Professional Documents

Culture Documents

P4059zor 62 22 0 T1001 001 001 - D

Uploaded by

Shravan ThangallapalliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P4059zor 62 22 0 T1001 001 001 - D

Uploaded by

Shravan ThangallapalliCopyright:

Available Formats

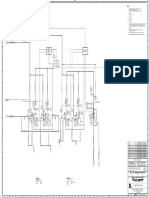

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

DESIGN DATA

API 650 12th EDITION-MARCH 2013,

DESIGN CODE ADDENDUM 1 :SEPTEMBER 2014,

A ERRATA 1, JULY 2013 & A

ERRATA 2, DECEMBER 2014

N9 N8 C APPLICABLE APPENDIXES E&P

STORED PRODUCT FIRE WATER

N12 TANK CAPACITY (WORKING) m3 25200

HANDRAILING M4 TANK CAPACITY (GROSS) m3 35000.9

ALL AROUND N11 N13 QUANTITY 2 NOS.

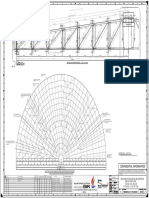

ROOF PLATE N7 M5 M3 TYPE OF ROOF SUPPORTED CONE ROOF

5 THK. ANNULAR/BOTTOM=1.5, SHELL=1.5, ROOF=0.0,

TOP LANDING CURB ANGLE

MANHOLE NECK & FLANGES & COVER=1.5,

B PLATFORM 1 1 L 75X75X10

CORROSION ALLOWANCE (mm) SHELL NOZZLES NECK & FLANGES=1.5, B

12 12 1

A @@@@@ SPIRAL STAIRWAY 12 ROOF PLATE ROOF NOZZLES NECK & FLANGES=0.0,

STRINGER TYPE. 5 THK. REMOVABLE INTERNALS COMPONENTS = 1.5

(TOTAL), NON-REMOVABLE INTERNALS

EL.+15800 EL.+15800

N1

S7

COMPONENTS = 1.5 (EACH EXPOSED SURFACE)

HHLL EL.+15427 N3

EL.+15165

HLL EL.+14665 DESIGN SPECIFIC GRAVITY 1

EL.+14220 NLL EL.+14165 PRODUCT SPECIFIC GRAVITY 0.987 @ 40° C

W.G. ROOF STRUCTURE EL.+14220

N10 W.G.

MAX. DESIGN LIQUID LEVEL (mm) 17000 (FOR SHELL DESIGN)

S6

MAX. FILLING HEIGHT (mm) 15165

C DESIGN/VAPOUR PRESSURE INTERNAL (mm)WC 0.00 C

LLL EL.+11715 VACUUM PRESSURE EXTERNAL (mm)WC 25.49

OPERATING PRESSURE. ATMOSPHERIC

S5

DESIGN TEMPERATURE MIN./MAX. °C -3 / 85

OPERATING TEMPERATURE MIN./MAX. °C -3 / 85

SUPPORT RADIOGRAPHY AS PER API 650 CL 8.1.2

HYDROSTATIC TEST PRESSURE FULL OF WATER(NOTE 7 & 29)

YES - AS PER API 650

S4

P.W.H.T.

PARAGRAPH 5.7.4.

D 45.9 (3 SEC GUST) FOR WIND GIRDER & WIND

D

WIND SPEED (m/sec)

LOAD (OVERTURNING STABILITY)

SEISMIC ZONE/CLASS 1/C

S3

N4 STILL WELL

IMPORTANCE FACTOR 1.25

INSULATION (mm) NIL

LADDER MAX. FILL / EMPTY RATE (m3/hr) 336/3150

EL.+3500 LLLL EL.+5000 PRIMER / PAINTING GENERAL NOTE=13 & 14

S2

L.R. ELBOW

AS PER DESIGN CODE, DEP 34.51.01.33-GEN &

SHELL COURSE (TYP) JOINT EFFICIENCY

E EL.+260

N5 SHELL I.D.

P4049N-0000-DE10-VAR-0015 E

EL.+1536 EL.+1500 51200 TESTING OF SHELL,BOTTOM,R.F.PAD,SHELL TO AS PER DESIGN CODE , DEP 34.51.01.33 - GEN &

N2 NAME PLATE BOTTOM PLATE P4049N-0000-DE10-VAR-0015 CLAUSE 7,8 & ANNEX C.

EL.+500 BOTTOM,F.R.TESTING & HYDROTESTING

S1

EL.+800 8 THK

DESIGN LIFE 25 YEARS

EL.+00 EL.+69.88

N6

DRIP RING 18-SETTLEMENT EARTHING LUGS BOTTOM PLATE 51223.5 MEAN DIA

DRIP RING

VORTEX MARKER M1 (3NOS.) EQUISPACED 8 THK

BREAKER 1 1 ANNULAR PLT.

120 120 UNDERSIDE EPOXY 800 WIDE (min.) X 9THK. 9 THK.

LOAD DATA FOR FOUNDATION

F M2 BOTTOM PLATE SLOPE COATING NOTE 13(d) ANNULAR PLATE EMPTY WEIGHT kN/MT. 7353.18/ 749.82 F

OPERATING WEIGHT kN/MT. 302481.75/ 30844.71

M6 D HYDROTEST WEIGHT kN/MT. 343556.35 / 35033.18

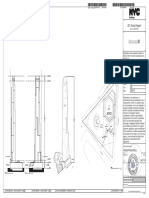

ELEVATION

SCALE NTS WIND SHEAR kN 584.36

DETAIL OF SHELL GIRTH WIND MOMENT kN-m 46314.30

SCALE NTS SEISMIC SHEAR kN 14696.59

SEISMIC MOMENT kN-m 96498.59

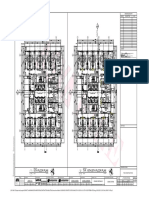

CONSTRUCTION DETAILS GENERAL NOTES :-

G TANK SHELL: 1. ALL DIMENSIONS ARE IN mm. UNLESS OTHERWISE SPECIFIED. G

2. DESIGN, CONSTRUCTION,MATERIAL,INSPECTION & TESTING OF THE TANK SHALL BE IN ACCORDANCE WITH

No. OF SHELL COURSES : 7 (SEVEN)

DESIGN CODE AND PROJECT SPECIFICATION.

