Professional Documents

Culture Documents

Tank Painting Specifications

Uploaded by

Khyle Laurenz DuroCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tank Painting Specifications

Uploaded by

Khyle Laurenz DuroCopyright:

Available Formats

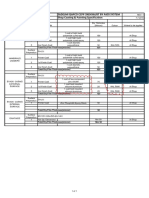

Tank Painting Specifications:

Southern PP

Service Location Primer DFT Intermidiate DFT Final DFT Total Min. DFT

Bottom Plate Underside

Coal Tar Epoxy 150 -- -- Coal Tar Epoxy 150 300

apply Epoxy

apply Epoxy Resin Epoxy resin forth

Fibreglass Reinforced Resin on primed

on primed surface+ coat 250micron to

Epoxy for bottom plate Eposy resin+680 surface+ one

one layer of make min final

and internal shell where 500 to 625 grams woven 750-875 layer of 750-875

450g/m2 fibre DFT 2125. Apply

minor corrosion roving 450g/m2 fibre

glass mat on wet gel coat 300-350

occurred glass mat on

resin micron on top

wet resin

High Build

Diesel Surface Tolerant Surface Tolerant

Surface

External (Coastal) High Build Mastic 120 Epoxy 120 100 250

Tolerant

Aluminium Aluminium

Polyurathane

Surface Tolerant

Polyamide Epoxy Aluminium

External (Non-Coastal) High Build Mastic 125 50 50 225

amine adduct Polyurathane

Aluminium

Single or two

Two component Two component

Internal including component High

50 amine cured coal 150 amine cured 150 350

bottom plate bulid epoxy for

tar epoxy coal tar epoxy

immersion service

Bottom Plate Underside

Coal Tar Epoxy 150 -- -- Coal Tar Epoxy 150 300

apply Epoxy

apply Epoxy Resin Epoxy resin forth

Fibreglass Reinforced Resin on primed

on primed surface+ coat 250micron to

Epoxy for bottom plate Eposy resin+680 surface+ one

one layer of make min final

and internal shell where 500 to 625 grams woven 625-750 layer of 750-875

450g/m2 fibre DFT 2125. Apply

minor corrosion roving 450g/m2 fibre

glass mat on wet gel coat 300-350

occurred glass mat on

resin micron on top

wet resin

High Build

Crude Surface Tolerant Surface Tolerant

Surface

External (Coastal) High Build Mastic 120 Epoxy 120 100 250

Tolerant

Aluminium Aluminium

Polyurathane

Surface Tolerant

Polyamide Epoxy Aluminium

External (Non-Coastal) High Build Mastic 125 50 50 225

amine adduct Polyurathane

Aluminium

Single or two

Two component Two component

Internal including component High

50 amine cured coal 150 amine cured 150 350

bottom plate bulid epoxy for

tar epoxy coal tar epoxy

immersion service

Bottom Plate Underside

Coal Tar Epoxy 150 -- -- Coal Tar Epoxy 150 300

apply Epoxy

apply Epoxy Resin Epoxy resin forth

Fibreglass Reinforced Resin on primed

on primed surface+ coat 250micron to

Epoxy for bottom plate Eposy resin+680 surface+ one

one layer of make min final

and internal shell where 500 to 625 grams woven 625-750 layer of 750-875

450g/m2 fibre DFT 2125. Apply

minor corrosion roving 450g/m2 fibre

glass mat on wet gel coat 300-350

occurred glass mat on

resin micron on top

wet resin

High Build

Water Surface Tolerant Surface Tolerant

Surface

External (Coastal) High Build Mastic 120 Epoxy 120 100 250

Tolerant

Aluminium Aluminium

Polyurathane

Surface Tolerant

Polyamide Epoxy Aluminium

External (Non-Coastal) High Build Mastic 125 50 50 225

amine adduct Polyurathane

Aluminium

Single or two

Two component Two component

Internal including component High

50 amine cured coal 150 amine cured 150 350

bottom plate bulid epoxy for

tar epoxy coal tar epoxy

immersion service

You might also like

- Forensic Science International: David Doughty, Ben Painter, Paul E. Pigou, Martin R. JohnstonDocument12 pagesForensic Science International: David Doughty, Ben Painter, Paul E. Pigou, Martin R. JohnstonjavasoloNo ratings yet

- Secretary: Department of Trade and IndustryDocument7 pagesSecretary: Department of Trade and IndustryHalmen ValdezNo ratings yet

- Unit Price For Retrofitting WorksDocument2 pagesUnit Price For Retrofitting Workslaxmi29No ratings yet

