Professional Documents

Culture Documents

Venkatesh and Bhaghavi

Venkatesh and Bhaghavi

Uploaded by

larryCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Venkatesh and Bhaghavi

Venkatesh and Bhaghavi

Uploaded by

larryCopyright:

Available Formats

Mukt Shabd Journal Issn No : 2347-3150

OPTIMIZATION OF DIESEL ENGINE PERFORMANCE BY

PALM OIL BIODIESEL

Dr. G PRASANTHI

Professor, Department of Mechanical Engineering, J.N.T.U. College of

Engineering & Director of Faculty Development & I.Q.A.C., J.N.T.U.A.,

Anantapuramu, Andhra Pradesh, India

B VENKATESH

Assistant Professor, Department of Mechanical Engineering, Annamacharya

Institute of Technology & Sciences, Rajampet, Kadapa, Andhra Pradesh, India.

B BHARGAVI

Assistant Professor, Department of Computer Science Engineering, Annamacharya

Institute of Technology & Sciences, Kadapa, Andhra Pradesh, India

ABSTRACT

Biodiesel was produced from edible and non-edible. Palm is the primary source of usage in

India for cooking purposes. Waste cooking palm in a form of Palm Oil Methyl Ester used

in various ratios of blends for measuring the engine performance measure parameters on a

4-stroke single-cylinder diesel engine. The present work involves experimental design to

experiment. The Taguchi orthogonal array introduced to maximize the experimental data

with a minimum combination of experiments. The solicitation of the Taguchi method in

blend with grey relational analysis has applied for solving multiple response optimization

problems. A grey relational grade, evaluated with grey relational analysis, has been

espoused to conceal an optimal parameter amalgamation. Using grey relational class and

signal to noise ratio as a performance index, finally performed the parametric optimization

by predicting the results and then verified it with confirmatory experiment.

Keywords: 4-stroke single-cylinder diesel engine, Optimization, Palm Oil Methyl Ester,

Taguchi Design of Experiments, Grey relational analysis

1. INTRODUCTION

The quest for useful energy and the desire to have a clean and green environment is always

of great interest to any researcher. The rapidly declining petroleum reserves have already

given the worldwide warning signal for alternative ways to meet rising energy needs.

Furthermore, harmful emissions of fossil fuels must also take care of [1]. Biodiesel made

from different renewable sources has become a viable alternative for use as a fuel in

Compression Ignition (CI) engines. Biodiesel referred to as mono-alkyl esters of long-

chain fatty acids. With the help of a chemical process known as transesterification, the

biodiesel is produced from vegetable oils and used for compression ignition (CI) engines.

The deviation of the percentage concentration of methyl esters in biodiesel from different

Volume IX Issue V, MAY/2020 Page No : 231

Mukt Shabd Journal Issn No : 2347-3150

sources leads to considerable changes in the physical and chemical properties of biodiesel,

which in turn affects the characteristics of the engine used. Biodiesel from a choice of

feedstocks has been tried by different researchers to learn and analyze the performance,

emission, and combustion characteristics of the CI engine. Encouraging results such as the

decrease in emissions like hydrocarbon (HC), a decrease in brake power (BP), and finally

increase in brake specific fuel consumption (BSFC) has been reported [2]. However, the

major obstacle in commercializing biodiesel produced from vegetable oil (PALM OIL) is

the cost of its production.

Meanwhile, an enormous quantity of used cooking oil wasted worldwide. Disposal

of such oil is again a concern as pollution problems arise when placing such materials in

rivers and landfills. It can lead to problems in maintaining environmental balance. The best

way to avoid contamination of the waste cooking palm oil used to produce biodiesel and

use it in CI engines. Therefore, biodiesel produced from waste frying oil or junk cooking

oil is the cheapest alternative to pure diesel in many parts of the world [3]. Waste cooking

methyl esters oil from different origins used as fuel for diesel engines to study their effects.

Experimented with waste cooking oil from palm oil and with blends of waste oil and pure

diesel and analyzed the emission and performance characteristics of a single-cylinder four-

stroke water-cooled diesel engine.

Waste cooking oil used as an exciting agent to reduce the overall viscosity and

cloud point of the mixture as well as the ester. The purpose of the present work is to

investigate the effects of palm oil-based biofuels on the performance and the emission

characteristics of a diesel engine fuelled with those fuels. Preheated palm oil, PO/diesel

blends, and methyl/ethyl esters of the PO mixture in different proportions used.

Performance and emission tests performed at different engine loads and constant engine

speed for each type of fuel. The cause that biodiesel is not utilizing usually in the region of

the world is due to the high cost of raw materials. To overwhelm this, one can use lower

worth oils, for example, waste cooking oils or animal fats that produced in excess in food

processing trades. Utilize waste cooking oil can as well help to lighten the problem of

waste oil disposal [4].

Much research has conceded out on the production of biodiesel from fresh

vegetable and animal oil cradles, but the use of waste cooking oil, such as palm oil, where

Malaysia is a leading manufacturer of palm oil, has not been well recognized, although

frequently mentioned. The main objectives of the present research are to optimize the

conditions for waste baking oil to biodiesel production, identify fatty acid methyl esters

produced and classify them based on their viscosity, total acid count, elemental

composition, emission rate and engine performance [5].

