Professional Documents

Culture Documents

Metal Core Wires & Fluxes For Submerged Arc Welding

Uploaded by

Rodrigo RojasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Metal Core Wires & Fluxes For Submerged Arc Welding

Uploaded by

Rodrigo RojasCopyright:

Available Formats

Submerged Arc Welding History of

After 90 years in the business, Training and expertise are key to

Hobart Brothers is Welding. And Hobart Brothers.

Welding is Hobart Brothers. Such a respectable past can only be built by

knowledgeable people. That’s why, whether

Metalloy Wire Diameter Offerings Much has changed in industry since 1920; efforts on welding research and product

you have a question on technique, materials

Metal Core Melt Off Characteristics vs Solid Wire • Metalloy EM13K-S AWS: EC1 5/64", 3/32", 1/8", 5/32"

Hobart Brothers was there every step of

or applications, you know who to call. development and, as a result, now offer one

the way. You might even say the company of the most complete product lines in the

• Metalloy EM13K-S MOD AWS: EC1 3/32", 1/8", 5/32" 1-800-532-2618

did more than simply keep up with new industry today. Recognized worldwide as

• Metalloy N1-S AWS: ECNi1 3/32", 1/8", 5/32"

Metal cored technologies and processes. The company who started that first the “specialists in flux-cored and metal-cored

wire has • Metalloy W-S AWS: ECW 3/32", 1/8", 5/32"

higher

It helped forge them. spark over 90 years ago. wires,” Hobart Brothers features over 52

current • Metalloy F2-S AWS: ECF2 5/64", 3/32", 1/8", 5/32"

density

Hobart has become a world leader in the Hobart Brothers has served major metal different products for welding carbon and

• Metalloy 92-S AWS: ECM1 3/32", 1/8", 5/32"

Metal Core Wires & Fluxes

for higher

deposition

field. Today you can find the broadest fabrication markets as a top-quality low alloy steels, in addition to special

• Metalloy 100F3-S AWS: ECF3 3/32", 1/8", 5/32"

selection of filler metals in the United States. manufacturer of stick, flux-cored and metal- formulations for applications in the ship-

• Metalloy 112-S AWS: ECM3 3/32", 1/8", 5/32"

cored wires for over 25 years. Throughout

for Submerged Arc Welding

• Metalloy 120-S AWS: ECM4 3/32", 1/8", 5/32" & are well building, infrastructure construction, offshore

known brands of Hobart Brothers. that time, we’ve consistently focused our oil, and heavy equipment industries.

Metal cored • Metalloy B2-S AWS: ECB2 5/64", 3/32", 1/8", 5/32"

wire has wider

projection area • Metalloy B3-S AWS: ECB3 5/64", 3/32", 1/8", 5/32"

Hobart Distributors

with less

turbulent Standard Packaging: 60lb (27.2 Kg) coils and 600lb (272 Kg) drums

weld pool

• Contact Hobart Brothers for additional available diameters.

To locate your nearest Hobart distributor call 1-937-332-4000 or 1-937-332-5188

Diameter Conversions:

or visit our Web site www.hobartbrothers.com www.MillerWelds.com 800-4-A-MILLER

5/64"= 2.0mm 3/32"= 2.4mm 1/8"= 3.2mm 5/32"= 4.0mm Headquarters (800-426-4553)

Hobart Brothers Company 101 Trade Square East Troy, OH 45373 Phone: 937-332-4000 Fax: 937-332-5700

Hobart Fluxes:

Neutral and active agglomerated fluxes are now available to provide

a single source for both flux and wire. These fluxes are high in International Headquarters Regional Office - Mexico Ecuador, Peru, Bolivia, Chile,

Phone: 937-332-5188 Phone: +52-55-5366-7370 Argentina, Uruguay, Paraguay www.smithequipment.com | 800-843-7912

performance, quality, and generate weld deposits with excellent FAX: 937-332-5064 FAX : +52-55-5366-7376 Phone: 920-968-7508

mechanical properties. Flux particle size is uniform through controlled Regional Office - Canada E-mail: jflore@millerwelds.com E-mail: mferna@millerwelds.com

mesh screening. The flux is free flowing with consistent weld puddle Canadian Welding Products Group Web site: www.itwweldingmexico.com Guatemala, El Salvador, Honduras,

degassing due to the minimum number of fines. Phone: (519)-537-6291 Welding Industries of Australia Nicaragua, Costa Rica, Belize

Fax: (519)-421-0480 Phone: +61-1300-300-884 Phone: 525553667370 www.bernardwelds.com | 800-946-2281

Regional Office - Middle East FAX: +61-8-827-66327 FAX: 525553667388

Electrode/Flux – Cross Reference Available flux types: E-mail: intc@welding.com.au E-mail: ventas@itwwelding.com.mx

Phone: +971-4299-6621

Hobart Brand Packaging Part Number Web site: www.welding.com.au

Submerged Arc Wire FAX: +971-4299-6681 Bahamas, Barbados, Dominican

• HN-590 N=Neutral 55lb (25kg) bag S669610-055 E-mail: itwme@emirates.net.ae Weldwell New Zealand Republic, Jamaica, Puerto Rico,

www.weldcraft.com | 800-752-7620

Composite Composite • HN-511 N=Neutral 55lb (25kg) bag S669310-055 Regional Office - India Phone: +64-6-834-1600 Virgin Islands

TriMark Wire AWS Class Wire AWS Class Lincoln ESAB • HA-495 A=Active 55lb (25kg) bag S669410-055 Phone: +91-222520-7388 FAX: +64-6-835-4568 Phone: 937-332-5188

FAX: +91-222520-7389 E-mail: admin@weldwell.co.nz FAX: 937-332-5064

Metalloy EC1 EM13K L-50 SPOOLARC 29S See product data sheets for AWS deposited weld Web site: www.weldwell.co.nz E-mail: quafile@hobartbrothers.com

E-mail: itwweldi@satyam.net.in

EM13K-S L-61 SPOOLARC 81 metal class, weld metal chemistry, and mechanical Regional Office - Northern Europe Manufacturers:

Regional Office - Asia www.tempil.com | 800-757-8301

Metalloy N1-S ECNi1 ECNi1 LA-75 SPOOLARC 75 properties with specific flux/wire combinations. Phone: 65-6552-1223 Phone: 46-031-726-4600

Tien Tai Electrode Co., LTD

FAX: 65-6552-1929 FAX: 46-031-726-4700

Phone: 886-6-2663721

Metalloy F2-S ECF2 EF2 LA-82 Please remember there is no AWS class for flux!! AWS E-mail: per.gelang@itw-welding.se

E-mail: vmarta@millerwelds.com Fax: 886-6-2664301

classifies flux/wire combinations with a deposited weld Web site: www.elga.se

Metalloy W-S ECW Beijing Miller Electric Web site: www.tientai.com

metal classification system under A5.17 for carbon (mild) Regional Office - Russia

Phone: +86-10-8739-7900 Tien Tai Electrode (Kun Shan) Co. www.jetline.com | 949-951-1515

Metalloy 92-S ECM1 steel filler metals and A5.23 for low alloy filler metals. Phone: +7-812-961-5481

FAX: +86-10-8739-7600

E-mail: infosvarka@itw-welding.ru Phone: 86-51257446669

Examples: A5.17:F7A6-EC1, A5.23:F7A10-ECNi1-Ni1 E-mail: lisa.li@millerchina.com

Metalloy 100F3-S ECF3 EF3 LA-84 Web site: www.itw-welding.ru FAX: 86-51257448416

Regional Office - Brazil E-mail fuhu.chen@tientai.com.cn

Metalloy 112-S ECM3 Phone: +55-11-5514-3366 Regional Office - Spain

Web site: www.tientai.com

FAX: +55-11-5891-7679 Phone: 34-963935398 www.magnaflux.com | 847-657-5300

Metalloy 120-S ECM4 FAX: 34-963629516 Elga AB

E-mail: itwsoldagem@osite.com.br

E-mail: vcubero@itw-welding.es Phone: +46-31-726-46 00

Metalloy B2-S ECB2 LAC-B2 SPOOL ARC Web site: www.itwsoldagem.com.br

FAX: +46-31-726-47-00

Regional Office - France Regional Office - Africa

U515 Phone: +44-7770562799

Web site: www.elgawelding.com

Phone: +33-1-6004-1166 ®

Metalloy B3-S ECB3 EB3 LA-93 FAX : +33-1-6004-8860 FAX: +44-1204-473039

E-mail: miller@itw-welding.fr E-mail: Andy.Foster@itw-welding.co.uk

www.welding.org 800-332-9448

Web site: www.miller-france.com Web site: www.itw-welding.co.uk

937-332-5000

Submerged Arc Flux Regional Office - Italy Regional Office for:

Phone: +39-02-9829-0218 Colombia, Venezuela,

HOBART LINCOLN ESAB

FAX : +39-02-9828-1552 Trinidad & Tobago, Panama

HN-590 860 OK Flux 429, OK Flux 10.71 E-mail: millerit@itw-welding.it Phone: 920-968-7508

Regional Office - Netherlands FAX: 920-735-4125

HN-511 880M, 8500 OK Flux 10.62 Phone: +311-866-41456 E-mail: mferna@millerwelds.com www.tregaskiss.com 877-737-3111

519-737-3000

HA-495 761, 780 OK Flux 231, OK Flux 350 FAX : +311-866-49020

E-mail: info@itw-welding.nl

Web site: www.itw-welding.com

REV. 2/10

Metal Cored Wires & Fluxes for Submerged Arc Welding

(Composite Electrodes)

Classification for Carbon Steel Electrodes and Fluxes

Example: F7A8-EC1 per AWS A5.17

Principles of Operation

The submerged arc welding process introduced in the early 1930’s

Deposition Rate % Increases with Metal Core versus Solid Wire

Diameter Amperage Voltage Approx Wire Feed Deposition Rate Deposition

FXXX – ECXXX (A5.17) Table for Electrode/Flux Classifications

was originally developed to weld longitudinal seams in large pipe. (DCEP) Speed IPM Lbs/hr (Kg/hr) Rate % “F” indicates a Submerged TRI-MARK COMPOSITE WIRES HOBART FLUX ELECTRODE/FLUX APPROVALS

The process was developed to provide high quality weld metal Increase arc welding flux

Metalloy Solid Metalloy Solid

deposits by shielding the arc and the molten weld puddle from the Metalloy EM13K-S HA-495 F7A4-EC1 CWB F49A4-EC1

contaminating effects of the air through the melting of a blanket of 5/64" 200 29 71 63 4.9 (2.2) 4.8 (2.2) 2.08

Indicates the minimum Tensile Strength

granular flux. (2.0mm) 250 30 89 80 6.5 (2.9) 6.3 (2.8) 3.17 “E” indicates electrode and “C” Metalloy EM13K-S HN-511 F7A10-EC1 CWB F49A7-EC1

(in increments of 10,000 psi)

indicates composite electrode F7P8-EC1 CWB F43P7-EC1

300 31 115 96 8.4 (3.8) 8.1 (3.7) 3.70

Sub Arc Advantages Designates the condition of (refer to Table 2 of AWS A5.17)

350 32 154 114 11.0 (4.9) 9.4 (4.3) 17.02 Metalloy EM13K-S HN-590 F7A8-EC1 ABS TO AWS F7A8-EC1

• High deposition and travel speed heat treatment. “A” for as-welded

400 33 190 137 13.7 (6.2) 11.3 (5.1) 21.24 and “P” for postweld heat treated F7P8-EC1 CWB F49A6-EC1

• High quality welds

450 34 233 167 16.6 (7.5) 13.6 (6.2) 22.06 CWB F43P6-EC1

• Minimal arc visibility Indicates the temperature in °F at

• Easily automated 500 36 284 199 20.5 (9.3) 16.0 (7.3) 28.13 Metalloy EM13K-S MOD HN-511 F7A8-EC1

which the impact strength of the weld

• Good weld bead shapes and toe lines 3/32" 300 29 85 70 8.7 (3.9) 8.1 (3.7) 7.4 F7P4-EC1

metal meets or exceeds 20 ft-lbs

• Excellent chemical and mechanical properties (2.4mm) 350 30 105 80 10.7 (4.9) 9.2 (4.2) 16.3 Metalloy EM13K-S MOD HN-590 F7A8-EC1

The submerged arc process is widely used in heavy plate 400 30 125 89 12.9 (5.9) 10.6 (4.8) 21.7 Composite Chemical Composition F7P4-EC1

fabrication. This includes the welding of: 450 32 150 103 15.4 (7.0) 12.6 (5.7) 22.2 Product Electrode Class Requirements for Weld Metal

500 37 175 121 17.8 (8.1) 14.8 (6.7) 20.2 CARBON WELD METAL (A5.23) Table for Electrode/Flux Classifications

• Structural – bridge, building, and structure manufacturing

• Pipe – both longitudinal seams and circumferential welds Metalloy EM13K-S EC1 Carbon Steel

550 37 210 139 21.1 (9.6) 16.6 (7.5) 27.1 Metalloy N1-S HN-511 F7A8-ECNi1-Ni1

• Vessels and tanks for pressure storage use Metalloy EM13K-S MOD EC1 Carbon Steel

600 38 240 156 24.3 (11.0) 18.9 (8.6) 28.6 F6P10-ECNi1-Ni1

• Heavy machine components CHROMIUM-MOLYBDENUM WELD METAL

• Railcar manufacturing 1/8" 450 31 76 60 12.1 (5.5) 11.8 (5.4) 2.5 Metalloy B2-S ECB2 1.00 - 1.50% Chromium, .40 - .65% Molybdenum Metalloy N1-S HN-590 F7A10-ECNi1-Ni1

• Heavy construction/mining/crane (3.2mm) 500 32 87 68 14.7 (6.7) 13.1 (5.9) 12.2 Metalloy B3-S ECB3 2.00 - 2.50% Chromium, .90 - 1.20% Molybdenum F6P10-ECNi1-Ni1

Welded metal thickness ranges from a minimum of 1/16" (1.6mm) 550 32 100 75 17.3 (7.8) 14.5 (6.6) 19.3 NICKEL-MOLYBDENUM WELD METAL Metalloy W-S HN-590 F8A4-ECW-W

up to unlimited for single pass welds and unlimited metal thickness 600 35 116 80 20.0 (9.1) 15.6 (7.1) 28.2 Metalloy F2-S ECF2 .40 - .80% Nickel, .40 - .65% Molybdenum

Metalloy 92-S HN-511 F8A8-ECM1-M1

on multi-pass welds using the proper joint preparation and electrode 650 36 135 86 23.0 (10.4) 17.6 (8.0) 30.7 Metalloy 100F3-S ECF3 .70 - 1.10% Nickel, .40 - .65% Molybdenum

flux combination. MANGANESE-NICKEL-MOLYBDENUM WELD METAL F8P8-ECM1-M1

700 37 153 94 25.7 (11.7) 19.3 (8.7) 33.2

Metalloy 92-S ECM1 .60 - 1.60% Manganese, 1.25 - 2.00% Nickel, .35% Molybdenum Metalloy 92-S HN-590 F8A8-ECM1-M1

5/32" 400 30 45 37 11.2 (5.1) 10.9 (4.9) 2.7

Benefits of Metal Core Wire vs. Solid Wire Metalloy 112-S ECM3 .90 - 1.80% Manganese, 1.80 - 2.60% Nickel, .20 - .70% Molybdenum F8P8-ECM1-M1

(4.0mm) 500 33 58 47 15.5 (7.0) 14.0 (6.4) 10.7

• Increased deposition rates, typically 15-30% higher (See Table 1) Metalloy 120-S ECM4 1.30 - 2.25% Manganese, 2.00 - 2.80% Nickel, .30 - .80% Molybdenum

Metalloy F2-S HN-511 F9A8-ECF2-F2

• Increased travel speeds 600 35 69 55 19.5 (8.8) 17.2 (7.8) 13.4 NICKEL WELD METAL

• Higher wire burnoff rates F9P6-ECF2-F2

700 38 90 64 23.8 (10.5) 19.6 (8.9) 21.4 Metalloy N1-S ECNi1 .75 - 1.10% Nickel

• Higher quality weld deposits 800 40 113 75 29.8 (13.5) 23.5 (10.7) 26.8 WELD METAL FOR WEATHERING STEELS Metalloy F2-S HN-590 F9A8-ECF2-F2

• A wider broader shaped penetration and fusion pattern Metalloy W-S ECW Chromium, Copper & Nickel Alloy for Weathering Steel F9P6-ECF2-F2

900 42 143 88 38.7 (17.6) 28.2 (12.8) 37.2

• Greater tolerance to gaps, poor fit up, and burn through

• Easily modified for special applications Table 1 Metalloy B2-S HN-511 F9P*-ECB2-B2

Similar to welding with gas shielded metal core, in most submerged

Classification for Low-Alloy Steel Electrodes and Fluxes Metalloy B3-S HN-511 F9P*-ECB3-B3

arc applications, the maximum productivity and quality benefits are Example: F7A8-ECNi1-Ni1 per AWS A5.23

