Professional Documents

Culture Documents

Laticrete 226 Thick Bed Adhesive: Technical Data Sheet

Uploaded by

YASHICA VAITTIANATHAN0 ratings0% found this document useful (0 votes)

117 views3 pagesOriginal Title

LATICRETE-226-TDS-NF

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

117 views3 pagesLaticrete 226 Thick Bed Adhesive: Technical Data Sheet

Uploaded by

YASHICA VAITTIANATHANCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

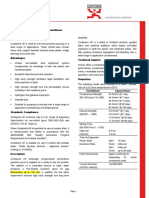

Technical Data Sheet

LATICRETE® 226

Thick Bed Adhesive

Factory prepared cementitious powder

designed for use with LATICRETE® 3642 Latex

Concentrate to produce high strength, latex

fortified Thick bed adhesive, screed mortar that

meets international standards.

Substrates

• Concrete & Concrete Masonry

• VDF / Tremix Concrete

Features / Benefits • Cement Mortar Beds

• Cement Plaster

• Two component, just add water • Wood floor**

• High strength, polymer fortified • Brick Masonry

• Easy to use • Cement Backer Board**

• Bonds to various substrates • Cement Terrazzo

• Exceeds ANSI A118.7 requirements • Calcium Silicate Board**

• Gypsum Wallboard**

• Complieswith EN 13813 with a CT-

C20F10B1.5 classification. **Consult the backer board manufacturer's data

sheet for the specific recommendations and load

• Water and shock resistant.

bearing capacity of specific board intended for

use.

Application Certifications

Designed especially for interior and exterior floor

EN: 13813

and wall installations of all types of ceramic tile,

vitreous, semi-vitreous tile, precast terrazzo and

natural stones over concrete and on a variety of

substrates. Good underwater shear bond allows this

product to be used for wet areas like swimming

pools, sauna, water bodies and wash rooms.

A118.7

TECHNICAL DATA

Performance Properties: Working Properties at 70° F (21° C)

LATICRETE® 226, Thick Bed Adhesive mixed with Laticrete LATICRETE®226 thick bed Adhesive mixed Laticrete 3642

3642 diluted with Water Latex liquid diluted with Water.

PROPERTY TYPICAL VALUES

Applicable Standards: Recommended Ratio of 1 :3 or 1: 4

ANSI A118.7; EN 13813

L-3642 : Water

ANSI Data Dry Mortar Density 1950 – 2100 kg/m3

Property : Test Requirement Typical Values Pot Life 1 Hour

method Time for Foot Traffic ≥ 24 Hours

Compressive 20 N/mm2 22-25 N/mm2 Time for Heavy Traffic ≥ 72 Hours

Strength - ASTM

C 109 Specifications subject to change without notification.

Flexural Strength 7 N/mm2 9.5-11 N/mm2 Results shown are typical but reflect test procedures used.

- ASTM C 580 Actual field performance will depend on installation

Tensile Strength - 3.50 3.75-4.5 N/mm2 methods and site conditions.

ASTM C 307 N/mm2

The adhesive mortar conforms to ANSI A118.7

INSTALLATION

EN Data Surface Preparation:

Property: Test Requirement Typical Values

Method All surfaces should be between 40oF(4oC) and

Compressive 20 N/mm2 21-24 N/mm2 90oF(32oC) and structurally sound, clean and free of all

Strength - EN dirt, oil, grease, loose peeling paint, concrete sealers or

13892-2 curing compounds.

Flexural Strength 10 N/mm2 10 – 12 N/mm2 Dry, dusty concrete slabs or masonry should be

- EN 13892-2 dampened and excess water swept off. Installation may

Bond Strength - 1.50 1.50 – 2.00 N/mm2 be made on a damp surface. All slabs must be plumb

EN 13892-8 N/mm2 and true to within ¼”(6mm) in 10 ft(3m).