For biodiesel production, vegetable oil as an essential feedstock. Vegetable oil has

collected from the from street shops in Kolkata has used for preparing biodiesel. Alcohol

ratio, catalyst concentration, stirring rate, time, and temperatures are affected in

transesterification. The process parameters were optimized, and the highest biodiesel

capitulate of 94% has been achieved [6].

They were agreed on experimental work to investigate the operating situations that

maximize the biodiesel production after waste cooking oil. The conversion of waste

cooking oil from the domestic dwelling by transesterification reaction is useful to obtain

biodiesel. The tests carried out on waste cooking oil samples coming from domestic

dwelling and characterized by an FFA content equal to 3%, have shown that NaOH

Volume IX Issue V, MAY/2020 Page No : 232

Mukt Shabd Journal Issn No : 2347-3150

concentration of 0.5% w/w oil and 100% of methanol surplus represent the best-operating

conditions. Indeed they permit to obtain a reaction yield of 94.3% and a biodiesel density

of 0.875 g/cm3 [7].

Leisurely the combustion characteristics and emissions of compression ignition

diesel engines using biodiesel as an alternative fuel. The experiments are conducted at 4-

stroke 1-cylinder diesel engine variable speed 1200-2600 rpm. They collected oil from the

Tafila Technical University restaurant and converted it into biodiesel for experimentation.

The test had conducted on B5, and the B20 blend without engine modification and

observed emission reduced at satisfactory loads. The final results observed that while

compared with diesel CO, HC significantly reduce, and NOx raised. Biodiesel has a 5.95

% increasing in brake-specific fuel consumption due to its worse heating rate. However,

waste cooking oil blends B20 and B5 gave better performance and emissions. The

experimental results illustrate that the fuel consumption rate, brake thermal efficiency, and

exhaust gas temperature increased while the BSFC, emission indices of CO2, CO

decreased with an increase of engine speed. Also, the engine power increased while

increasing the biodiesel percentage; the brake specific power consumption varied from

16.8 to 13.81 MJ / kW kg for the standard diesel while the B20 for the standard diesel was

between 16.8 and 13.81 MJ / kW for the B5. Biodiesel CO2, produced in conjunction with

the peroxidation process, has the lowest equivalence ratio and emission index of CO [8].

A.M. Liaquat et al. [9] approved the experimental work to analyze engine

performance and emissions characteristics for diesel engines using different blend fuels

without any engine modification. A total of four fuel samples, such as DF, JB5, JB10, and

J5W5 in that order, were used in this study. The test was conducted at full load at a

variable speed of 1500 rpm to 2400 rpm to maintain a fully open throttle valve. Whereas,

emission tests passed out at 2300 rpm at 100% and 80% throttle position. Finally, the

investigators observed that JB5, JB10, and J5W5 show torque reduction of 0.6%, 1.6%,

and 1.4% and power reduction 0.7%, 1.7%, and 1.5%, respectively. Average amplify in

BSFC compared to DF was observed as 0.54%, 1.0% JB10, and 1.14% for JB5, JB10, and

J5W5, respectively. In exhaust gas emission case, when compared with diesel observed

average decrement in hydrocarbons for JB5, JB10 and J5W5 at 100% throttle position and

2300 rpm found as 8.9%, 11.3%, and 12.6%, whereas, at 80% throttle position, lessening

was 16.3%, 30.3%, and 32% respectively. Near 2300 rpm CO reduced at fully open throttle

position for JB5, JB10, and J5W5 found as 17.3%, 25.9%, and 26.99%, where, at 80%

throttle position, the reduction observed 20.70%, 33.24%, and 35.57%. Similarly, for JB5,

JB10, and J5W5, the CO2 reduction was 12.10%, 20.51%, and 24.91% compared to DF for

2300 rpm and 100% throttle position, while for 80% throttle position, the reductions were

5.98%, 10.38%, and 18.49% respectively. However, some NOx emissions increased for all

composite fuels compared to DF. For fear that of noise emission, the sound level for all

blend fuels was reduced compared to DF. Finally concluded that the JB5, JB10, and J5W5

blends could use in diesel engines. However, the W5B5 gave some excellent results

compared to the JB10. Change in compression ratio ranges 14 to 18 resulted in 18.4%,

27.5%, 18.5%, and 19.8% increase in brake thermal efficiency in the case of B10, B20,

B30, and B50, respectively. When the compression ratio increased from 14 to 18, CO2

emissions increased by 14.28%, HC emissions by 52%, CO emissions by 37.5%, and NOx

emissions by 36.84%.

The purpose of this work is to determine the optimum mixtures of diesel and palm

oil, resulting in improved performance of the engine along with minimum emissions.

Volume IX Issue V, MAY/2020 Page No : 233

Mukt Shabd Journal Issn No : 2347-3150

Following the Gray-Taguchi approach, the multi-response problem converted into one

using the weighting factors of the grey relational analysis. Finally, the validation results

were carried out by experimentation results.

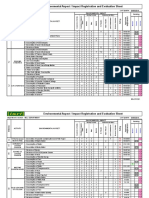

Table 1. Levels with parameters.

Levels

Design factor

1 2 3 4 5

Load 0 25 50 75 100

Blend 0 20 40 60 80

2. EXPERIMENTAL SETUP

The experiment beleaguered on a single-cylinder four-stroke diesel engine. A gas

analyzer used for the measurement of carbon monoxide (CO), oxides of nitrogen (NOX),

unburned hydrocarbon (HC), oxygen O2), and carbon dioxide also. CO measured as

percentage volume, and NO, HC measured as n-hexane equivalent, parts per million

(ppm). The engine was subjected to different loads (0 kg, 3 kg, 6 kg, 9 kg, and 12 kg),

corresponding to load ranging from 0% at the lowest level and 100% at the highest level.