Metalloy 112-S HN-511 F11A8-ECM3-M3

realized when stepping up one wire diameter from the current solid

wire size. FXXX - ECXX - XX Metalloy 100F3-S HN-511

F10P4-ECM3-M3

F10A6-ECF3-F3

“F” indicates a Submerged Indicates the chemical composition

F10P6-ECF3-F3

arc welding flux of the weld metal obtained with the

flux and the electrode Metalloy 100F3-S HN-590 F10A4-ECF3-F3

Indicates the minimum Tensile Strength

(in increments of 10,000 psi) F10P2-ECF3-F3

Indicates the chemical composition

Designates the condition of heat treatment. of the electrode Metalloy 120-S HN-511 F11A10-ECM4-M4 ABS F11A10-ECM4-M4 H10

“A” for as-welded and

“E” indicates electrode and “C” * Contact Hobart Brothers for Charpy V-Notch Toughness

“P” for postweld heat treated

indicates composite electrode

Indicates the temperature in °F at

which the impact strength of the weld

metal meets or exceeds 20 ft-lbs

Metal Cored Wires & Fluxes for Submerged Arc Welding

(Composite Electrodes)

Classification for Carbon Steel Electrodes and Fluxes

Example: F7A8-EC1 per AWS A5.17

Principles of Operation

The submerged arc welding process introduced in the early 1930’s

Deposition Rate % Increases with Metal Core versus Solid Wire

Diameter Amperage Voltage Approx Wire Feed Deposition Rate Deposition

FXXX – ECXXX (A5.17) Table for Electrode/Flux Classifications

was originally developed to weld longitudinal seams in large pipe. (DCEP) Speed IPM Lbs/hr (Kg/hr) Rate % “F” indicates a Submerged TRI-MARK COMPOSITE WIRES HOBART FLUX ELECTRODE/FLUX APPROVALS

The process was developed to provide high quality weld metal Increase arc welding flux

Metalloy Solid Metalloy Solid

deposits by shielding the arc and the molten weld puddle from the Metalloy EM13K-S HA-495 F7A4-EC1 CWB F49A4-EC1

contaminating effects of the air through the melting of a blanket of 5/64" 200 29 71 63 4.9 (2.2) 4.8 (2.2) 2.08

Indicates the minimum Tensile Strength

granular flux. (2.0mm) 250 30 89 80 6.5 (2.9) 6.3 (2.8) 3.17 “E” indicates electrode and “C” Metalloy EM13K-S HN-511 F7A10-EC1 CWB F49A7-EC1

(in increments of 10,000 psi)

indicates composite electrode F7P8-EC1 CWB F43P7-EC1

300 31 115 96 8.4 (3.8) 8.1 (3.7) 3.70

Sub Arc Advantages Designates the condition of (refer to Table 2 of AWS A5.17)

350 32 154 114 11.0 (4.9) 9.4 (4.3) 17.02 Metalloy EM13K-S HN-590 F7A8-EC1 ABS TO AWS F7A8-EC1

• High deposition and travel speed heat treatment. “A” for as-welded

400 33 190 137 13.7 (6.2) 11.3 (5.1) 21.24 and “P” for postweld heat treated F7P8-EC1 CWB F49A6-EC1

• High quality welds

450 34 233 167 16.6 (7.5) 13.6 (6.2) 22.06 CWB F43P6-EC1

• Minimal arc visibility Indicates the temperature in °F at

• Easily automated 500 36 284 199 20.5 (9.3) 16.0 (7.3) 28.13 Metalloy EM13K-S MOD HN-511 F7A8-EC1

which the impact strength of the weld

• Good weld bead shapes and toe lines 3/32" 300 29 85 70 8.7 (3.9) 8.1 (3.7) 7.4 F7P4-EC1

metal meets or exceeds 20 ft-lbs

• Excellent chemical and mechanical properties (2.4mm) 350 30 105 80 10.7 (4.9) 9.2 (4.2) 16.3 Metalloy EM13K-S MOD HN-590 F7A8-EC1

The submerged arc process is widely used in heavy plate 400 30 125 89 12.9 (5.9) 10.6 (4.8) 21.7 Composite Chemical Composition F7P4-EC1

fabrication. This includes the welding of: 450 32 150 103 15.4 (7.0) 12.6 (5.7) 22.2 Product Electrode Class Requirements for Weld Metal

500 37 175 121 17.8 (8.1) 14.8 (6.7) 20.2 CARBON WELD METAL (A5.23) Table for Electrode/Flux Classifications

• Structural – bridge, building, and structure manufacturing

• Pipe – both longitudinal seams and circumferential welds Metalloy EM13K-S EC1 Carbon Steel

550 37 210 139 21.1 (9.6) 16.6 (7.5) 27.1 Metalloy N1-S HN-511 F7A8-ECNi1-Ni1

• Vessels and tanks for pressure storage use Metalloy EM13K-S MOD EC1 Carbon Steel

600 38 240 156 24.3 (11.0) 18.9 (8.6) 28.6 F6P10-ECNi1-Ni1

• Heavy machine components CHROMIUM-MOLYBDENUM WELD METAL

• Railcar manufacturing 1/8" 450 31 76 60 12.1 (5.5) 11.8 (5.4) 2.5 Metalloy B2-S ECB2 1.00 - 1.50% Chromium, .40 - .65% Molybdenum Metalloy N1-S HN-590 F7A10-ECNi1-Ni1

• Heavy construction/mining/crane (3.2mm) 500 32 87 68 14.7 (6.7) 13.1 (5.9) 12.2 Metalloy B3-S ECB3 2.00 - 2.50% Chromium, .90 - 1.20% Molybdenum F6P10-ECNi1-Ni1

Welded metal thickness ranges from a minimum of 1/16" (1.6mm) 550 32 100 75 17.3 (7.8) 14.5 (6.6) 19.3 NICKEL-MOLYBDENUM WELD METAL Metalloy W-S HN-590 F8A4-ECW-W

up to unlimited for single pass welds and unlimited metal thickness 600 35 116 80 20.0 (9.1) 15.6 (7.1) 28.2 Metalloy F2-S ECF2 .40 - .80% Nickel, .40 - .65% Molybdenum

Metalloy 92-S HN-511 F8A8-ECM1-M1

on multi-pass welds using the proper joint preparation and electrode 650 36 135 86 23.0 (10.4) 17.6 (8.0) 30.7 Metalloy 100F3-S ECF3 .70 - 1.10% Nickel, .40 - .65% Molybdenum

flux combination. MANGANESE-NICKEL-MOLYBDENUM WELD METAL F8P8-ECM1-M1

700 37 153 94 25.7 (11.7) 19.3 (8.7) 33.2

Metalloy 92-S ECM1 .60 - 1.60% Manganese, 1.25 - 2.00% Nickel, .35% Molybdenum Metalloy 92-S HN-590 F8A8-ECM1-M1

5/32" 400 30 45 37 11.2 (5.1) 10.9 (4.9) 2.7

Benefits of Metal Core Wire vs. Solid Wire Metalloy 112-S ECM3 .90 - 1.80% Manganese, 1.80 - 2.60% Nickel, .20 - .70% Molybdenum F8P8-ECM1-M1

(4.0mm) 500 33 58 47 15.5 (7.0) 14.0 (6.4) 10.7

• Increased deposition rates, typically 15-30% higher (See Table 1) Metalloy 120-S ECM4 1.30 - 2.25% Manganese, 2.00 - 2.80% Nickel, .30 - .80% Molybdenum

Metalloy F2-S HN-511 F9A8-ECF2-F2

• Increased travel speeds 600 35 69 55 19.5 (8.8) 17.2 (7.8) 13.4 NICKEL WELD METAL

• Higher wire burnoff rates F9P6-ECF2-F2

700 38 90 64 23.8 (10.5) 19.6 (8.9) 21.4 Metalloy N1-S ECNi1 .75 - 1.10% Nickel

• Higher quality weld deposits 800 40 113 75 29.8 (13.5) 23.5 (10.7) 26.8 WELD METAL FOR WEATHERING STEELS Metalloy F2-S HN-590 F9A8-ECF2-F2

• A wider broader shaped penetration and fusion pattern Metalloy W-S ECW Chromium, Copper & Nickel Alloy for Weathering Steel F9P6-ECF2-F2

900 42 143 88 38.7 (17.6) 28.2 (12.8) 37.2

• Greater tolerance to gaps, poor fit up, and burn through

• Easily modified for special applications Table 1 Metalloy B2-S HN-511 F9P*-ECB2-B2