BRE Drop 2-3mm 2-3 mm

Hammer Test – Expansion joints shall be provided through the tile work

from all construction or expansion joints in the substrate.

BS:8204 Follow ANSI Specification AN-3.8

“Requirements for Expansion Joints” or TCA Detail EJ171

The adhesive mortar conforms to EN13813 as CT-

C20F10B1.5 “Expansion Joints”. Do not cover expansion joints with

mortar.

Glass Mesh Mortar Unit: follow TCA installation detail

Packaging: W244. In temperatures over 95°F (35°C).

50 kg bags Mixing:

Colour: Stir LATICRETE® 3642 admixture thoroughly before use.

Grey and white Dilute the admixture as required with water.

Coverage: Use approx. 50kg of Laticrete 226 thick bed adhesive

Coverage will be based on following mix design. mortar with Laticrete 3642 & potable water as per

coverage table given above. Mix by hand or with a slow

Thickness L226 L3642 Water Coverage speed mixer to semi dry consistency.

12 mm 50 kg 1.25 liter 3.75 liter 25 Sft

25 mm 50 kg 1.25 liter 3.75 liter 12 Sft

35 mm 50 kg 1.0 liter 4.0 liter 8 Sft

50 mm 50 kg 0.83 liter 4.17 liter 5 Sft

Coverage will vary depending on flatness and evenness of substrate

MYKL-TDS- L 226 – REV 01; 06/18

HOT & COLD WEATHER TILING:

APPLICATION: * Please refer technical document on Hot & Cold weather

tiling

a) Thick bed adhesive Grouting:

Before placing mortar, apply a slurry bond coat made

from Laticrete® 3642 latex concentrate pre-diluted with Grout installation shall be commenced after a minimum of

water 1:1 and mix with cement & sand 1:1.While the 24 hours curing time at 70°F (21° C). Grout with MYK

slurry bond coat is wet spread mortar & compact well. LATICRETE® Sanded or Unsanded Grout mixed with MYK

For placing tiles apply another slurry bond coat over the LATICRETE® 1776 Grout Admix Plus.

mortar bed & install tiles. Laticrete SBA 20 mixed with

approximately 8 Liters of water is best for installation of For maximum stain resistance of Internal spacer joints

tiles. The tiles shall be placed & beaten in the mortar applications, use SpectraLOCK® Pro Premium Grout OR

while the slurry bond coat is wet and sticky. LATAPOXY® SP-100 Stainfree Grout.

For maximum stain resistance of External spacer joints

b) Floor Screeds

Before placing mortar, apply bonding slurry of applications, use MYK Laticrete Stellar Grout, which can

LATICRETE® 3642 pre-diluted with water 1:1 and accommodate movements and is UV resistant.

cement: sand 1:1 to the mortar.

While the bonding slurry is wet spread the mortar and

compact well. MYK Laticrete India Pvt Ltd warrants that LATICRETE®

Follow the standard rules of creating the movement joints 226 Thick Bed Mortar is free from manufacturing defects

for Adhered screeds, Floating screeds and the thicknesses and will not break down, deteriorate or under normal

of respective screeds as per the international standards. usage for a period of one (1) year from manufacturing of

For better performance of screeds, it is also the product subject to the terms and conditions stated in

recommended to use wire mesh as specified by the disintegrate LATICRETE® Product Warranty.

engineer at site.

c) Plaster CUSTOMER CARE

Plumb, square and true wall with applications of mortar.

MYK LATICRETE India Pvt Ltd.

Level, fill and patch block with site mix mortar or

LATICRETE® 226 Thick Bed Mortar Mix gauged with pre- 8-2-703/A, Fourth Floor, Leela Gopal Towers,

diluted LATICRETE® 3642. Road No-12, Banjara Hills, Hyderabad – 500034

Plasters made with LATICRETE® 226 can be applied in

(T.S.) Tel: +91-40-30413100

thicknesses as great as 25 mm without the plaster

slumping. Customer Care: cc@myklaticrete.com

Website: www.myklaticrete.com

Cleaning

Clean tools and tile work with water while mortar is fresh.

