Professional Documents

Culture Documents

Enzyme Assay: Effects of Modified Conditions and Inhibitor B On Enzyme 4

Enzyme Assay: Effects of Modified Conditions and Inhibitor B On Enzyme 4

Uploaded by

Jonald PINONGPONGOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Enzyme Assay: Effects of Modified Conditions and Inhibitor B On Enzyme 4

Enzyme Assay: Effects of Modified Conditions and Inhibitor B On Enzyme 4

Uploaded by

Jonald PINONGPONGCopyright:

Available Formats

BIO107.

2 • Grp 3 • LR 1

ENZYME ASSAY: EFFECTS OF MODIFIED CONDITIONS

AND INHIBITOR B ON ENZYME 4

Alarcon AR, Arsad H, Frenila R Jr., Namion J, Pinongpong J

BIO107.2 Experiment 1 Group 3

Science Department, College of Natural Sciences and Mathematics

Mindanao State University-General Santos

Brgy. Fatima, General Santos City 9500, Philippines

15 October 2021

ABSTRACT

This laboratory activity was conducted to determine if the activity of the enzyme is

affected by some important factors and conditions – adding a competitive inhibitor,

change in pH, incubation time, amount of enzyme, incubation temperature, and

substrate concentration. Using the simulated laboratory, the students ran the

simulation using Enzyme 4 at maximum range and with no inhibitor as an initial setup.

After performing the initial setup, each condition was modified three times with the

presence of inhibitor B to observe different enzyme activity and to determine the

optimum for each condition. For the pH of incubation, the optimum observed is around

9.2. The optimum incubation time is at 12 min while the optimum incubation

temperature is at 66 ℃. Moreover, when the amount of enzyme increased, it also

increases the rate of activity of the enzyme. Similarly, increasing substrate

concentration also resulted in the increasing rate of enzyme activity. Finally, the

addition of Inhibitor B decreases the activity of the enzyme for any condition.

Introduction

In a living organism, an enzyme is a protein that accelerates the pace of a chemical process. It

is a protein that works as a catalyst in chemical processes, transforming one set of reactants (called

substrates) into another set of products. The shape of an enzyme's active site, which is determined by

the three-dimensional arrangement of amino acids, determines its specificity. Enzymes alter shape at

the active site during catalysis as a result of their flexibility. Small metabolites (inhibitors) in cells can

also interact with, prevent the substrates from binding, and change the shapes of several enzymes due

to this flexibility (Bergtrom, G., 2018). Furthermore, this research will also look at the effects of pH, time,

enzyme concentration, incubation temperature, and substrate concentration on enzyme 4 activity. In

addition, this research also aims to see how changing the parameter/condition affects enzyme activity.

Finally, this research seeks to discover the enzyme 4 optimum under each condition as well as the

influence of inhibitor B on enzyme 4 activity.

Methodology

This activity aims to systematically evaluate the effect of an enzyme in different incubation

conditions by using an online laboratory platform, the simulated virtual laboratory: Enzymes assay which

was developed by David A. Bender (1982-2005) of the Department of Biochemistry and Molecular

Biology, UCL. The group is tasked to run the simulation using Enzymes 4, inhibitor B as per the

instruction of the instructor. the experiment includes the pH of incubation (between 1-14), incubation

time (between 0-60 min), Amount of Enzymes (between 0-250µL), incubation temperature (between 0-

100 °C), and concentration of substrates (0-250mmol/L).

Alarcon et al. Page 1 of 18

BIO107.2 • Grp 3 • LR 1

Data Gathering

1. Without inhibitor

1.1 Initial set-up for pH incubation

The experiment used the incubation of enzyme 4, inhibitor B on this set-up. Minimum

and maximum pH levels from 1.0-14.0 respectively are used with the selected condition that is

specified directly by the simulation that includes: 250µL of enzymes, the temperature at 70°C,

incubation time of 12min and 250mmol/L of substrates. The optimum pH level is determined to

be the best enzymes condition.

1.2. Initial set-up for incubation time

A 0-60 minutes incubation time of enzyme 4 is used in this set-up. The optimum pH

level, the pH Buffer of 8.80 that was obtained on 1.1 is used, thus another condition is specified

default.

1.3. Initial set-up for the number of Enzymes

The amount of Enzymes ranges from 0-250µL on the incubation of enzyme 4 is used

in the experiment. In this set-up, the group used the optimum incubation time, which is 12

minutes obtained from 1.2 to determine the optimum amount of enzymes and the optimum pH

level of 8.80 as the other condition are specified by default.