Similar to welding with gas shielded metal core, in most submerged

Classification for Low-Alloy Steel Electrodes and Fluxes Metalloy B3-S HN-511 F9P*-ECB3-B3

arc applications, the maximum productivity and quality benefits are Example: F7A8-ECNi1-Ni1 per AWS A5.23

Metalloy 112-S HN-511 F11A8-ECM3-M3

realized when stepping up one wire diameter from the current solid

wire size. FXXX - ECXX - XX Metalloy 100F3-S HN-511

F10P4-ECM3-M3

F10A6-ECF3-F3

“F” indicates a Submerged Indicates the chemical composition

F10P6-ECF3-F3

arc welding flux of the weld metal obtained with the

flux and the electrode Metalloy 100F3-S HN-590 F10A4-ECF3-F3

Indicates the minimum Tensile Strength

(in increments of 10,000 psi) F10P2-ECF3-F3

Indicates the chemical composition

Designates the condition of heat treatment. of the electrode Metalloy 120-S HN-511 F11A10-ECM4-M4 ABS F11A10-ECM4-M4 H10

“A” for as-welded and

“E” indicates electrode and “C” * Contact Hobart Brothers for Charpy V-Notch Toughness

“P” for postweld heat treated

indicates composite electrode

Indicates the temperature in °F at

which the impact strength of the weld

metal meets or exceeds 20 ft-lbs

Metal Cored Wires & Fluxes for Submerged Arc Welding

(Composite Electrodes)

Classification for Carbon Steel Electrodes and Fluxes

Example: F7A8-EC1 per AWS A5.17

Principles of Operation

The submerged arc welding process introduced in the early 1930’s

Deposition Rate % Increases with Metal Core versus Solid Wire

Diameter Amperage Voltage Approx Wire Feed Deposition Rate Deposition

FXXX – ECXXX (A5.17) Table for Electrode/Flux Classifications

was originally developed to weld longitudinal seams in large pipe. (DCEP) Speed IPM Lbs/hr (Kg/hr) Rate % “F” indicates a Submerged TRI-MARK COMPOSITE WIRES HOBART FLUX ELECTRODE/FLUX APPROVALS

The process was developed to provide high quality weld metal Increase arc welding flux

Metalloy Solid Metalloy Solid

deposits by shielding the arc and the molten weld puddle from the Metalloy EM13K-S HA-495 F7A4-EC1 CWB F49A4-EC1

contaminating effects of the air through the melting of a blanket of 5/64" 200 29 71 63 4.9 (2.2) 4.8 (2.2) 2.08

Indicates the minimum Tensile Strength

granular flux. (2.0mm) 250 30 89 80 6.5 (2.9) 6.3 (2.8) 3.17 “E” indicates electrode and “C” Metalloy EM13K-S HN-511 F7A10-EC1 CWB F49A7-EC1

(in increments of 10,000 psi)

indicates composite electrode F7P8-EC1 CWB F43P7-EC1

300 31 115 96 8.4 (3.8) 8.1 (3.7) 3.70

Sub Arc Advantages Designates the condition of (refer to Table 2 of AWS A5.17)

350 32 154 114 11.0 (4.9) 9.4 (4.3) 17.02 Metalloy EM13K-S HN-590 F7A8-EC1 ABS TO AWS F7A8-EC1

• High deposition and travel speed heat treatment. “A” for as-welded

400 33 190 137 13.7 (6.2) 11.3 (5.1) 21.24 and “P” for postweld heat treated F7P8-EC1 CWB F49A6-EC1

• High quality welds

450 34 233 167 16.6 (7.5) 13.6 (6.2) 22.06 CWB F43P6-EC1

• Minimal arc visibility Indicates the temperature in °F at

• Easily automated 500 36 284 199 20.5 (9.3) 16.0 (7.3) 28.13 Metalloy EM13K-S MOD HN-511 F7A8-EC1

which the impact strength of the weld

• Good weld bead shapes and toe lines 3/32" 300 29 85 70 8.7 (3.9) 8.1 (3.7) 7.4 F7P4-EC1

metal meets or exceeds 20 ft-lbs

• Excellent chemical and mechanical properties (2.4mm) 350 30 105 80 10.7 (4.9) 9.2 (4.2) 16.3 Metalloy EM13K-S MOD HN-590 F7A8-EC1

The submerged arc process is widely used in heavy plate 400 30 125 89 12.9 (5.9) 10.6 (4.8) 21.7 Composite Chemical Composition F7P4-EC1

fabrication. This includes the welding of: 450 32 150 103 15.4 (7.0) 12.6 (5.7) 22.2 Product Electrode Class Requirements for Weld Metal

500 37 175 121 17.8 (8.1) 14.8 (6.7) 20.2 CARBON WELD METAL (A5.23) Table for Electrode/Flux Classifications

• Structural – bridge, building, and structure manufacturing

• Pipe – both longitudinal seams and circumferential welds Metalloy EM13K-S EC1 Carbon Steel

550 37 210 139 21.1 (9.6) 16.6 (7.5) 27.1 Metalloy N1-S HN-511 F7A8-ECNi1-Ni1

• Vessels and tanks for pressure storage use Metalloy EM13K-S MOD EC1 Carbon Steel

600 38 240 156 24.3 (11.0) 18.9 (8.6) 28.6 F6P10-ECNi1-Ni1

• Heavy machine components CHROMIUM-MOLYBDENUM WELD METAL

• Railcar manufacturing 1/8" 450 31 76 60 12.1 (5.5) 11.8 (5.4) 2.5 Metalloy B2-S ECB2 1.00 - 1.50% Chromium, .40 - .65% Molybdenum Metalloy N1-S HN-590 F7A10-ECNi1-Ni1

• Heavy construction/mining/crane (3.2mm) 500 32 87 68 14.7 (6.7) 13.1 (5.9) 12.2 Metalloy B3-S ECB3 2.00 - 2.50% Chromium, .90 - 1.20% Molybdenum F6P10-ECNi1-Ni1

Welded metal thickness ranges from a minimum of 1/16" (1.6mm) 550 32 100 75 17.3 (7.8) 14.5 (6.6) 19.3 NICKEL-MOLYBDENUM WELD METAL Metalloy W-S HN-590 F8A4-ECW-W

up to unlimited for single pass welds and unlimited metal thickness 600 35 116 80 20.0 (9.1) 15.6 (7.1) 28.2 Metalloy F2-S ECF2 .40 - .80% Nickel, .40 - .65% Molybdenum

Metalloy 92-S HN-511 F8A8-ECM1-M1

on multi-pass welds using the proper joint preparation and electrode 650 36 135 86 23.0 (10.4) 17.6 (8.0) 30.7 Metalloy 100F3-S ECF3 .70 - 1.10% Nickel, .40 - .65% Molybdenum

flux combination. MANGANESE-NICKEL-MOLYBDENUM WELD METAL F8P8-ECM1-M1

700 37 153 94 25.7 (11.7) 19.3 (8.7) 33.2

Metalloy 92-S ECM1 .60 - 1.60% Manganese, 1.25 - 2.00% Nickel, .35% Molybdenum Metalloy 92-S HN-590 F8A8-ECM1-M1

5/32" 400 30 45 37 11.2 (5.1) 10.9 (4.9) 2.7

Benefits of Metal Core Wire vs. Solid Wire Metalloy 112-S ECM3 .90 - 1.80% Manganese, 1.80 - 2.60% Nickel, .20 - .70% Molybdenum F8P8-ECM1-M1

(4.0mm) 500 33 58 47 15.5 (7.0) 14.0 (6.4) 10.7

• Increased deposition rates, typically 15-30% higher (See Table 1) Metalloy 120-S ECM4 1.30 - 2.25% Manganese, 2.00 - 2.80% Nickel, .30 - .80% Molybdenum

Metalloy F2-S HN-511 F9A8-ECF2-F2

• Increased travel speeds 600 35 69 55 19.5 (8.8) 17.2 (7.8) 13.4 NICKEL WELD METAL

• Higher wire burnoff rates F9P6-ECF2-F2

700 38 90 64 23.8 (10.5) 19.6 (8.9) 21.4 Metalloy N1-S ECNi1 .75 - 1.10% Nickel

• Higher quality weld deposits 800 40 113 75 29.8 (13.5) 23.5 (10.7) 26.8 WELD METAL FOR WEATHERING STEELS Metalloy F2-S HN-590 F9A8-ECF2-F2

• A wider broader shaped penetration and fusion pattern Metalloy W-S ECW Chromium, Copper & Nickel Alloy for Weathering Steel F9P6-ECF2-F2