PLATE WIDTH & THICKNESS : 1) 2500x23.5 2) 2000x20 3) 2500x17.5 4) 2500x14.5 5) 2500x11

3. BOLT HOLES SHALL STRADDLE CENTER LINES. ACCESSORIES

6) 2500X10.5 7) 2425x8

4. REINFORCEMENT SHALL BE AS PER DESIGN CODE/SHELL STD.

TANK BOTTOM: ANCHOR BOLT YES NO EXTERNAL CLIPS YES NO

SEAL WELDING 5. NOZZLES 50 NB AND BELOW SHALL BE STIFFENED BY 2 NOS. 30x6 THK. FLAT AT 90° APART.

SHELL I.D. PLATE THICKNESS : 8 THK (LAP WELDED) STRINGER TYPE SPIRAL STAIRWAY YES NO DIP PIPE YES NO

DRIP RING 6. THE FLANGE FACE FINISH FOR NOZZLE SHALL HAVE 125 AARH AND FOR MANHOLE SHALL HAVE

BOTTOM SLOPE : 1:120 (CONE-UP TO CENTER) NAME PLATE & BRACKET YES NO MANHOLE DAVIT/HINGE YES NO

(C.S 3t MIN.) 250AARH(FOR GASKET SEATING).

ANNULAR PLATE WIDTH & THICKNESS : 800 WIDE (min.) X 9THK. 7. FILL WATER UPTO OVER FLOW NOZZLE AT THE TIME OF HYDROTEST. EARTHING BOSS YES NO LEVEL TRANSMITTER YES NO

H 8. ALL ERECTION CLEATS, LUGS ETC. TEMPORARY ATTACHMENTS SHALL BE REMOVED BEFORE HYDROTEST. TEMPERATURE GAUGE YES NO BREATHER VALVE YES NO H

TANK ROOF: PRESSURE TRANSMITTER YES NO GAUGE HATCH YES NO

9. MANHOLE NECK/NOZZLE NECK 300NB. & ABOVE SHALL BE FABRICATED FROM ASTM A 573 Gr.70/ASTM A 283 Gr.C

ROOF TYPE : SUPPORTED CONE ROOF SETTLEMENT MARKER YES NO VORTEX BREAKER YES NO

PLATE AS THE PENETRATED SHELL MATERIAL & WELDED JOINT SHALL BE FULL PENETRATION & 100% RADIOGRAPHED.

ROOF SLOPE : 1:12 FIRE PROTECTION YES NO CATHODIC PROTECTION SYSTEM

FOUNDATION 10. FLANGE DIMENSION SHALL CONFORM TO ASME B16.5 UPTO 600NB EXCEPT MANHOLE (MANHOLE AS PER API 650). YES NO

ROOF PLATE THICKNESS : 5 THK OF TANK BOTTOM(NOTE 22)

FLANGE FOR NOZZLE ABOVE 600NB SHALL CONFORM TO ASME B16.47 SERIES A.

TANK WIND GIRDER: 11. REFER STATIC DESIGN CALCULATION FOR TANK CAPACITY & TANK HEIGHT CALCULATION.

NOZZLE PROJECTION & ELEVATION 12. a) LEAK TEST METHOD = ROOF :- AS PER SPEC./CODE

SECONDARY WIND GIRDER : 142X150X8THK- 1 NOS.

SHELL :- WATER TEST

DRIP RING PAINT OR LINING: (NOTE 13 & 14) SHELL MANHOLE/NOZZLE REIN PLT. :- AIR TEST

I BOTTOM. :- VACUUM BOX I

SHELL & ROOF : EXTERIOR

: : YES NO INTERIOR : YES NO

b) LEAK TEST SHALL BE CARRIED OUT AS PER PROCEDURE P4059ZOR-67-10-22-462. MATERIAL OF CONSTRUCTION

BOTTOM : UNDERSIDE : YES NO INTERIOR : YES NO

13. a) EXTERNAL PAINTING SHALL BE AS PER P4049N-0000-DE-10-VAR-0011 (30.48.00.31-4049NRP-00-PV). ANNULAR PLATE ASTM A 573 Gr.70

SURFACE PREPARATION : YES NO

b) FOR INTERNAL LINIING COATING FOLLOW P4059ZOR-00-10-22-030 & P4059N-0000-DE00-SPC-0036. BOTTOM PLATE ASTM A 283 Gr.C

GRINDING & BLENDING: c) THE TOP & BOTTOM OF THE DRIP RING, THE TOP OF THE TANK BOTTOM EDGE PROJECTION BEYOND THE SHELL & SHELL 1st TO 5th COURSE ASTM A 573 Gr.70

INTERIOR WELDS & SURFACES : YES NO 75 mm HEIGHT OF THE TANK SHELL SHALL BE PAINTED WITH A 250-300 MICRONS THICK EPOXY COATING. SHELL 6th & 7th COURSE ASTM A 283 Gr.C

WELD EXAMINATION : d) TANK BOTTOM PLATE UNDERSIDE SHALL BE PAINTED WITH ONE COAT OF HIGH BUILD EPOXY WITH CATHODIC ROOF PLATE ASTM A 283 Gr.C

