Professional Documents

Culture Documents

Rig 6

Rig 6

Uploaded by

ahmed otmanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rig 6

Rig 6

Uploaded by

ahmed otmanCopyright:

Available Formats

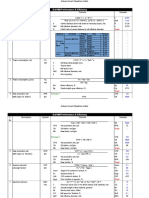

Rig 6 Main Features

1. MAST

DRECO Open Face Cantilever Mast, 142 Feet Clear

Height x 1,000,000 lbs.

2. SUBSTRUCTURE

Dreco Sling Shot style substructure

Floor height 22 ft., 18ft. Clear height below Rotary Beams

3. CROWN BLOCK

Dreco Flat Running Crown 500 Ton Sheaves 60” grooved for

1.3/8" wireline

4. DRAWWORKS

1,400 HP Oilwell 840E

5. DRIVE GROUP

General Electric GE 752 Generators (6)

13. SHALE SHAKER

6. POWER SYSTEM Thule Model VSM120 Dual (two units)

Two (2) Trailers comprising of the following:

Two (2) each Trailers accommodating 4 x Caterpillar D398 14. BLOWOUT PREVENTERS

Engines with brush less KAT0 Generators for SCR a. One (1) Single Gate 13 5/8" x 5,000 PSI Cameron

Rated at 1030 KW, 600 Volts, 3 Phase with full Ross Hill SCR Preventor

system Model 1000, Rated at 1800 Amps D.C. b. One (1) Hydril 20" MSP 2000 Annular Preventor

c. One (1) Hydril 13 5/8" 5000 GK Annular Preventor

7. TRAVELLING BLOCK d. One (1) Cameron Type U Double 13 5/8" 5000 PSI W.P. +

Oilwell B500 Combination Block Hook, 6 Sheaves 60” for One Single Ram.

1.3/8” Wireline. e. Complete with all associated Ram sizes, Valves, Mus

BJ 500 Ton Unimatic Hook & Adaptor Assembly with Cross and Coflex hose to Choke Manifold. Coflex hose can

positioner. be replaced with steel choke Manifold line.

f. Choke Manifold 5,000 PSI W.P. with SWACO Choke.

8. SWIVEL Choke Manifold mounted on Gooseneck of Shaker Tank

Continental Emsco Model LB 500 Trailer.

9. ROTARY TABLE 15. KOOMEY UNIT MAIN CONTROL – TRAILER MOUNTED

Oilwell 27 ½ ", Rated 500 Ton supportable dead load. Model MB200-11SB3 M Series with remote stations.

One (1) Koomey Test Pump with Chart Recorder 0-10,000 PSI

10. MUD PUMPS 1 & 2 Triplex (Trailerized) Also Housing Workshop, Brake Water Tank, Heat Exchanger

Oilwell A 1400 PT (7 ½ " X 10") and Junk Bin.

Maximum Input H.P.---1400 HP

Powered by Two each GE 752 Electric Motors. 16. HANDLING EQUIPMENT

Pumps mounted cross-wise on flat set Trailer with Hydraulic Rig has all relevant tools for normal tubular sizes.

Jacks to raise and lower, front and rear for loading.

17. SAFETY EQUIPMENTS

11. ACTIVE MUD SYSTEM Adequately equipped

Comprising of two flat set Trailers.

Suction Tank Trailer, capacity--- 750 bbls with 2 x 18. MAIN CAMP

10 HP Agitators Fully equipped Camp and facilities for 75 men.

Shaker Tank Trailer, capacity--- 750 bbls with 2 x

10 HP Agitators 19. WELLSITE FACILITIES

2 x 500 BBLs Skid Mounted Mud Tanks. Offices/bath/sleeper facilities for Company man & Toolpusher,

Double end sleeper with bathroom for Geologist and Mud

12. RESERVED SYSTEM, TRAILERIZED Engineer.

Two (2) Flat set Water/Mud Tank Trailers, capacity 800 bbls

each. Can be unitized to hold agitated mud or water as 20. AUTOMOTIVE EQUIPMENT

required, complete with Pumps on One Trailer, and 2 x 10 HP One 953 Kenworth, one forklift Cat 966, crew car, and two

Agitators. pickups.