900 42 143 88 38.7 (17.6) 28.2 (12.8) 37.2

• Greater tolerance to gaps, poor fit up, and burn through

• Easily modified for special applications Table 1 Metalloy B2-S HN-511 F9P*-ECB2-B2

Similar to welding with gas shielded metal core, in most submerged

Classification for Low-Alloy Steel Electrodes and Fluxes Metalloy B3-S HN-511 F9P*-ECB3-B3

arc applications, the maximum productivity and quality benefits are Example: F7A8-ECNi1-Ni1 per AWS A5.23

Metalloy 112-S HN-511 F11A8-ECM3-M3

realized when stepping up one wire diameter from the current solid

wire size. FXXX - ECXX - XX Metalloy 100F3-S HN-511

F10P4-ECM3-M3

F10A6-ECF3-F3

“F” indicates a Submerged Indicates the chemical composition

F10P6-ECF3-F3

arc welding flux of the weld metal obtained with the

flux and the electrode Metalloy 100F3-S HN-590 F10A4-ECF3-F3

Indicates the minimum Tensile Strength

(in increments of 10,000 psi) F10P2-ECF3-F3

Indicates the chemical composition

Designates the condition of heat treatment. of the electrode Metalloy 120-S HN-511 F11A10-ECM4-M4 ABS F11A10-ECM4-M4 H10

“A” for as-welded and

“E” indicates electrode and “C” * Contact Hobart Brothers for Charpy V-Notch Toughness

“P” for postweld heat treated

indicates composite electrode

Indicates the temperature in °F at

which the impact strength of the weld

metal meets or exceeds 20 ft-lbs

Submerged Arc Welding History of

After 90 years in the business, Training and expertise are key to

Hobart Brothers is Welding. And Hobart Brothers.

Welding is Hobart Brothers. Such a respectable past can only be built by

knowledgeable people. That’s why, whether

Metalloy Wire Diameter Offerings Much has changed in industry since 1920; efforts on welding research and product

you have a question on technique, materials

Metal Core Melt Off Characteristics vs Solid Wire • Metalloy EM13K-S AWS: EC1 5/64", 3/32", 1/8", 5/32"

Hobart Brothers was there every step of

or applications, you know who to call. development and, as a result, now offer one

the way. You might even say the company of the most complete product lines in the

• Metalloy EM13K-S MOD AWS: EC1 3/32", 1/8", 5/32" 1-800-532-2618

did more than simply keep up with new industry today. Recognized worldwide as

• Metalloy N1-S AWS: ECNi1 3/32", 1/8", 5/32"

Metal cored technologies and processes. The company who started that first the “specialists in flux-cored and metal-cored

wire has • Metalloy W-S AWS: ECW 3/32", 1/8", 5/32"

higher

It helped forge them. spark over 90 years ago. wires,” Hobart Brothers features over 52

current • Metalloy F2-S AWS: ECF2 5/64", 3/32", 1/8", 5/32"

density

Hobart has become a world leader in the Hobart Brothers has served major metal different products for welding carbon and

• Metalloy 92-S AWS: ECM1 3/32", 1/8", 5/32"

Metal Core Wires & Fluxes

for higher

deposition

field. Today you can find the broadest fabrication markets as a top-quality low alloy steels, in addition to special

• Metalloy 100F3-S AWS: ECF3 3/32", 1/8", 5/32"

selection of filler metals in the United States. manufacturer of stick, flux-cored and metal- formulations for applications in the ship-

• Metalloy 112-S AWS: ECM3 3/32", 1/8", 5/32"

cored wires for over 25 years. Throughout

for Submerged Arc Welding

• Metalloy 120-S AWS: ECM4 3/32", 1/8", 5/32" & are well building, infrastructure construction, offshore

known brands of Hobart Brothers. that time, we’ve consistently focused our oil, and heavy equipment industries.

Metal cored • Metalloy B2-S AWS: ECB2 5/64", 3/32", 1/8", 5/32"

wire has wider

projection area • Metalloy B3-S AWS: ECB3 5/64", 3/32", 1/8", 5/32"

Hobart Distributors

with less

turbulent Standard Packaging: 60lb (27.2 Kg) coils and 600lb (272 Kg) drums

weld pool

• Contact Hobart Brothers for additional available diameters.

To locate your nearest Hobart distributor call 1-937-332-4000 or 1-937-332-5188

Diameter Conversions:

or visit our Web site www.hobartbrothers.com www.MillerWelds.com 800-4-A-MILLER

5/64"= 2.0mm 3/32"= 2.4mm 1/8"= 3.2mm 5/32"= 4.0mm Headquarters (800-426-4553)

Hobart Brothers Company 101 Trade Square East Troy, OH 45373 Phone: 937-332-4000 Fax: 937-332-5700

Hobart Fluxes:

Neutral and active agglomerated fluxes are now available to provide

a single source for both flux and wire. These fluxes are high in International Headquarters Regional Office - Mexico Ecuador, Peru, Bolivia, Chile,

Phone: 937-332-5188 Phone: +52-55-5366-7370 Argentina, Uruguay, Paraguay www.smithequipment.com | 800-843-7912

performance, quality, and generate weld deposits with excellent FAX: 937-332-5064 FAX : +52-55-5366-7376 Phone: 920-968-7508

mechanical properties. Flux particle size is uniform through controlled Regional Office - Canada E-mail: jflore@millerwelds.com E-mail: mferna@millerwelds.com

mesh screening. The flux is free flowing with consistent weld puddle Canadian Welding Products Group Web site: www.itwweldingmexico.com Guatemala, El Salvador, Honduras,

degassing due to the minimum number of fines. Phone: (519)-537-6291 Welding Industries of Australia Nicaragua, Costa Rica, Belize

Fax: (519)-421-0480 Phone: +61-1300-300-884 Phone: 525553667370 www.bernardwelds.com | 800-946-2281

Regional Office - Middle East FAX: +61-8-827-66327 FAX: 525553667388

Electrode/Flux – Cross Reference Available flux types: E-mail: intc@welding.com.au E-mail: ventas@itwwelding.com.mx

Phone: +971-4299-6621

Hobart Brand Packaging Part Number Web site: www.welding.com.au

Submerged Arc Wire FAX: +971-4299-6681 Bahamas, Barbados, Dominican

• HN-590 N=Neutral 55lb (25kg) bag S669610-055 E-mail: itwme@emirates.net.ae Weldwell New Zealand Republic, Jamaica, Puerto Rico,

www.weldcraft.com | 800-752-7620

Composite Composite • HN-511 N=Neutral 55lb (25kg) bag S669310-055 Regional Office - India Phone: +64-6-834-1600 Virgin Islands

TriMark Wire AWS Class Wire AWS Class Lincoln ESAB • HA-495 A=Active 55lb (25kg) bag S669410-055 Phone: +91-222520-7388 FAX: +64-6-835-4568 Phone: 937-332-5188

FAX: +91-222520-7389 E-mail: admin@weldwell.co.nz FAX: 937-332-5064

Metalloy EC1 EM13K L-50 SPOOLARC 29S See product data sheets for AWS deposited weld Web site: www.weldwell.co.nz E-mail: quafile@hobartbrothers.com

E-mail: itwweldi@satyam.net.in

EM13K-S L-61 SPOOLARC 81 metal class, weld metal chemistry, and mechanical Regional Office - Northern Europe Manufacturers:

Regional Office - Asia www.tempil.com | 800-757-8301

Metalloy N1-S ECNi1 ECNi1 LA-75 SPOOLARC 75 properties with specific flux/wire combinations. Phone: 65-6552-1223 Phone: 46-031-726-4600

Tien Tai Electrode Co., LTD

FAX: 65-6552-1929 FAX: 46-031-726-4700

Phone: 886-6-2663721

Metalloy F2-S ECF2 EF2 LA-82 Please remember there is no AWS class for flux!! AWS E-mail: per.gelang@itw-welding.se

E-mail: vmarta@millerwelds.com Fax: 886-6-2664301

classifies flux/wire combinations with a deposited weld Web site: www.elga.se

Metalloy W-S ECW Beijing Miller Electric Web site: www.tientai.com

metal classification system under A5.17 for carbon (mild) Regional Office - Russia

Phone: +86-10-8739-7900 Tien Tai Electrode (Kun Shan) Co. www.jetline.com | 949-951-1515

Metalloy 92-S ECM1 steel filler metals and A5.23 for low alloy filler metals. Phone: +7-812-961-5481