- JEFFSOL Alkylene Carbonates Brochure)Document36 pagesJEFFSOL Alkylene Carbonates Brochure)Myeong Il Jeong100% (1)

- 1.4 CompositesDocument3 pages1.4 CompositesFuzail NaseerNo ratings yet

- Compost Tea Provides No Real Benefits - Garden MythsDocument91 pagesCompost Tea Provides No Real Benefits - Garden Mythsakshay0% (1)

- IOCL Painting Schedule - AELDocument1 pageIOCL Painting Schedule - AELZuber KhanNo ratings yet

- HIRENOL BrochureDocument1 pageHIRENOL BrochureTasos PapadopoulosNo ratings yet

- Engineered Plastic Characteristics II: Bakelite, Epoxy Glass and CeramicsDocument1 pageEngineered Plastic Characteristics II: Bakelite, Epoxy Glass and CeramicsKmgsa BandaraNo ratings yet

- Paint Requirement For SGTF / Igcar KalpakkamDocument3 pagesPaint Requirement For SGTF / Igcar KalpakkamRadhakrishnan SreerekhaNo ratings yet

- Civil Engineering / Coatings Epikure Curing Agent 8545-W-52 Versatile Waterborne Amine Curing Agent For Civil Engineering and Floor CoatingsDocument4 pagesCivil Engineering / Coatings Epikure Curing Agent 8545-W-52 Versatile Waterborne Amine Curing Agent For Civil Engineering and Floor CoatingsDonnaNo ratings yet

- ENCOR® Flex 192: Product DescriptionDocument5 pagesENCOR® Flex 192: Product DescriptionLong An ĐỗNo ratings yet

- Chapter 2-RRL BindersDocument4 pagesChapter 2-RRL BindersAlfred Louie RimorinNo ratings yet

- Table of Standards 1 Voc Limits Grams of VOC Per Liter of Coating, Less Water and Less Exempt CompoundsDocument3 pagesTable of Standards 1 Voc Limits Grams of VOC Per Liter of Coating, Less Water and Less Exempt CompoundsphassornNo ratings yet

- PaintsDocument5 pagesPaintsTawfiq ZidanNo ratings yet

- Intumescent Paint Top Coat ListDocument1 pageIntumescent Paint Top Coat Listamanpreet_ahujaNo ratings yet

- Raft Footing - General-ModelDocument1 pageRaft Footing - General-ModelJustin MusopoleNo ratings yet

- Filament Vs Convolute TubesDocument1 pageFilament Vs Convolute TubesGanesh.MahendraNo ratings yet

- A External Painting For RoofDocument4 pagesA External Painting For RoofMythri Metallizing Pvt Ltd ProjectsNo ratings yet

- Mir 001Document2 pagesMir 001MCCIN L&WNo ratings yet

- Specification For VOCDocument3 pagesSpecification For VOCThilan SenarathneNo ratings yet

- Brochure EpotecDocument18 pagesBrochure Epotectrường phạmNo ratings yet

- BASF Products Guide PDFDocument22 pagesBASF Products Guide PDFAtiq uRehman100% (1)

- Royale Luxury Emulsion: Product BenefitsDocument2 pagesRoyale Luxury Emulsion: Product BenefitsMoin RazaNo ratings yet

- Price List March 23Document4 pagesPrice List March 23Rahul SsdotraNo ratings yet

- Fdocuments - in - Derakane Epoxy Vinyl Esters PDFDocument7 pagesFdocuments - in - Derakane Epoxy Vinyl Esters PDFJuanNo ratings yet

- Stack Painting SpecsDocument1 pageStack Painting SpecsAmer Y KNo ratings yet

- Carbozinc 859Document2 pagesCarbozinc 859Khemaraj PathNo ratings yet

- MMC-Finishes Schedule-R2 220519Document5 pagesMMC-Finishes Schedule-R2 220519Sandip PaulNo ratings yet

- Section Aa - Aa Section BB - BB: M/115 Mr. Bolaji Maleek BabajideDocument1 pageSection Aa - Aa Section BB - BB: M/115 Mr. Bolaji Maleek BabajideAngelina MarieNo ratings yet

- WWW Epochemie Com Products Cycloaliphatic AminesDocument2 pagesWWW Epochemie Com Products Cycloaliphatic AminesNIKESH PRAKASHNo ratings yet

- General Specifications For Car Park, Back of House, Typical Superstructure WaterproofingDocument3 pagesGeneral Specifications For Car Park, Back of House, Typical Superstructure WaterproofingVisam SagarNo ratings yet