NOTE TO THE SPECIFIER AND INSTALLER:

While installing tile/stone on the external walls and floors,

we need to provide the joints by creating spaces between

the tiles/stones and fill them up with MYK LATICRETE®

cement based grout mixed with MYK Laticrete 1776 grout

admix plus or MYK Laticrete Stellar, flexible grout (In the

absence of spacer joints, the surface movements can

push tiles/stones away from the substrate causing de-

bonding of tiles or stones)

The exterior tile / stone installations are provided with

joints (spaces) on the periphery of the area without

allowing the tile / stone to be bound by the peripheral

masonry work or plaster.

MYKL-TDS- L 226 – REV 01; 06/18

You might also like

- L 9237 WaterproofDocument4 pagesL 9237 WaterproofAbdul Raheem SyedNo ratings yet

- Tec 302 HF (UAE) : Highly Fluid Expansive Bedding GroutDocument3 pagesTec 302 HF (UAE) : Highly Fluid Expansive Bedding Groutmanikandan4strlNo ratings yet

- Conbextra HFDocument4 pagesConbextra HFm.elsanee.cubicNo ratings yet

- Laticrete Hydroban Tds NFDocument6 pagesLaticrete Hydroban Tds NFAbdul Raheem SyedNo ratings yet

- Fosroc Conbextra HF precision groutDocument4 pagesFosroc Conbextra HF precision groutThrtThrthNo ratings yet

- Renderoc HF: Constructive SolutionsDocument3 pagesRenderoc HF: Constructive SolutionsAbdul Nazir - 11858 Hawiyah Branch - QCNo ratings yet

- 10 - TDS - Emaco S22 NBDocument3 pages10 - TDS - Emaco S22 NBaahtagoNo ratings yet

- Datasheet File Conbextra - HFDocument4 pagesDatasheet File Conbextra - HFandikaNo ratings yet

- Levelquik® Rs (Rapid Setting) Self Leveling Underlayment: Surface Prep / Tds-108Document5 pagesLevelquik® Rs (Rapid Setting) Self Leveling Underlayment: Surface Prep / Tds-108Alex TronNo ratings yet

- Redgard® Waterproofing and Crack Prevention Membrane / Tds 104Document5 pagesRedgard® Waterproofing and Crack Prevention Membrane / Tds 104DavidNo ratings yet

- TDS 104 Spanish RedGardDocument6 pagesTDS 104 Spanish RedGardgrisselNo ratings yet

- 00 Flowcrete Uk Technical DataDocument2 pages00 Flowcrete Uk Technical DataCAITLIN AndrewNo ratings yet

- Laticrete 335 Multipurpose Adhesive: Technical Data SheetDocument4 pagesLaticrete 335 Multipurpose Adhesive: Technical Data SheetmukeshNo ratings yet

- 12 - TDS - Emaco S42 NTDocument3 pages12 - TDS - Emaco S42 NTaahtagoNo ratings yet

- Laticrete 252 TDSDocument5 pagesLaticrete 252 TDSDilon FernandoNo ratings yet

- Prescribed Screed Technical Data SheetDocument5 pagesPrescribed Screed Technical Data Sheetsales02No ratings yet

- Laticrete 254 TDS NF PDFDocument4 pagesLaticrete 254 TDS NF PDFMohitTripathiNo ratings yet

- TDS Renderoc HF Saudi ArabiaDocument3 pagesTDS Renderoc HF Saudi ArabiaMuhammed KunnappillyNo ratings yet

- AERC8 Ramset-EpconC8 PDSDocument11 pagesAERC8 Ramset-EpconC8 PDSZilong ZhangNo ratings yet

- Laticrete 252 TDS 2 PDFDocument5 pagesLaticrete 252 TDS 2 PDFvikash singh tomarNo ratings yet

