Professional Documents

Culture Documents

CT Hydraulic Calculations

Uploaded by

jose perozo0 ratings0% found this document useful (0 votes)

17 views1 pageThis document contains calculations for frictional pressure losses in coil tubing for a power-law fluid. It provides fluid properties, geometry of the coil tubing system, flow data, and calculations for the straight and curved tubing sections. The total string pressure loss is calculated to be 1304.8 psi. Rheological data for some typical fluids is also presented.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document contains calculations for frictional pressure losses in coil tubing for a power-law fluid. It provides fluid properties, geometry of the coil tubing system, flow data, and calculations for the straight and curved tubing sections. The total string pressure loss is calculated to be 1304.8 psi. Rheological data for some typical fluids is also presented.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views1 pageCT Hydraulic Calculations

Uploaded by

jose perozoThis document contains calculations for frictional pressure losses in coil tubing for a power-law fluid. It provides fluid properties, geometry of the coil tubing system, flow data, and calculations for the straight and curved tubing sections. The total string pressure loss is calculated to be 1304.8 psi. Rheological data for some typical fluids is also presented.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 1

552169474.

xls

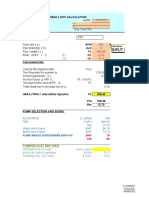

FRICTIONAL PRESSURE LOSSES FOR POWER-LAW FLUIDS IN COIL TUBING

Fluid Properties Geometry

Density = 8.6 lb/gal Reel Diameter = 100 in

n = 0.669 CT OD = 1.750 in

K = ### lbf sec^n/100ft^ CT Wall = 0.134 in

String Length = 10000 ft

Flow Data Tubing off Reel = 3987 ft

Flow Rate = 50 gpm

Tubing on Reel = 6013 ft

Velocity = 558.06 ft/min

Reynolds Number, Re = 9102 Tubing ID = 1.482 in

a = ### Flow Area = 1.725 in^2

b = ###

Straight Tubing Calculations Curved Tubing Calculations

Max Re for Laminar = 2553 Max Re for Laminar = 4459

Min Re for Turbulent = 3353 Min Re for Turbulent = 5259

Flow Regime, Straight = Turbulent Flow Regime, Curved = Turbulent

fHS = ### fHC = 0.00709

Straight Pressure Loss = 475.0 psi Curved Pressure Loss = 829.7 psi

otal String Pressure Loss = 1304.8 psi fHC/fHS = 1.158

Rheological data for Fluid MW (ppg) n K

some typical fluids water - fresh 8.4 1.000 0.0021

water - salt 8.5 1.000 0.0020

Cell Border Color Code water/gel 8.6 0.669 0.1942

GREEN = User Input water/gel 8.7 0.605 1.0673

BLUE = Calculated Value water/gel 8.8 0.507 4.5712

10/25/2021

You might also like

- All System Pump Head LoosDocument33 pagesAll System Pump Head LoosEngFaisal Alrai100% (1)

- Handbook of Heating, Ventilating and Air ConditioningFrom EverandHandbook of Heating, Ventilating and Air ConditioningRating: 4 out of 5 stars4/5 (6)

- Stuck Point WorksheetDocument5 pagesStuck Point Worksheetjose perozoNo ratings yet

- ESP DesignDocument28 pagesESP DesignShahin KhanNo ratings yet

- Volume and StrokeDocument39 pagesVolume and StrokeHarpreetSinghNo ratings yet

- Perhitungan Kekuatan PipelineDocument9 pagesPerhitungan Kekuatan PipelineRAHMAN HakimNo ratings yet

- HydraulicDocument10 pagesHydraulicsushil deshmukhNo ratings yet

- Steel Column FOR SCRIBDDocument8 pagesSteel Column FOR SCRIBDdarshika.jaganiNo ratings yet

- Pressure Drop Calc. v.1Document34 pagesPressure Drop Calc. v.1bermana2010No ratings yet

- Water Resources & Environmental Depth Exam SolutionsDocument22 pagesWater Resources & Environmental Depth Exam SolutionsibrahimsalahNo ratings yet

- Barrel Type O.T1Document23 pagesBarrel Type O.T1gurumurthy38No ratings yet

- Venturi Scrubber DesignDocument2 pagesVenturi Scrubber DesignSung Woong Moon67% (3)