The experiments were conducted using B 0 (0% PO, 100% diesel),B20 (20% PO, 80%

diesel), B40 (40% PO, 60% diesel), B60 (60% PO, 40% diesel), and B80 (80% PO, 20%

diesel) under different load conditions on the engine and the results are noted. Engine

speed kept constant 1500 rpm. While at the time of experimentation, whenever the blend

has changed, the fuel supply line was clean and left the engine on a no-load condition for a

half-hour. By AVL DIG AS 444, five gas analysers used for analysing engine emissions.

Table 2. Specifications of engines and instruments

Manufacturer Kirloskar Oil Engines Ltd.

BHP 5 HP

Speed 1500 rpm

Number of cylinders One

Compression ratio 16.5:1

Bore diameter 80 mm

Length of stroke 110 mm

Volume IX Issue V, MAY/2020 Page No : 234

Mukt Shabd Journal Issn No : 2347-3150

Type of loading Rope brake

Method of cooling Water cooling

Method of ignition Compression ignition

Specifications of the AVL gas analyser

Manufacturer AVL India Pvt. Ltd.

Type DiGas 444

Model 5 gas analyser

Figure 1. Single-cylinder 4-stroke diesel engine.

Table 3. Fuel property table of diesel and biodiesel blends

Kinematic Flash and Specific gravity Calorific

S.No Fuel tested viscosity at (cSt) fire point(oC) (gm/m3) value(kJ/kg)

1 B0 3.7 54&63 0.83 41500

2 B20 4.9 59&70 0.84 38237

3 B40 6.2 65&77 0.87 36908

Volume IX Issue V, MAY/2020 Page No : 235

Mukt Shabd Journal Issn No : 2347-3150

4 B60 6.9 73&89 0.88 35783

5 B80 7.3 89&102 0.89 34863

3. DESIGN OF EXPERIMENT

Taguchi Method of DOE [10]

The Taguchi method helps to design a minimum possible number of experiments.

Taguchi method uses a unique design of orthogonal arrays to study the entire restriction

space with a small number of trials. For more accurate resulting Signal to Noise (S/N)

ratios are was planned for analyzing the performance. Based on the Taguchi design, the

L25 orthogonal array has selected for the experiments in MINITAB 17. All of this data

used for the analysis and evaluation of a combination of optimal parameters.

Grey Relational Analysis [11]

In this analysis, maintain responses first normalized range 0 to 1. Based on these

statistics, grey relation coefficients are premeditated to represent the correlation between

the ideal (best) and the actual normalized experimental data. Then the average grey

correlation is determined to the selected responses by overall grey relation grade. For

calculating the grey relation grade, it depends on the multi-response process and its

characteristics.

Normalization

Normalization of the signal to noise ratio performed to prepare raw data for the

analysis where the original sequence transformed into a comparable sequence. Generally, a

linear generalization is necessary since the range and unit in one data series may differ

from the others [12].

If the bull's eye value of the original order is infinite, it has the characteristic of

"higher is the better one." The original sequence can be generalized as follows:

When "small is better" is a characteristic of the original sequence, the original

sequence should be generalized as follows:

Though there is having a definite desired value (target value) to attain, the

normalizing sequence is in the form of:

Volume IX Issue V, MAY/2020 Page No : 236

Mukt Shabd Journal Issn No : 2347-3150

Otherwise, the unique sequence can simply normalize by the elementary method,

i.e., let the values of the original sequence divided by the first value of the sequence [13]:

Where i = 1 . . . m; k = 1. . . n. m is the number of experimental data items, and n is the

number of parameters. Xio(k) denotes the original sequence, Xi* the sequence after the data

pre-processing, max Xio (k), the largest value of Xio (k), min Xio (k) the smallest value of

Xio (k) and Xo is the desired value.

(1) Determination of deviation sequences Δ0i(k):

The deviation categorization, Δ0i(k), is the obvious difference between the

reference sequence x0*(k) and the comparability sequence xi*(k) after normalization. It is

determined using the equation:

(2) Calculation of grey relational coefficient (GRC)

GRC for all the sequences expresses the relationship between the ideal (best) and

actual normalized S/N ratio. If the two orders approve at all points, then their grey

relational coefficient is 1. The grey relational coefficient ξi(k) for the kth performance

characteristics in the ith experiment can express as:

Where Δ0i is the aberration sequence of the reference. The value of ζ is the smaller,

and the unique ability is the larger. ζ = 0.5 is generally used. Grey relational coefficient for

27 comparability sequences.

(3) Calculation of grey relational grade (GRG) [14]

After the grey relational coefficient is consequent, it is customary to take the

average value of the grey relational coefficients as the grey relational grade. The grey

relational grade is defined as follows:

However, in a real manufacturing system, the importance of several factors varies.

Through various diseases of ineffective weight, the grey relational grade define as chronic

and above. The grey relational grade γi epitomizes the level of correlation between the

position sequence and the comparability sequence. If the two sequences are

indistinguishable, then the value of grey relational grade is equal to 1. The grey relational

grade also qualifies the level of motivation to which the comparison sequence applies

rather than the reference sequence. Then, if the comparison sequence is more important

than the other comparison sequences for the reference sequence, the grey relational grade

for that comparison sequence and the orientation sequence is higher than the other grey

relational grades [15].