- 15ifiziegftenioneers Standard Specification For Surface Preparation and Protective Coating 6-79-0020 Rev. 0Document3 pages15ifiziegftenioneers Standard Specification For Surface Preparation and Protective Coating 6-79-0020 Rev. 0Chinmay DaveNo ratings yet

- High Strength Solutions To Your Toughest Reinforcement ChallengesDocument2 pagesHigh Strength Solutions To Your Toughest Reinforcement ChallengesLei WuNo ratings yet

- Aesthetic Topcoat Guide SWDocument8 pagesAesthetic Topcoat Guide SWjennifergiannouNo ratings yet

- Product Line Sheet: Liquid Coatings Petrolatum Tapes & Protective OuterwrapsDocument3 pagesProduct Line Sheet: Liquid Coatings Petrolatum Tapes & Protective OuterwrapsIm ChinithNo ratings yet

- Technical Data Sheet ZLA - 250 - 450Document3 pagesTechnical Data Sheet ZLA - 250 - 450Θανάσης ΓεωργακόπουλοςNo ratings yet

- HB Epoxy Zinc Rich Primer - TDSDocument2 pagesHB Epoxy Zinc Rich Primer - TDSazam RazzaqNo ratings yet

- Acrylic ResinsDocument2 pagesAcrylic ResinsNouhaila koussourNo ratings yet

- Roof FlyerDocument2 pagesRoof FlyerSmith JohnNo ratings yet

- Apcolite Clear Synthetic Varnish PDFDocument2 pagesApcolite Clear Synthetic Varnish PDFmeg4frenzNo ratings yet

- E 1605 SikaCor 255 277Document5 pagesE 1605 SikaCor 255 277manoj_sitecNo ratings yet

- B3-ER101-ELECTRICAL ROOM 160KVA-TYPE A-Elevations-R02Document1 pageB3-ER101-ELECTRICAL ROOM 160KVA-TYPE A-Elevations-R02Yannick SanouNo ratings yet

- Carboguard Low Haps Epoxy: Selection & Specification Data Substrates & Surface PreparationDocument2 pagesCarboguard Low Haps Epoxy: Selection & Specification Data Substrates & Surface PreparationImran AhmadNo ratings yet

- Trucare Grey 1-Pack Epoxy Primer: Product BenefitsDocument2 pagesTrucare Grey 1-Pack Epoxy Primer: Product BenefitsSakthivelNo ratings yet

- SpecsDocument5 pagesSpecsGo farNo ratings yet

- Water-Based Resins For Coatings: Portfolio SheetDocument1 pageWater-Based Resins For Coatings: Portfolio SheetCu Caicon100% (1)

- General Specifications For Industrial Flooring, UnderlaymentsDocument2 pagesGeneral Specifications For Industrial Flooring, UnderlaymentsVisam SagarNo ratings yet

- Decoprime Premium Metal PrimerDocument2 pagesDecoprime Premium Metal PrimerPritam DharNo ratings yet

- Ethacure 300Document12 pagesEthacure 300scorpionbadshahNo ratings yet

- Polyclad ARO-ProductFlyer-0914Document2 pagesPolyclad ARO-ProductFlyer-0914BERSE MAJU INDONESIANo ratings yet

- Polymer ConcreteDocument34 pagesPolymer ConcreteSrijaJuluruNo ratings yet

- Anti CarbonationDocument3 pagesAnti Carbonationhanna.costantinNo ratings yet

- Elevating Polymeric Compounds With Enhanced Scratch and Abrasion Resistance Using Silicon Additives OCTOBER 2023Document24 pagesElevating Polymeric Compounds With Enhanced Scratch and Abrasion Resistance Using Silicon Additives OCTOBER 2023enbuscadepalabrasbookNo ratings yet

- Fevicol CatalogueDocument11 pagesFevicol CatalogueSonu SimonNo ratings yet

- Cabot - Cab-O-Sil® Fumed Metal Oxides For CoatingsDocument2 pagesCabot - Cab-O-Sil® Fumed Metal Oxides For CoatingsLin NiuNo ratings yet

- Primers For Metal SurfacesDocument2 pagesPrimers For Metal SurfacesLHYT NTUANo ratings yet

- Evonik-Anquamine 287Document5 pagesEvonik-Anquamine 287ridho.afifiNo ratings yet

- FevicolDocument5 pagesFevicolTanvirH.ChowdhuryNo ratings yet

- Asianpaints Products Premium Gloss EnamelDocument2 pagesAsianpaints Products Premium Gloss EnamelHaider ImamNo ratings yet

