Professional Documents

Culture Documents

Manual SFL2 Eng

Uploaded by

Javier Eduardo Alzate BogotaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual SFL2 Eng

Uploaded by

Javier Eduardo Alzate BogotaCopyright:

Available Formats

Technical \Specification

&

Operation Manual

SFL2 & RTIL

Sequence Flashing Light

&

Runway End Identification Light

Specification & Operation Manual SFL & RTIL

Contents

1. System General

2. System Description

3. System Composition

4. System Function Description

5. Composition of Communication

6. System Problem and Solution

Value Creating Partner

YOUYANG 2

Specification & Operation Manual SFL & RTIL

>> PRECAUTION <<

Even though the power switch is placed at “off” position, the remaining of voltages in this control

circuit may cause the fatal damage for human body.

Therefore must do work after cutting off the power at a full discharge state. (on earth)

1. System general

SFL(Sequence Flashing Light) consists of main transformer, flash head(flashing light),

junction box, master timer unit and power supply unit installed on the approach area in

order to inform the landing air-craft of landing direction. According to the regulation of

FAA CAT-I, FAA CAT-II, and ICAO this system is manufactured.

2. System Description

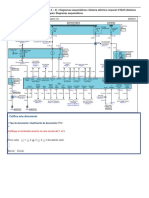

2-1 SFL composition diagram

SFL(Sequence Flashing Light) consists of main transformer, flash head(flashing light),

junction box, master timer unit and power supply unit.

2-2 MSASTER TIMER

SFL system Control, observation, monitoring and communication power supply are

operated in master timer.

Mater timer consists of power supply part, CPU & setting part, Drive part and Elapsed

time meter.

Value Creating Partner

YOUYANG 3

Specification & Operation Manual SFL & RTIL

POWER MASTER TIMER DRIVER ELAPSED TIME METER

CONTROL INTENSITY RTIL MODE SFL LAMP TEST

POWER

POSITION CONTROL CONTROL SELECTION MONITORING & SETTING

LAMP

LOCAL LOW RTIL ON SFL 30 ON

TEST

1

0 SFL 21

R B1 SEC

C B2 RTIL SFL 2

REMOTE MEDIUM SFL 5

FAULT ALARM

B3 SFL

0 ALARM

ON

30 5 SFL

SERIAL HIGH RTIL SFL

MODE SW. WARNING

OFF 21 WARNING

LAMP STATUS

31

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

32

RESET

RESET

2-2-1 Power supply part

Picture 4-2

Power supply part supplies DC power for master timer. C(communication), R(Remote) or

L(Local) is selected as Control Position by mode switch. In case of Local, 0(OFF), B1(LOW

intensity), B2(MEDIUM intensity) or B3(HIGH intensity) can be selected by mode switch.

2-2-1-1 LOCAL

Intensity is changed according to input of mode switch - 0(OFF), B1(LOW),

B2(MEDIUM) or B3(HIGH)

Value Creating Partner

YOUYANG 4

Specification & Operation Manual SFL & RTIL

1) “0” : OFF status

Control position -> Local LED “ON” / Remote LED “OFF”/Serial LED “OFF”

Intensity Control-> All LED “OFF”

2) “B1” : Intensity step becomes LOW status

Recharging one condenser

Control position -> Local LED “ON” /Remote LED “OFF”/Serial LED “OFF”

Intensity Control-> LOW LED “ON/OFF”(flickering)

MIDIUM LED “OFF”/HIGH LED “OFF”

3) “B2” : Intensity step becomes MEDIUM status

Recharging two condensers

Control position -> Local LED “ON” /Remote LED “OFF”/Serial LED “OFF”

Intensity Control-> LOW LED “OFF”

MIDIUM LED “OFF/ON” (flickering)

HIGH LED “OFF”

4) “B2” : Intensity step becomes HIGH status

Recharging three condensers

Control position -> Local LED “ON” /Remote LED “OFF”/Serial LED “OFF”

Intensity Control-> LOW LED “OFF”

MIDIUM LED “OFF”

HIGH LED “ON/OFF” (flickering)

2-2-1-2 REMOTE

When R is selected by mode switch, mode is changed to Remote.

Signal of Remote control uses AC120V. In this case, master timer is operated

according to received signal of ON/OFF of SFL & RTIL(REIL) or intensity step from

Control tower or remote distance.

Intensity is changed as 0(OFF), B1(LOW), B2(MEDIUM) or B3(HIGH)

Value Creating Partner

YOUYANG 5

Specification & Operation Manual SFL & RTIL

1) “R”- 0 : OFF status

In this case, setting of master timer can be changed by remote input.

Control position -> Remote LED “ON”/Local LED “OFF” /Serial LED “OFF”

Intensity Control-> All LED “OFF”

2) “R”-B1 : Intensity step becomes LOW status.

On selecting both of “R” on mode switch and “BI” on remote operation

switch.

Recharging one condenser

Control position -> Remote LED “ON” /Local LED “OFF” /Serial LED “OFF”

Intensity Control-> LOW LED “ON/OFF”(flickering)

MIDIUM LED “OFF”/HIGH LED “OFF”

3) “R”-B2 : Intensity step becomes MEDIUM status

On selecting both of “R” on mode switch and “B2” on remote operation

switch.

Recharging two condensers

Control position -> Remote LED “ON” /Local LED “OFF” /Serial LED “OFF”

Intensity Control-> LOW LED “OFF”

MIDIUM LED “OFF/ON” (flickering)

HIGH LED “OFF”

4) “R”-B3 : Intensity step becomes HIGH status

On selecting both of “R” on mode switch and “B3” on remote operation

switch.

Recharging three condensers

Control position -> Remote LED “ON” /Local LED “OFF” /Serial LED “OFF”

Intensity Control-> LOW LED “OFF”

MIDIUM LED “OFF”

HIGH LED “ON/OFF” (flickering)

Value Creating Partner

YOUYANG 6

Specification & Operation Manual SFL & RTIL

5) SFL 0N/0FF

On Remote mode, working of power supply unit which is set in Mode selection is

determined.

6) RTIL ON/OFF

On Remote mode, working of RTIL(REIL) which is set in RTIL control is

determined.

2-2-1-3 Serial

When S is selected by mode switch, mode is changed to Serial. In this case,

master timer is operated according to received signal of ON/OFF of SFL &

RTIL(REIL) or intensity step from computer of Control tower. Communication of

Mater timer uses RS-485 communication and converter of computer on control

tower changes RS-485 to RS-232.

Intensity is changed as 0(OFF), B1(LOW), B2(MEDIUM) or B3(HIGH)

1) “S”- 0 : OFF status

In this case, setting of master timer can be changed by computer RS485

communication input.