Total capacity, both tank Trailers --- 1,600 bbls

You might also like

- Manual Ingles d6bDocument141 pagesManual Ingles d6bgustavo50% (2)

- Daftar Peralatan Rig #01Document4 pagesDaftar Peralatan Rig #01abel saingNo ratings yet

- Short MODU Specs of Tam Dao 02Document2 pagesShort MODU Specs of Tam Dao 02Them Bui XuanNo ratings yet

- 750HP DW PDFDocument6 pages750HP DW PDFilkerkozturkNo ratings yet

- Ideco h25 Technical SpecsDocument20 pagesIdeco h25 Technical SpecsSergio Fabian VasicekNo ratings yet

- Adc RigsDocument23 pagesAdc Rigsgplese067% (3)

- Operating Instructions DVD Recorder Model No. DMR-EZ17Document72 pagesOperating Instructions DVD Recorder Model No. DMR-EZ17fmick576847No ratings yet

- Rig 5Document1 pageRig 5ahmed otmanNo ratings yet

- Rig 1Document1 pageRig 1ahmed otmanNo ratings yet

- Eni - Saipem, Semi-Sub DesignDocument4 pagesEni - Saipem, Semi-Sub DesignMuh. Saeful MHNo ratings yet

- Short Spec - Platinum ExplorerDocument2 pagesShort Spec - Platinum ExplorertphsbNo ratings yet

- Short MODU Specs of MMWU2Document2 pagesShort MODU Specs of MMWU2Them Bui XuanNo ratings yet

- Ficha TecnicaDocument2 pagesFicha TecnicaKevin GuarderasNo ratings yet

- 1038scarabeo 5Document16 pages1038scarabeo 5Bogdan Bdy100% (1)

- 6 - BlackHawk2Document1 page6 - BlackHawk2nikNo ratings yet

- ShortSpec TopazDriller Rev8 PDFDocument2 pagesShortSpec TopazDriller Rev8 PDFBorysNo ratings yet

- COSLBoss PDFDocument2 pagesCOSLBoss PDFDenny HermawanNo ratings yet

- Cosl Boss: Keppel Fels "Mod V B Class" Jack-UpDocument2 pagesCosl Boss: Keppel Fels "Mod V B Class" Jack-UpNABIL FIKRIENo ratings yet

- Sem-Logo QG-II MAIO 2014 PDFDocument2 pagesSem-Logo QG-II MAIO 2014 PDFPablo Rivas RNo ratings yet

- Chikyu SpecificationsDocument1 pageChikyu SpecificationstphsbNo ratings yet

- 6 - BlackHawkDocument1 page6 - BlackHawkYap SguanNo ratings yet

- Laker SeriesDocument4 pagesLaker SeriesalbustamanteNo ratings yet

- Saipem 3000Document8 pagesSaipem 3000Nkechi KokoNo ratings yet

- Ocean Rig OlympiaDocument6 pagesOcean Rig OlympiaFateNo ratings yet

- Apache II Brochure - Basic ChangesDocument8 pagesApache II Brochure - Basic ChangesJhon HernandezNo ratings yet

- Rig 9Document1 pageRig 9Tamer AghaNo ratings yet

- Short MODU Specs of MMWU1Document2 pagesShort MODU Specs of MMWU1Them Bui XuanNo ratings yet

- Main Particulars Villa de TerorDocument8 pagesMain Particulars Villa de TerorHakim HaddouchiNo ratings yet

- 13 - EndeavorDocument1 page13 - EndeavorBima MahendraNo ratings yet

- Ensco DS 8Document1 pageEnsco DS 8Yap SguanNo ratings yet

- Spec Rig 550 HP TMSDocument21 pagesSpec Rig 550 HP TMSAli AkbarNo ratings yet

- Parker Drilling Company Rig 257: Submersible Shallow Water - Barge Drilling Rig - Caspian Sea (ABS & RMRS Certified)Document2 pagesParker Drilling Company Rig 257: Submersible Shallow Water - Barge Drilling Rig - Caspian Sea (ABS & RMRS Certified)Seyedeh Roghayeh SeyediNo ratings yet

- Atwood Admiral Brochure Apr2016(2019年前交付()Document2 pagesAtwood Admiral Brochure Apr2016(2019年前交付()wangnaNo ratings yet

- Advantage Light Well Servicing RigDocument2 pagesAdvantage Light Well Servicing RigJohn SimancaNo ratings yet

- Short MODU Specs of Tam Dao 05 PDFDocument2 pagesShort MODU Specs of Tam Dao 05 PDFThem Bui XuanNo ratings yet