DISBONDMENT RESISTANCE PAINT TO DFT 200 TO 300 MICRON AS PER P4059ZOR-00-10-22-030. WIND GIRDER ASTM A 283 Gr.C

RADIOGRAPHIC AND OTHER NDE AS PER DESIGN CODE AND PROJECT SPECIFICATION.

e) INTERNAL & EXTERNAL COATING/ PAINTING SHALL BE CARRIED OUT AS PER PROCEDURE P4059ZOR-67-10-22-461 NOZZLE NECKS < 12"NB ASTM A 106 Gr.B

J J

& P4059ZOR-67-10-22-463 RESPECTIVELY . NOZZLE NECKS > 12"NB ASTM A 573 Gr.70/ASTM A 283 Gr.C

14. INTERNAL EPOXY COATING ON BOTTOM PLATE, ALL SHELL COURSES AND ROOF UNDERSIDE TO BE PROVIDED NOZZLE FLANGES ASTM A 105

AS PER P4049N-0000-BA30-DCN-0456_1. SHELL MANWAY NECKS/FLANGES/COVER ASTM A 573 Gr.70

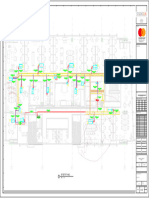

LIST OF DRAWINGS 15. A DEAD STOCK HEIGHT OF 400 MM HAS BEEN USED FOR TANK DUE TO THE ASSUMED HEIGHT OF REQUIRED VORTEX REINFORCING PADS ASTM A 573 Gr.70 (SAME AS COMPONENT)

BREAKER ON TANK OUTLET.

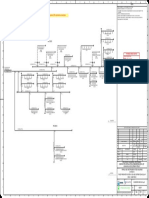

DOCUMENT TYPE DRAWING No./DOCUMENT No. REINFORCING PADS ASTM A 283 Gr.C (SAME AS COMPONENT)

TITLE 16. GAUGE HATCH SHALL BE PROVIDED WITH STILLING WELL AND SHALL ALSO BE OF THE SELF CLOSING TYPE AS PER

PLATFORM, STAIRWAY & STRUCTURAL ASTM A 36

DEP 34.51.01.33-GEN (V.32).

FIRE WATER TANK - STATIC DESIGN CALCULATION (TAG NO-62-T-1001A/B) ANALYSIS & CALCULATIONS P4059ZOR-00-62-22-C-076 CURB ANGLE ASTM A 36

17. ALL NOZZLE ELEVATION ARE FROM TOP OF ANNULAR PLATE.

FIRE WATER TANK - ROOF STRUCTURE DESIGN CALCULATIONS (TAG NO-62-T-1001A/B) ANALYSIS & CALCULATIONS P4059ZOR-00-62-22-C-077 PIPE ASTM A 53 GR.B/ASTM A 106 Gr.B

18. MANUFACTURER TO CARRY OUT PWHT, WHERE REQUIRED IN ACCORDANCE WITH API 650, SHELL DEP

K FIRE WATER TANK - NOZZLE LOAD CALCULATION (TAG NO-62-T-1001A/B) ANALYSIS & CALCULATIONS P4059ZOR-00-62-22-C-078 PIPE FITTINGS ASTM A 234 Gr.WPB K

34.51.01.33-GEN & P4049N-0000-DE10-VAR-0015'

FIRE WATER TANK - GENERAL ARRANGEMENT DRAWING (TAG NO-62-T-1001A/B) JOB DRAWING P4059ZOR-62-22-0-T1001-001-001 HANDRALING ASTM A 36

19. PLATFORMS, STAIRWAYS AND RAILINGS (HANDRAILS) PAINTED PER DEP-30.48.00.31-GEN. &

FIRE WATER TANK - BOTTOM PLATE DEVELOPMENT DRAWING (TAG NO-62-T-1001A/B) JOB DRAWING P4059ZOR-62-22-1-T1001-002-001 & 002 STUDS/NUTS ASTM A 193 Gr. B7 / ASTM A 194 Gr.2H

P4049N-0000-DE10-VAR-0011, WITH GRATING AND TREADS GALVANIZED PER P4049NRP.00.10.48.002

FIRE WATER TANK - BOTTOM PLATE CUTTING LAYOUT DRAWING (TAG NO-62-T-1001A/B) JOB DRAWING P4059ZOR-62-22-1-T1001-003-001 & 002 GASKET FOR MANHOLE FLEXIBLE GRAPHITE

STANDARD DETAILS 20. THREE PLATE LAP JOINT TO BE SUITABLY JOGGLED TO LENGTH OF 150mm MIN TO FACILITATE WELDING.

FIRE WATER TANK - SHELL PLATE DEVELOPMENT DRAWING (TAG NO-62-T-1001A/B) JOB DRAWING P4059ZOR-62-22-1-T1001-004-001 & 002 GASKET FOR NOZZLE SPIRAL WOUND GRAPHITE FILLED,

21. THREE PLATE LAP JOINT ON BOTTOM SHALL NOT BE CLOSER THAN 300mm FROM EACH OTHER, TANK

$ AS PER STD. NO. S51.068-B: ROOF NOZZLE FIRE WATER TANK- SHELL PLATE CUTTING LAYOUT & SETTLEMENT MARKER SS INNER RING, CS OUTER RING.