- Mondéco Crystal Floor FinishDocument2 pagesMondéco Crystal Floor FinishQuoc AnNo ratings yet

- Aac Block Adhesive: Product DescriptionDocument2 pagesAac Block Adhesive: Product DescriptionmaznahNo ratings yet

- Specifying Ceramic Tile With ANSI and ISO StandardsDocument45 pagesSpecifying Ceramic Tile With ANSI and ISO StandardsAlQuon for U100% (1)

- Ucrete Ud200 AseanDocument2 pagesUcrete Ud200 AseanDoby YuniardiNo ratings yet

- CCRR-0467 Omega DiamondWallDocument17 pagesCCRR-0467 Omega DiamondWallj.saiyathNo ratings yet

- CCW-3751 606939 R2plus Matte Tech Data Sheet 10-7-15 0Document4 pagesCCW-3751 606939 R2plus Matte Tech Data Sheet 10-7-15 0amanraza.canNo ratings yet

- Enershield - HP: Vapor Permeable Air/Water-Resistive Barrier MembraneDocument8 pagesEnershield - HP: Vapor Permeable Air/Water-Resistive Barrier MembranePramod V PatilNo ratings yet

- Skim Coat & Plaster Cementitious WaterproofingDocument2 pagesSkim Coat & Plaster Cementitious WaterproofingginasuhandiniNo ratings yet

- Webercol FlexDocument3 pagesWebercol FlexTauqeer AhmedNo ratings yet

- Sarojini Nagar Under The Guidance of MR Laksham HansdashDocument37 pagesSarojini Nagar Under The Guidance of MR Laksham HansdashShubhanshu MishraNo ratings yet

- Annexure-6 FOSROC - Lokfix & Nitobond Technical DataDocument10 pagesAnnexure-6 FOSROC - Lokfix & Nitobond Technical DatadineshNo ratings yet

- A1-80-2 External Wall Tiling - 1 PDFDocument15 pagesA1-80-2 External Wall Tiling - 1 PDFZYWNo ratings yet

- 3.7.11 PTS E-101sl - 170522 (Web)Document4 pages3.7.11 PTS E-101sl - 170522 (Web)betoaranoNo ratings yet

- L 310TDS 1Document4 pagesL 310TDS 1Chetan MahajanNo ratings yet

- Is 8329 - PPTDocument46 pagesIs 8329 - PPTVignesh NadimuthuNo ratings yet

- QTN For Epoxy and ESD Flooring Dtd.28!2!2012Document9 pagesQTN For Epoxy and ESD Flooring Dtd.28!2!2012dox4printNo ratings yet

- Plant Building - Epoxy PaintDocument2 pagesPlant Building - Epoxy PaintNavaneethan NatarajanNo ratings yet

- Roff NEW CONSTRUCTION TILE ADHESIVE NCA TDS DownloadDocument5 pagesRoff NEW CONSTRUCTION TILE ADHESIVE NCA TDS DownloadprakashnethaNo ratings yet

- Lokfix: Polyester Resin Anchoring GroutDocument3 pagesLokfix: Polyester Resin Anchoring GroutMuneer ahmed100% (1)

- Ucrete MF AsDocument2 pagesUcrete MF AsDoby YuniardiNo ratings yet

- Masteremaco S 422Document3 pagesMasteremaco S 422shahidNo ratings yet

- Sikadur-42 HF PDS PDFDocument4 pagesSikadur-42 HF PDS PDFMiljan MilanovicNo ratings yet

- SS013 - Concrete Wall PanelsDocument55 pagesSS013 - Concrete Wall PanelsfathervmotherNo ratings yet

- Conbextra HF - High Strength Shrinkage Compensated GroutDocument4 pagesConbextra HF - High Strength Shrinkage Compensated Groutabhay_joshi2002No ratings yet

- TDS Renderoc LAXtra India3Document2 pagesTDS Renderoc LAXtra India3ARCHANA GUPTANo ratings yet