1.4. Initial set-up for incubation temperature

In this experiment, an incubation temperature range from 0-100 °C is used on the

incubation of enzymes 4. The optimum value was obtained from 1.3. the amount of Enzymes

which is 250µL, optimum incubation time of 12 min, and the optimum pH level of 8.80 is used

to obtain the optimum incubation temperature as the other condition is specified default

1.5. Initial set-up for the concentration of substrates

A concentration of substrates ranging from 0-250mmol/Lon the incubation of enzyme

4 is used in the experiment. the optimum value of 1.1., 1.2, 1.3, and 1.4 is used to obtain the

optimum condition of the concentration of substrates.

2. With inhibitor

2.1 Modification on pH incubation

The group performs three modifications in this set-up which includes three different pH

ranges. The first modification, has a pH range of 1-6, the second modification with a 6-8 range,

and the third modification with 8-14 pH ranges. This includes the addition of 125-1000 mmol/L

inhibitor B and a different set of condition that obtained from the optimum value in the initial set-

up of 1.2, 1.3, 1.4 and 1.5. It also shows that the optimum value of pH in this setting is 9.2 that

differs from the initial set up which is 8.8.

2.2. Modification of incubation time

Three modification is performed in this experiment with three different ranges of

incubation time. The first modification has an incubation time of 0-20min, the second

modification with 20-40 min, and the third modification with 40-60min incubation time. This

includes the addition of 125-1000 mmol/L inhibitor B and a different set of condition that

obtained from the optimum value in the initial set-up of 1.1, 1.3, 1.4 and 1.5.

2.3. Modification of Amount of Enzymes

The group performs three modifications in this set-up which includes three different

amounts of enzymes. The first modification, have an enzyme concentration of 0-80µL, the

second modification with 80µL-160µL, and the third modification with the 160µL-250µL amount

of enzymes. This includes the addition of 125-1000 mmol/L inhibitor B and a different set of

condition that obtained from the optimum value in the initial set-up of 1.1, 1.2, 1.4 and 1.5.

2.4. Modification of Incubation Temperature

Three modification is performed in this experiment with three different ranges of

incubation temperature. The first modification has incubation temperature of 0°C-33°C, second

modification with 33°C-66°C and third modification of 66°C-100°C incubation temperature. This

Alarcon et al. Page 2 of 18

BIO107.2 • Grp 3 • LR 1

includes the addition of 125-1000 mmol/L inhibitor B and a different set of condition that

obtained from the optimum value in the initial set-up of 1.1, 1.2, 1.3 and 1.5.

2.5. modification of concentration of substrates

Three modification is performed in this experiment with three different ranges of

concentration of substrates. The first modification has a concentration of substrates of 0mM-

80mM, the second modification with 80mM-160mM, and the third modification of 160mM-

1250mM concentration of substrates. This includes the addition of 125-1000 mmol/L inhibitor

B and a different set of condition that obtained from the optimum value in the initial set-up of

1.1, 1.2, 1.3 and 1.4.

This method will prove that in a different range of inhibitor concentrations, there is an enzymatic

reaction that occurs. Sometimes it will give a little difference in the result if the inhibitor is too little and

a big difference if it is simulated with higher ranges, thus the student always remembers that to yield a

big difference in inhibitor they should choose a higher range of incubation.

Results

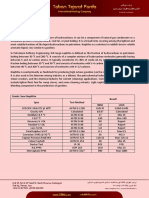

The effect of pH on enzymatic activity

To investigate the effect of pH of incubation in enzyme activity, 250 μL of enzyme 4 was

incubated with 250 mmol/L of the substrate at 70 ℃ for 12 min. at varying pH. The initial setup with no

inhibitor, consisting of 11 incubations whose pH ranges from 1-14, shows the maximum enzyme activity

is at 8.80 pH, which produced 213.43 μmol of product.

The pH of incubation ranging from 1-6, showed little to no enzyme activity. With the pH of

incubation ranging from 6-8 with an inhibitor, an increasing enzyme activity as the pH of incubation

approaches alkalinity was observed. Moreover, the third modified setup depicted in Figure 1 (left), with

pH of incubations ranging from 8-14 showed the pH optimum of enzyme 4 is at 9.2. At the optimum pH,

219.42 μmol of the product was formed, the highest among other incubations. However, at pH levels

9.8-11, enzyme activity has started to decrease. Beyond pH 11, where alkalinity is becoming more

extreme, there was no enzyme activity at all.

The effect of Incubation time on enzyme activity

Assessment of enzyme activity at varying incubation times revealed that most products were

formed at the 12-minute duration of incubation. As seen on the initial setup in Figure 2 (right), enzyme

activity increased at 0 minutes and peaked at 12 mins, wherein 213.18 μmol of products were formed.

However, beyond 12 minutes, enzyme activity has started to decrease, and at 24 minutes of incubation,

enzyme activity has ceased. No enzyme activity was observed at the 40-60 minutes of incubation.