Volume IX Issue V, MAY/2020 Page No : 237

Mukt Shabd Journal Issn No : 2347-3150

4. ANALYSIS AND DISCUSSION OF EXPERIMENTAL RESULTS

The grey relational grade γi signifies the near of correlation between the positioning

order and the comparability sequence the weighted grey relational grade calculated for

each sequence has taken as a response for the further analysis. The large-is-better attribute

used to analyze the GRG because the considerable value indicates the improved

performance of the process. The number of repetitive tests is one since only one relational

grade assimilated in each group for this calculation of S/N. Grey relationship grades have

analyzed with Taguchi in the Minitab 17 software.

The corresponding main effect plots are shown on the next page. In the main effect

plot, if the line for the parameter is nearly horizontal, the parameter has a less significant

effect. On the other hand, the highest tilt parameter for the line has the most significant

effect. From the main effect plot, parameter A (load) has the most significant effect among

these two parameters [16].

The optimum process parameter combination for minimum emission and improved

engine performance is the maximum value for the noise ratio and the grey relational grade

for the signal. Thus, from the 2 plots of means, the optimum process parameter

combination is found to be A5B2, i.e., load (A) at 100%, blend of fuel (B) at B 20.

In other words, the optimum combination is B 20 (diesel 80% + biodiesel 20%),

100 % engine load, where engine performance is maximum, and the exhaust emission is

minimum.

The optimal combination obtained from the S/N ratio Fig.2. is shown in below

Table 4.

Figure 2. Main effects plot for SN ratio and Grey relational grade for optimum

conditions.

Table 4. Optimal combinations of process parameters.

Factor Load Blend

Level 100% (12kg) 20%

Volume IX Issue V, MAY/2020 Page No : 238

Mukt Shabd Journal Issn No : 2347-3150

5. CONCLUSIONS

This work, it appears that biodiesel is going to be a natural choice for our future

transportation fuel. The other combination of experience and reasoning is possible to distill

some conclusions about biodiesel as an automotive fuel, particularly in a developing

country like India. The present work establishes the following facts.

From the above study, the multi-response parameters (engine performance and

emission study) are optimized using grey relational analysis and converted into a single

response. Then Taguchi's methodology is used to analyze the experimental data. The main

effects plot for both mean of average grey grade and signal to noise ratio the optimized

combination is found to be A5B2. In that combination, it predicts from the experimental

data that the engine performance is comparable to that of diesel. Moreover, the emissions

are less than that for diesel. That means from the used blends of biodiesel and diesel, and

the B 20 blend found to be the most suitable blend for use in the diesel engine without any

engine modification. The corresponding load applied on the engine is 100% load, I .e.12 kg

load. The confirmation test is also carried out to verify it and finally observed the

improvements of grey relational grade and signal to noise ratios.

Finally, it can conclude that without any engine modifications, biodiesels can use.

And from our experimental view, the best blend is the B20 blend, where the engine

performance is comparable to that of diesel, and the emissions are less than from diesel.

REFERENCES

1. Kathirvel, S., Apurba Layek, and S. Muthuraman (2016). Exploration of waste

cooking oil methyl esters (WCOME) as fuel in compression ignition engines: a

critical review. Engineering Science and Technology, an International

Journal 19.2: 1018-1026.

2. Banapurmath, N. R., P. G. Tewari, and V. N. Gaitonde (2012). Experimental

investigations on performance and emission characteristics of Honge oil biodiesel

(HOME) operated compression ignition engine. Renewable Energy 48: 193-201.

3. Xue, Jinlin (2013). Combustion characteristics, engine performances and emissions

of waste edible oil biodiesel in diesel engine. Renewable and Sustainable Energy

Reviews 23: 350-365.

4. Ndayishimiye, Pascal, and Mohand Tazerout (2011). Use of palm oil-based biofuel

in the internal combustion engines: performance and emissions

characteristics. Energy 36.3: 1790-1796.

5. Abdullah, Ahmad Zuhairi, et al (2009). Current status and policies on biodiesel

industry in Malaysia as the world's leading producer of palm oil. Energy

Policy 37.12: 5440-5448.

6. NabanitaBanerjeea, RiticaRamakrishnana, and TusharJash, (2013), Biodiesel

production from used vegetable oil collected from shops selling fritters in Kolkata,

4th International Conference on Advances in Energy Research, In Proc.ICAER

2013, Elsevier, Energy Procedia 54, 161 – 165.

7. Maurizio Carlinia, Sonia Castellucci and Silvia Cocchia, (2013), A Pilot-Scale

Study of Waste Vegetable Oil Transesterification with Alkaline and Acidic

Volume IX Issue V, MAY/2020 Page No : 239

Mukt Shabd Journal Issn No : 2347-3150

Catalysts. Conference of the Italian Thermal Machines Engineering Association,

Elsevier, In Proc. ATI 2013. Energy Procedia, 45, 198 – 206.

8. Wail M. Adaileh and Khaled S. AlQdah, (2012). Performance of Diesel Engine

Fuelled by a Biodiesel Extracted From A Waste Cooking Oil. Elsevier, SciVerse

Science Direct, 18, 1317 – 1334.