Control position ->Serial LED “ON”/ Remote LED “OFF” /Local LED “OFF”

Intensity Control-> All LED “OFF”

2) “S”-B1 : Intensity step becomes LOW status

On selecting both of “C” on mode switch and receiving LOW data

Recharging one condenser

Control position -> Serial LED “ON”/ Remote LED “OFF” /Local LED “OFF”

Intensity Control-> LOW LED “ON/OFF”(flickering)

MIDIUM LED “OFF”/HIGH LED “OFF”

3) “S”-B2 : Intensity step becomes Medium status

Value Creating Partner

YOUYANG 7

Specification & Operation Manual SFL & RTIL

On selecting both of “C” on mode switch and receiving Medium data

Recharging two condensers

Control position -> Serial LED “ON”/ Remote LED “OFF” /Local LED “OFF”

Intensity Control-> LOW LED “OFF”

MIDIUM LED “OFF/ON” (flickering)

HIGH LED “OFF”

4) “S”-B3 : Intensity step becomes High status

On selecting both of “C” on mode switch and receiving High data

Recharging three condensers

Control position -> Serial LED “ON”/ Remote LED “OFF” /Local LED “OFF”

Intensity Control-> LOW LED “OFF”

MIDIUM LED “OFF”

HIGH LED “ON/OFF” (flickering)

-. Reception status information on communication of SFL system

Start signal of Detection signal of

SFL/RTIL ON/OFF Intensity

communication error

00 01

0F 02

02 CHK_SUM

F0 03

FF 04

․ 1 FRAME : 02 - > Start signal of communication

․ 2 FRAME : 00 -> 0 - SFL OFF, 0 - RTIL OFF

0F - > 0 - SFL OFF, F - RTIL ON

F0 -> 0 - SFL ON , F - RTIL OFF

FF -> F - SFL ON, F - RTIL ON

․ 3 FRAME : 01 - > No intensity

02 - > Low Intensity

03 - > Medium Intensity

04 - > High Intensity

․ 4 FRAME : CHK _ SUM

Value Creating Partner

YOUYANG 8

Specification & Operation Manual SFL & RTIL

- Transmission status information on communication of SFL system

1-8 9 - 16 17 - 24 25 - 32

Status Status Status Status

SFL SFL

02 information information information information CHK _

Operation STATUS

start of lamp of of lamp of of lamp of of lamp of SUM

information BIT

power power power power

supply unit supply unit supply unit supply unit

표 4-2

․ 1 FRAME : 02 - > Start signal of communication

․ 2 FRAME : 00 -> SFL ON

FF -> SFL OFF

․ 3 FRAME : LAMP 0

․ 4 FRAME : LAMP 1

․ 5 FRAME : LAMP 2

․ 6 FRAME : LAMP 3

․ 7 FRAME : SFL Operation information

․ 8 FRAME : SFL STATUS BIT

․ 9 FRAME : CHK _ SUM

-.SFL informaton

0 1 2 3 4 5 6 7

L/M/H RTIL ON SEC Number of fault one

․ L / M / H : step of intensity

․ RTIL ON : Yes/No of RTIL setting

․ SEC : number of flashing per second

-.SFL STATUS BIT

0 1 2 3 4 5 6 7

SFL RTIL

ALARM WARNING C / R /L 5 / 21 / 30

ON/OFF FAULT

Value Creating Partner

YOUYANG 9

Specification & Operation Manual SFL & RTIL

․ SFL ON/OFF : Yes/No of SFLworking

․ RTIL FAULT : Information of RTIL FAULT

․ ALARM : Yes/No of number of fault lamp which is set for Alarm.

․ WARNING : Yes/No of number of fault lamp which is set for Warning.

․C / R / L : Operation mode of SFL

․ 5 / 21 / 30 : Information of SFL formation (number of SFL).

2-2-2 CPU & setting part

Setting, Control, observation and monitoring of SFL system is processed by using

microprocessor.

2-2-2-1 CPU part

1) This part receives input from setting part.

To control configuration formation, intensity step, number of flashing per sec

of SFL and working RTIL.

2) To supply, after receipt of lamp fault information of power supply unit, the

information for setting part.

2-2-2-2 Setting part

1) Setting and indication of SFL

2) To all information of setting part board is sent to CPU part and is transmitted to

power supply unit. Information on lamp status of power supply unit is shown

through LED of `Lamp Status`.

3) Showing present SFL operation status

MASTER TIMER

CONTROL INTENSITY RTIL MODE SFL LAMP TEST

POSITION CONTROL CONTROL SELECTION MONITORING & SETTING

LAMP

LOCAL LOW RTIL ON SFL 30 ON

TEST

1

SFL 21

SEC

RTIL SFL 2

REMOTE MEDIUM SFL 5

FAULT ALARM

SFL

0 ALARM

ON

30 5 SFL

SERIAL HIGH RTIL SFL

WARNING

OFF 21 WARNING

LAMP STATUS

31

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

32

RESET

Value Creating Partner

YOUYANG 10

Specification & Operation Manual SFL & RTIL

Control Position: Showing operation mode through LED

- LOCAL: “ON” on Local operation

- REMOTE: “ON” on Remote operation

- SERIAL: “ON” on Serial operation

Intensity Control: Showing intensity step through LED

- LOW / MERIUM / HIGH - flickering

RTIL Control

- RTIL ON: “ON” on setting RTIL

- RTIL FAULT : LED “ON” – 8 times consecutive defect

- RTIL: ON – connecting with SFL configuration

OFF – not connecting with SFL configuration

Mode Selection: Change of System configuration formation(5/21/30) is fixed by

using BCD switch. The change can be set on Intensity step “0”.

- SFL 30: input of BCD switch 30

- SFL 21: input of BCD switch 21

- SFL 5: input of BCD switch 5

- BCD SWITCH: 0 -> SETTING 0 CONFIGURATION

Except RTIL, All power supply unit is excluded in setting

configuration.

5 -> SETTING 5 CONFIGURATIONS

Except RTIL, Working 1-5 SFL, the rest power supply is

excluded in setting configuration.

21 -> SETTING 21 CONFIGURATIONS

Except RTIL, Working 1-21 SFL, the rest power supply is

excluded in setting configuration.

30 -> SETTING 30 CONFIGURATIONS

Except RTIL, Working 1-30 SFL, the rest power supply is

excluded in setting configuration.

SFL Monitoring: Yes /No of operation status of SFL system

Visual indication of alarm & warning of power supply unit by

LED

- ON: Yes or No of operation

Flickering ON LED-> showing on communication

- SFL ALARM: In case the actual no. of defective power supply unit is more

than fixed No. of power supply unit for alarm, the LED becomes “ON”.

- SFL WARNING: In case the actual no. of defective power supply unit is more

than fixed No. of power supply unit for warning, the LED becomes “ON”.

Value Creating Partner

YOUYANG 11

Specification & Operation Manual SFL & RTIL

Lamp Test & Setting

- SFL ALARM: Fixing Alarm value by BCD switch

- SFL WARNING: Fixing Warning value by BCD switch

- LAMP TEST: Determining whether whole power supply unit connected withL

system is out of order or not.

Operation – on Intensity step: 0

On starting operation, master timer orders high intensity with 2 flashing per

second. After 10 flashing, in case there is some problem, the status is

shown on LED of `Lamp Status` board.

- SEC: Setting Number of flashing per sec of SFL and RTIL(REIL).

1 -> 1 flashing per sec

2 -> 2 flashing per sec

Lamp Status

- Showing information from LAMP TEST result

- Indication ON/OFF status of power supply unit which power supply unit

transmits in operating (B1, B2 & B3).