The effect of the Amount of Enzyme

Results from the present experiment showed a linear relationship between the amount of

enzyme and the number of products formed, at optimal conditions. As the amount of enzyme increases,

the product formed has increased as well. Figure 3 shows that the least amount of product formed was

at 0 μL of enzyme 4, while the most amount of product formed was at 250.0 μL of enzyme

4.

The effect of Incubation Temperature

Assessment on the effect of incubation of temperature revealed that 66°C is the optimum

incubation temperature for enzyme 4. According to Figure 4, which shows the initial setup (without an

inhibitor), an increase in enzyme activity is observed as temperature increases from 0 to 60°C.

However, there is a drastic decrease in enzyme activity as the temperature increased beyond 60°C.

The second modified setup, with temperatures ranging from 60 - 80°C and has an inhibitor, allowing for

Alarcon et al. Page 3 of 18

BIO107.2 • Grp 3 • LR 1

the precise identification of the optimum temperature. As seen in Figure 4, the greatest number of

products produced, and thereby the optimum temperature, is at 66° C.

The effect of the concentration of substrate

The investigation on the effect of concentration showed a linear relationship between the

concentration of substrate and the number of products formed at optimal pH and temperature. As seen

in Figure 5, an increase in the concentration of substrate had also marked an increase in the formation

of products as well. Figure 5 shows that the least amount of product formed was at 0mM of the

substrate, while the greatest amount of product formed was at 250.0mM of the substrate.

The effect of adding inhibitor B

It was observed from all the experimented conditions that the addition of inhibitor B had

significantly limited the product yield of enzyme 4. Moreover, the addition of a higher concentration of

inhibitor also elicits higher limitations to the enzyme activity of enzyme 4. As seen in Figures 1-5, the

product yield of 125 mM of inhibitor B is higher compared to that of 1000 mM of inhibitor B.

Figure 1. Products formed at varying levels of pH. (Right) The numerical data and graph from the initial

setup of varying pH (1-14) without an inhibitor. (Left) The numerical data and graph from the third modified

setup with varying pH (8-14) and the amount of product yield. Both showing the increase in enzyme activity

as pH levels reach the optimum and decrease in activity as the pH exceeds the optimum.

Alarcon et al. Page 4 of 18

BIO107.2 • Grp 3 • LR 1

Figure 2. Products formed at varying incubation times. (Left) The numerical data and graph from the

initial setup, whose incubation time ranges from 0-60 mins., with no inhibitor. (Right) The data from the

modified setup with an inhibitor whose incubation time ranges from 0-60 mins. Both show that maximum

products are formed at 12 minutes.

Figure 3. Products are formed at varying amounts of enzymes. (Left) The numerical data and graph from

the initial setup, with varying amounts of enzyme (0-250 μL), with no inhibitor. (Right) The data from the

modified setup with an inhibitor whose amount of enzyme ranges from 80-60 μL. Both show the linear

relationship between the amount of enzyme and the number of products formed.

Figure 4. Products formed at varying incubation temperatures. (Left) The numerical data and graph from

the initial setup, whose incubation temperature ranges from 0-100°C., with no inhibitor. (Right) The data from

the modified setup with an inhibitor whose incubation temperature ranges from 33-66 °C. Both show that

enzyme 4 has an optimum temperature, at which it works best.

Alarcon et al. Page 5 of 18

BIO107.2 • Grp 3 • LR 1

Figure 5. Products formed at varying substrate concentrations. (Left) The numerical data and graph

from the initial setup, whose substrate concentration ranges from 0-250 mM, with no inhibitor. (Right) The

data from the modified setup with an inhibitor whose substrate concentration ranges from 160-250 mM. Both

show that maximum product yield is formed at 250 mM of a substrate and the linear relationship between

substrate concentration and the number of products formed at optimum conditions.

Discussion

pH of incubation

Enzyme activity varies with pH changes. The amino acids regulate substrate specificity and

limit enzyme activity to certain pH ranges. Enzymes have an optimum pH at which most enzymes work

best, often in slightly acidic or basic conditions. However, some enzymes are native to extremely acidic

or basic environments; thus, they are most active in these pH ranges (Voet, D., Voet, J. G., and Pratt,

C.W., 2006).

Based on the results shown in figure 1 (left), enzyme 4 shows maximum activity at 8.80, the

optimum pH. The observed downward trend, in terms of products produced, at acidic levels and extreme

alkaline conditions is due to the denaturation of the enzyme. At the extremes of pH, the tertiary structure

of the enzyme, particularly, the active site is disrupted. This explains the little to no activity observed at

pH ranges 1-6 and 11-14. However, upon modifying the pH ranges, particularly in the third modification

with pH level ranges 8-14, the result presented in figure 1 (right) reveals an optimum pH at 9.2. This

is contrary to the results in the initial setup shown in figure 1 right. Modification of parameters helps to

reveal the real optimum pH value as it stretches the ranges and emphasizes each value, producing

more precise results.