9. A.M. Liaquat, H.H. Masjukia, M.A.Kalama, M.Varmana, M.A. Hazrata, M.

Shahabuddin and M. Mofijur, (2011). International Conference on Advances in

Energy Engineering (ICAEE 2011), Elsevier, SciVerse Science Direct, Energy

Procedia, 14, 1124 – 1133.

10. Kumar, Atul, et al (2017). Comparative study of Parametric Optimization of the

End Milling of Al2024-SiC MMC on Surface Roughness using Taguchi Technique

with Applied Statistical Plots. International Journal of Applied Engineering

Research 12.21: 10816-10823.

11. Azhiri, Reza Bagherian, et al (2014). Application of Taguchi, ANFIS and grey

relational analysis for studying, modeling and optimization of wire EDM process

while using gaseous media. The International Journal of Advanced Manufacturing

Technology 71.1-4 : 279-295.

12. Sreenivasulu, Reddy (2014). MULTI RESPONSE CHARACTERISTICS OF

PROCESS PARAMETERS DURING END MI LLING OF GFRP USING GREY-

BASED TAGUCHI METHOD. Independent Journal of Management &

Production 5.2 : 299-313.

13. Venkatasubbareddy, O. Y., Palaiam Siddikali, and S. Mahammad Saleem (2016).

Improving the Dimensional Accuracy and Surface Roughness of FDM Parts Using

Optimization Techniques." IOSR Journal of Mechanical and Civil Engineering 3.5:

18-22.

14. Jayaraman, P (2014). Multi-response optimization of machining parameters of

turning AA6063 T6 aluminium alloy using grey relational analysis in Taguchi

method. Procedia Engineering 97: 197-204.

15. Raut, Mr Vinit, Mrs Meeta Gandhi, and Mr Nilesh Nagare3 Mr Aniket Deshmukh.

Application of Taguchi Grey Relational Analysis to optimize the process

parameters in wire electrical discharge machine.

16. Ganesan, S., J. Senthil Kumar, and J. Hemanandh (2020). Optimisation of CI

engine parameter using blends of biodiesel by the Taguchi method. International

Journal of Ambient Energy 41.2: 205-208.

Volume IX Issue V, MAY/2020 Page No : 240

You might also like

- AGS-688 ManualDocument60 pagesAGS-688 Manualvatcslav0% (1)

- DSOME Bio DieselDocument28 pagesDSOME Bio DieselManish PatilNo ratings yet

- Owners Manual ISL9 CM2350 L101: Cummins Customer Assistance Center 1-800-DIESELS Applicable Only in U.S.A. and CanadaDocument219 pagesOwners Manual ISL9 CM2350 L101: Cummins Customer Assistance Center 1-800-DIESELS Applicable Only in U.S.A. and Canadasergey100% (2)

- Moot GovtDocument38 pagesMoot GovtDhriti SharmaNo ratings yet

- Engine CharacteristicsDocument7 pagesEngine Characteristicss sivaNo ratings yet

- Experimental Studies On The Combustion and Emission Characteristics of A Diesel Engine Fuelled With Used Cooking Oil Methyl Ester and Its Diesel BlendsDocument7 pagesExperimental Studies On The Combustion and Emission Characteristics of A Diesel Engine Fuelled With Used Cooking Oil Methyl Ester and Its Diesel BlendsAshokNo ratings yet

- 01 - Review Suresh2018Document12 pages01 - Review Suresh2018Chirag PatidarNo ratings yet

- 5 Ijmperddec20185Document12 pages5 Ijmperddec20185TJPRC PublicationsNo ratings yet

- Biodiesel Production From Waste Chicken Fat Based Sources and Evaluation With MG Based Additive in A Diesel EngiDocument7 pagesBiodiesel Production From Waste Chicken Fat Based Sources and Evaluation With MG Based Additive in A Diesel EngiwhutecompressorNo ratings yet

- Biodiesel Production From Palm Oil Technology: Research Journal of Agricultural Science, 43 (4), 2011Document6 pagesBiodiesel Production From Palm Oil Technology: Research Journal of Agricultural Science, 43 (4), 2011Sywie ARydivolyaNo ratings yet

- Calophyllum Inophyllum Methyl Ester Biodiesel Blend As An Alternate Fuel For Diesel Engine ApplicationsDocument9 pagesCalophyllum Inophyllum Methyl Ester Biodiesel Blend As An Alternate Fuel For Diesel Engine Applicationsridho febriNo ratings yet

- A Study On Suitability of Biodiesel Produced From Milk Scum For Enhancement of Engine EfficiencyDocument11 pagesA Study On Suitability of Biodiesel Produced From Milk Scum For Enhancement of Engine EfficiencySanthosh NagarajaNo ratings yet

- Performance, Emission Chars BiodieselDocument10 pagesPerformance, Emission Chars BiodieselBragadish BragsNo ratings yet

- A Production of Biodiesel From Waste Cotton Seed Oil and Testing On Small Capacity Diesel EngineDocument8 pagesA Production of Biodiesel From Waste Cotton Seed Oil and Testing On Small Capacity Diesel EngineYeabsira WorkagegnehuNo ratings yet

- Performance and Emission Analysis of DI Diesel Engine Fuelled With Methyl Esters of Beef Tallow and Diesel BlendsDocument17 pagesPerformance and Emission Analysis of DI Diesel Engine Fuelled With Methyl Esters of Beef Tallow and Diesel BlendsM tejaswiniNo ratings yet