FAX: +86-10-8739-7600

E-mail: infosvarka@itw-welding.ru Phone: 86-51257446669

Examples: A5.17:F7A6-EC1, A5.23:F7A10-ECNi1-Ni1 E-mail: lisa.li@millerchina.com

Metalloy 100F3-S ECF3 EF3 LA-84 Web site: www.itw-welding.ru FAX: 86-51257448416

Regional Office - Brazil E-mail fuhu.chen@tientai.com.cn

Metalloy 112-S ECM3 Phone: +55-11-5514-3366 Regional Office - Spain

Web site: www.tientai.com

FAX: +55-11-5891-7679 Phone: 34-963935398 www.magnaflux.com | 847-657-5300

Metalloy 120-S ECM4 FAX: 34-963629516 Elga AB

E-mail: itwsoldagem@osite.com.br

E-mail: vcubero@itw-welding.es Phone: +46-31-726-46 00

Metalloy B2-S ECB2 LAC-B2 SPOOL ARC Web site: www.itwsoldagem.com.br

FAX: +46-31-726-47-00

Regional Office - France Regional Office - Africa

U515 Phone: +44-7770562799

Web site: www.elgawelding.com

Phone: +33-1-6004-1166 ®

Metalloy B3-S ECB3 EB3 LA-93 FAX : +33-1-6004-8860 FAX: +44-1204-473039

E-mail: miller@itw-welding.fr E-mail: Andy.Foster@itw-welding.co.uk

www.welding.org 800-332-9448

Web site: www.miller-france.com Web site: www.itw-welding.co.uk

937-332-5000

Submerged Arc Flux Regional Office - Italy Regional Office for:

Phone: +39-02-9829-0218 Colombia, Venezuela,

HOBART LINCOLN ESAB

FAX : +39-02-9828-1552 Trinidad & Tobago, Panama

HN-590 860 OK Flux 429, OK Flux 10.71 E-mail: millerit@itw-welding.it Phone: 920-968-7508

Regional Office - Netherlands FAX: 920-735-4125

HN-511 880M, 8500 OK Flux 10.62 Phone: +311-866-41456 E-mail: mferna@millerwelds.com www.tregaskiss.com 877-737-3111

519-737-3000

HA-495 761, 780 OK Flux 231, OK Flux 350 FAX : +311-866-49020

E-mail: info@itw-welding.nl

Web site: www.itw-welding.com

REV. 2/10

Submerged Arc Welding History of

After 90 years in the business, Training and expertise are key to

Hobart Brothers is Welding. And Hobart Brothers.

Welding is Hobart Brothers. Such a respectable past can only be built by

knowledgeable people. That’s why, whether

Metalloy Wire Diameter Offerings Much has changed in industry since 1920; efforts on welding research and product

you have a question on technique, materials

Metal Core Melt Off Characteristics vs Solid Wire • Metalloy EM13K-S AWS: EC1 5/64", 3/32", 1/8", 5/32"

Hobart Brothers was there every step of

or applications, you know who to call. development and, as a result, now offer one

the way. You might even say the company of the most complete product lines in the

• Metalloy EM13K-S MOD AWS: EC1 3/32", 1/8", 5/32" 1-800-532-2618

did more than simply keep up with new industry today. Recognized worldwide as

• Metalloy N1-S AWS: ECNi1 3/32", 1/8", 5/32"

Metal cored technologies and processes. The company who started that first the “specialists in flux-cored and metal-cored

wire has • Metalloy W-S AWS: ECW 3/32", 1/8", 5/32"

higher

It helped forge them. spark over 90 years ago. wires,” Hobart Brothers features over 52

current • Metalloy F2-S AWS: ECF2 5/64", 3/32", 1/8", 5/32"

density

Hobart has become a world leader in the Hobart Brothers has served major metal different products for welding carbon and

• Metalloy 92-S AWS: ECM1 3/32", 1/8", 5/32"

Metal Core Wires & Fluxes

for higher

deposition

field. Today you can find the broadest fabrication markets as a top-quality low alloy steels, in addition to special

• Metalloy 100F3-S AWS: ECF3 3/32", 1/8", 5/32"

selection of filler metals in the United States. manufacturer of stick, flux-cored and metal- formulations for applications in the ship-

• Metalloy 112-S AWS: ECM3 3/32", 1/8", 5/32"

cored wires for over 25 years. Throughout

for Submerged Arc Welding

• Metalloy 120-S AWS: ECM4 3/32", 1/8", 5/32" & are well building, infrastructure construction, offshore

known brands of Hobart Brothers. that time, we’ve consistently focused our oil, and heavy equipment industries.

Metal cored • Metalloy B2-S AWS: ECB2 5/64", 3/32", 1/8", 5/32"

wire has wider

projection area • Metalloy B3-S AWS: ECB3 5/64", 3/32", 1/8", 5/32"

Hobart Distributors

with less

turbulent Standard Packaging: 60lb (27.2 Kg) coils and 600lb (272 Kg) drums

weld pool

• Contact Hobart Brothers for additional available diameters.

To locate your nearest Hobart distributor call 1-937-332-4000 or 1-937-332-5188

Diameter Conversions:

or visit our Web site www.hobartbrothers.com www.MillerWelds.com 800-4-A-MILLER

5/64"= 2.0mm 3/32"= 2.4mm 1/8"= 3.2mm 5/32"= 4.0mm Headquarters (800-426-4553)

Hobart Brothers Company 101 Trade Square East Troy, OH 45373 Phone: 937-332-4000 Fax: 937-332-5700

Hobart Fluxes:

Neutral and active agglomerated fluxes are now available to provide

a single source for both flux and wire. These fluxes are high in International Headquarters Regional Office - Mexico Ecuador, Peru, Bolivia, Chile,

Phone: 937-332-5188 Phone: +52-55-5366-7370 Argentina, Uruguay, Paraguay www.smithequipment.com | 800-843-7912

performance, quality, and generate weld deposits with excellent FAX: 937-332-5064 FAX : +52-55-5366-7376 Phone: 920-968-7508

mechanical properties. Flux particle size is uniform through controlled Regional Office - Canada E-mail: jflore@millerwelds.com E-mail: mferna@millerwelds.com

mesh screening. The flux is free flowing with consistent weld puddle Canadian Welding Products Group Web site: www.itwweldingmexico.com Guatemala, El Salvador, Honduras,

degassing due to the minimum number of fines. Phone: (519)-537-6291 Welding Industries of Australia Nicaragua, Costa Rica, Belize

Fax: (519)-421-0480 Phone: +61-1300-300-884 Phone: 525553667370 www.bernardwelds.com | 800-946-2281

Regional Office - Middle East FAX: +61-8-827-66327 FAX: 525553667388

Electrode/Flux – Cross Reference Available flux types: E-mail: intc@welding.com.au E-mail: ventas@itwwelding.com.mx

Phone: +971-4299-6621

Hobart Brand Packaging Part Number Web site: www.welding.com.au

Submerged Arc Wire FAX: +971-4299-6681 Bahamas, Barbados, Dominican

• HN-590 N=Neutral 55lb (25kg) bag S669610-055 E-mail: itwme@emirates.net.ae Weldwell New Zealand Republic, Jamaica, Puerto Rico,

www.weldcraft.com | 800-752-7620

Composite Composite • HN-511 N=Neutral 55lb (25kg) bag S669310-055 Regional Office - India Phone: +64-6-834-1600 Virgin Islands

TriMark Wire AWS Class Wire AWS Class Lincoln ESAB • HA-495 A=Active 55lb (25kg) bag S669410-055 Phone: +91-222520-7388 FAX: +64-6-835-4568 Phone: 937-332-5188

FAX: +91-222520-7389 E-mail: admin@weldwell.co.nz FAX: 937-332-5064

Metalloy EC1 EM13K L-50 SPOOLARC 29S See product data sheets for AWS deposited weld Web site: www.weldwell.co.nz E-mail: quafile@hobartbrothers.com

E-mail: itwweldi@satyam.net.in

EM13K-S L-61 SPOOLARC 81 metal class, weld metal chemistry, and mechanical Regional Office - Northern Europe Manufacturers:

Regional Office - Asia www.tempil.com | 800-757-8301

Metalloy N1-S ECNi1 ECNi1 LA-75 SPOOLARC 75 properties with specific flux/wire combinations. Phone: 65-6552-1223 Phone: 46-031-726-4600

Tien Tai Electrode Co., LTD

FAX: 65-6552-1929 FAX: 46-031-726-4700

Phone: 886-6-2663721

Metalloy F2-S ECF2 EF2 LA-82 Please remember there is no AWS class for flux!! AWS E-mail: per.gelang@itw-welding.se