Incubation time

The longer time an enzyme spends in contact with its substrate, the more product it produces.

However, the enzyme activity would not always produce a linear function at the time of incubation. All

proteins lose their catalytic function due to denaturation. In addition, if the incubation time continues to

proceed, the enzymes will be fully saturated by the substrates over time; thus, decreasing the amount

of product yield. This was observed in the results shown in figure 2 (left), which shows a remarkable

increase in enzyme activity at 0-12 minutes of incubation. However, the product yield decreases when

it reaches 24-60 minutes of incubation.

Furthermore, in figure 2 both left and right shows the same optimum time at 12 minutes.

Nevertheless, the initial setup at the left produces more products than the modified setup at the right

due to the inhibitor B added to the modified setup.

Amount of enzyme

The amount of enzyme affects its rate of activity. As long as there are substrates, higher

enzyme concentration will increase the rate of reaction. More enzyme molecules are accessible to

process the substrate when the enzyme concentration is higher. Because of the high quantities of the

enzyme-substrate complex, the reaction has a faster initial catalytic rate, giving it a head start in the

shift toward reactant-product equilibrium (Voet, D., Voet, J. G., and Pratt, C. W., 2006). In figure 3, both

the initial and modified setups show the same optimum concentration of enzyme at 250uL. This reveals

that the higher the concentrations of enzyme, the more product it produces.

Incubation Temperature

An increase in temperature increases the rate of enzyme activity as the molecules are moving

more quickly and make contact with one another. Changing the temperature outside of the optimal

range, on the other hand, can disrupt chemical bonding inside the enzyme and modify its shape (Daniel,

R. M. et al., 2008). If the enzyme's shape changes, the active site may lose its ability to bind to the

correct substrate, slowing the reaction rate. In addition, each enzyme operates best at its optimal

Alarcon et al. Page 6 of 18

BIO107.2 • Grp 3 • LR 1

temperature, thus; any temperature change affects an enzyme's activity, and it can also lead to enzyme

denaturation (Vitolo, M., 2020).

In the experiment, it was observed that an increase in temperature also marked an increase in

the rate of enzyme activity. Based on the result shown in figure 4 left (the initial setup), the optimum

temperature falls at 60℃. However, when the setup was modified with ranges 33-66℃ shown in figure

4 (right), the results revealed a more precise optimum temperature at 66℃. In addition, enzyme activity

started to decrease as the temperature continued to increase at 80℃, which is beyond the optimum

temperature of the enzyme. This means that the enzymes are starting to modify the shape of their active

site, losing their ability to bind with the correct substrate, thus; decreasing the reaction. Hence, enzyme

4 loses its ability to bind with the correct substrate, which decreases the rate of reaction and the amount

of product yield.

Concentration of substrate

When a geometrically and electrically complementary substrate can access the active site,

enzyme activity occurs. The active residues form a temporary bond with the substrate, accelerating the

substrate's transition into a product. As a result, the higher the enzyme activity and the faster the shift

toward enzyme-product equilibrium, the more substrate-occupied active sites there are (Boyer, R.,

2006).

Based on the result in figure 5 (left and right), both the initial and modified setups show the

same optimum concentration of substrates at 250mM. Noticeably, the product yield increases when the

concentration of substrate also increases. This thus reveals that the higher the concentration of

substrates, the higher the enzyme activity as well.

Addition of Inhibitor

The inhibitor prevents the enzyme from binding to its substrate; thus, a decrease in the

enzyme’s activity would be observed (Bergtrom, G., 2018). This explains why the addition of an inhibitor

B to an enzyme 4 in the experiment leads to little to no enzymatic activity results at all. Before the

addition of an inhibitor, our initial setups had shown a high product yield, indicating a high enzyme

activity. However, the addition of inhibitor B in the modified setups drastically decreased the amount of

products yield, which indicates lesser enzyme activity. Since it was clear from the observations that the

initial setup which lacks an inhibitor has a higher enzymatic activity compared to the modified setups

with the addition of inhibitor B. Therefore, that adding inhibitors to the enzymes decreases the rate of

enzyme activity.

Conclusion

The addition of competitive inhibitor B decreased the rate of activity of the enzyme for each

condition. The ranges of each condition were modified at least three times to produce a more accurate

result in determining the optimum level. Altering pH level affects the rate of activity of the enzyme,

however, there is an optimal value that the enzyme works best, which is 9.2. Similar to pH, there is also

an optimum in the incubation of time. The number of products produced increased until around 12 min

of incubation. For the amount of enzyme and substrate concentration, it was observed that the rate of

enzyme activity increased as the amount of enzyme and substrate concentration increased. Lastly, in

the incubation temperature, an optimum was also observed. The rate of activity keeps increasing until

it reached 66 ℃, it decreased as the temperature went higher. Overall, it is important to perform

modifications for each condition to find out the effects of these conditions on the production and rate of

enzyme activity.