- Energy Conversion and Management: Ekrem Buyukkaya, Serdar Benli, Salih Karaaslan, Metin GuruDocument8 pagesEnergy Conversion and Management: Ekrem Buyukkaya, Serdar Benli, Salih Karaaslan, Metin GuruArul KumarNo ratings yet

- v4 2 11Document7 pagesv4 2 11api-19662887No ratings yet

- Analysis of Four Stroke Single Cylinder Compression Ignition Engine Operated With Blends of Waste Cooking Oil Biodiesel DieselDocument6 pagesAnalysis of Four Stroke Single Cylinder Compression Ignition Engine Operated With Blends of Waste Cooking Oil Biodiesel Dieselshreshthagandhi13No ratings yet

- Modifying Soybean Oil For Enhanced Performance in Biodiesel BlendsDocument11 pagesModifying Soybean Oil For Enhanced Performance in Biodiesel BlendsLudiele SiuchNo ratings yet

- 149 Ijmperdfeb2018149Document12 pages149 Ijmperdfeb2018149TJPRC PublicationsNo ratings yet

- Journal Pre-Proof: Process Safety and Environmental ProtectionDocument31 pagesJournal Pre-Proof: Process Safety and Environmental ProtectionChirag PatidarNo ratings yet

- Performance and Emission Characteristics of A CI Engine Fueled With Diesel-Waste Fried Oil Blend With Dee As AdditiveDocument21 pagesPerformance and Emission Characteristics of A CI Engine Fueled With Diesel-Waste Fried Oil Blend With Dee As AdditiveLOKESHNo ratings yet

- Performance Analysis of Ci Engine Fueled With Diesel and Used Vegetable Oil BlendDocument8 pagesPerformance Analysis of Ci Engine Fueled With Diesel and Used Vegetable Oil BlendYohannes AlemuNo ratings yet

- RajuDocument7 pagesRajuTatiana VargasNo ratings yet

- Calophyllum Inophyllum Methyl Ester Biodiesel Blend As An Alternate Fuel For Diesel Engine ApplicationsDocument9 pagesCalophyllum Inophyllum Methyl Ester Biodiesel Blend As An Alternate Fuel For Diesel Engine ApplicationsalfianNo ratings yet

- Ashok PDFDocument9 pagesAshok PDFalfianNo ratings yet

- A Technical Seminar ON: "Bio Diesel and Its Importance"Document18 pagesA Technical Seminar ON: "Bio Diesel and Its Importance"Dhinesh GanesanNo ratings yet

- Ijmet 10 01 014Document10 pagesIjmet 10 01 014IAEME PUBLICATIONNo ratings yet

- FileserveDocument9 pagesFileserveCao Đào NamNo ratings yet

- ManuscriptDocument5 pagesManuscriptAanshu SinghNo ratings yet

- A Comparative Study On Characterization of Used Cooking Oil and Mustard Oil For Biodiesel Production - Engine Performance - ScienceDirectDocument3 pagesA Comparative Study On Characterization of Used Cooking Oil and Mustard Oil For Biodiesel Production - Engine Performance - ScienceDirectsdfdNo ratings yet

- Experimental Study of Using Hybrid Vegetable Oil Blends in Diesel EngineDocument4 pagesExperimental Study of Using Hybrid Vegetable Oil Blends in Diesel EngineSerenityNo ratings yet

- Utilization of Karanja (Pongamia Pinnata) As A Major Raw Material For The Production of BiodieselDocument5 pagesUtilization of Karanja (Pongamia Pinnata) As A Major Raw Material For The Production of BiodieselMithila AkterNo ratings yet

- Performance and Evaluation of Pongamia (Karanj) Oil As An Alternative Fuel For Surface TransportationDocument7 pagesPerformance and Evaluation of Pongamia (Karanj) Oil As An Alternative Fuel For Surface Transportationrahuldbajaj2011No ratings yet

- 42 Ijmperdapr201842Document8 pages42 Ijmperdapr201842TJPRC PublicationsNo ratings yet

- Load and Emission Characteristics of Pongamia Pinnata Oil in ACI EngineDocument9 pagesLoad and Emission Characteristics of Pongamia Pinnata Oil in ACI EngineJournals MECNo ratings yet

- Conversão de Nergia 2Document6 pagesConversão de Nergia 2Ricardo PereiraNo ratings yet

- Research Journal of Pharmaceutical, Biological and Chemical SciencesDocument9 pagesResearch Journal of Pharmaceutical, Biological and Chemical Sciences1307114613 Handerson PanjaitanNo ratings yet

- 03 - Literature ReviewDocument14 pages03 - Literature Reviewanon_865386332No ratings yet

- Investigatory ProjectDocument10 pagesInvestigatory Projectjoana dequinaNo ratings yet

- Biodiesel Development From High Acid Value Polanga Seed Oil and Performance Evaluation in A CI EngineDocument7 pagesBiodiesel Development From High Acid Value Polanga Seed Oil and Performance Evaluation in A CI Enginesrinithims78No ratings yet

- Biodiesel As An Alternative Fuel A StateDocument24 pagesBiodiesel As An Alternative Fuel A Statepadam0088No ratings yet

- Compression RatioDocument15 pagesCompression RatioVenkateshNo ratings yet

- Heteregenous CatalystDocument8 pagesHeteregenous CatalystShruti Maity AchariyaNo ratings yet

