.7.11Document21 pagesKenneth Kaliski Slides 6.7.11Northeast Wind Resource Center (NWRC)No ratings yet

- AcousticInsulation enDocument97 pagesAcousticInsulation enBernardo ArevalilloNo ratings yet

- 1 ISTIQ Acoustic DoorDocument6 pages1 ISTIQ Acoustic DoorjaladimudaNo ratings yet

- ISVR Offical Report On CalmerDocument39 pagesISVR Offical Report On CalmerJorge Apodaca AisaNo ratings yet

- Acoustics Course NotesDocument162 pagesAcoustics Course NotesBelaliaNo ratings yet

- White Book C04 Partitions Section 3Document180 pagesWhite Book C04 Partitions Section 3Chris FindlayNo ratings yet

- HSE-Acoustic & Fire DoorsDocument6 pagesHSE-Acoustic & Fire DoorsInterior ProjectsNo ratings yet

- Silencer PRINTDocument2 pagesSilencer PRINTChandima WijesekeraNo ratings yet

- Interior Architecture Building Science 142 ASCIE 1202: Room AcousticsDocument18 pagesInterior Architecture Building Science 142 ASCIE 1202: Room AcousticsMuhamad Helmi Hairi ZulkifliNo ratings yet

- Chapter12 Noise Vibration PDFDocument16 pagesChapter12 Noise Vibration PDFFrank Rubio CNo ratings yet

- Ger 4248 Acoustic Terms Definitions General InformationDocument14 pagesGer 4248 Acoustic Terms Definitions General InformationsipurmanNo ratings yet

- Engineering Controls Reduce Hydro Powerplant NoiseDocument33 pagesEngineering Controls Reduce Hydro Powerplant Noisepradip panthaNo ratings yet

- Design of An Acoustic Anechoic Chamber For Application in Hearing Aid REsearchDocument6 pagesDesign of An Acoustic Anechoic Chamber For Application in Hearing Aid REsearchJude SudarioNo ratings yet

- Chapter 4.5 Noise and Vibration PDFDocument31 pagesChapter 4.5 Noise and Vibration PDFMinho OnionsNo ratings yet

- Acoustical Considerations For Hotels and Hostels As Per NBCDocument10 pagesAcoustical Considerations For Hotels and Hostels As Per NBCashNo ratings yet

- Discussion 13 - Acoustical ControlDocument25 pagesDiscussion 13 - Acoustical ControlDough NutNo ratings yet

- Architectural Acoustics SolutionsDocument56 pagesArchitectural Acoustics Solutionsshyma_97No ratings yet

- Control of Reverberation Times in Dome1Document4 pagesControl of Reverberation Times in Dome1haiobNo ratings yet

- Crosstalk Attenuators Reduce Duct Noise TransmissionDocument2 pagesCrosstalk Attenuators Reduce Duct Noise TransmissionabdulzameerNo ratings yet

- Acoutics Applications Related To Wind Turbines WebinarDocument29 pagesAcoutics Applications Related To Wind Turbines WebinarBelaliaNo ratings yet

- Building Services IV Module 05Document26 pagesBuilding Services IV Module 05hardik MajethiyaNo ratings yet

- AEI Wind Farm Noise 2012: Science and Policy OverviewDocument122 pagesAEI Wind Farm Noise 2012: Science and Policy OverviewJim CummingsNo ratings yet

- ATSL Brochure (201310)Document30 pagesATSL Brochure (201310)dgtdejanNo ratings yet

- Acoustics GuidelinesDocument20 pagesAcoustics Guidelinesrommel duran100% (1)

- Effectiveness of en 12354-6Document6 pagesEffectiveness of en 12354-6Neeskens D'melloNo ratings yet

- Reverberation Time FormularDocument33 pagesReverberation Time FormularAzril Azalan100% (1)

- Method Statement - Sound Test (Recovered)Document6 pagesMethod Statement - Sound Test (Recovered)Oliver OroscoNo ratings yet

- Engineering Acoustics Lecture 11Document27 pagesEngineering Acoustics Lecture 11Isuru Kasthurirathne100% (1)

- Sysnoise PDFDocument74 pagesSysnoise PDFOm Parkash SharmaNo ratings yet

- NRCC 46274Document9 pagesNRCC 46274fredormNo ratings yet

- Updated Silencers Bro PDFDocument20 pagesUpdated Silencers Bro PDFdimchienNo ratings yet