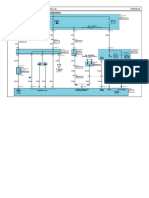

2-2-3 Drive part

1) Transmission of controlled communication signal in CPU part to Power supply

unit

2) Supply of lamp status information, which is sent from power supply unit, to

CPU part

SCR2

Input

SCR1

SCR 1 SCR 2

Control

Information

(SCR)

Output

Power Supply Power Supply Power Supply

unit 1 unit 15 unit 32

2-2-4 Elapsed Time meter

Regardless of operation mode, this displays using time of each intensity step after

receipt of intensity information.

Value Creating Partner

YOUYANG 12

Specification & Operation Manual SFL & RTIL

ELAPSED TIME METER

RESET

H STEP: 0000.00 HOUR -> HIGH INTENSITY

M STEP: 0000.00 HOUR -> MEDIUM INTENSITY

L STEP: 0000.00 HOUR -> LOW INTENSITY

T STEP: 0000.00 HOUR -> TOTAL INTENSITY

2-2-5 MATER PCB

To connect power supply unit, CPU board and elapsed time meter.

2-2-6 Transformer

2-2-6-1 Transformer for supplying power

This receives AC 110V/220/240V/380V and supplies power with changed AC

voltage, which fits each DC, to power supply part.

Value Creating Partner

YOUYANG 13

Specification & Operation Manual SFL & RTIL

2-2-6-2 Transformer for power control

1) To supply power for control of SFL

2) Power

․AC36V : For communication

․AC120V : For REMOTE

․AC120V : For detecting lamp fault

․AC220V : For driving MC

2- 2-7 FRONT PANEL

This receives whole power of SFL system. Input power is sent to TB1 and the

power becomes on/off by MCCB. Mater timer is protected from input power by

fuse(F1).

Value Creating Partner

YOUYANG 14

Specification & Operation Manual SFL & RTIL

-. Input power: AC110V, AC220V, AC230V, AC380V

-. Frequency: 50HZ, 60HZ

-. Phase : Single

-. Designed power: 6KW

-. Output voltage: AC220V, AC380V

2 -2- 8 REAR PANEL1

To input and output signals of POWER SUPPLY and REMOTE, SERIAL .

2-2-8-1. Terminal of REMOTE

On REMOTE operation, this receives signals of intensity step and ON/OFF of

RTIL & SFL.

-. T701 -> COM

-. T702 -> B1

-. T704 -> B2

-. T705 -> B3

-. T706 -> SFL ON

-. T707 -> RTIL ON

-. T703 -> N

2-2-8-2. Terminal of COM&MONITOR

-. T301 -> RS422 communication with Computer

-. T302 -> RS422 communication with Computer

Value Creating Partner

YOUYANG 15

Specification & Operation Manual SFL & RTIL

-. T401 -> communication line of POWER SUPPLY UNIT -1

-. T402 -> communication line of POWER SUPPLY UNIT -2

-. T403 -> line for lamp fault of POWER SUPPLY UNIT -1

-. T404 -> line for lamp fault of POWER SUPPLY UNIT -2

2_2_8_3. Terminal of SFL STATUS

-. T801 -> SFL ON/OFF

-. T802 -> RTIL FAULT

-. T803 -> ALARM

-. T804 -> WARNING

-. T805 -> C / R / L

-. T806 -> C / R / L

-. T807 -> 5 / 21 / 30

-. T808 -> 5 / 21 / 30

-. T809 -> COM

-. T810 -> COM

-. T811 -> Output of control of MC contact

-. T812 -> Output of control of MC contact

2-2-9. REAR PANEL2

1) This controls and outputs secondary power of MAIN TRANSFORMER.

2) To keep safety by using fuse(F2, F3)

3) To connect a grounding by using arrestor.

4) AC220V for heater power

5) AC380V for power supply unit is controlled by MC (on/off)

-. Input power: AC220V, AC380V

-. Frequency: 50HZ, 60HZ

-. Phase: single

-. Designed power: 6KW

-. Output voltage: AC 220V, AC380V

Value Creating Partner

YOUYANG 16

Specification & Operation Manual SFL & RTIL

2-3 Power Supply Unit

Control board / Power board / Controllers of temperature and humidity /

Heating/TNR board

CONTROL BOARD

TR1

TH1

POWER BOARD

TH2

2_3_1. CONTRIL BOARD

1) To Use communication information of master timer

2) To Determine Yes or No of operation & intensity step

3) To Control Power supply unit

Transmission

Part Detection

Lamp fault Part

information Communication

LAMP

FAULT

TEST

POWER

COMMAND OFF

ACTION

Signal

Address Input s/w

BCD 1 BCD 2

DC 12V MICRO PROCESSOR

SMPS

DC 5V Power

SMPS Control Signal of

Power Supply

TEST

Value Creating Partner

YOUYANG 17

Specification & Operation Manual SFL & RTIL

2-3-1-1 Input of self address by BCD switch

2-3-1-2 Lamp test

Having no connection with mater timer, when Power Supply Unit check

lamp operation status by turning on TEST switch, Lamp flashes 2 times

per second with high intensity.

2-3-1-3 Self check on operation by master timer

All status of operation which is controlled by master timer is displayed

by LED

Power LED / Working LED / Order OFF LED / Lamp fault LED /

Lamp test LED

2-3-1-4 Detect of defective lamp

To send Defective Lamp information to master timer by using SSR

2-3-2 Power board

1) Recharging condenser by control board’s order

2) Discharging recharged voltage through lamp when trigger signal is

inputted.

3) After discharging, sending lamp fault information to control board

DOOR S/W Discharge resistance

DC 500V Recharge resistance

AC 360V

12V

Recharge

signal

12V

12V

Recharge Trigger

signal

Signal

12V

12V

Recharge

signal

12V

Prevention Signal

of over recharge perception

Detection Signal

signal

Defective Lamp

of over

recharge

Value Creating Partner

YOUYANG 18

Specification & Operation Manual SFL & RTIL

2-3-2-1 Power supply of DC500V

This part receive AC 360V and change to DC 500V using hi-voltage diode. This

voltage is used for recharging condenser.

Picture 4-13

2-3-2-2 Recharging condenser

Control board -> recharging signal -> pulse transformer -> SCR working

-> Recharging condenser

2-3-2-3 Discharging lamp

1) When fixed address of control board is same as number of cycle,

discharging signal comes.

2) Discharging signal -> trigger coil -> high voltage pulse more than

10,000 V ->supplying to trigger terminal -> discharging lamp

2-3-2-4 Detect of discharging by checking residual voltage of condenser

2-3-2-5 Prevention of over voltage

To turn off SCR when over voltage more than standard is rescharged.

In case recharge signal

come in, recharge voltage

is not increased.

Standard voltage of

detection of over recharge

recharge voltage of condenser.

Recharge signal Recharge signal

Value Creating Partner

YOUYANG 19

Specification & Operation Manual SFL & RTIL

2-3-2-6 Resistance of discharge

For safety, when door is opened, recharged voltage is discharged

within 10 second through resistance of discharge.

2-3-2-7 Resistance of recharge

To insert input resistance in order to control input AC360V.

2-3-4 TNR PCB

To prevent damage of power supply unit by sending external impact noise

to earth.

2-3-5 Controllers of temperature and humidity

2-3-5-1 Controllers of temperature

To prevent wrong working owing to extreme temperature

Temperature controller is adjustable between +15°C ~+30°C.