Alarcon et al. Page 7 of 18

BIO107.2 • Grp 3 • LR 1

References

Bergtrom, G. (2018). Basic Cell and Molecular Biology: What We Know & How We Found Out-4e.

Daniel, R. M., Danson, M. J., Eisenthal, R., Lee, C. K., & Peterson, M. E. (2008). The effect of

temperature on enzyme activity: new insights and their implications. Extremophiles, 12(1), 51-59.

Jibran (2021). Factors That Affect Enzyme Activity. Enzymology, Science. Retrieved October 8, 2021,

from https://conductscience.com/factors-that-affect-enzyme-activity/

John Wiley & Sons. Boyer, R. (2006). Concepts in Biochemistry, 3rd edition. New Jersey: John Wiley

& Sons.

The Effect of pH on Enzyme Kinetics. (2016, April 3). Retrieved October 8, 2021, from

https://chem.libretexts.org/@go/page/20287

Tomasik, P. and Horton, D. (2012). Chapter 2 - Enzymatic conversions of starch. Advances in

Carbohydrate Chemistry and Biochemistry, Academic Press, 68, 59-436.

Vitolo, M. (2020). Brief review on enzyme activity. World Journal of Pharmaceutical Research, 9(2), 60-

76

Voet, D., Voet, J. G., & Pratt, C. W. (2016). Fundamentals of biochemistry: life at the molecular level.

Appendices

pH of Incubation

Initial Setup: 1-14 No Inhibitor

Alarcon et al. Page 8 of 18

BIO107.2 • Grp 3 • LR 1

First Modification: 1-6, with Inhibitor B

Second Modification: 6-8, with Inhibitor B

Alarcon et al. Page 9 of 18

BIO107.2 • Grp 3 • LR 1

Third Modification: 8-14, with Inhibitor B

Incubation Time

Initial Setup: 1-14, No Inhibitor

Alarcon et al. Page 10 of 18

BIO107.2 • Grp 3 • LR 1

First Modification: 0-20 mins, with Inhibitor B

Second Modification: 20-40 mins, with Inhibitor B

Alarcon et al. Page 11 of 18

BIO107.2 • Grp 3 • LR 1

Third Modification: 40-60 mins, with Inhibitor B

Amount of Enzyme

Initial Setup: 0 – 250 μL, No Inhibitor

Alarcon et al. Page 12 of 18

BIO107.2 • Grp 3 • LR 1

First Modification: 0 – 80 μL, with Inhibitor B

Second Modification: 80 – 160 μL, with Inhibitor B

Alarcon et al. Page 13 of 18

BIO107.2 • Grp 3 • LR 1

Third Modification: 160 – 250 μL, with Inhibitor B

Incubation Temperature

Initial Setup: 0 – 100 ℃, No Inhibitor

Alarcon et al. Page 14 of 18

BIO107.2 • Grp 3 • LR 1

First Modification: 0 – 33 ℃, with Inhibitor B

Second Modification: 33 – 66 ℃, with Inhibitor B

Alarcon et al. Page 15 of 18

BIO107.2 • Grp 3 • LR 1

Third Modification: 66 – 100 ℃, with Inhibitor B

Concentration of Substrate

Initial Setup: 0 – 250 mM, No Inhibitor

Alarcon et al. Page 16 of 18

BIO107.2 • Grp 3 • LR 1

First Modification: 1 – 80 mM, with Inhibitor B

Second Modification: 80 – 160 mM, with Inhibitor B

Alarcon et al. Page 17 of 18

BIO107.2 • Grp 3 • LR 1

Third Modification: 160 – 250 mM, with Inhibitor B

Alarcon et al. Page 18 of 18

You might also like

- Ib Chem Bonding NotesDocument19 pagesIb Chem Bonding Notesapi-293306937100% (1)

- Enzymes: Biological CatalystsDocument9 pagesEnzymes: Biological CatalystsChamzelleNo ratings yet

- Lab ReportDocument6 pagesLab Reportsagarchawla100% (5)

- Pseudomonas SP, Salmonella SP, Escherichia Coli) - Gram-Positive Bacteria and Fungi Also ProduceDocument9 pagesPseudomonas SP, Salmonella SP, Escherichia Coli) - Gram-Positive Bacteria and Fungi Also ProduceMingielee100% (1)

- BIOCHEM LAB - Enzymatic Activity of Salivary AmylaseDocument6 pagesBIOCHEM LAB - Enzymatic Activity of Salivary AmylaseIsmael Cortez100% (2)

- Eccc Eccc Data Sheets Approved On Behalf of Eccc DateDocument150 pagesEccc Eccc Data Sheets Approved On Behalf of Eccc DateAlkku100% (1)