- Screed Material: European Standard EN 13813: 2002 Has The Status of A DIN StandardDocument33 pagesScreed Material: European Standard EN 13813: 2002 Has The Status of A DIN StandardDumitruNo ratings yet

- Classroom Acoustics Report Printed VersionDocument44 pagesClassroom Acoustics Report Printed Versionnr2006No ratings yet

- NTi Audio AppNote Sound Insulation Measurement With XL2Document31 pagesNTi Audio AppNote Sound Insulation Measurement With XL2Nguyen Thanh Binh100% (1)

- Introduction To Acoustics by B&K PDFDocument44 pagesIntroduction To Acoustics by B&K PDFSuhas BharadwajNo ratings yet

- Objective.: Audio EqualizersDocument6 pagesObjective.: Audio EqualizersFernando Aarón Ortiz RicárdezNo ratings yet

- Academic Mediacal Center DSO Dubai DD AR R 0003 GEN R02 Acoustic ReportDocument23 pagesAcademic Mediacal Center DSO Dubai DD AR R 0003 GEN R02 Acoustic ReportNeeskens D'melloNo ratings yet

- Architectural AcousticsDocument8 pagesArchitectural AcousticsNupur BhadraNo ratings yet

- Soundproofing Solutions-En 2019 02 PDFDocument182 pagesSoundproofing Solutions-En 2019 02 PDFTanase MariusNo ratings yet

- Acoustics PPTDocument22 pagesAcoustics PPTankiw89100% (1)

- Cooling Tower Noise Control Silencers Reduce SoundDocument37 pagesCooling Tower Noise Control Silencers Reduce SoundUllas EK100% (1)

- Acoustic Simulation with Actran: Acoustic Field Maps and Transmission LossDocument45 pagesAcoustic Simulation with Actran: Acoustic Field Maps and Transmission Lossvivashwanth paiNo ratings yet

- ISO 3382 2 2008 en PreviewDocument7 pagesISO 3382 2 2008 en PreviewHoang TraNo ratings yet

- Studio PhaseDocument74 pagesStudio PhaseLeonel Molina AlvaradoNo ratings yet

- Caice Acoustic Design GuideDocument12 pagesCaice Acoustic Design GuideBuddhikaNo ratings yet

- FunctionsDocument38 pagesFunctionsZanyar S. MuhamadNo ratings yet

- DeltaLight Hospitality - enDocument52 pagesDeltaLight Hospitality - enMarko TodorovNo ratings yet

- Acoustic Report - Stage 4Document117 pagesAcoustic Report - Stage 4Neeskens D'melloNo ratings yet

- Design Report Acoustics and Vibration - 24223 OME RP T0 YA XXX 0 YA0001Document70 pagesDesign Report Acoustics and Vibration - 24223 OME RP T0 YA XXX 0 YA0001Neeskens D'melloNo ratings yet

- Reverberation Time - The Mother of All Room Acoustical ParametersDocument6 pagesReverberation Time - The Mother of All Room Acoustical ParametersNeeskens D'melloNo ratings yet

- AcousticClassificationHousing ISOCD19488 VDI4100 DEGA103Document4 pagesAcousticClassificationHousing ISOCD19488 VDI4100 DEGA103Neeskens D'melloNo ratings yet

- Section 089000 - Louvers and VentsDocument17 pagesSection 089000 - Louvers and VentsNeeskens D'melloNo ratings yet

- ANC Comments On Proposed BS 8233Document21 pagesANC Comments On Proposed BS 8233Neeskens D'melloNo ratings yet

- Effectiveness of en 12354-6Document6 pagesEffectiveness of en 12354-6Neeskens D'melloNo ratings yet

- International Proposal For An Acoustic Classification Scheme For DwellingsDocument8 pagesInternational Proposal For An Acoustic Classification Scheme For DwellingsNeeskens D'melloNo ratings yet

- Technical Specification Crafft Bookshelf SpeakerDocument1 pageTechnical Specification Crafft Bookshelf SpeakerNeeskens D'melloNo ratings yet

- 5.1 Background Noise Criteria: EchanicalDocument11 pages5.1 Background Noise Criteria: EchanicalNeeskens D'melloNo ratings yet