2-3-5-2 Controllers of humidity

To prevent wrong working owing to extreme humidity

Humidity controller is adjustable between +30% ~ +80%.

2-3-6 Heater

To receive power from Controllers of temperature and humidity and work.

To work (80W – 100W) by AC220V on under setting temperature degree or

over setting humidity degree.

2-4-1 Flash Head

This receives DC500V from power supply unit and when trigger signal comes,

this is discharged through lamp.

* High Intensity

=================================================

Main beam Intensity

=================================================

Horizontal 30° 15,000CD+-50%

Vertical 10° 15,000CD +-50%

=================================================

2-1-4-1 Trigger PCB

1) This receives DC 500V from Power board and supplies for lamp.

2) This receives control board signal from Power board and make trigger pulse

through trigger coil. After that, the trigger pulse is supplied for trigger

terminal of lamp.

3) Xenon Lamp / 40J - When the lamp receive trigger signal that discharges.

Value Creating Partner

YOUYANG 20

Specification & Operation Manual SFL & RTIL

2-4-2 Interlock Switch

When the cover of flash head is opened, power with AC360V, which is supplied to

power supply unit, is stopped by interlock switch for safety of worker.

3. SFL System composition

Various system composition and operation is possible bysetting part of master timer.

3-1 5 configuration

3-1-1 Setting SFL 5 configuration

When switch of `Light Configuration` on Indication board of master timer is in

position “5”, 5 configuration is set. The address of each power supply unit should

be fixed in sequence. The LED lamp from 6 to 30 is OFF.

Together with above configuration, RTIL can be set according to customer

requirement.

MASTER TIMER

CONTROL INTENSITY RTIL MODE SFL LAMP TEST

POSITION CONTROL CONTROL SELECTION MONITORING & SETTING

LAMP

LOCAL LOW RTIL ON SFL 30 ON

TEST

1

SFL 21

SEC

RTIL SFL 2

REMOTE MEDIUM SFL 5

FAULT ALARM

SFL

0 ALARM

ON

30 5 SFL

SERIAL HIGH RTIL SFL

WARNING

OFF 21 WARNING

LAMP STATUS

31

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

32

RESET

SFL WORK

SFL NO WORK

31

RTIL

THRESHOLD

SFL

300m

5 4 3 2 1

Final 300m of Approach

without Flashlights

32

Value Creating Partner

YOUYANG 21

Specification & Operation Manual SFL & RTIL

3-1-2 Operation of SFL 5 configuration – 3 modes

1) Mode 1: SFL 5 configuration (ON) + RTIL(OFF)

2) Mode 2: SFL 5 configuration (ON) + RTIL(ON)

3) Mode 2: SFL 5 configuration (OFF) + RTIL(ON) – SFL switch ”0”

(SFL switch”0”)

31

RTIL

THRESHOLD

SFL

300m

5 4 3 2 1

Final 300m of Approach

without Flashlights

32

MODE 1

31

RTIL

THRESHOLD

SFL

300m

5 4 3 2 1

Final 300m of Approach

without Flashlights

32

MODE 2

31

RTIL

THRESHOLD

SFL

300m

5 4 3 2 1

Final 300m of Approach

without Flashlights

32

MODE 3

■ : SFL Light on

□ : SFL Light off

■ : RTIL Light on

□ : RTIL Light off

Picture 2-5

Value Creating Partner

YOUYANG 22

Specification & Operation Manual SFL & RTIL

3-2 21 configuration

3-2-1 Setting SFL 21 configuration

When switch of `Light Configuration` on Indication board of master timer is in

position “21”, 21 configuration is set. The address of each power supply unit

should be fixed in sequence. The LED lamp from 22 to 30 is OFF.

Together with above configuration, RTIL can be set according to customer

requirement.

31

RTIL

THRESHOLD

SFL

300m

21 20 5 4 3 2 1

Final 300m of Approach

without Flashlights

32

3-2-2 Operation of SFL 21 configuration – 5 modes

1) Mode 1: SFL 21 configuration (ON) + RTIL(OFF)

2) Mode 2: SFL 21 configuration (ON) + RTIL(ON)

3) Mode 3: SFL 5 configuration (ON) + RTIL(OFF)

4) Mode 4: SFL 5 configuration (ON) + RTIL(ON)

5) Mode 5: SFL 5 configuration (OFF) + RTIL(ON)

(SFL switch”0”)

31

RTIL

THRESHOLD

SFL

300m

21 20 19 6 5 4 3 2 1

Final 300m of Approach

without Flashlights

32

MODE 1

Value Creating Partner

YOUYANG 23

Specification & Operation Manual SFL & RTIL

31

RTIL

THRESHOLD

SFL

300m

21 20 19 6 5 4 3 2 1

Final 300m of Approach

without Flashlights

32

MODE 2

31

RTIL

THRESHOLD

SFL

300m

21 20 19 6 5 4 3 2 1

Final 300m of Approach

without Flashlights

32

MODE 3

31

RTIL

THRESHOLD

SFL

300m

21 20 19 6 5 4 3 2 1

Final 300m of Approach

without Flashlights

32

MODE 4

Value Creating Partner

YOUYANG 24

Specification & Operation Manual SFL & RTIL

31

RTIL

THRESHOLD

SFL

300m

21 20 19 6 5 4 3 2 1

Final 300m of Approach

without Flashlights

32

MODE 5

■ : SFL Light on

□ : SFL Light off

■ : RTIL Light on

□ : RTIL Light off

3-3 30 configuration

3-3-1 Setting SFL 30 configuration

When switch of `Light Configuration` on Indication board of master timer is in

position “30”, 30 configuration is set. The address of each power supply unit

should be fixed in sequence.

Together with above configuration, RTIL can be set according to customer

requirement.

31

RTIL

THRESHOLD

SFL

30 29 5 4 3 2 1

32

Value Creating Partner

YOUYANG 25

Specification & Operation Manual SFL & RTIL

3-3-2 Operation of SFL 30 configuration – 7 modes

1) Mode 1: SFL 30 configuration (ON) + RTIL(OFF)

2) Mode 2: SFL 30 configuration (ON) + RTIL(ON)

3) Mode 3: SFL 21 configuration (ON) + RTIL(OFF)

4) Mode 4: SFL 21 configuration (ON) + RTIL(ON)

5) Mode 5: SFL 5 configuration (ON) + RTIL(OFF)

6) Mode 6: SFL 5 configuration (ON) + RTIL(ON)

7) Mode 7: SFL 5 configuration (OFF) + RTIL(ON)

(SFL switch”0”)

31

RTIL

THRESHOLD

SFL

30 29 28 6 5 4 3 2 1

32

MODE 1

31

RTIL

THRESHOLD

SFL

30 29 28 6 5 4 3 2 1

32

MODE 2

31

RTIL

THRESHOLD

SFL

30 29 21 20 5 4 3 2 1

32

MODE 3

Value Creating Partner

YOUYANG 26

Specification & Operation Manual SFL & RTIL

31

RTIL

THRESHOLD

SFL

30 29 21 20 5 4 3 2 1

32

MODE 4

31

RTIL

THRESHOLD

SFL

30 29 21 20 5 4 3 2 1

32

MODE 5

31

RTIL

THRESHOLD

SFL

30 29 21 20 5 4 3 2 1

32

MODE 6

Value Creating Partner

YOUYANG 27

Specification & Operation Manual SFL & RTIL

31

RTIL

THRESHOLD

SFL

30 29 21 20 5 4 3 2 1

32

MODE 7

■ : SFL Light on

□ : SFL Light off

■ : RTIL Light on

□ : RTIL Light off

3-4 RTIL(REIL)

3-4-1Setting RTIL(REIL) configuration

When switch of `RTIL Control` on Indication board of master timer is in position

“ON”, RTIL(1set – 2 EA) works. RTIL is linked with 30th power supply unit and

st

RTIL ( 31st & 32nd) flash at once on 31 cycle.