- Extraction and Purification of CaffeineDocument3 pagesExtraction and Purification of CaffeineAnonymous GO6JVW9Wud100% (2)

- Enyzmatic Activity of Salivary AmylaseDocument6 pagesEnyzmatic Activity of Salivary AmylaseGio Punsalan50% (2)

- Splice Connection CHSDocument180 pagesSplice Connection CHSRaveendra Babu Cherukuri100% (2)

- Hydrogen Peroxide DecompositionDocument17 pagesHydrogen Peroxide DecompositionChristian Eduardo Fabian50% (2)

- Polyphenol Oxidase Activity of Bananas 2Document5 pagesPolyphenol Oxidase Activity of Bananas 2Victor Nyarugwe100% (3)

- Determination of Enzymatic Activity of Salivary Amylase Depending On The Effect of Temperature and PHDocument11 pagesDetermination of Enzymatic Activity of Salivary Amylase Depending On The Effect of Temperature and PHAmberValentineNo ratings yet

- A Correlation For Calculating Elemental Composition From Proximate Analysis of Biomass MaterialsDocument10 pagesA Correlation For Calculating Elemental Composition From Proximate Analysis of Biomass Materialsapi-3799861100% (2)

- Astm D 5299 - 99Document16 pagesAstm D 5299 - 99cormolio100% (1)

- Alkaline Phosphatase KineticsDocument16 pagesAlkaline Phosphatase KineticsIna Keyser78% (9)

- Enzyme Activity and AssaysDocument6 pagesEnzyme Activity and Assaysapi-318629889No ratings yet

- @airbus: Component Maintenance Manual With Illustrated Part ListDocument59 pages@airbus: Component Maintenance Manual With Illustrated Part ListAnh Tuan PhamNo ratings yet

- Articulo 1Document8 pagesArticulo 1Andre PaRdo DGNo ratings yet

- AbstractDocument14 pagesAbstractlinda83514100% (3)

- Kinetic Properties of β-glucosidase/ Cellobiase from Aspergillus NigerDocument20 pagesKinetic Properties of β-glucosidase/ Cellobiase from Aspergillus Nigerapi-340517298No ratings yet

- 2009 Yandri Lipase ModificationDocument8 pages2009 Yandri Lipase ModificationTria YuliarniNo ratings yet

- Enzyme AssaysDocument28 pagesEnzyme Assaysshamit big SAMNo ratings yet

- An Experiment in Enzyme Characterization: Banana Polyphenoloxidase Michael C. Archer and James K. PalmerDocument3 pagesAn Experiment in Enzyme Characterization: Banana Polyphenoloxidase Michael C. Archer and James K. PalmerThu HàNo ratings yet

- Kelompok 1 PDFDocument8 pagesKelompok 1 PDFAmeliaNo ratings yet

- Enzymatic ActivityDocument15 pagesEnzymatic ActivityChristian J. GonzálezNo ratings yet

- Enzyme Lab ReportDocument15 pagesEnzyme Lab ReportJessa Marie UseroNo ratings yet

- 1-6 Virtual Enzyme LabDocument5 pages1-6 Virtual Enzyme Labapi-277221863No ratings yet

- Phosphatase EnzymeDocument12 pagesPhosphatase Enzymekab560No ratings yet

- 9 - Factors Affecting EnzymesDocument31 pages9 - Factors Affecting EnzymesEL HassaryNo ratings yet

- 2.5 Lactase Enzyme Activity Kanika KumarDocument4 pages2.5 Lactase Enzyme Activity Kanika KumarKanika KumarNo ratings yet

- Effect of PH On Invertase ActivityDocument3 pagesEffect of PH On Invertase ActivitytancmielleNo ratings yet

- Artigo ImobilizaçãoDocument6 pagesArtigo ImobilizaçãocterrasanNo ratings yet

- Lab 3 - Biology 1003A (Joseph)Document8 pagesLab 3 - Biology 1003A (Joseph)JosephDionNo ratings yet

- Effect of PH On Invertase ActivityDocument4 pagesEffect of PH On Invertase ActivityToni Sy Encinares100% (2)

- Total Protein Determination: Unit Intended Learning OutcomesDocument12 pagesTotal Protein Determination: Unit Intended Learning OutcomesMaria ClaraNo ratings yet

- The Effects of PH and Temperature On The Enzymatic Activity of Salivary AmylaseDocument9 pagesThe Effects of PH and Temperature On The Enzymatic Activity of Salivary AmylaseMoira Mochie C. BasilioNo ratings yet

- Comparative Evaluation of Pyrogens Tests in Pharmaceutical ProductsDocument6 pagesComparative Evaluation of Pyrogens Tests in Pharmaceutical Productsnamchin parkNo ratings yet

- Enzymes Are Proteins That Help Speed Up Chemical Reactions in Our BodiesDocument4 pagesEnzymes Are Proteins That Help Speed Up Chemical Reactions in Our BodiesTSHIRELETSO KOLAAGANONo ratings yet