DRAWING (TAG NO-62-T-1001A/B) JOB DRAWING P4059ZOR-62-22-1-T1001-005-001 & 002 SHELL AND ANNULAR PLATE.

$$ AS PER STD. NO. S51.127-C: ROOF MANHOLE SIZE 20"-24" INCL 22. FOR CATHODIC PROTECTION OF TANK BOTTOM EXTERNAL SURFACES NACE RP0193 DEP 30.10.73.10-GEN. AND DRIP RING ASTM A 283 Gr.C

$$$ ASME B16.47 SERIES A. FIRE WATER TANK - CONE ROOF PLATE DEVELOPMENT DRAWING (TAG NO-62-T-1001A/B) JOB DRAWING P4059ZOR-62-22-1-T1001-006-001 & 002

P4059ZOR-00-10-64-502 SHALL BE FOLLOWED. GRATINGS(PLATFORM, STAIRWAY) GALVANIZED

@@ AS PER STD. NO. S51.226-P4049NRP-00-PV: TANK SHELL NOZZLES-FLANGED CLASS 150 FIRE WATER TANK - CONE ROOF PLATE CUTTING LAYOUT DRAWING (TAG NO-62-T-1001A/B) JOB DRAWING P4059ZOR-62-22-1-T1001-007-001 & 002 23. TANK REQUIRED WORKING CAPACITY CORESPONDING TO 8 HOURS WITH 3 NUMBER FIREWATER PUMPS RUNNING AT STAIRWAY STRINGER PLATE ASTM A 283 Gr.C / ASTM A 36

L @@@ AS PER STD. NO. S51.227:SHELL MANHOLE TANKS UP TO A HEIGHT OF 25m FIRE WATER TANK - ROOF STRUCTURE DETAIL DRAWING (TAG NO-62-T-1001A/B ) JOB DRAWING P4059ZOR-62-22-1-T1001-008 TO 011-001 1050 M3/H EACH. WORKING CAPACITY TO BE STORED BETWEEN NLL (14165 MM) AND MINIMUM WORKING LEVEL L

ROOF STRUCTURE PLATES ASTM A 283 Gr.C

@@@@ AS PER STD. NO. S10.070-P4049NRP-00-PV DAVIT FOR ANSI OR BS BLIND FLANGES NOM. SIZE 12"-24" INCL., FIRE WATER TANK - SECONDARY WIND GIRDER DRAWING (TAG NO-62-T-1001A/B ) JOB DRAWING P4059ZOR-62-22-1-T1001-013-001 OF 1925 MM ABOVE TANK BOTTOM

C NAME PLATE/BRACKET SS 304/ASTM A 573 Gr.70

FIRE WATER TANK - SHELL APPURTENANCES DETAIL DRAWING (TAG NO-62-T-1001A/B) JOB DRAWING P4059ZOR-62-22-1-T1001-014 TO 016-001 24. FOR SHOP INSPECTION, CLAUSE 6.2 OF DESIGN CODE SHALL BE FOLLOWED.

CLASS 150-600 INCL. BACKING STRIP ASTM A 36 / EQUIVALENT

FIRE WATER TANK - ROOF APPURTENANCES DETAIL DRAWING (TAG NO-62-T-1001A/B) JOB DRAWING P4059ZOR-62-22-1-T1001-017 & 018-001 25. EXAMINATION, INSPECTION AND REPAIRS SHALL BE DONE AS PER CLAUSE 7.3 OF DESIGN CODE.

@@@@@ AS PER STD. NO. S51.087 SPIRAL TYPE STAIRCASE A 26. WELD JOINT INSPECTION SHALL BE DONE AS PER CLAUSE 8.1 TO 8.6 OF DESIGN CODE.

WATER TANK - SPIRAL STAIRWAY & PLATFORM DRAWING (TAG NO-62-T-1001A/B ) JOB DRAWING P4059ZOR-62-22-1-T1001-019 TO 021-001

27. FOR NDE , ANNEX 'T' OF DESIGN CODE SHALL BE FOLLOWED.

FIRE WATER TANK - NOZZLE ORIENTATION DRAWING (TAG NO-62-T-1001A/B ) JOB DRAWING P4059ZOR-62-22-1-T1001-023-001 & 002 28. EASY ACCESSIBLE ROOF HATCHES PLACED 180 DEGREES EACH OTHER WITH LADDER TO ACCESS THE TANK FLOOR

FIRE WATER TANK - NAME PLATE DRAWING (TAG NO-62-T-1001A/B ) JOB DRAWING P4059ZOR-62-22-1-T1001-024-001 ACCORDING TO NFPA 22.

FIRE WATER TANK - MISC ITEM DRAWING (PIPING SUPPORT CLEAT, EARTHING LUG ETC.) 29. HYDROTEST WILL BE CARRIED OUT AS PER P4059ZOR-00-10-10-417.

JOB DRAWING P4059ZOR-62-22-1-T1001-025-001

(TAG NO-62-T-1001A/B )

M M

FIRE WATER TANK - DRIP RING DETAILED DRAWING (TAG NO-62-T-1001A/B ) JOB DRAWING P4059ZOR-62-22-1-T1001-026-001

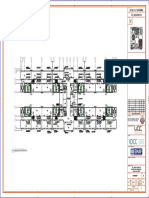

NOZZLE SCHEDULE

SHELL APPURTENANCES @@

NOZZLE SIZE DN QTY. SCH/ FLANGE ELEVATION PROJECTION

MARK (mm) THK SERVICE REMARKS ORIENTATION

STANDARD RATING TYPE FACE "A" "B"

W/COVER & DAVIT APPLICABLE PROJECT SPECIFICATIONS AND DEP

M1/M2/ 600 3 10THK AS PER API 650 SHELL MANHOLE @@@ 800 25924.5

DRAWINGS P4059ZOR-62-22-1-

M6 D @@@@

SEE NOZZLE ORIENTATION

ABOVEGROUND VERTICAL STORAGE TANKS START-UP / COMMISSIONING SPARES

DEP 34.51.01.33-GEN (AMENDMENTS/SUPPLEMENTS TO API STANDARD 650)

N N1 250 1 80 ASME B16.5 150# SO RF INLET 15800 25846 N

T0601-023-001 TO 002

1) ONE SET OF GASKETS (200%) FOR BLIND FLANGES, MANWAYS AND SPECIAL COVER FLANGES.