- Isocrete K Screed Technical Data SheetDocument2 pagesIsocrete K Screed Technical Data SheetIoan PiuNo ratings yet

- SECTION 09 05 16 Subsurface Preparation For Floor FinishesDocument7 pagesSECTION 09 05 16 Subsurface Preparation For Floor FinishesRima Baz FadousNo ratings yet

- PDF LectureDocument49 pagesPDF LectureRuru YTNo ratings yet

- Tile InstallationDocument28 pagesTile InstallationEmre Dalgic100% (1)

- TDS Renderoc UW India3Document3 pagesTDS Renderoc UW India3ARCHANA GUPTANo ratings yet

- Conbextra atDocument4 pagesConbextra atsathishbe5No ratings yet

- Non-shrink precision groutDocument4 pagesNon-shrink precision groutEngr.Mohammed KhaledNo ratings yet

- Asphaltic Plug Joint - Bridge Repair ManualDocument4 pagesAsphaltic Plug Joint - Bridge Repair ManualJohn Rheynor MayoNo ratings yet

- 18 Vetogrout EG340 - 180321Document2 pages18 Vetogrout EG340 - 180321Maha MuflehNo ratings yet

- Cement Board Exterior Applications Guide: PermabaseDocument8 pagesCement Board Exterior Applications Guide: PermabaseSyarifNo ratings yet

- Epoxy and ESD FlooringDocument4 pagesEpoxy and ESD Flooringdox4printNo ratings yet

- Epoxy Coating Solvent Free TDSDocument3 pagesEpoxy Coating Solvent Free TDSMohamed MagdiNo ratings yet

- MS A02 S 0002 R00 Epoxy Grout FillingDocument55 pagesMS A02 S 0002 R00 Epoxy Grout FillingRabee BataynehNo ratings yet

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- Role of Pesticide Formulations For Sustainable Crop Protection and Environment Management: A ReviewDocument8 pagesRole of Pesticide Formulations For Sustainable Crop Protection and Environment Management: A ReviewYASHICA VAITTIANATHANNo ratings yet

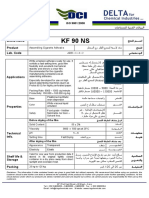

- KF 90 NS DatasheetDocument1 pageKF 90 NS DatasheetYASHICA VAITTIANATHANNo ratings yet

- Craybond 81-10 MSDSDocument4 pagesCraybond 81-10 MSDSYASHICA VAITTIANATHANNo ratings yet

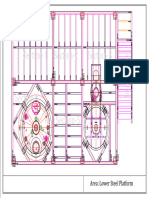

- Steel Platform DrawingDocument11 pagesSteel Platform DrawingYASHICA VAITTIANATHANNo ratings yet

- Cyber Saftey (Yaashica Vaittianathan, 2C)Document15 pagesCyber Saftey (Yaashica Vaittianathan, 2C)YASHICA VAITTIANATHANNo ratings yet

- Sika Anchorfix - 1Document5 pagesSika Anchorfix - 1YASHICA VAITTIANATHANNo ratings yet

- Giliomee Pesticidesin Fuggleand RabieDocument20 pagesGiliomee Pesticidesin Fuggleand RabieZuber JabreNo ratings yet

- MaterialData 196958Document1 pageMaterialData 196958YASHICA VAITTIANATHANNo ratings yet

- b28109788 PDFDocument822 pagesb28109788 PDFSiddhartha KumarNo ratings yet

- Sikagrout - 105Document3 pagesSikagrout - 105YASHICA VAITTIANATHANNo ratings yet

- Sikagrout Cable PtsaDocument3 pagesSikagrout Cable PtsaYASHICA VAITTIANATHANNo ratings yet

- Sikagrout Cable PTDocument3 pagesSikagrout Cable PTYASHICA VAITTIANATHANNo ratings yet