E-mail: vmarta@millerwelds.com Fax: 886-6-2664301

classifies flux/wire combinations with a deposited weld Web site: www.elga.se

Metalloy W-S ECW Beijing Miller Electric Web site: www.tientai.com

metal classification system under A5.17 for carbon (mild) Regional Office - Russia

Phone: +86-10-8739-7900 Tien Tai Electrode (Kun Shan) Co. www.jetline.com | 949-951-1515

Metalloy 92-S ECM1 steel filler metals and A5.23 for low alloy filler metals. Phone: +7-812-961-5481

FAX: +86-10-8739-7600

E-mail: infosvarka@itw-welding.ru Phone: 86-51257446669

Examples: A5.17:F7A6-EC1, A5.23:F7A10-ECNi1-Ni1 E-mail: lisa.li@millerchina.com

Metalloy 100F3-S ECF3 EF3 LA-84 Web site: www.itw-welding.ru FAX: 86-51257448416

Regional Office - Brazil E-mail fuhu.chen@tientai.com.cn

Metalloy 112-S ECM3 Phone: +55-11-5514-3366 Regional Office - Spain

Web site: www.tientai.com

FAX: +55-11-5891-7679 Phone: 34-963935398 www.magnaflux.com | 847-657-5300

Metalloy 120-S ECM4 FAX: 34-963629516 Elga AB

E-mail: itwsoldagem@osite.com.br

E-mail: vcubero@itw-welding.es Phone: +46-31-726-46 00

Metalloy B2-S ECB2 LAC-B2 SPOOL ARC Web site: www.itwsoldagem.com.br

FAX: +46-31-726-47-00

Regional Office - France Regional Office - Africa

U515 Phone: +44-7770562799

Web site: www.elgawelding.com

Phone: +33-1-6004-1166 ®

Metalloy B3-S ECB3 EB3 LA-93 FAX : +33-1-6004-8860 FAX: +44-1204-473039

E-mail: miller@itw-welding.fr E-mail: Andy.Foster@itw-welding.co.uk

www.welding.org 800-332-9448

Web site: www.miller-france.com Web site: www.itw-welding.co.uk

937-332-5000

Submerged Arc Flux Regional Office - Italy Regional Office for:

Phone: +39-02-9829-0218 Colombia, Venezuela,

HOBART LINCOLN ESAB

FAX : +39-02-9828-1552 Trinidad & Tobago, Panama

HN-590 860 OK Flux 429, OK Flux 10.71 E-mail: millerit@itw-welding.it Phone: 920-968-7508

Regional Office - Netherlands FAX: 920-735-4125

HN-511 880M, 8500 OK Flux 10.62 Phone: +311-866-41456 E-mail: mferna@millerwelds.com www.tregaskiss.com 877-737-3111

519-737-3000

HA-495 761, 780 OK Flux 231, OK Flux 350 FAX : +311-866-49020

E-mail: info@itw-welding.nl

Web site: www.itw-welding.com

REV. 2/10

You might also like

- Pocket Welding Guide - A Guide To Better Welding-Hobart Institute of Welding Technology (2010) PDFDocument149 pagesPocket Welding Guide - A Guide To Better Welding-Hobart Institute of Welding Technology (2010) PDFDivya Khan100% (1)

- 10 129Document15 pages10 129Vasanth PrasadNo ratings yet

- Goodreach Wilcox Weld 9781631263286 - ch11Document30 pagesGoodreach Wilcox Weld 9781631263286 - ch11Anonymous nw5AXJqjdNo ratings yet

- Flux Cored Arc Welding PDFDocument106 pagesFlux Cored Arc Welding PDFalidad100% (2)

- Handbook MetrodeDocument371 pagesHandbook Metrodejf2587No ratings yet

- Why Cored Wire - 2. General Introduction To Elga and Elga Cored Wire Types 4. Productivity and Profitability 5. Heavy Vehicals 6.Document19 pagesWhy Cored Wire - 2. General Introduction To Elga and Elga Cored Wire Types 4. Productivity and Profitability 5. Heavy Vehicals 6.jojoNo ratings yet

- 015 02 PDFDocument3 pages015 02 PDFSandeep PatilNo ratings yet

- 99-5056-00 Tweld World Master CatalogDocument324 pages99-5056-00 Tweld World Master CatalogSahbi FattoumNo ratings yet

- Welding News 03-08Document6 pagesWelding News 03-08skisharkNo ratings yet

- Welding Principles and PracticesDocument141 pagesWelding Principles and PracticesEvan Jared L. GalvezNo ratings yet

- Welding-Process 222Document63 pagesWelding-Process 222Jasm OmranNo ratings yet

- Coring Rods and Casing CatalogDocument84 pagesCoring Rods and Casing CatalogPedro GallardoNo ratings yet

- Project On: Relaibility Improvement of Chain Conveyor at Battery 5,6 & 7 TSL (India)Document8 pagesProject On: Relaibility Improvement of Chain Conveyor at Battery 5,6 & 7 TSL (India)saurabh kumarNo ratings yet

- Steel Foundation Solutions: General Catalogue 2017Document64 pagesSteel Foundation Solutions: General Catalogue 2017Imran HaiderNo ratings yet

- Catalog Sheet Piles ARCELORDocument64 pagesCatalog Sheet Piles ARCELORpolpositionNo ratings yet

- Thermal Power ApplicationsDocument27 pagesThermal Power ApplicationsKrisNo ratings yet

- Amana Steel Buildings Contracting LLCDocument108 pagesAmana Steel Buildings Contracting LLCrexNo ratings yet

- Welding Processe1Document3 pagesWelding Processe1Balaji SrinivasanNo ratings yet

- AM General Catalogue 2018 PDFDocument64 pagesAM General Catalogue 2018 PDFAde SetiawanNo ratings yet

- Guide For Aluminum Welding: 19-0Xxxx - Maxal-Aluminumproductguide - 46Pg-La2.Indd 1 3/5/19 1:29 PMDocument46 pagesGuide For Aluminum Welding: 19-0Xxxx - Maxal-Aluminumproductguide - 46Pg-La2.Indd 1 3/5/19 1:29 PMRaphael BoulisNo ratings yet

- Ductile Iron: 2002 Issue 2Document47 pagesDuctile Iron: 2002 Issue 2karthikkandaNo ratings yet

- Creepresistant Hightemperature FCAW ENGDocument12 pagesCreepresistant Hightemperature FCAW ENGRuben Dario Mamani ArellanoNo ratings yet

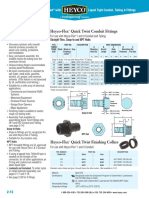

- Heyco-Flex Quick Twist Conduit FittingsDocument2 pagesHeyco-Flex Quick Twist Conduit FittingsNgô Mạnh TiếnNo ratings yet

- Kobe SteelDocument13 pagesKobe SteelmilalaNo ratings yet

- Carbide Hobs: Pfauter-:Maaig Cutting Tools - .Iud.Document8 pagesCarbide Hobs: Pfauter-:Maaig Cutting Tools - .Iud.Mohanraj SelvakumarNo ratings yet

- WM Dry Lubricants GB Fiche A4 R0120 BDDocument2 pagesWM Dry Lubricants GB Fiche A4 R0120 BDDr ZoggNo ratings yet

- 02a-Pipe Manuf FabDocument31 pages02a-Pipe Manuf FabRaizen KingNo ratings yet

- Wood, Matusewicz, Reuter - 2009 - Ausmelt C3 Converting - International Peirce - Smith Converting CentennialDocument11 pagesWood, Matusewicz, Reuter - 2009 - Ausmelt C3 Converting - International Peirce - Smith Converting CentennialÁlvaro JaraNo ratings yet

- Flux Cored Arc Welding Equipment Setup and OperationDocument70 pagesFlux Cored Arc Welding Equipment Setup and OperationMuhammailNo ratings yet

- Standards Handbook Copper and Copper AlloyDocument36 pagesStandards Handbook Copper and Copper AlloyMuthuswamyNo ratings yet

- CuproBraze 34Document2 pagesCuproBraze 34Vinod SaleNo ratings yet

- Kennametal Stellite - Cored Weld Wire DatasheetDocument2 pagesKennametal Stellite - Cored Weld Wire DatasheetharikrishnanNo ratings yet

- Welding Filler Metals For Power Generation: Voestalpine Böhler Welding Voestalpine Böhler WeldingDocument27 pagesWelding Filler Metals For Power Generation: Voestalpine Böhler Welding Voestalpine Böhler WeldingKrisNo ratings yet

- Electrical Connection Accesories: 807.xxx / ZUBDocument3 pagesElectrical Connection Accesories: 807.xxx / ZUBtadiganeshNo ratings yet