P4049N-0000-DE10-VAR-0015 PROJECT VARIATION TO SHELL DEP 34.51.01.33

N2 750 1 14.5THK $$$ 150# WN RF PRODUCT OUTLET W/VORTEX BREAKER 1536 25928.5 2) 10% OF BOLTING (MINIMUM 4 PIECES OF BOLTS AND NUTS) REQUIRED FOR BLIND CONNECTIONS, MAN WAYS,

DEP 34.00.01.30-GEN STRUCTURAL DESIGN & ENGINEERING SPECIAL FLANGES AND INTERNALS.

N3 300 1 14.5THK ASME B16.5 150# SO RF OVERFLOW 15427 25846 P4049N-0000-DD00-VAR-0001_2 PROJECT VARIATION TO SHELL DEP 34.00.01.30 3) ONE COMPLETE SET OF GASKETS FOR INTERNAL FLANGE CONNECTIONS.

N4 50 1 160 ASME B16.5 150# SO RF TEMPERATURE GAUGE 3500 25773.5 35.072-00-2.10-0001-E REV.0 PROCEDURES FOR DEVELOPING SITE SPECIFIC SEISMIC DESIGN PARAMETERS

P4049N-0000-DE00-SPC-0036_0 PROJECT SPECIFICATION FOR INTERNAL LINING

N5 100 1 120 ASME B16.5 150# SO RF LEVEL TRANSMITTER 260 25804 C P4049N-0000-DE10-VAR-0011_2 PROTECTIVE COATING FOR ONSHORE FACILITIES

N6 200 1 100 ASME B16.5 150# SO RF FLUSH-TYPE SHELL DRAIN 69.88 25893 P4049N-0000-DE00-SPC-0037_0 GALVANIZING

O

N10 350 1 14.5 THK. ASME B16.5 150# SO RF PUMPS TEST HEADER 15800 25863 P4049N-0000- DF00-SPC-0014

DEP 30.10.73.10-GEN

PROJECT SPECIFICATION FOR CATHODIC PROTECTION

CATHODIC PROTECTION

CONFIDENTIAL INFORMATION O

ROOF APPURTENANCES $ NOTICE: THIS DRAWING HAS NOT BEEN PUBLISHED AND IS THE SOLE PROPERTY OF KIPIC. IT IS LENT TO THE BORROWER

FOR HIS CONFIDENTIAL USE ONLY. IN CONSIDERATION OF THE LOAN OF THIS DRAWING, THE BORROWER PROMISES

AND AGREES TO RETURN IT UPON REQUEST, AGREES THAT IT SHALL NOT BE REPRODUCED, COPIED, LENT OR OTHERWISE

NOZZLE SCH/ FLANGE RADIUS PROJECTION

MARK (mm) QTY THK SERVICE REMARKS DISPOSED OF DIRECTLY OR INDIRECTLY AND, THAT IT SHALL NOT BEUSED FOR ANY PURPOSE OTHER THAN THAT FOR WHICH

STANDARD RATING TYPE FACE "R" "H" IT IS FURNISHED.

CONTRACTOR APPROVAL KNPC APPROVAL DRAWN BY

M3-M4 600 2 6THK. AS PER API 650 ROOF HATCH W/LADDER (NOTE-28) REV DATE REVISION DESCRIPTION DRAWN CHECK

CSA PIPING MECH. ELEC. PROCESS CIT PROJ. ENGR PROJ. DWG. NO. TITLE VIJAY BHOR

M5 500 1 6THK. AS PER API 650 ROOF MANHOLE $$ W/COVER O

NO

03-11-16 ISSUED FOR APPROVAL V.B. M.G. XX XX XX XX XX XX XX XX XX P4059ZOR-0062-80R90

PROCESS DATA SHEET FOR FIRE WATER TANKS

(62-T-1001 A/B)

GENERAL ARRANGEMENT FOR

APPURTENANCES

APPURTENANCES

P4059ZOR-62-22-1

P4059ZOR-62-22-1

P4059ZOR-62-22-1

CHECKED BY

FIRE WATER TANKS

ORIENTATION

MECHINICAL DATA SHEET FOR FIRE WATER TANKS MANORANJAN GOUDA

SEE NOZZLE

A 29-11-16 RE-ISSUED FOR APPROVAL (REVISED AS MARKED ) V.B. M.G. XX XX XX XX XX XX XX XX XX P4059ZOR-62-10-22-069 & 70

A

T1001-017 &

T1001-017 &

(62-T-1001 A/B)

DRAWINGS

DRAWINGS

DRAWINGS

W/STILL WELL

-T0601-023-

N7 200 1 40 ASME B16.5 150# SO RF GAUGE HATCH

001 TO 002

SEE ROOF

SEE ROOF

SUPERVISOR RELEASE DATE

TAG. NO. 62-T-1001 A/B

018-001

018-001

B 17-12-16 ISSUED FOR USE (REVISED AS MARKED ) V.B. M.G. XX XX XX XX XX XX XX XX XX P4059ZOR-62-08-1-J-001-001

B WATER SYSTEMS UNIT 62 M. GOUDA 03-11-16

N8-N9 750 2 12.7THK. $$$ 150# WN RF VENT GOOSE NECK W/ BIRD SCREEN C 07-03-18 ISSUED FOR CONSTRUCTION (REVISED AS MARKED

C ) V.B. M.G. XX XX XX XX XX XX XX XX XX

RECIRCULATION D 23-08-18 ISSUED FOR CONSTRUCTION (REVISED AS MARKED ) D.S. J.L. XX XX XX XX XX XX XX XX XX

SUPERVISOR ENGR.