- Sikagrout - 214 SaDocument3 pagesSikagrout - 214 SaYASHICA VAITTIANATHANNo ratings yet

- SikaGrout-212 SA: Cementitious, Shrinkage Compensated GroutDocument3 pagesSikaGrout-212 SA: Cementitious, Shrinkage Compensated GroutYASHICA VAITTIANATHANNo ratings yet

- Sikagrout - 114 AeDocument3 pagesSikagrout - 114 AeYASHICA VAITTIANATHANNo ratings yet

- Sikagrout - 212 AeDocument3 pagesSikagrout - 212 AeYASHICA VAITTIANATHANNo ratings yet

- Sikagrout - 114Document3 pagesSikagrout - 114YASHICA VAITTIANATHANNo ratings yet

- Product Data Sheet: Product Description Technical SpecificationDocument1 pageProduct Data Sheet: Product Description Technical SpecificationYASHICA VAITTIANATHANNo ratings yet

- MSDS Starcem 2K-LIQUIDDocument5 pagesMSDS Starcem 2K-LIQUIDYASHICA VAITTIANATHANNo ratings yet

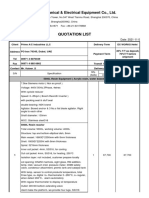

- Quotation List: Shanghai Sower Mechanical & Electrical Equipment Co., LTDDocument5 pagesQuotation List: Shanghai Sower Mechanical & Electrical Equipment Co., LTDYASHICA VAITTIANATHANNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance / Preparation and of The Company / UndertakingDocument4 pagesSafety Data Sheet: 1. Identification of The Substance / Preparation and of The Company / UndertakingYASHICA VAITTIANATHANNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance / Preparation and of The Company / UndertakingDocument4 pagesSafety Data Sheet: 1. Identification of The Substance / Preparation and of The Company / UndertakingYASHICA VAITTIANATHANNo ratings yet

- TDS-Starfix C1-SLDocument3 pagesTDS-Starfix C1-SLYASHICA VAITTIANATHANNo ratings yet

- Safety Data Sheet for HVAC Duct Insulation CoatingDocument4 pagesSafety Data Sheet for HVAC Duct Insulation CoatingYASHICA VAITTIANATHANNo ratings yet

- Marble & Granite Glue: Product Data SheetDocument2 pagesMarble & Granite Glue: Product Data SheetYASHICA VAITTIANATHANNo ratings yet

- Kraton D1101 A - TDSDocument2 pagesKraton D1101 A - TDSYASHICA VAITTIANATHANNo ratings yet

- Starproof Rbe-F Product Data Sheet: Rubberized Bitumen Emulsion CoatingDocument1 pageStarproof Rbe-F Product Data Sheet: Rubberized Bitumen Emulsion CoatingYASHICA VAITTIANATHANNo ratings yet

- Gum Rosin WW - TDS - HinataDocument1 pageGum Rosin WW - TDS - HinataYASHICA VAITTIANATHANNo ratings yet

- OH-POLYMER 107-80k TDSDocument1 pageOH-POLYMER 107-80k TDSYASHICA VAITTIANATHANNo ratings yet

- PDMS 350 TDSDocument1 pagePDMS 350 TDSYASHICA VAITTIANATHANNo ratings yet

- English Form 2 Mod23042022001Document10 pagesEnglish Form 2 Mod23042022001Qiash JontezNo ratings yet

- PN Junction Formation and Barrier PotentialDocument9 pagesPN Junction Formation and Barrier PotentialchristlllNo ratings yet

- Sibling RivalryDocument2 pagesSibling Rivalrycarlokim14No ratings yet

- Thermo Fluids LabDocument23 pagesThermo Fluids LabMuket AgmasNo ratings yet

- Umer Afzal 70073638 Ass# 1Document3 pagesUmer Afzal 70073638 Ass# 1Muhammad Umer AfzalNo ratings yet

- Personal Development Course for Senior High StudentsDocument7 pagesPersonal Development Course for Senior High StudentsLucelle PalarisNo ratings yet