- 1827 ApprovedpaperDocument20 pages1827 ApprovedpaperMahtab SajnaniNo ratings yet

- Fuel Properties of Biodiesels Produced From Blends of Canola Oil and Animal TallowDocument10 pagesFuel Properties of Biodiesels Produced From Blends of Canola Oil and Animal TallowdckristantoNo ratings yet

- Applied Energy: K. Muralidharan, D. VasudevanDocument10 pagesApplied Energy: K. Muralidharan, D. VasudevanSubhadip DasNo ratings yet

- Diesel Engine Performance Emissions andDocument13 pagesDiesel Engine Performance Emissions andTamer FahmyNo ratings yet

- Production of Biodiesel From Used Cooking OilDocument7 pagesProduction of Biodiesel From Used Cooking OilDennis OrlandoNo ratings yet

- 9.IJAEST Vol No 5 Issue No 1 Comparisons of Diesel Performance Neat and Preheated Transesterfied Cotton Seed Oil 067 071Document5 pages9.IJAEST Vol No 5 Issue No 1 Comparisons of Diesel Performance Neat and Preheated Transesterfied Cotton Seed Oil 067 071iserpNo ratings yet

- The Performance and Emissions of A Diesel Engine Fueled With Biodiesel From Yellow Grease and Soybean OilDocument17 pagesThe Performance and Emissions of A Diesel Engine Fueled With Biodiesel From Yellow Grease and Soybean OilSmith SteinNo ratings yet

- Papaya BiodieselDocument10 pagesPapaya BiodieselDineshNo ratings yet

- Gökhan Tüccar, Kadir Aydın: HighlightsDocument5 pagesGökhan Tüccar, Kadir Aydın: HighlightsjohnkirubaNo ratings yet

- H. Sharon, R. Jayaprakash, M. Karthigai Selvan, D.R. Soban Kumar, A. Sundaresan, K. KaruppasamyDocument7 pagesH. Sharon, R. Jayaprakash, M. Karthigai Selvan, D.R. Soban Kumar, A. Sundaresan, K. KaruppasamyHarihara sakthi sudhan mechNo ratings yet

- Experimental Analysis of Engine Performance and Combustion Characteristics Using Dual Biodiesel BlendsDocument7 pagesExperimental Analysis of Engine Performance and Combustion Characteristics Using Dual Biodiesel BlendsMadhurjya SaikiaNo ratings yet

- Performance and Emission Characteristic Analysis of Cucurbita Pepo L. and Tectona Grandis Seed Oil Biodiesel Blends in Ci Engine With AdditiveDocument16 pagesPerformance and Emission Characteristic Analysis of Cucurbita Pepo L. and Tectona Grandis Seed Oil Biodiesel Blends in Ci Engine With AdditiveJISENNIA MARLENY VARA GARCIANo ratings yet

- Experimental Investigations On Single Cylinder 4-Stroke Diesel Engine Using NanofuelsDocument5 pagesExperimental Investigations On Single Cylinder 4-Stroke Diesel Engine Using NanofuelsT Hari PrasadNo ratings yet

- Biodiesel Emissions and Its Effect To Environment - A ReviewDocument11 pagesBiodiesel Emissions and Its Effect To Environment - A ReviewDuc TranNo ratings yet

- Karanja OilDocument16 pagesKaranja OilM tejaswiniNo ratings yet

- Modeling, Analysis and Optimization For The Biodiesel Production Process From Waste Cooking OilDocument10 pagesModeling, Analysis and Optimization For The Biodiesel Production Process From Waste Cooking Oilkivumbi AchileoNo ratings yet

- Research 2Document12 pagesResearch 2Gelo LunarioNo ratings yet

- Ju 18Document16 pagesJu 18Sherin Novia Dwi PareraNo ratings yet

- Comparison of Diesel and Petrol EnginesFrom EverandComparison of Diesel and Petrol EnginesRating: 2.5 out of 5 stars2.5/5 (3)

- Acoustic Emission-Based Monitoring Approach For Friction Stir Welding of Aluminum Alloy AA6063-T6 With Different Tool Pin ProfilesDocument10 pagesAcoustic Emission-Based Monitoring Approach For Friction Stir Welding of Aluminum Alloy AA6063-T6 With Different Tool Pin ProfileslarryNo ratings yet

- Material Data Sheet SuperelasticDocument1 pageMaterial Data Sheet SuperelasticlarryNo ratings yet

- Wedm OutputDocument36 pagesWedm OutputlarryNo ratings yet

- Microstructure and Mechanical Properties of Dissimilar Al Cu Joints by Friction Stir WeldingDocument8 pagesMicrostructure and Mechanical Properties of Dissimilar Al Cu Joints by Friction Stir WeldinglarryNo ratings yet

- Parametric Study and Optimization of Wedm Parameters For Titanium Diboride TibDocument5 pagesParametric Study and Optimization of Wedm Parameters For Titanium Diboride TiblarryNo ratings yet

- Al-Cu Optimal FeedDocument6 pagesAl-Cu Optimal FeedlarryNo ratings yet

- A Fully Coupled Thermo-Mechanical Model of Friction Stir WeldingDocument16 pagesA Fully Coupled Thermo-Mechanical Model of Friction Stir WeldinglarryNo ratings yet

- Materials: Machinability Analysis and Optimization in Wire Edm of Medical Grade Nitinol Memory AlloyDocument17 pagesMaterials: Machinability Analysis and Optimization in Wire Edm of Medical Grade Nitinol Memory AlloylarryNo ratings yet