P.MAMANIA

INITIALS

51.2 M. DIA. x 17 M. HT. (CR)

N11 350 1 STD ASME B16.5 150# SO FF D

PROJECT ENGR. APP. DATE

CONTRACTOR DRAWING NUMBER SCALE DRAWING NUMBER

N12 350 1 STD ASME B16.5 150# SO FF RECIRCULATION H.PANCHAL 07-09-16 REVISION

N13 350 1 STD ASME B16.5 150# WN FF RECIRCULATION C

CLIENT APP. DATE

07-09-2016

1:1

P4059ZOR-62-22-0-T1001-001-001 D

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

You might also like

- Opt-3 - 2 - Ground CommDocument1 pageOpt-3 - 2 - Ground CommHasmeet SinghNo ratings yet

- Instant Assessments for Data Tracking, Grade 1: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 1: Language ArtsNo ratings yet

- July 2020 Calendars Landscape SundayDocument5 pagesJuly 2020 Calendars Landscape SundayQueen ANo ratings yet

- July 2020 Calendars LandscapeDocument5 pagesJuly 2020 Calendars LandscapeQueen ANo ratings yet

- 08 SwitchgearDocument12 pages08 SwitchgearMuhammad AsifNo ratings yet

- 918 - AR - (13) Clinic Level Reflected CeilingDocument1 page918 - AR - (13) Clinic Level Reflected CeilingJelson RumuarNo ratings yet

- KEP PLAN 30-1 Service Corridor TitleDocument1 pageKEP PLAN 30-1 Service Corridor TitleSenthilmurugan KumaresanNo ratings yet

- Unit 6900 Area 01Document1 pageUnit 6900 Area 01Khairul IdhamNo ratings yet

- 2021 Monthly Monday - BlueDocument12 pages2021 Monthly Monday - BlueTamara SmithNo ratings yet

- Entrega Corte 1Document1 pageEntrega Corte 1Rebecka Galvez MoraNo ratings yet

- For Construction: 1 No Beam Required As Drawn MKD ' L0R0011Be111PDocument1 pageFor Construction: 1 No Beam Required As Drawn MKD ' L0R0011Be111PrajendraNo ratings yet

- Male Closed WardDocument1 pageMale Closed Wardvenkat rajuNo ratings yet

- General notes for structural steel and stairs design drawingDocument1 pageGeneral notes for structural steel and stairs design drawingrajendraNo ratings yet

- Attachement-1 RFC-29-18Document14 pagesAttachement-1 RFC-29-18Mohamed ArafaNo ratings yet

- Ed 0100 PRS Pid 000 01005uDocument1 pageEd 0100 PRS Pid 000 01005uMohamed ArafaNo ratings yet

- Clay Tiles Shop Drawing - SDDocument1 pageClay Tiles Shop Drawing - SDAhmed MohamedNo ratings yet

- Va 1302 070822Document1 pageVa 1302 070822api-3698996No ratings yet

- G-102-01 (790DBBC) Al-Shahaniya: Qatar Armed ForcesDocument1 pageG-102-01 (790DBBC) Al-Shahaniya: Qatar Armed ForcesAslamNo ratings yet

- 26071-203-M6-315-00005 - Piping and Instrumentation Diagram Fuel Oil and Fuel Gas System (Unit 315) Fuel Gas KO DrumDocument1 page26071-203-M6-315-00005 - Piping and Instrumentation Diagram Fuel Oil and Fuel Gas System (Unit 315) Fuel Gas KO DrumJeroan AyamNo ratings yet

- Ellectric Office - 1Document1 pageEllectric Office - 1kom1984No ratings yet

- Kitchen Store: Shop Shop Shop Shop Shop Shop Shop Shop Shop ShopDocument1 pageKitchen Store: Shop Shop Shop Shop Shop Shop Shop Shop Shop Shopyash ayreNo ratings yet

- Ie2-Mcb-Ele Aa P9Document1 pageIe2-Mcb-Ele Aa P9Maria JoseNo ratings yet

- Raghunath Ghorai Paushi Final SheetDocument1 pageRaghunath Ghorai Paushi Final SheetSoham DeNo ratings yet

- CH BB SLD El 01 06Document1 pageCH BB SLD El 01 06Ahmed MarzokNo ratings yet

- Legend: Project Name: LPIC EPC1 SCUDocument1 pageLegend: Project Name: LPIC EPC1 SCUjeswinNo ratings yet

- Attachment - 2 - GA For Shop Fabricated Tanks PDFDocument3 pagesAttachment - 2 - GA For Shop Fabricated Tanks PDFShah Newaz KabirNo ratings yet

- Drawing plan for plinth beamDocument1 pageDrawing plan for plinth beamyash ayreNo ratings yet

- RAB03-DRA-IDOM-FAZ-300-0361 - Rev02 - Air Backwash Shelter. Foundation - FormworksDocument1 pageRAB03-DRA-IDOM-FAZ-300-0361 - Rev02 - Air Backwash Shelter. Foundation - FormworksHatemS.MashaGbehNo ratings yet

- Hyd Schematic 2658487205 - 005Document3 pagesHyd Schematic 2658487205 - 005Angelo Solorzano100% (2)

- Bom DetailsDocument1 pageBom DetailsAzad QureshiNo ratings yet

- Unit 330Document22 pagesUnit 330mohamed ghorabNo ratings yet

- Pull Out Mar4Document1 pagePull Out Mar4Félix AdventoNo ratings yet

- 4th Storey Plumbing Layout Plan Rev 0Document1 page4th Storey Plumbing Layout Plan Rev 0ZenChanNo ratings yet

- Vezalna Shema Wiring Diagram: No. Yy-Mm-DdDocument2 pagesVezalna Shema Wiring Diagram: No. Yy-Mm-Ddenermac projetosNo ratings yet

- Em-2006-Mep-Eom-Mt-Sd-Plb-104 (Rev-1)Document1 pageEm-2006-Mep-Eom-Mt-Sd-Plb-104 (Rev-1)shreeNo ratings yet