RTIL

THRESHOLD

32

Picture 2-4

3-4-1 Operation of RTIL(REIL)

Without any SFL, Only RTIL is operated.

Value Creating Partner

YOUYANG 28

Specification & Operation Manual SFL & RTIL

31

RTIL

THRESHOLD

32

■ : REIL Light on

□ : RTIL Light off

4. System function description

4-1 Control signal

SFL system uses control signal with AC and communicates. The signal is composed of

synchronizing signal, order signal and data signal

Signals is classified according to the number of AC signal by SCR

Value Creating Partner

YOUYANG 29

Specification & Operation Manual SFL & RTIL

4-1-1 Synchronizing signal

Input Signal

SCR Control SCR 1 SCR 2

Signal

Output Signal

Synchronizing Signal

Detect Signal Of

Power Suppiy Unit

Above picture shows wave of synchronizing signal. Synchronizing signal makes

communication line about Zero Voltage status by preventing supplying power for

communication line through instant short circuit of AC 36V power.

1) On supplying AC 36V 60Hz – period of short circuit: 16.666ms

2) On supplying AC 36V 50Hz– period of short circuit: 20ms

4-1-2 Order signal

Input Signal

SCR 1 SCR 2 SCR 1 SCR 2

SCR Control

Signal

Output Signal

Communication Signal

Detect Signal Of

Power Suppiy Unit

Above picture shows wave of order signal. Order signal makes communication

line

about Zero Voltage status by preventing supplying power for communication line

through instant short circuit of AC 36V power.

1) On supplying AC 36V 60Hz– period of short circuit: 33.333ms

2) On supplying AC 36V 50Hz– period of short circuit: 40ms

Value Creating Partner

YOUYANG 30

Specification & Operation Manual SFL & RTIL

4-1-3 Data signal

1 Cycle

Data 1

Detect Signal Of

Power Suppiy Unit

2 Cycle

Data 2

Detect Signal Of

Power Suppiy Unit

3 Cycle

Data 3

Detect Signal Of

Power Suppiy Unit

4 Cycle

Data 4

Detect Signal Of

Power Suppiy Unit

Above picture shows wave of data signal. Data signal makes communication line

about Zero Voltage status by preventing supplying power for communication line

through instant short circuit of AC 36V power.

2) On supplying AC 36V 60Hz– period of short circuit

- 1 cycle : 16.666ms

- 2 cycle : 33.333ms

- 3 cycle : 49.999ms

- 4 cycle : 66.666ms

3) On supplying AC 36V 50Hz– period of short circuit

- 1 cycle : 20ms

- 2 cycle : 40ms

- 3 cycle : 60ms

- 4 cycle: 80ms

4-2 Communication signal

Communication signal is composed of 4 frames (system configuration, flash

intensity, RTIL On/Off and number of flashing per second).

4-2-1 System configuration information transmission

System configuration information is transmitted. One cycle is broken so fixed

configuration becomes “0”.

Value Creating Partner

YOUYANG 31

Specification & Operation Manual SFL & RTIL

Order Data

Detect Signal Of

Power Suppiy Unit

1) In case of supplying AC 36V 50Hz– period of short circuit

- 1 cycle : 20ms -> fixed 0 configuration. SFL 1 ~ 30 OFF

- 2 cycle : 40ms-> fixed 5 configuration. SFL 6 ~ 30 OFF

- 3 cycle : 60ms-> fixed 21 configuration. SFL 22 ~ 30 OFF

- 4 cycle: 80ms-> fixed 30 configuration. SFL 1 ~ 30 ON

4-2-2 RTIL ON/OFF control information transmission

RTIL ON/OFF control information is transmitted. One cycle is broken and RTIL

ON/OFF order is determined according to cycle after transmission of order.

Communication

Signal

Communication Signal Data

Detect Signal Of

Power Suppiy Unit

1) In case of supplying AC 36V 50Hz– period of short circuit

- 1 cycle : 20ms -> RTIL OFF

- 2 cycle : 40ms-> RTIL ON

-

4-2-3 Flash intensity transmission

Flash intensity information is transmitted.

Communication

Signal

Communication Signal Data

Detect Signal Of

Power Suppiy Unit

Above picture shows medium intensity after two cycles are broken.

1) In case of supplying AC 36V 50Hz– period of short circuit

- 1 cycle : 20ms -> transmission of Low intensity information

Value Creating Partner

YOUYANG 32

Specification & Operation Manual SFL & RTIL

- 2 cycle : 40ms-> transmission of Medium intensity information

- 3 cycle : 80ms-> transmission of High intensity information

4-2-4 flashing sequence of 1 or 2 per second of SFL & RTIL information transmission

A flashing sequence of 1 or 2 per second of SFL & RTIL information is

transmitted.

Communication

Signal

Communication Signal Data

Detect Signal Of

Power Suppiy Unit

Above picture shows a flash sequence of 1 per second after one cycle is broken.

A flashing sequence of 1 or 2 per second is determined according to cycle after

transmission of order.

1) In case of supplying AC 36V 50Hz– period of short circuit

- 1 cycle : 20ms -> A flashing sequence of 1 per second

- 1 cycle : 20ms -> A flashing sequence of 2 per second

4-3 Flash Intensity

Indication board of Master time sets flash intensity by mode switch. On each position

of Local , Remote and Communication, setting of flash intensity is possible.

Value Creating Partner

YOUYANG 33

Specification & Operation Manual SFL & RTIL

LOW -> Discharging lamp by using one condenser in power supply unit

MIDIUM -> Discharging lamp by using two condensers in power supply unit

Value Creating Partner

YOUYANG 34

Specification & Operation Manual SFL & RTIL

HIGH -> Discharging lamp by using three condensers in power supply unit

4-4 Flash Sequence

SFL + RTIL are operated from 1 to 32 in sequence.

31

RTIL

THRESHOLD

SFL

30 29 28 6 5 4 3 2 1

32

Direction of sequence flashing

(From farthest light from Runway)

Number of flashing: 1 or 2 per second

1 ~ 30 : SFL / 31 ~ 32: RTIL

RTIL (2 light) flashes at once.

* Flashing sequence two per second

31 X 20ms+ 20ms(Synchronized signal) + 20ms(Starting signal) = 680ms

Value Creating Partner

YOUYANG 35

Specification & Operation Manual SFL & RTIL

4-5 RTIL(REIL)

The address of RTIL is 31 & 32. In case one of two RTIL lights is out or order and turns

off, master timer transmits OFF order and makes the other RTIL OFF also.

Two lights of RTIL flash at once but defective information of RTIL- two lights( address

– 31 & 32) is transmitted respectively.