- Trucare Grey 1-Pack Epoxy Primer: Product BenefitsDocument2 pagesTrucare Grey 1-Pack Epoxy Primer: Product BenefitsSubish PunnooseNo ratings yet

- ND-6 - Painting SpecificationsDocument5 pagesND-6 - Painting SpecificationsKhubaib ziaNo ratings yet

- Ciclo Di Verniciatura: SpecificaDocument1 pageCiclo Di Verniciatura: SpecificaMaffone NumerounoNo ratings yet

- Kcse Agriculture Notes: Topic 6: Soil Fertility I (Organic Manures)Document13 pagesKcse Agriculture Notes: Topic 6: Soil Fertility I (Organic Manures)Lubnaa JanNo ratings yet

- Chemistry Class 11 Part 2Document161 pagesChemistry Class 11 Part 2maupravin1230% (1)

- Preparation OintmentDocument1 pagePreparation OintmentLyanlie MinamotoNo ratings yet

- Chemistry NEP SyllabusDocument51 pagesChemistry NEP SyllabusHimanshu KumarNo ratings yet

- Chapter 1-2 (Revised)Document16 pagesChapter 1-2 (Revised)Ron Y ANNo ratings yet

- 1 3dibromoDocument6 pages1 3dibromoUmesha shankra ShettyNo ratings yet

- Ethylene: Structure and PropertiesDocument8 pagesEthylene: Structure and PropertiesChaseF31ckzwhrNo ratings yet

- D 4837 - 97 - Rdq4mzctotcDocument2 pagesD 4837 - 97 - Rdq4mzctotcHHans MSilvaNo ratings yet

- Capstone Final Paper Stem 12c Group5Document126 pagesCapstone Final Paper Stem 12c Group5arboso.trishamaurice.cabralNo ratings yet

- Extraembryonic MembranesDocument4 pagesExtraembryonic MembranesShafiullah Habib LitonNo ratings yet

- Resina Cationica A4000 AlamoDocument1 pageResina Cationica A4000 AlamoChristian M. PaucarNo ratings yet

- Chemistry ProjectDocument16 pagesChemistry ProjectDinesh Singh PanwarNo ratings yet

- B SC Sem V 504 Unit 3 Analitical (Acid Base and Complexometric Titration)Document2 pagesB SC Sem V 504 Unit 3 Analitical (Acid Base and Complexometric Titration)Lukhi VishalNo ratings yet

- V5.00 Reagent Info ABX PENTRADocument7 pagesV5.00 Reagent Info ABX PENTRALince WijoyoNo ratings yet

- All About Relative Biocidal Effectiveness of Hocl (Hypochlorous Acid) and Hobr (Hypobromous Acid) in Alkaline PH?Document2 pagesAll About Relative Biocidal Effectiveness of Hocl (Hypochlorous Acid) and Hobr (Hypobromous Acid) in Alkaline PH?Mutasim Hasan MehranNo ratings yet

- Assignment 2: Waste To Wealth (Anaerobic Digestion)Document22 pagesAssignment 2: Waste To Wealth (Anaerobic Digestion)Ulvi Al ZidaneNo ratings yet

- Lab ReportDocument6 pagesLab ReportAmanda IvesterNo ratings yet

- MetablosimDocument17 pagesMetablosimM IrfanNo ratings yet

- Vol16 2Document19 pagesVol16 2Aivan BandiolaNo ratings yet

- 2019.08.19 The List of Hazardous Chemicals Prohibited From Transportation in China Inland Waters - 2019 Version (00000002)Document12 pages2019.08.19 The List of Hazardous Chemicals Prohibited From Transportation in China Inland Waters - 2019 Version (00000002)hoan888No ratings yet

- Medicinal Properties of Elettaria CardamomumDocument4 pagesMedicinal Properties of Elettaria CardamomumBasit khanNo ratings yet

- Name Reactions YhcDocument5 pagesName Reactions Yhcpcyathish37100% (1)

- Oe Repsol Polimeros Site 21nov2018Document52 pagesOe Repsol Polimeros Site 21nov2018Paola Plazas AlarcónNo ratings yet

- Intro Exp Benzaldehyde of Benzylic AcidDocument2 pagesIntro Exp Benzaldehyde of Benzylic AcidberjalankehadapanNo ratings yet

- Susan Koswan & Lawrence's Home PageDocument2 pagesSusan Koswan & Lawrence's Home PageuncleadolphNo ratings yet

- Soil Organic Matter and HumusDocument11 pagesSoil Organic Matter and Humusfarinoosh askariNo ratings yet