- PosterSSCHE2014 ReactEngineeringnCatalysisPosterSessionDocument1 pagePosterSSCHE2014 ReactEngineeringnCatalysisPosterSessionDiana Noor IsmailNo ratings yet

- The Effects of PH and Inhibitor Concentration On The Activity of A Phosphatase EnzymeDocument12 pagesThe Effects of PH and Inhibitor Concentration On The Activity of A Phosphatase EnzymeLucas Man75% (4)

- BetaDocument3 pagesBetacrg1234No ratings yet

- Laboratory Report Pharmaceutical Biotechnology: National University of Ho Chi Minh City International UniversityDocument19 pagesLaboratory Report Pharmaceutical Biotechnology: National University of Ho Chi Minh City International UniversityAn Ngoc HoaiNo ratings yet

- 12 59 Lipolytic Enzymesarticle27Document8 pages12 59 Lipolytic Enzymesarticle27Furqoni Nurul UmmahNo ratings yet

- Lab ReportDocument7 pagesLab ReportJavier Fuentes100% (2)

- Enzyme Assays: Michaelis-Menten Kinetics Enzyme ActivityDocument7 pagesEnzyme Assays: Michaelis-Menten Kinetics Enzyme ActivityIan KirkNo ratings yet

- Enzymatic Activity of Salivary Amylase Formal ReportDocument7 pagesEnzymatic Activity of Salivary Amylase Formal ReportKatrina Lee Gagan100% (2)

- Activity 2Document4 pagesActivity 2german guazaNo ratings yet

- Formalreport INVERTASEDocument2 pagesFormalreport INVERTASEyamsytron50% (4)

- BT 0413 BioseparationTechnologyLaboratoryDocument21 pagesBT 0413 BioseparationTechnologyLaboratoryvijaygovindarajNo ratings yet

- Practical 2Document8 pagesPractical 2Ibrahim Muhamad0% (1)

- Rapid TestDocument16 pagesRapid TestBorahae Bora boraNo ratings yet

- 9 Immunochemical Techniques: Itself) and DetailsDocument12 pages9 Immunochemical Techniques: Itself) and DetailsJOHN94No ratings yet

- Licheniformis: Enzymatic Hydrolysis of Soluble Starch With An R-Amylase From BacillusDocument5 pagesLicheniformis: Enzymatic Hydrolysis of Soluble Starch With An R-Amylase From BacillusInsha Khan 10ENo ratings yet

- Test Instructions For Measuring The Microbial Metabolic Activity in Water Samples - ObstDocument3 pagesTest Instructions For Measuring The Microbial Metabolic Activity in Water Samples - ObstgotcanNo ratings yet

- Cellulase Enzyme Production by Streptomyces SP Using Fruit Waste As SubstrateDocument5 pagesCellulase Enzyme Production by Streptomyces SP Using Fruit Waste As SubstrateHamka NurkayaNo ratings yet

- Research Journal of Pharmaceutical, Biological and Chemical SciencesDocument7 pagesResearch Journal of Pharmaceutical, Biological and Chemical SciencesMaslakhatun NisakdiyahNo ratings yet

- Drugs - Assays and TestsDocument10 pagesDrugs - Assays and Testsaliciadsouza2498No ratings yet

- Chapter C Enzymes PART 2Document3 pagesChapter C Enzymes PART 2Gilbert HTNo ratings yet

- Enzyme AssayDocument6 pagesEnzyme AssayJaydeep Das100% (1)

- EnzymesDocument5 pagesEnzymesjimmer9No ratings yet

- Data LoggerDocument10 pagesData LoggerMuhamad IkramNo ratings yet

- Enzyme Biochem Lab KGDocument13 pagesEnzyme Biochem Lab KGKimberly George-Balgobin50% (2)

- Optimization of A Fed-Batch Fermentation Process For Production of Bleomycin by Streptomyces Mobaraensis ATCC 15003Document6 pagesOptimization of A Fed-Batch Fermentation Process For Production of Bleomycin by Streptomyces Mobaraensis ATCC 15003jmrozo3No ratings yet

- CHEM Sample 2Document12 pagesCHEM Sample 2Obada DyabNo ratings yet

- An Experiment in Enzyme Characterization-Banana PolyphenoloxidaseDocument3 pagesAn Experiment in Enzyme Characterization-Banana PolyphenoloxidaseKristiani SuhermanNo ratings yet

- WINSEM2020-21 BIT3012 ELA VL2020210501829 Reference Material I 25-Mar-2021 Amylase Enzyme KineticsDocument8 pagesWINSEM2020-21 BIT3012 ELA VL2020210501829 Reference Material I 25-Mar-2021 Amylase Enzyme KineticsVijayasarathy Sampath KumarNo ratings yet