- Horizontal KO PotDocument4 pagesHorizontal KO Pothk168No ratings yet

- Tech Manual 1222B: Booster Cylinder Assembly EH34-BC03Document21 pagesTech Manual 1222B: Booster Cylinder Assembly EH34-BC03jose perozoNo ratings yet

- Hole Volume CalculationsDocument6 pagesHole Volume CalculationsaNo ratings yet

- Line Sizing Calculation 1Document9 pagesLine Sizing Calculation 1SAMUEL UDOHNo ratings yet

- PETE 661: Drilling EngineeringDocument50 pagesPETE 661: Drilling Engineeringcmrig74No ratings yet

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 3From EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 3Rating: 3 out of 5 stars3/5 (2)

- Mud CalcDocument7 pagesMud CalcmehrdadNo ratings yet

- 05 - SRB Hydraulic ProgramsDocument22 pages05 - SRB Hydraulic ProgramsnelsonhugoNo ratings yet

- Products CodesDocument23 pagesProducts Codesjose perozoNo ratings yet

- Texas Oil Tools: "EH34" 3.06" 10M Quad BOPDocument32 pagesTexas Oil Tools: "EH34" 3.06" 10M Quad BOPjose perozo100% (2)

- Head Loss Calculation - Fire Hydrant Sys..Temporary ReiserDocument15 pagesHead Loss Calculation - Fire Hydrant Sys..Temporary ReiserEngFaisal AlraiNo ratings yet

- Expansion Loop Design SheetDocument6 pagesExpansion Loop Design SheetSaqib LaeeqNo ratings yet

- Rect. Tanks SampleDocument31 pagesRect. Tanks Samplenamasral100% (9)

- CalculationDocument13 pagesCalculationajit kumarNo ratings yet

- CO2 Condenser 02-03-2023-15 PMDocument37 pagesCO2 Condenser 02-03-2023-15 PMahmad santosoNo ratings yet

- L.3.1. EVAPORATOR - 01 (EV-01) : 1 o o o oDocument9 pagesL.3.1. EVAPORATOR - 01 (EV-01) : 1 o o o omedias indah monica sariNo ratings yet

- CT Hydraulic CalculationsDocument1 pageCT Hydraulic CalculationsRamanamurthy PalliNo ratings yet

- Horizontal KO Pot V1.2Document6 pagesHorizontal KO Pot V1.2hk168No ratings yet

- hk25 35watercassetteDocument1 pagehk25 35watercassetteMuhamad SanusiNo ratings yet

- Abut (LRFD) On Spread FTG Bellissima BridgeDocument16 pagesAbut (LRFD) On Spread FTG Bellissima BridgeAnthony GravagneNo ratings yet

- PKG 6 Hydrology BinderDocument12 pagesPKG 6 Hydrology BinderFooti-Kothi ProjectNo ratings yet

- Chasma Barrage Complete DseignDocument35 pagesChasma Barrage Complete Dseignsyed muneeb haiderNo ratings yet

- 3558783Document44 pages3558783สิทธิไชย อรุณวํฒนชัยNo ratings yet

- 07 - Nowsco Calculation SheetsDocument21 pages07 - Nowsco Calculation SheetsJunaid MateenNo ratings yet

- Wellbore Hydraulics, Pressure Drop Calculations - Asi o Mas ExplicadoDocument28 pagesWellbore Hydraulics, Pressure Drop Calculations - Asi o Mas ExplicadoroedusanNo ratings yet

- PipeanalysisDocument5 pagesPipeanalysisYANIshaNo ratings yet

- Power Law Pressure LosesesDocument2 pagesPower Law Pressure LosesesMohamad TayeaNo ratings yet

- Projet Name Water Supply Pipe LineDocument3 pagesProjet Name Water Supply Pipe LinesheshuNo ratings yet

- Power Law Pressure LosesesDocument2 pagesPower Law Pressure LosesesMohamad TayeaNo ratings yet

- Power Law Pressure LosesesDocument2 pagesPower Law Pressure LosesesMohamad TayeaNo ratings yet

- Welding ProblemsDocument11 pagesWelding ProblemsJohn BarrogaNo ratings yet

- International Well Control Forum Surface BOP Kill Sheet-Deviated Well (API Field Units)Document3 pagesInternational Well Control Forum Surface BOP Kill Sheet-Deviated Well (API Field Units)Quo EtaNo ratings yet