- Advantages and DisAdvantages of Cored ElectrodeDocument7 pagesAdvantages and DisAdvantages of Cored ElectrodeFolarin AyodejiNo ratings yet

- Welding Technology 2018-2019 Fall: Kocaeli University Engineering Faculty Dept. of Mechanical EngineeringDocument19 pagesWelding Technology 2018-2019 Fall: Kocaeli University Engineering Faculty Dept. of Mechanical EngineeringENZO PEREZNo ratings yet

- Crouse Hinds Eyd Ezd Sealing Fittings With Drain Catalog PageDocument2 pagesCrouse Hinds Eyd Ezd Sealing Fittings With Drain Catalog PageS&E Seguridad y EntrenamientoNo ratings yet

- CastingDocument3 pagesCastingBogdan PopescuNo ratings yet

- Soldering & WeldingDocument3 pagesSoldering & WeldingOgechi AbaribeNo ratings yet

- WLD 290 Submerged Arc WeldingDocument52 pagesWLD 290 Submerged Arc WeldingDanem HalasNo ratings yet

- Myers-Hubs Crusse Hinds PDFDocument7 pagesMyers-Hubs Crusse Hinds PDFAdrian Mauricio VelandiaNo ratings yet

- Bohler Welding Catalogue EriksDocument32 pagesBohler Welding Catalogue Eriksfarshid KarpasandNo ratings yet

- Esab - Covered Electrodes - Brochure - CEP-10009Document6 pagesEsab - Covered Electrodes - Brochure - CEP-10009YgcdwhNjdshNo ratings yet

- Corrosion Protection BoltingDocument4 pagesCorrosion Protection BoltingachmaddachNo ratings yet

- HKE 478 and Shrouds Accessories DatasheetDocument1 pageHKE 478 and Shrouds Accessories DatasheetNovia SariNo ratings yet

- AFL CopperweldDocument24 pagesAFL CopperweldFedilino P. FornollesNo ratings yet

- E1214s NaenDocument4 pagesE1214s NaenJesus DavalosNo ratings yet

- Connecting Water and Land Transporting Water: Across The CivilizationsDocument10 pagesConnecting Water and Land Transporting Water: Across The CivilizationsAhmad AliNo ratings yet

- (H) RADOXDATABUS120OHMnx0.5XMDocument3 pages(H) RADOXDATABUS120OHMnx0.5XM다원시스No ratings yet

- 15 MM 74Document28 pages15 MM 74Sravan Kumar50No ratings yet

- INDUSTEEL Duplex PDFDocument2 pagesINDUSTEEL Duplex PDFClaudio SampaioNo ratings yet

- Gulf Cable & Electrical Ind. Co.: Product Range IDocument19 pagesGulf Cable & Electrical Ind. Co.: Product Range Iraghs74No ratings yet

- Welding ConsumablesDocument128 pagesWelding ConsumablesErick Hogan75% (4)

- The Manual Metal Arc ProcessDocument4 pagesThe Manual Metal Arc ProcessMehmet SoysalNo ratings yet

- Oil & Gas Pipeline PDFDocument12 pagesOil & Gas Pipeline PDFrolandobtNo ratings yet

- Cable 10g 6a F Utp Cable International SsDocument2 pagesCable 10g 6a F Utp Cable International SsCarlos Javier Rincón PinzónNo ratings yet

- Adaptors Reducers Brochure PDFDocument20 pagesAdaptors Reducers Brochure PDFvikkoo7No ratings yet

- Shielded Metal Arc Welding: PrinciplesDocument18 pagesShielded Metal Arc Welding: PrinciplesAnonymous cgcKzFtXNo ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- 780 L61Document1 page780 L61Rodrigo RojasNo ratings yet

- Lincoln Electric Welding Stick Maual c210Document48 pagesLincoln Electric Welding Stick Maual c210Kaan çelikoğlu100% (1)

- Shielded Metal Arc Welding SMAW Vertical Down and Vertical Up Welding of PipelinesDocument48 pagesShielded Metal Arc Welding SMAW Vertical Down and Vertical Up Welding of PipelinesspahicdaniloNo ratings yet

- C1.10 Consumables SAWDocument56 pagesC1.10 Consumables SAWRodrigo RojasNo ratings yet

- C1.10 Consumables SAWDocument56 pagesC1.10 Consumables SAWRodrigo RojasNo ratings yet

- Lincoln SuperArc MIG Wire Product CatalogDocument28 pagesLincoln SuperArc MIG Wire Product CatalogRodrigo RojasNo ratings yet

- TLE 10 EPAS Week1Document6 pagesTLE 10 EPAS Week1Sittie Fahieda AloyodanNo ratings yet

- Technical Data Welding Standard: Date 5 NOV 2010Document6 pagesTechnical Data Welding Standard: Date 5 NOV 2010Aob April100% (1)

- Market Study of Alloy Steel With Special Reference To RMG Alloy Steel LTDDocument75 pagesMarket Study of Alloy Steel With Special Reference To RMG Alloy Steel LTDabhinavNo ratings yet

- How To Install ESD PVC FLOORDocument18 pagesHow To Install ESD PVC FLOORabdulrahman abosteetNo ratings yet

- Workshop ManualDocument41 pagesWorkshop ManualNarappaNo ratings yet

- Double Dip - Greater Thickness - American Galvanizers AssociationDocument1 pageDouble Dip - Greater Thickness - American Galvanizers AssociationNsidibe Michael EtimNo ratings yet

- 2020-2021 Lab Equipment ChecklistDocument2 pages2020-2021 Lab Equipment ChecklistAnthony MerleNo ratings yet

- Smelting and Refining Section 2011Document42 pagesSmelting and Refining Section 2011GalaaBoldooNo ratings yet

- WoodsDocument35 pagesWoodsGlen Michael WongNo ratings yet

- PVC Coated Conduit SubmittalDocument1 pagePVC Coated Conduit Submittaladan valdovinosNo ratings yet

- CommodityDocument14 pagesCommodityChamp DsouzaNo ratings yet

- Pallet 0age ofDocument26 pagesPallet 0age oflaacostam93No ratings yet

- GRATINGS Rev.1Document7 pagesGRATINGS Rev.1mohdNo ratings yet

- BEDRA-wire Solutions For Brazing and WeldingDocument5 pagesBEDRA-wire Solutions For Brazing and Weldingcentaury2013No ratings yet

- Project Jig & Fixture 20122013Document43 pagesProject Jig & Fixture 20122013adibah ismail100% (11)

- RRU AISG Cable Assembly SpecificationDocument9 pagesRRU AISG Cable Assembly SpecificationBayu AndriantoNo ratings yet

- Press Part Nut-Spot-Mig Stud Welding Defects SheetDocument3 pagesPress Part Nut-Spot-Mig Stud Welding Defects SheetSanjayNo ratings yet

- MMMM Co Located Show Exhibtor List 2022Document12 pagesMMMM Co Located Show Exhibtor List 2022Aamir SaleemNo ratings yet

- Hudson Transfer Press BrochureDocument2 pagesHudson Transfer Press BrochureSean GribbenNo ratings yet

- Kat Draco 2021 GB 10cover 1Document60 pagesKat Draco 2021 GB 10cover 1Marius BaicanNo ratings yet

- M12a XXPFFS SH8XXXDocument1 pageM12a XXPFFS SH8XXXdmaslachNo ratings yet

- WPS GmawDocument2 pagesWPS GmawBasel MohammadNo ratings yet

- Module 01 - Cutting ProcessesDocument34 pagesModule 01 - Cutting ProcessesNaveen AgrawalNo ratings yet

- Wrapidbond: Anti-Corrosion System For Protection of Steel SubstratesDocument2 pagesWrapidbond: Anti-Corrosion System For Protection of Steel SubstratesDhim131267No ratings yet

- Jinasena Traning ReportDocument55 pagesJinasena Traning ReportTharinda100% (1)

- CWI, SCWI-Renewal (3 or 6 Years) - International PDFDocument4 pagesCWI, SCWI-Renewal (3 or 6 Years) - International PDFIbrahim Levent AkkoyunluNo ratings yet

- Casting Training MaterialDocument40 pagesCasting Training Materialregassa rajiNo ratings yet

- Ficha Tecnica - Abrigo Retractil S430Document2 pagesFicha Tecnica - Abrigo Retractil S430Mauricio Aranda MillaNo ratings yet

- Welded Wire Mesh SolutionsDocument12 pagesWelded Wire Mesh SolutionsDilhara WickramaarachchiNo ratings yet

- Jared Hazen: Work ExperienceDocument2 pagesJared Hazen: Work Experienceconfused597No ratings yet