- Oligonucleotide-Based Drugs and Therapeutics: Preclinical and Clinical Considerations for DevelopmentFrom EverandOligonucleotide-Based Drugs and Therapeutics: Preclinical and Clinical Considerations for DevelopmentNicolay FerrariNo ratings yet

- Pinongpong-Mendelian Genetics 2Document8 pagesPinongpong-Mendelian Genetics 2Jonald PINONGPONGNo ratings yet

- Proximate Analysis of Dragon Fruit (Hylecereus Polyhizus)Document3 pagesProximate Analysis of Dragon Fruit (Hylecereus Polyhizus)Jonald PINONGPONGNo ratings yet

- ZOO102-E328-Group-4-Activity-2Scientific-Report Arsad Frenila Pinongpong Alarcon Namion LuengoDocument32 pagesZOO102-E328-Group-4-Activity-2Scientific-Report Arsad Frenila Pinongpong Alarcon Namion LuengoJonald PINONGPONGNo ratings yet

- ZOO100 LAB Exercise 4 Group 5 AB328Document7 pagesZOO100 LAB Exercise 4 Group 5 AB328Jonald PINONGPONGNo ratings yet

- Calorimetry Lab ReportDocument3 pagesCalorimetry Lab ReportDylan CusterNo ratings yet

- Acrylamide IDocument8 pagesAcrylamide IAna María TorresNo ratings yet

- Proximate Analysis: A. Total MoistureDocument4 pagesProximate Analysis: A. Total MoistureDhvanit JoshiNo ratings yet

- Ansi Asabe Ep411.4 Mar2002 (R2007)Document7 pagesAnsi Asabe Ep411.4 Mar2002 (R2007)StephanNo ratings yet

- Human Eye and Colourful World Important QuestionsDocument11 pagesHuman Eye and Colourful World Important QuestionsAdarsh BhushanNo ratings yet

- Sources of New Drugs: Molecular Pharmacology Combinatorial SynthesisDocument14 pagesSources of New Drugs: Molecular Pharmacology Combinatorial SynthesisJasper JangNo ratings yet

- Naphtha: Grade: Sour Naphtha Result Spec Test Method 9002 LimitDocument1 pageNaphtha: Grade: Sour Naphtha Result Spec Test Method 9002 LimitHarikrishnan HNo ratings yet

- ID M113-Edited 912020Document11 pagesID M113-Edited 912020erwanNo ratings yet

- Assignment 2 Reactor Design Single ReactionDocument4 pagesAssignment 2 Reactor Design Single ReactionNitin MauryaNo ratings yet

- Vision Test Series ScheduleDocument16 pagesVision Test Series ScheduleNaveen Kumar SinghNo ratings yet

- Document 3Document5 pagesDocument 3SOLOMON RIANNANo ratings yet

- Emaco S88C TDSDocument2 pagesEmaco S88C TDSMerdan JumagylyjovNo ratings yet

- Design of IC Engine Components PDFDocument22 pagesDesign of IC Engine Components PDFDilshad S FaisalNo ratings yet

- A Review of Hydrogen Production Using Coal Biomass and Other Solid FuelsDocument22 pagesA Review of Hydrogen Production Using Coal Biomass and Other Solid FuelsBamrung SungnoenNo ratings yet

- Physics 571 Lecture #23: 1 Acousto-Optic Modulators (AOM)Document4 pagesPhysics 571 Lecture #23: 1 Acousto-Optic Modulators (AOM)ss626No ratings yet

- VCE Chemistry Study Design 2013-2016Document61 pagesVCE Chemistry Study Design 2013-2016SarahGeorgieNo ratings yet

- Complete vs. Incomplete Fertilizers: Cultural Requirements A. Applying FertilizerDocument7 pagesComplete vs. Incomplete Fertilizers: Cultural Requirements A. Applying FertilizerEmil BuanNo ratings yet

- Quitosano: Un Coagulante Natural Alternativo para El Tratamiento de Aguas Con Alta TurbidezDocument7 pagesQuitosano: Un Coagulante Natural Alternativo para El Tratamiento de Aguas Con Alta TurbidezGianela Madyori Zegarra YaringañoNo ratings yet

- Fretting Corrosion PDFDocument8 pagesFretting Corrosion PDFharishkumar.ravichandranNo ratings yet

- Butane Oxidation To Maleic Anhydride Kin PDFDocument13 pagesButane Oxidation To Maleic Anhydride Kin PDFPrasad ShahNo ratings yet

- SK Gupta Biochemistry PDF 14Document3 pagesSK Gupta Biochemistry PDF 14akashverma17123No ratings yet

- ARS Agriculture Biotechnology 2009 Question PaperDocument3 pagesARS Agriculture Biotechnology 2009 Question PaperAbhay Kumar92% (12)