- Petronas Carigali SDN BHD: Document Review StatusDocument1 pagePetronas Carigali SDN BHD: Document Review StatusMohd KhaidirNo ratings yet

- Hpcl-Mittal Energy LTD., P Ih LKH, Y & Ferry, Uzth FyfevsmDocument1 pageHpcl-Mittal Energy LTD., P Ih LKH, Y & Ferry, Uzth Fyfevsmiqbal6982No ratings yet

- Top View Section X-X: Design DataDocument1 pageTop View Section X-X: Design DatakishoreNo ratings yet

- Anexo 17 - DE SERVICIO_INSTRUMENTACION (plano de ruta)Document1 pageAnexo 17 - DE SERVICIO_INSTRUMENTACION (plano de ruta)Angel Luis Paredes PierolaNo ratings yet

- GRGRGDocument3 pagesGRGRGSenthilmurugan KumaresanNo ratings yet

- Ug-Til-43-Sin1-415702 - 02 - Afc - 20220623 - JBR09 To JBR08Document2 pagesUg-Til-43-Sin1-415702 - 02 - Afc - 20220623 - JBR09 To JBR08AHMED LASSOUEDNo ratings yet

- Request Form for ID Badge and EAC AccessDocument1 pageRequest Form for ID Badge and EAC AccessTengku Nizarul AslamiNo ratings yet

- 15-032!00!033 - Fire Protection System Ground Floor Plan Part-2Document1 page15-032!00!033 - Fire Protection System Ground Floor Plan Part-2Amit BiswasNo ratings yet

- 15TH FLOOR & 16-25TH FLOOR TRIBE HOTEL-Layout1Document1 page15TH FLOOR & 16-25TH FLOOR TRIBE HOTEL-Layout1Mark Joey DavidNo ratings yet

- 001 - CC - Tierra N - SDP - 200629 - Final - 1593395965 PDFDocument1 page001 - CC - Tierra N - SDP - 200629 - Final - 1593395965 PDFPatrick manuelNo ratings yet

- CMN.18.477 Smart Plant Documentation Ruwais NGL Train 3: From El.93 800 To Above LP Flare Piping Ga Plan Area TD Zone 736Document1 pageCMN.18.477 Smart Plant Documentation Ruwais NGL Train 3: From El.93 800 To Above LP Flare Piping Ga Plan Area TD Zone 736steepa22No ratings yet

- ZD1 Zoning Diagram: 340 Flatbush Avenue Extension Brooklyn 149 100 3396179Document3 pagesZD1 Zoning Diagram: 340 Flatbush Avenue Extension Brooklyn 149 100 3396179kasugagNo ratings yet

- 06 - Appendix E - Technical Reports and DrawingsDocument617 pages06 - Appendix E - Technical Reports and Drawingsmartin solarNo ratings yet

- APO Security - PT WCP-14 - SignDocument3 pagesAPO Security - PT WCP-14 - SignTengku Nizarul AslamiNo ratings yet

- Sliding Plate Installation DetailsDocument1 pageSliding Plate Installation DetailsNiwrati HolkarNo ratings yet

- Frontier Iii: Planta ArquitectónicaDocument5 pagesFrontier Iii: Planta ArquitectónicaIsrael Josue Valladares VargasNo ratings yet

- Shop Drawing: Refer To Comments On Overall PlanDocument1 pageShop Drawing: Refer To Comments On Overall PlanKhaled SaberNo ratings yet

- 05-KSCPP-B-1906 - A - Code 2Document1 page05-KSCPP-B-1906 - A - Code 2Mohd KhaidirNo ratings yet

- 0-8936-2 Golden Triangle Polymers Company LLCDocument1 page0-8936-2 Golden Triangle Polymers Company LLCLester MuscaNo ratings yet

- 1er NivelDocument1 page1er Nivellady TantaquispeNo ratings yet

- December Calendar2 PDFDocument1 pageDecember Calendar2 PDFc9annNo ratings yet

- 00UMF611 - LAYOUT A ARRANGEMENT POWER HOUSE - Equipment Location Plan - 002Document9 pages00UMF611 - LAYOUT A ARRANGEMENT POWER HOUSE - Equipment Location Plan - 002tiantaufikNo ratings yet

- Revisions: Research in MotionDocument2 pagesRevisions: Research in MotionAshardgsm kroyaNo ratings yet

- Revisions: Research in MotionDocument2 pagesRevisions: Research in MotionIntel_Pentium_INo ratings yet

- Confidential Information: Details of Main Rafters - Qty. 20 Nos. Det 'A' Det 'B'Document1 pageConfidential Information: Details of Main Rafters - Qty. 20 Nos. Det 'A' Det 'B'Shravan ThangallapalliNo ratings yet

- Steel roof truss assembly detailsDocument1 pageSteel roof truss assembly detailsShravan ThangallapalliNo ratings yet

- Drilling SAFETY OIL and GAS Land Drilling Operations Rev 1 1Document0 pagesDrilling SAFETY OIL and GAS Land Drilling Operations Rev 1 1jsembiringNo ratings yet

- COD - Bolting Flange & Cover Flange Cutting Details For 69-T-501-502Document1 pageCOD - Bolting Flange & Cover Flange Cutting Details For 69-T-501-502Shravan ThangallapalliNo ratings yet

- Is.4130.1991 0 PDFDocument16 pagesIs.4130.1991 0 PDFraheem vNo ratings yet

- Veera Brahmam Rigging Supervisor Experince CertificateDocument1 pageVeera Brahmam Rigging Supervisor Experince CertificateShravan ThangallapalliNo ratings yet