- Vvsizing: Prepared By: Muhamad NizarDocument4 pagesVvsizing: Prepared By: Muhamad Nizarnizar ahmadNo ratings yet

- Two Phase Flow HorizontalDocument7 pagesTwo Phase Flow HorizontalAkshay bhuranNo ratings yet

- Cnvertion FactorsDocument1 pageCnvertion FactorsOmed. HNo ratings yet

- Orifice SizingDocument2 pagesOrifice SizingXheikhKaleemNo ratings yet

- Structural Requirements For The In-Service Inspection of Eroded/Corroded PipingDocument4 pagesStructural Requirements For The In-Service Inspection of Eroded/Corroded PipingSundersingh RubanNo ratings yet

- A9 Pumplift SolutionsDocument11 pagesA9 Pumplift SolutionsVatsal ShahNo ratings yet

- M=350.17 (γ Wor Γ Gor Ρ γ: 6,000 bbl/dDocument23 pagesM=350.17 (γ Wor Γ Gor Ρ γ: 6,000 bbl/dHoa NguyenNo ratings yet

- Steel Design StudyDocument52 pagesSteel Design StudyEJ Dela CruzNo ratings yet

- SafeDocument3 pagesSafeMadhubalan AlagarNo ratings yet

- Manufacture of EthanolDocument46 pagesManufacture of EthanolRam DevNo ratings yet

- Datasheet UHD Umbilical 39-5mm - A307667Document2 pagesDatasheet UHD Umbilical 39-5mm - A307667Tenner CorrêaNo ratings yet

- Plate Heat Exchanger Customer Data Sheet: Duty 1 Process Data Hot ColdDocument1 pagePlate Heat Exchanger Customer Data Sheet: Duty 1 Process Data Hot ColdzhyhhNo ratings yet

- Plate Heat Exchanger Customer Data Sheet: Duty 1 Process Data Hot ColdDocument1 pagePlate Heat Exchanger Customer Data Sheet: Duty 1 Process Data Hot ColdzhyhhNo ratings yet

- Pr-2 Teknik Produksi I: Catur Kristiawan 124.16.021Document8 pagesPr-2 Teknik Produksi I: Catur Kristiawan 124.16.021Reynold AvgNo ratings yet

- Project Client Calc. Title Ref. Stress Calc NoDocument14 pagesProject Client Calc. Title Ref. Stress Calc NoSubhadip SadhukhanNo ratings yet

- Ykfrfrq7 CRGDocument4 pagesYkfrfrq7 CRGMisael RodríguezNo ratings yet

- NdrcrossRD29RPcrossaug7 eDocument110 pagesNdrcrossRD29RPcrossaug7 epmu hmhNo ratings yet

- Feasibility Study Pengebangan Stasiun LCNG Untuk Kendaraan Bermotor Di Jawa Barat ProcessDocument7 pagesFeasibility Study Pengebangan Stasiun LCNG Untuk Kendaraan Bermotor Di Jawa Barat ProcessAgus SupriadiNo ratings yet

- Case Studies in Fluid Mechanics with Sensitivities to Governing VariablesFrom EverandCase Studies in Fluid Mechanics with Sensitivities to Governing VariablesNo ratings yet

- Texas Oil Tools: "DSH4" Side Door Stripper Packer 3.06" 10MDocument14 pagesTexas Oil Tools: "DSH4" Side Door Stripper Packer 3.06" 10Mjose perozoNo ratings yet

- MERCADEODocument204 pagesMERCADEOjose perozoNo ratings yet

- Treatment Report: Well: KTC1Document4 pagesTreatment Report: Well: KTC1jose perozoNo ratings yet

- Injector Head Operation Graphs: HR 560 HR 580 HR 440 HR 480Document14 pagesInjector Head Operation Graphs: HR 560 HR 580 HR 440 HR 480jose perozoNo ratings yet

- TimeTable SD-T SP #10234Document4 pagesTimeTable SD-T SP #10234jose perozoNo ratings yet

- CTS Web and Intouch Reference PageDocument6 pagesCTS Web and Intouch Reference Pagejose perozoNo ratings yet

- CT Mechanical CalculationsDocument12 pagesCT Mechanical Calculationsjose perozoNo ratings yet

- Acid Neutralizing ClacsDocument4 pagesAcid Neutralizing Clacsjose perozoNo ratings yet