- ACI 2014 Webinar Guide To Formed Concrete Surfaces SPDocument330 pagesACI 2014 Webinar Guide To Formed Concrete Surfaces SPJohn PaulsyNo ratings yet

- Circular (198) 2014 Implementation of GBRSDocument4 pagesCircular (198) 2014 Implementation of GBRSNeeskens D'melloNo ratings yet

- Academic Mediacal Center DSO Dubai DD AR R 0003 GEN R02 Acoustic ReportDocument23 pagesAcademic Mediacal Center DSO Dubai DD AR R 0003 GEN R02 Acoustic ReportNeeskens D'melloNo ratings yet

- Safat Book English Spread PDFDocument49 pagesSafat Book English Spread PDFMadan Kumar100% (2)

- Dubai Municipality Regulations For Green BuildingsDocument77 pagesDubai Municipality Regulations For Green Buildingsfaith-7100% (4)

- EMEC Important QuestionsDocument3 pagesEMEC Important QuestionsHarish KumarNo ratings yet

- Using TI Technology To Simplify Bluetooth® Pairing Via NFCDocument25 pagesUsing TI Technology To Simplify Bluetooth® Pairing Via NFCTi MicrocontrollersNo ratings yet

- Understanding Big O Notation and Time Complexity AnalysisDocument28 pagesUnderstanding Big O Notation and Time Complexity AnalysisSally JarkasNo ratings yet

- Bollhoff Quicksert Expansion InsertsDocument4 pagesBollhoff Quicksert Expansion InsertsAce Industrial SuppliesNo ratings yet

- Kinetic Modeling of The Hydrolysis of Acetic Anhydride at Higher Temperatures Using Adiabatic Batch Reactor (Thermos-Flask)Document8 pagesKinetic Modeling of The Hydrolysis of Acetic Anhydride at Higher Temperatures Using Adiabatic Batch Reactor (Thermos-Flask)Angie FiorellaNo ratings yet

- RC Datasheet ISCOM2600G 20160128 PDFDocument5 pagesRC Datasheet ISCOM2600G 20160128 PDFJhovanny PasaranNo ratings yet

- QDocument27 pagesQHassanAhmedNo ratings yet

- Rediant-Supplier Audit Check Sheet RevisedDocument8 pagesRediant-Supplier Audit Check Sheet RevisedRohit TripathiNo ratings yet

- Stoichiometry and Chemical Equations (LE2 Reviewer)Document2 pagesStoichiometry and Chemical Equations (LE2 Reviewer)Tidal SurgesNo ratings yet

- Deep-Learning Based SAR Ship Detection With Generative Data AugmentationDocument9 pagesDeep-Learning Based SAR Ship Detection With Generative Data AugmentationRana UsmanNo ratings yet

- Electrolux Dish Washer Service ManualDocument117 pagesElectrolux Dish Washer Service ManualJun Aballe100% (6)

- Load Classification of CranesDocument4 pagesLoad Classification of CranesNarayan Prasad100% (3)

- S&CDocument39 pagesS&CRey GussyNo ratings yet

- 3.2.A UnitConversionDocument6 pages3.2.A UnitConversionevan martinezNo ratings yet

- A400MDocument29 pagesA400MHikari Nazuha100% (1)

- DVG CatalogDocument7 pagesDVG CatalogDinesh ChouguleNo ratings yet

- Job Procedure For Procedure NoDocument7 pagesJob Procedure For Procedure NoUmesh SharmaNo ratings yet

- Electrical Safety 3 Steps To Test Your RCCB PosterDocument1 pageElectrical Safety 3 Steps To Test Your RCCB PosterGoogool YNo ratings yet

- Delivery BedDocument137 pagesDelivery BedAdil LatifNo ratings yet

- Pressure Vessels 1 PDFDocument24 pagesPressure Vessels 1 PDFDasari VenkateshNo ratings yet

- Engineering Rock Mass Classific - Bhawani SinghDocument46 pagesEngineering Rock Mass Classific - Bhawani Singhtita zhafira100% (1)

- OLED65B6PUDocument95 pagesOLED65B6PUyakaka33No ratings yet

- Evc20 Manual en R20160905Document10 pagesEvc20 Manual en R20160905Khiareddine KadhemNo ratings yet