- ShortSpec TopazDriller Rev8Document2 pagesShortSpec TopazDriller Rev8byedNo ratings yet

- Semi-Submersible SDO IDocument2 pagesSemi-Submersible SDO IWilliam NgNo ratings yet

- 18 - MonarchDocument1 page18 - MonarchBima MahendraNo ratings yet

- Shelf Drilling Fortress - Spec Sheet NSH Oct 2022Document2 pagesShelf Drilling Fortress - Spec Sheet NSH Oct 2022ДимаNo ratings yet

- Ensco Ds-10: General InformationDocument1 pageEnsco Ds-10: General Informationmsm.ele2009No ratings yet

- 800 Dreco Diesel Electric Land Drilling RigDocument3 pages800 Dreco Diesel Electric Land Drilling RigGufron Amrony100% (2)

- Ensco 108Document1 pageEnsco 108Ahmed ElkhoulyNo ratings yet

- Rig 162 Specifications: Hoisting, Rotating & Pipe-Handling EquipmentDocument1 pageRig 162 Specifications: Hoisting, Rotating & Pipe-Handling EquipmentShanbo Hao0% (1)

- Shelf Drilling Enterprise - Spec Sheet Nov 2021 10KDocument2 pagesShelf Drilling Enterprise - Spec Sheet Nov 2021 10Kpramodh kumarNo ratings yet

- Atwood Achiever Brochure1Document2 pagesAtwood Achiever Brochure1wangnaNo ratings yet

- ED3R3Document3 pagesED3R3prabNo ratings yet

- Semi-Submersible - SDO IIDocument2 pagesSemi-Submersible - SDO IIWilliam NgNo ratings yet

- Nov/Iri Cabot 1200 W/ Top Drive Inventory of EquipmentDocument1 pageNov/Iri Cabot 1200 W/ Top Drive Inventory of EquipmentPablo Rivas RNo ratings yet

- Atwood Advantage Brochure1Document2 pagesAtwood Advantage Brochure1wangnaNo ratings yet

- ATWOOD Advantage BrochureDocument2 pagesATWOOD Advantage Brochurespong1ertzNo ratings yet

- Ensco 106Document1 pageEnsco 106michael voonNo ratings yet

- T685WS11 05Document2 pagesT685WS11 05govindsr0% (1)

- 1613 Scarabeo 9Document2 pages1613 Scarabeo 9La Ode Hadi AugustmanNo ratings yet

- AchieverDocument2 pagesAchieverL'Usine NouvelleNo ratings yet

- Rig 122 Inventory SheetDocument1 pageRig 122 Inventory SheetCosersum Int C ANo ratings yet

- 10017Document2 pages10017Alex RamirezNo ratings yet

- NOF Short Specifications - Energy Enticer - Nov2021Document2 pagesNOF Short Specifications - Energy Enticer - Nov2021Adeel AliNo ratings yet

- Lady Cynthia - 310709Document5 pagesLady Cynthia - 310709andrewmaldersonNo ratings yet

- 1019spm S7000re L03Document12 pages1019spm S7000re L03Farid TataNo ratings yet

- Rig 37Document1 pageRig 37ahmed otmanNo ratings yet

- Rig 5Document1 pageRig 5ahmed otmanNo ratings yet

- Well-Control Worksheet: Driller's MethodDocument2 pagesWell-Control Worksheet: Driller's Methodahmed otmanNo ratings yet

- Rig 1Document1 pageRig 1ahmed otmanNo ratings yet

- 9 - 1 - Drilling Fluid Products & SystemsDocument13 pages9 - 1 - Drilling Fluid Products & Systemsahmed otmanNo ratings yet

- Binary Salt CalcDocument64 pagesBinary Salt Calcahmed otmanNo ratings yet

- Drilling Fluid Contamination and Treatment Drilling Fluid Contamination and TreatmentDocument77 pagesDrilling Fluid Contamination and Treatment Drilling Fluid Contamination and Treatmentahmed otmanNo ratings yet

- 3 - Coring FluidsDocument19 pages3 - Coring Fluidsahmed otmanNo ratings yet

- Pressure Indicators Engineering & GeologicalDocument16 pagesPressure Indicators Engineering & Geologicalahmed otmanNo ratings yet

- 1 - 1 The Drilling RigDocument46 pages1 - 1 The Drilling Rigahmed otmanNo ratings yet