When a light more than number 8 is detected as ON signal, RTIL transmits OFF signal.

Setting of 1 or 2 flash per second of RTIL & SFL is possible.

Cycle 30 31 32

31.32Simultaneous

Flashing

Flashing Light

Lamp status 31 32

Output Of

Information

4-6 Detection of defective SFL

Power supply unit measures residual voltage of low intensity condenser. In case voltage

more than standard voltage does not remain after trigger signal generates, Power supply

unit determine that discharge by flash tube happened and transmits ON information of

light to master timer.

Master timer shows status of power supply unit by making LED of Lamp Status on

Indication board OFF after receipt of ON information of light. When power supply unit is

out of order, ON signal of light is not detected so OFF of light is shown.

Recharge Voltate Of Condenser

Stundard Voltage

Detected By

Condenser

Detection Of Flashing Detection Of Flashing

Value Creating Partner

YOUYANG 36

Specification & Operation Manual SFL & RTIL

4-7 Heating

Power supply unit operate ON/OFF of heating using contact of controllers of

temperature and humidity.

Heating works when temperature is less than setting value by temperature controller

which is adjustable between +15°C ~+30°C.

Heating works when humidity is more than setting value by humidity controller which

is adjustable between +30% ~ +80%.

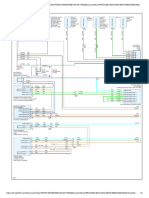

5. Composition of Communication

On remote mode, between Control tower and master timer and between Master timer

and power supply, the communication uses AC power so when communication cable is

connected, a worker need to pay attention to polarity.

5.1 Polarity connection of supply power

0V cable should be connected at 0V end and the each power should be divided by

resistive tube on final work.

5.2 Communication cable connection between Master timer and Junction box

1) Connection quantity: Same quantity as number of power supply unit on Parallel

connection

2) Input – power 4 cables, communication – 2 cables & Lamp fault -2 cables

3) Output (2 parts) – Power supply unit and next junction box

Value Creating Partner

YOUYANG 37

Specification & Operation Manual SFL & RTIL

MASTER TIMER JUNCTION BOX

REAR PANEL1

REAR PANEL2

5.3 Connection between Power supply timer and Junction box

1) Pay attention to polarity

2) Two terminal blocks (2P)

Bigger one – for power

Small one - for communication and detection of lamp fault

POWER SUPPLY UNIT JUNCTION BOX

Value Creating Partner

YOUYANG 38

Specification & Operation Manual SFL & RTIL

5.3 Connection between Master time and Remote

The connection is done between remote control and master time. The master timer

receive SFL On/Off, intensity and RTIL On/Off communication signal on AC120V

MASTER TIEMR

REMOTE REAR PANEL2

6. System problem and solution

6.1 MASTER TIMER

Symptom Expected cause Solution

Check of Front Panel input

MAIN power

power

Fuse F1, F2, F3 Replacement

Problem on supplying Transformer for supplying

Replacement

power power

Power supply part Replacement

Bad connection of SUB-RACK

Check connection situation

Power switch

No working on mode Bad connection between

Check connection situation

change and intensity power supply part and switch

change DC power Check DC 12V

Power Check AC 220V

LED Lamp OFF on Fron

Check Assembly and

panel Connection of PCB

connection situation

Check Assembly and

No working master timer Connection of PCB

connection situation

Value Creating Partner

YOUYANG 39

Specification & Operation Manual SFL & RTIL

6.2 POWER SUPPLY UNIT

Symptom Expected cause Solution

Power Check AC 360V

Problem Fuse Check Fuse

on supplying INTER-LOCK switch Replacement

power Check ouput voltage of T1

Defective T1(Transformer)

(AC9V, AC15V)

Check LAMP FAULT LED of Control part.

Defective lamp

Replacement

No flashing

Bad connection Check Connector.

Defective trigger COIL Replacement of PCB(SFL-4089)

Cable between control part and

Check cable connection.

power supply part

No control. Replacement CPU(SFL-4087 internal

Defective CPU

CPU)

Defective recharging resistance Replacement(R1,R2)

No

recharging. Defective recharging circuit Replacement of power BOARD(SFL-4088)

6.3 SYTEM connection

Symptom Expected cause Solution

Check ACTION LED of control

Bad connection of communication

part

cable

Check communication line

Check voltage of both

No communication Problem on communication ends(AC36V)

voltage Replacement of Drive PCB and

TRANSFORMER of control part.

Opposite connection of

Check `ON` time of ACTION LED

Communication cable

Bad connection of Lamp fault

Check connection status,

detection cable

No detection of lamp

Check the power (AC120V)

fault

Problem of power Replacement of Drive PCB and

TRANSFORMER of control part

Value Creating Partner

YOUYANG 40

Specification & Operation Manual SFL & RTIL

7. Technical Data

System capacity

Supply Voltage: 110V, 220V, 240V

Frequency: 50Hz/60Hz

Output voltage: 220V, 360V

Phase: Single

Operation capacity: 3KW (on 23 lights operation, heater operation)

Designed capacity: 6KW

Power consumption on working high intensity: 45W

Heater: 80W

Operation temperature: 0°C ~+55°C

Relative humidity: 99% (no condensation)

5-1 MAIN TRANSFORMER

Supply Voltage: 110V, 220V, 240V

Frequency: 50Hz/60Hz

Output voltage: 220V, 360V

Operation temperature: -0°C ~+55°C

Relative humidity: 99% (no condensation)

5-2 Master timer

Supply Voltage: 110V, 220V, 240V

Frequency: 50Hz/60Hz

Control voltage of Communication: AC36V

Control voltage of Remote: AC120V

Internal used voltage: DC24V, DC+ - 12V, DC5V

Operation temperature: -0°C ~+55°C

Relative humidity: 99% (no condensation)

5-3 Power supply unit

Supply Voltage: AC220V, AC360V

Internal used voltage: DC12V, DC5V

Control voltage of controllers of temperature and humidity

: AC220V

Supply voltage of heater: AC220V

Power consumption of heating: 80W

5-4 Flash head

Value Creating Partner

YOUYANG 41

Specification & Operation Manual SFL & RTIL

Input power: DC500V

Trigger voltage: 10,000V

Reflector & body: aluminum

Value Creating Partner

YOUYANG 42

You might also like

- AVR R450 4531k - en PDFDocument24 pagesAVR R450 4531k - en PDFroy fadliNo ratings yet

- Leroy Somer - Voltage Regulator R450 Installation and MaintenanceDocument20 pagesLeroy Somer - Voltage Regulator R450 Installation and MaintenanceMohamed Essam75% (4)

- Autopilot (Pt500) : Block Diagram: Steering ProcedureDocument5 pagesAutopilot (Pt500) : Block Diagram: Steering ProcedureAboody AL-ghamdyNo ratings yet

- Fms Mcdu DisplayDocument1 pageFms Mcdu DisplayAlp Erdem100% (1)

- 2011 D6CA (Euro-3) Engine Control (ETC) System Schematic DiagramsDocument1 page2011 D6CA (Euro-3) Engine Control (ETC) System Schematic DiagramsSamuel Yogui LaraNo ratings yet

- LG 32LF630V 32LF630V-ZA Series Service ManualDocument97 pagesLG 32LF630V 32LF630V-ZA Series Service Manualzepus89% (9)