- Viom Networks Becomes The First Indian Telecom Infrastructure Company To Receive ISO 14001 & OHSAS 18001 CertificationDocument2 pagesViom Networks Becomes The First Indian Telecom Infrastructure Company To Receive ISO 14001 & OHSAS 18001 CertificationViom NetworksNo ratings yet

- Comparative Population Growth and Losses Cause by Beetle Trogoderama Granarium (Everts) To Selected Past and Present Wheat GenotypesDocument12 pagesComparative Population Growth and Losses Cause by Beetle Trogoderama Granarium (Everts) To Selected Past and Present Wheat GenotypesInternational Network For Natural SciencesNo ratings yet

- Antibiotic Susceptibility TestDocument5 pagesAntibiotic Susceptibility Testfarhanna8100% (3)

- Cs Varnavrat Land SlideDocument7 pagesCs Varnavrat Land SlideBIJAY KRISHNA DASNo ratings yet

- Fault Tracing: FMI 3: Checking The Sensor CircuitDocument1 pageFault Tracing: FMI 3: Checking The Sensor Circuituser1No ratings yet

- Time and Motion Study of OPDDocument15 pagesTime and Motion Study of OPDsaurabh100% (1)

- Sectors of The Indian EconomyDocument5 pagesSectors of The Indian EconomyhavejsnjNo ratings yet

- Lab Report 2Document5 pagesLab Report 2adrianeNo ratings yet

- SupermanDocument3 pagesSupermanGlen Michael F. WongNo ratings yet

- Worthington LN 71576423-E PDFDocument32 pagesWorthington LN 71576423-E PDFPaul BrimhallNo ratings yet

- Sds d201 Diatro - Lyse-Diff v4.1Document7 pagesSds d201 Diatro - Lyse-Diff v4.1Fauzia BudimanNo ratings yet

- Lab Report P2 A1 - IDocument19 pagesLab Report P2 A1 - Inzirh 01No ratings yet

- English 1000 Most Repeated MCQs by Learning With Rizwan - 083731Document145 pagesEnglish 1000 Most Repeated MCQs by Learning With Rizwan - 083731Athleteboy7No ratings yet

- A Review of Empathy Education in NursingDocument11 pagesA Review of Empathy Education in Nursinglora ardyaNo ratings yet

- Exothermic & Endothermic Reactions 1 QPDocument23 pagesExothermic & Endothermic Reactions 1 QPGoogle map with MING HIN LINo ratings yet

- Dead ZoneDocument10 pagesDead ZoneariannaNo ratings yet

- 2017 Aso Security TrainingDocument60 pages2017 Aso Security TrainingTanzila SiddiquiNo ratings yet

- Adult Assessment: Head To Toe Assessment Is The Baseline and Ongoing Data That Is Needed OnDocument2 pagesAdult Assessment: Head To Toe Assessment Is The Baseline and Ongoing Data That Is Needed OnAldrin NavarroNo ratings yet

- Marketing Environment Analysis and Trends Impacting CompaniesDocument27 pagesMarketing Environment Analysis and Trends Impacting CompaniesSamoyed KalraNo ratings yet

- Electrical Isolation Work PermitDocument2 pagesElectrical Isolation Work PermitGreg GenoveNo ratings yet

- NURS 366 Exam 1 Study Guide and RubricDocument7 pagesNURS 366 Exam 1 Study Guide and RubriccmpNo ratings yet

- Survitec Mooring Ropes BrochureDocument20 pagesSurvitec Mooring Ropes Brochurearifsarwo_wNo ratings yet

- Transformer Protection Techniques for Fault DetectionDocument32 pagesTransformer Protection Techniques for Fault DetectionshashankaumNo ratings yet

- HANDOUT - Cell Transport Review WorksheetDocument4 pagesHANDOUT - Cell Transport Review WorksheetDenis Martinez100% (1)