- RheologyDocument53 pagesRheologyahmed otmanNo ratings yet

- Silicon Epitaxial Planar Transistor 2SA1179: Galaxy ElectricalDocument5 pagesSilicon Epitaxial Planar Transistor 2SA1179: Galaxy ElectricalsacralNo ratings yet

- Material Stage - 1 Update September 2020Document7 pagesMaterial Stage - 1 Update September 2020ccr gamNo ratings yet

- Lift Shaft Builders GuideDocument19 pagesLift Shaft Builders Guidesydney augustNo ratings yet

- Tbs Crossfire ManualDocument88 pagesTbs Crossfire ManualNatanaeL FreireNo ratings yet

- 26 Comb Gesamt EngDocument291 pages26 Comb Gesamt EngnonemoreNo ratings yet

- How To Use A Multimeter Beginners GuideDocument13 pagesHow To Use A Multimeter Beginners GuideAnja DewittNo ratings yet

- CAT22C10: 256-Bit Nonvolatile CMOS Static RAMDocument10 pagesCAT22C10: 256-Bit Nonvolatile CMOS Static RAMvanmarteNo ratings yet

- 3-Pin Plug: Based On The International Colour CodeDocument4 pages3-Pin Plug: Based On The International Colour CodesitiNo ratings yet

- ZAPI AC-1 ManualDocument62 pagesZAPI AC-1 ManualMarcos Gregorio da SilvaNo ratings yet

- Ip - M-Pact - ENGDocument135 pagesIp - M-Pact - ENGdejanoski_aNo ratings yet

- Student Name: Ganesh Kumar A/L Tinakaran ID Number: 1001025488 - Lab Report Assessment RubricDocument8 pagesStudent Name: Ganesh Kumar A/L Tinakaran ID Number: 1001025488 - Lab Report Assessment RubricMd Ashiqur RahmanNo ratings yet

- Actuators: Department of E&E EngineeringDocument14 pagesActuators: Department of E&E Engineeringmanavi naikNo ratings yet

- GE Versamax PLC DatasheetDocument2 pagesGE Versamax PLC Datasheetusamakhan205No ratings yet

- Sc-Equipment Communication Card: Product BulletinDocument4 pagesSc-Equipment Communication Card: Product BulletinHectorFalconLlenderrozosNo ratings yet

- Electronique - Audio - Microphone Valve PreampDocument7 pagesElectronique - Audio - Microphone Valve PreampkoukihamedNo ratings yet

- 154 TOP Theory of Machines - Mechanical Engineering Multiple Choice Questions and AnswersDocument31 pages154 TOP Theory of Machines - Mechanical Engineering Multiple Choice Questions and AnswersRavi kumarNo ratings yet

- Elite Pro Lead-Acid Battery ChargerDocument2 pagesElite Pro Lead-Acid Battery ChargerbtiscribdNo ratings yet

- 900VPR-2-280 520V-CE-RoHS-With Corrected UL LogoDocument2 pages900VPR-2-280 520V-CE-RoHS-With Corrected UL LogoPasindu PriyankaraNo ratings yet

- Hec v1500 Technical Characteristics - May2017Document14 pagesHec v1500 Technical Characteristics - May2017Juan Pablo Vazquez AlvarezNo ratings yet

- Parts List - KTZ411-61Document4 pagesParts List - KTZ411-61Mahmoud ElboraeNo ratings yet

- WS File 1Document13 pagesWS File 1rhythm 2021No ratings yet

- CCTV Ajay DubeyDocument2 pagesCCTV Ajay DubeyAjay DubeyNo ratings yet

- Sistema de Encendido Honda CBF 150 UnicornDocument12 pagesSistema de Encendido Honda CBF 150 UnicornjotabanNo ratings yet

- Apache 200Document260 pagesApache 200Agudelo Andrew100% (8)

- Various Addressing Modes of 8086 - 8088Document3 pagesVarious Addressing Modes of 8086 - 8088NeelmaniNo ratings yet

- Manual Distribution Network Operation ManualDocument113 pagesManual Distribution Network Operation ManualJorge Cáceres0% (1)

- M54/74HC160/161 M54/74HC162/163: Synchronous Presettable 4-Bit CounterDocument16 pagesM54/74HC160/161 M54/74HC162/163: Synchronous Presettable 4-Bit CounterMohammed El-AwamryNo ratings yet

- Ball Mill CalculationsDocument7 pagesBall Mill Calculationszainab alkhafafNo ratings yet