- Kuwait 20" Pipeline: OilstoneDocument3 pagesKuwait 20" Pipeline: OilstoneShravan ThangallapalliNo ratings yet

- Compalince, Hydraulic Calculations and Fire Water Demand Calculations For GGS I 8364Document33 pagesCompalince, Hydraulic Calculations and Fire Water Demand Calculations For GGS I 8364Shravan ThangallapalliNo ratings yet

- OISD-STD--226: Natural Gas Transmission Pipelines and City Gas Distribution NetworksDocument75 pagesOISD-STD--226: Natural Gas Transmission Pipelines and City Gas Distribution Networkssamsurendran_mech4020No ratings yet

- Ral ChartDocument10 pagesRal ChartShravan ThangallapalliNo ratings yet

- Registration of Hindu Marriage Application FormDocument2 pagesRegistration of Hindu Marriage Application Formjohn_lonerNo ratings yet

- En TracLocTankinsulation SB H57478 Tcm432 26458Document6 pagesEn TracLocTankinsulation SB H57478 Tcm432 26458ulasNo ratings yet

- Bracket System Alternate For Scaffolding For TanksDocument5 pagesBracket System Alternate For Scaffolding For TanksShravan ThangallapalliNo ratings yet

- CNC Vendor Suggested DrawingsDocument13 pagesCNC Vendor Suggested DrawingsShravan ThangallapalliNo ratings yet

- Analysis On Forgery Patterns For GPS Civil Spoofing SignalsDocument4 pagesAnalysis On Forgery Patterns For GPS Civil Spoofing SignalsMadhu KrishnaNo ratings yet

- Bharathidasan University UG/PG Exam ApplicationDocument2 pagesBharathidasan University UG/PG Exam ApplicationOppili yappanNo ratings yet

- PW 160-Taliban Fragmentation Fact Fiction and Future-PwDocument28 pagesPW 160-Taliban Fragmentation Fact Fiction and Future-Pwrickyricardo1922No ratings yet

- Using Previous Years AlmanacDocument1 pageUsing Previous Years AlmanacbhabhasunilNo ratings yet

- F 83179Document6 pagesF 83179pcmfilhoNo ratings yet

- Pcit Brochure TemplateDocument2 pagesPcit Brochure Templateapi-370829251No ratings yet

- The Control of Building Motion by Friction Dampers: Cedric MARSHDocument6 pagesThe Control of Building Motion by Friction Dampers: Cedric MARSHAlam Mohammad Parvez SaifiNo ratings yet

- Automation of Banking Service - EBL & EXIM BankDocument32 pagesAutomation of Banking Service - EBL & EXIM BankShaffyNo ratings yet

- Holy Week Labyrinth GuideDocument4 pagesHoly Week Labyrinth GuideEileen Campbell-Reed100% (1)

- Managerial Economics L4 Consumer BehaviourDocument50 pagesManagerial Economics L4 Consumer BehaviourRifat al haque DhruboNo ratings yet

- Conditions For The Emergence of Life On The Early Earth: Summary and ReflectionsDocument15 pagesConditions For The Emergence of Life On The Early Earth: Summary and Reflectionsapi-3713202No ratings yet

- Maam Approve Na Pls HuhuDocument28 pagesMaam Approve Na Pls HuhuErica Joy Escopete100% (1)

- A Detailed Lesson Plan in (Teaching Science)Document8 pagesA Detailed Lesson Plan in (Teaching Science)Evan Jane Jumamil67% (3)

- Albert Einstein - Wikipedia, The Free EncyclopediaDocument34 pagesAlbert Einstein - Wikipedia, The Free EncyclopediaalhanunNo ratings yet

- Consumer Notebook Price List For September 2010Document4 pagesConsumer Notebook Price List For September 2010Anand AryaNo ratings yet

- OYO Case Study SolutionDocument4 pagesOYO Case Study SolutionVIKASH GARGNo ratings yet

- MMC Fiori Cheat Sheet PDFDocument2 pagesMMC Fiori Cheat Sheet PDFAleksandar KNo ratings yet

- Developing Website Information ArchitectureDocument39 pagesDeveloping Website Information ArchitectureBizuNo ratings yet

- Presentation on Indentured LabourersDocument10 pagesPresentation on Indentured LabourersAshis karmakar100% (1)

- Chapter 24 Study QuestionsDocument3 pagesChapter 24 Study QuestionsAline de OliveiraNo ratings yet

- Bachelor of Arts (Psychology HR Management) Y3 V2Document1 pageBachelor of Arts (Psychology HR Management) Y3 V2Kenny sylvainNo ratings yet

- XII Class Assignment Programs 2023-24Document8 pagesXII Class Assignment Programs 2023-24Sudhir KumarNo ratings yet

- Battle Bikes 2.4 PDFDocument56 pagesBattle Bikes 2.4 PDFfranzyland100% (1)

- Method Overloading in JavaDocument6 pagesMethod Overloading in JavaPrerna GourNo ratings yet

- New Translation and Deciphering of ChineDocument14 pagesNew Translation and Deciphering of ChineRémyNo ratings yet

- Bridge Manual Retaining Walls - Section 3.62 Page 3.2-2Document1 pageBridge Manual Retaining Walls - Section 3.62 Page 3.2-2lomoscribdNo ratings yet

- ĐỀ THI HSGDocument13 pagesĐỀ THI HSGahmad amdaNo ratings yet

- Accounting For Non Specialists Australian 7th Edition Atrill Test BankDocument26 pagesAccounting For Non Specialists Australian 7th Edition Atrill Test BankJessicaMitchelleokj100% (49)

- ds923 Virtex Ultrascale PlusDocument81 pagesds923 Virtex Ultrascale Plusismail topcuNo ratings yet

- Chapter 9: Operating SystemsDocument166 pagesChapter 9: Operating SystemsGazzzeeNo ratings yet