- FSW With CodeDocument131 pagesFSW With CodelarryNo ratings yet

- Effect of Tool Rotational Speed On The MicrostructDocument11 pagesEffect of Tool Rotational Speed On The MicrostructlarryNo ratings yet

- Input Parameters Tool Transverse and Rotational SpeedDocument3 pagesInput Parameters Tool Transverse and Rotational SpeedlarryNo ratings yet

- FSW - FEM - HyperworksDocument12 pagesFSW - FEM - HyperworkslarryNo ratings yet

- Process Mechanics of Low Plasticity Burnishing of Nitinol AlloyDocument11 pagesProcess Mechanics of Low Plasticity Burnishing of Nitinol AlloylarryNo ratings yet

- Modeling and Optimization of Wire-EDM Parameters For Machining of Ni Ti Shape Memory Alloy Using Hybrid Approach of Taguchi and NSGA-IIDocument15 pagesModeling and Optimization of Wire-EDM Parameters For Machining of Ni Ti Shape Memory Alloy Using Hybrid Approach of Taguchi and NSGA-IIlarryNo ratings yet

- Jte 1120Document37 pagesJte 1120larryNo ratings yet

- Gamma Radiation Shielding: e I e I X IDocument4 pagesGamma Radiation Shielding: e I e I X IlarryNo ratings yet

- Kerf WidthDocument6 pagesKerf WidthlarryNo ratings yet

- Optimization of The WEDM Parameters On MDocument10 pagesOptimization of The WEDM Parameters On MlarryNo ratings yet

- Full Text 01Document56 pagesFull Text 01juanky079No ratings yet

- CDPF System PDFDocument16 pagesCDPF System PDFmanualNo ratings yet

- Cat 360kvaDocument7 pagesCat 360kvaMuhammad Aftab AhmedNo ratings yet

- Steam Generator PerformanceDocument7 pagesSteam Generator Performancervkumar61No ratings yet

- Baltur Pressure Jet BurnersDocument186 pagesBaltur Pressure Jet BurnersgeorgeNo ratings yet

- P11301EN Euro 6 Engines Ready For The MarketDocument9 pagesP11301EN Euro 6 Engines Ready For The MarketCalvin Tan YS0% (1)

- Ref7 PDFDocument7 pagesRef7 PDFJulian BermudezNo ratings yet

- Computer Simulated Plant Design For Waste Minimization & Pollution PreventionDocument178 pagesComputer Simulated Plant Design For Waste Minimization & Pollution PreventionAndreea Florea100% (1)

- Fleet Checklist TRICYCLEDocument16 pagesFleet Checklist TRICYCLEfavowritesNo ratings yet

- Scientific Report3Document17 pagesScientific Report3NaheedNo ratings yet

- CS 140 - Instrukcja Obsługi - ENDocument48 pagesCS 140 - Instrukcja Obsługi - ENagapitplNo ratings yet

- MC 10165111 9999Document15 pagesMC 10165111 9999ZuskerNo ratings yet

- 7693 BrochureDocument6 pages7693 BrochureTadala Paul MaluwaNo ratings yet

- Caterpillar 18MDocument28 pagesCaterpillar 18MnikbeamNo ratings yet

- DCA45SSIU2 Rev 7 STD ManualDocument160 pagesDCA45SSIU2 Rev 7 STD ManualRahmat Nur IlhamNo ratings yet

- Yamaha Generator Ef2800i, Yg2800i Lit 19626 01 13Document45 pagesYamaha Generator Ef2800i, Yg2800i Lit 19626 01 13kir0i100% (1)

- Hybrid Eletric Vehicle Notes 1Document10 pagesHybrid Eletric Vehicle Notes 1Anandhu ANo ratings yet

- 15.3. Operating Variables That Affect Si Engine Performance, Efficiency, and EmissionsDocument21 pages15.3. Operating Variables That Affect Si Engine Performance, Efficiency, and EmissionsDUVAN FELIPE MUNOZ GARCIANo ratings yet

- Environmental Aspect / Impact Registration and Evaluation SheetDocument3 pagesEnvironmental Aspect / Impact Registration and Evaluation SheetrewrtegamingNo ratings yet

- Elements and ProblemsDocument14 pagesElements and ProblemsEymann Jala0% (1)

- Design & Fabrication of Air Driven Engine: Sanketh S, Harsha R N, Manunath MVDocument10 pagesDesign & Fabrication of Air Driven Engine: Sanketh S, Harsha R N, Manunath MVretechNo ratings yet

- Recirculation Flue Gas FanDocument4 pagesRecirculation Flue Gas Fanhuynhthanhtamga1981No ratings yet

- Webasto AIRTOP 3500/5000 Installation InstructionsDocument32 pagesWebasto AIRTOP 3500/5000 Installation InstructionsDavid ButlerNo ratings yet

- 2014 Clean Air in Ports Workingpaper 4Document23 pages2014 Clean Air in Ports Workingpaper 4Ali SalahNo ratings yet

- Full Length Article: SciencedirectDocument15 pagesFull Length Article: SciencedirectJonas Drumond Alves SoaresNo ratings yet

- SCR Tier4bDocument112 pagesSCR Tier4blungu mihai100% (1)

- Tata Sumo Victa ManualDocument92 pagesTata Sumo Victa Manualxtemp100% (4)