- Wiring Diagram: DC GeneratorDocument1 pageWiring Diagram: DC GeneratorAndi Ka100% (1)

- FR A 500 ManualDocument242 pagesFR A 500 ManualkothuwonNo ratings yet

- Installation and Maintenance: 3 Ph. SensingDocument24 pagesInstallation and Maintenance: 3 Ph. SensingfararNo ratings yet

- Leroy SomerDocument20 pagesLeroy SomerRobson Souza100% (1)

- A - C Control System - Autoo PDFDocument4 pagesA - C Control System - Autoo PDFANH LÊNo ratings yet

- Far2xx7 Operators Quick GuideDocument4 pagesFar2xx7 Operators Quick GuideManta HaticeNo ratings yet

- Servotough - 1800 - ManualDocument27 pagesServotough - 1800 - ManualAlan RochaNo ratings yet

- Quick Start Manual: Servotough Oxy 1800Document27 pagesQuick Start Manual: Servotough Oxy 1800Ashish DharjiyaNo ratings yet

- Installation and Maintenance: 3 Ph. SensingDocument24 pagesInstallation and Maintenance: 3 Ph. SensingRivai GoBlogNo ratings yet

- 25 X 45 TruffDocument1 page25 X 45 Truffsudhansu8beheraNo ratings yet

- Galaxy Owners Manual DX2547Document12 pagesGalaxy Owners Manual DX2547bellscbNo ratings yet

- LMCPDocument1 pageLMCPhr KingsViewNo ratings yet

- Tableros de Control Ignicion Uv Tratador # 2 - Bat. 202 - Lote IiiDocument1 pageTableros de Control Ignicion Uv Tratador # 2 - Bat. 202 - Lote Iiidiego 10 xD OMG 2 CANAL oviedoNo ratings yet

- Bomba Diafragma1 PDFDocument24 pagesBomba Diafragma1 PDFMeriem ZAGRIRINo ratings yet

- Reguladores: Instalação e ManutençãoDocument20 pagesReguladores: Instalação e ManutençãoRicardo Nunes Pereira JuniorNo ratings yet

- Mitsubishi Manuals A 500Document257 pagesMitsubishi Manuals A 500Amador AguilaNo ratings yet

- A4955 DatasheetDocument11 pagesA4955 DatasheetShah ZaibNo ratings yet

- FAN 7311 - FairchildDocument13 pagesFAN 7311 - FairchildStevenNo ratings yet

- SBBR - Rnav Kogno 2a - Luvla 2a Rwy 11l 11r - Star - 20231005Document1 pageSBBR - Rnav Kogno 2a - Luvla 2a Rwy 11l 11r - Star - 20231005caiommalveiroNo ratings yet

- General Description: Digital Temperature ControllerDocument6 pagesGeneral Description: Digital Temperature ControllerMohamed MaherNo ratings yet

- Installation and Maintenance: 380V 220 110 0V E-E+ Z2 X1 Z1 X2Document24 pagesInstallation and Maintenance: 380V 220 110 0V E-E+ Z2 X1 Z1 X23efooNo ratings yet

- 100 Ma Low-Dropout Voltage Regulator: Features General DescriptionDocument30 pages100 Ma Low-Dropout Voltage Regulator: Features General Descriptionkishore_bulli6666No ratings yet

- Ka 3511Document28 pagesKa 3511analias100% (1)

- Avr 450 PDFDocument24 pagesAvr 450 PDFEdgar MartinezNo ratings yet

- en - E2 Control Panel Technical ManualDocument16 pagesen - E2 Control Panel Technical ManualChrisanto MangubatNo ratings yet

- SLM600-800-RevA - Manual 25500290 A1Document2 pagesSLM600-800-RevA - Manual 25500290 A1Alexis Rodrigo Tapia EstrellaNo ratings yet

- Neptune Ducati Rego Power Factor Controller ManualDocument15 pagesNeptune Ducati Rego Power Factor Controller ManualKu Bô0% (2)

- Clock and Lighter 2013 Kia SoulDocument1 pageClock and Lighter 2013 Kia SoulTed ThompsonNo ratings yet

- Installation and Maintenance: 380V 220 110 0V E-E+ Z2 X1 Z1 X2Document24 pagesInstallation and Maintenance: 380V 220 110 0V E-E+ Z2 X1 Z1 X2RawingNo ratings yet

- A N 1 2 0 E 0 4 A N 2 2 0 E 0 4: Field Programmable Analog Arrays - User ManualDocument40 pagesA N 1 2 0 E 0 4 A N 2 2 0 E 0 4: Field Programmable Analog Arrays - User ManualspotNo ratings yet

- JVA Electric FencingDocument8 pagesJVA Electric FencingJorge JimenezNo ratings yet

- 1 STFLRDocument1 page1 STFLRBiancaVillenoNo ratings yet

- EN - Ditec E1A Control Panel Technical ManualDocument20 pagesEN - Ditec E1A Control Panel Technical ManualDmitriiȘtirbuNo ratings yet

- Nu-Pulse, Half-Bridge and Push-Pull CCFL Inverter ControllerDocument12 pagesNu-Pulse, Half-Bridge and Push-Pull CCFL Inverter ControllerRicardo PiovanoNo ratings yet

- Etacs hd65 1Document1 pageEtacs hd65 1Alejandro Angel CárdenasNo ratings yet

- SBRJ - RNP Evkox 1f Rwy 02r 20l Ar - Iac - 20231228Document1 pageSBRJ - RNP Evkox 1f Rwy 02r 20l Ar - Iac - 20231228Peter RamosNo ratings yet

- 2017 D 2.0 TCI-R D 2.0 TCI-R Schematic Diagrams Engine Electrical System Engine Control System Schematic DiagramsDocument1 page2017 D 2.0 TCI-R D 2.0 TCI-R Schematic Diagrams Engine Electrical System Engine Control System Schematic Diagramslyanna120168No ratings yet

- Low Power Pulse Width Modulator: Description FeaturesDocument12 pagesLow Power Pulse Width Modulator: Description FeaturespatrykNo ratings yet

- Tps 2554Document25 pagesTps 2554cuong pham vuNo ratings yet

- LD 07myDocument236 pagesLD 07myصمدیNo ratings yet

- 2010 Picanto G 1.0 SohcDocument8 pages2010 Picanto G 1.0 SohcPaul GudiñoNo ratings yet

- Disabled Systems: Customer Name Reference Product Series NoDocument17 pagesDisabled Systems: Customer Name Reference Product Series NoАлександр КачеишвилиNo ratings yet

- Sơ Đ Shunt Strip + Fire AlarmDocument2 pagesSơ Đ Shunt Strip + Fire AlarmBuồnNgủNo ratings yet

- SD313 24 Engine Control System (D4BH: 4D56 TCI 2.5L) (4) : F5 10A F13 10A F20 10ADocument1 pageSD313 24 Engine Control System (D4BH: 4D56 TCI 2.5L) (4) : F5 10A F13 10A F20 10AhaiderNo ratings yet

- Captiva 15 CanDocument2 pagesCaptiva 15 CanrodrigoNo ratings yet

- Critical Conduction Mode PFC Controller: Features DescriptionDocument20 pagesCritical Conduction Mode PFC Controller: Features DescriptiondavidNo ratings yet

- Advanced Transition-Mode PFC Controller: FeaturesDocument39 pagesAdvanced Transition-Mode PFC Controller: FeaturesJohan GuanchezNo ratings yet

- XTR 111Document31 pagesXTR 111api-3725139No ratings yet

- FAN7529 (IC601) - Datasheet IIDocument20 pagesFAN7529 (IC601) - Datasheet IIJose BenavidesNo ratings yet

- Automotive Horn System CompleteDocument6 pagesAutomotive Horn System CompleteTaha Kassala100% (1)

- Conventional Fire Alarm Annunciator: Description FeaturesDocument2 pagesConventional Fire Alarm Annunciator: Description FeaturesGUDANG BERITA KITANo ratings yet

- Eil Job No.: A545: OwnerDocument35 pagesEil Job No.: A545: OwnerSandip SurNo ratings yet

- User'S Guide Operating & Maintenance: Constant Current RegulatorDocument70 pagesUser'S Guide Operating & Maintenance: Constant Current RegulatorJavier Eduardo Alzate BogotaNo ratings yet

- Tgs-Led: Taxiway Guidance Sign: Technical Specification & Operation ManualDocument26 pagesTgs-Led: Taxiway Guidance Sign: Technical Specification & Operation ManualJavier Eduardo Alzate BogotaNo ratings yet

- Faa L 824 Type C Sheathed 5kvDocument1 pageFaa L 824 Type C Sheathed 5kvJavier Eduardo Alzate BogotaNo ratings yet

- Youyang Airport Lighting Equipment Inc #738-2 Kwanyang-Dong Dongan-Ku, Anyang-Si Kyunggi-Do, KoreaDocument1 pageYouyang Airport Lighting Equipment Inc #738-2 Kwanyang-Dong Dongan-Ku, Anyang-Si Kyunggi-Do, KoreaJavier Eduardo Alzate BogotaNo ratings yet

- No Label: October 9th 2021 Andy Sole Wingframe v1.5.4Document4 pagesNo Label: October 9th 2021 Andy Sole Wingframe v1.5.4Javier Eduardo Alzate BogotaNo ratings yet

- User'S Manual Operating & Maintenance: RGL-L: Runway Guard Light (Led)Document21 pagesUser'S Manual Operating & Maintenance: RGL-L: Runway Guard Light (Led)Javier Eduardo Alzate BogotaNo ratings yet

- Specification and Maintenance Manual: Sequence Flashing Lights (SFL)Document13 pagesSpecification and Maintenance Manual: Sequence Flashing Lights (SFL)Javier Eduardo Alzate BogotaNo ratings yet

- X130 SVC Eng 091225Document92 pagesX130 SVC Eng 091225oiramlopesNo ratings yet

- K Factor PDFDocument2 pagesK Factor PDFAndrésLeónTovarNo ratings yet

- A 1.5V 1.5GHz CMOS LNADocument16 pagesA 1.5V 1.5GHz CMOS LNAptt3iNo ratings yet

- 0.3-3.0 GHZ High Dynamic Range Amplifier: Features Functional Block Diagram Cmm6004-ScDocument10 pages0.3-3.0 GHZ High Dynamic Range Amplifier: Features Functional Block Diagram Cmm6004-Scgonzalo2205No ratings yet

- Manufacturing Automation Using PLCsDocument19 pagesManufacturing Automation Using PLCssbpathiNo ratings yet

- IEEE 802.11g (54Mbps) Mini PCI Wireless LAN Module - D711035DDocument7 pagesIEEE 802.11g (54Mbps) Mini PCI Wireless LAN Module - D711035DEmil BlumeNo ratings yet

- TMS320F28021PTT PDFDocument129 pagesTMS320F28021PTT PDFChakib KaNo ratings yet

- T2600Document2 pagesT2600kylegazeNo ratings yet

- 7915Document24 pages7915Balkrushna KankotiyaNo ratings yet

- Fedral SignalDocument55 pagesFedral SignalMaahiNo ratings yet

- Tutorial Sheet Analog ElectronicsDocument7 pagesTutorial Sheet Analog ElectronicsPraney KalraNo ratings yet

- EECE 301 Signals & Systems: Prof. Mark FowlerDocument12 pagesEECE 301 Signals & Systems: Prof. Mark FowlerahmdNo ratings yet

- Sonora Design 5SATPL Power Inserter Polarity LockerDocument5 pagesSonora Design 5SATPL Power Inserter Polarity LockerDavid WardNo ratings yet

- Infinitely Expandable MPDP: User's ManualDocument34 pagesInfinitely Expandable MPDP: User's ManualFrancisco Rodriguez MartinezNo ratings yet

- On EIRP Control in Downlink Precoding For Massive MIMO ArraysDocument5 pagesOn EIRP Control in Downlink Precoding For Massive MIMO ArraysdrphraoNo ratings yet

- M.Abdullah FA19 BEE 110 ECA 2 LAb REPORT 8 PDFDocument6 pagesM.Abdullah FA19 BEE 110 ECA 2 LAb REPORT 8 PDFAtyia JavedNo ratings yet

- Fundamental of Electrical Power Systems (Ee 270) : Chapter 4 (II) Basic PrinciplesDocument39 pagesFundamental of Electrical Power Systems (Ee 270) : Chapter 4 (II) Basic PrinciplesJohn PetersNo ratings yet

- Schneider-Electronic Pressure SensorsDocument80 pagesSchneider-Electronic Pressure SensorsGirish OniyilNo ratings yet

- EL 01190604701000-A SBMXGM120235 Electrical BlowerDocument673 pagesEL 01190604701000-A SBMXGM120235 Electrical BlowerAli TradNo ratings yet

- K13-03-04 Digital Tehniques / Electronics Intrument System - Nama: NDP: Le 2: Recognize The Basic Computer StructureDocument12 pagesK13-03-04 Digital Tehniques / Electronics Intrument System - Nama: NDP: Le 2: Recognize The Basic Computer StructureGanesh Ruban AnathanNo ratings yet

- 74HC4851 74HCT4851: 1. General DescriptionDocument20 pages74HC4851 74HCT4851: 1. General DescriptionYousaf KhanNo ratings yet

- Power Electronics TrainersDocument84 pagesPower Electronics TrainersRama PrasadNo ratings yet

- Uk048e New Range LediDocument16 pagesUk048e New Range LediSayed HashemNo ratings yet

- Omron R88DKN01HECTDocument12 pagesOmron R88DKN01HECTSlah KhadhriNo ratings yet

- Lect # 06, Floyd, CH # 06 - Adder, Subtractor, Multiplier, Comparator PDFDocument35 pagesLect # 06, Floyd, CH # 06 - Adder, Subtractor, Multiplier, Comparator PDFMuhammad Adnan KhalidNo ratings yet

- Project 1Document5 pagesProject 1Luis SantosNo ratings yet

- Module 7 Operational AmplifierDocument10 pagesModule 7 Operational Amplifierjohnlester maggayNo ratings yet

- Release Notes - READDocument3 pagesRelease Notes - READHari KurniadiNo ratings yet

- Cad 1133 Powersupply FinalreportDocument47 pagesCad 1133 Powersupply Finalreportapi-300000636No ratings yet