Professional Documents

Culture Documents

Installation Instructions For FLCO Rupture Disks Between Companion Piping Flanges

Uploaded by

Gabriel0 ratings0% found this document useful (0 votes)

13 views1 pageThe document provides installation instructions for FLCO rupture disks between companion piping flanges in 3 steps:

1) Remove the previous gasket and clean the flange surfaces.

2) Position the FLCO assembly and bolt it in place, tightening the bolts sequentially and incrementally to the specified torque values.

3) Handle the rupture disk carefully to avoid damage and locate it to allow unrestricted discharge in case of overpressure.

Original Description:

Original Title

flco-installation-guide

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides installation instructions for FLCO rupture disks between companion piping flanges in 3 steps:

1) Remove the previous gasket and clean the flange surfaces.

2) Position the FLCO assembly and bolt it in place, tightening the bolts sequentially and incrementally to the specified torque values.

3) Handle the rupture disk carefully to avoid damage and locate it to allow unrestricted discharge in case of overpressure.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views1 pageInstallation Instructions For FLCO Rupture Disks Between Companion Piping Flanges

Uploaded by

GabrielThe document provides installation instructions for FLCO rupture disks between companion piping flanges in 3 steps:

1) Remove the previous gasket and clean the flange surfaces.

2) Position the FLCO assembly and bolt it in place, tightening the bolts sequentially and incrementally to the specified torque values.

3) Handle the rupture disk carefully to avoid damage and locate it to allow unrestricted discharge in case of overpressure.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

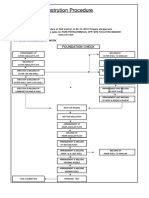

Installation Instructions for FLCO Rupture Disks Between

Companion Piping Flanges

TYPICAL FLCO INSTALLATION SHOWN

3. Remove the burst rupture disk assembly and examine

the mating companion piping flange gasket surfaces.

These gasket surfaces should be suitably cleaned to

remove all traces of the previous gasket seal in order to

create a good seal on the FLCO assembly being installed.

INSTALLING THE FLCO RUPTURE DISK

1. Position the new FLCO assembly within the companion

COMPANION piping flange bolt circle and install sufficient bolts to

OUTLET FLANGE maintain this position for the FLCO. Complete bolting

installation being careful to maintain the initial position of

the rupture disk assembly.

FLOW

2. Tighten nuts in a sequential manner, beginning with 10

FLOW

FLCO RUPTURE DISK

percent of the torque values depicted in the table below.

Increase the torque level in suitable increments until the

COMPANION

INLET FLANGE

value listed in the table below is achieved

FLANGE BOLTING TORQUE REQUIREMENTS FOR

FLCO COMPANION FLANGES

(FT-LBS)

Nominal Size 150 ANSI 300 ANSI

(inches)

1 17 21

1.5 34 51

CAUTION 2 59 30

All new rupture disk installations should be located to allow 3 93 56

full unrestricted discharge when overpressure of a 4 62 74

pressurized system occurs, causing a disk to burst. Never 6 111 74

locate a rupture disk assembly where the discharge from a 8 146 113

ruptured disk is directly impacting people or equipment. 10 139 119

12 174 168

IMPORTANT 14 283 191

A FLCO rupture disk is a precision piece of equipment. 16 283 283

Please handle it with extreme care! Avoid scratching, 18 415 307

bending, denting or otherwise damaging the flat rupture 20 415 384

disk. Do not allow sharp or pointed objects to pierce the 24 583 583

Teflon seals of this assembly. 30 “Series A” 600 700

RUPTURE DISK REMOVAL

1. Verify that system has been depressurized and is safe to Torque values are based on nuts and studs being lightly

open to ambient conditions. Remove companion flange lubricated and maintained in a “free running” condition.

bolting These values are based on gasket sealing loads for

2. Use extreme care when separating the companion flexatallic type gaskets.

piping flanges for removal of the ruptured disk due to the

sharp edges of this rupture disk assembly in the burst/open

condition.

P.O. Box 1327 / 1701 W. Tacoma/ Broken Arrow, OK 74012

Telephone: (918) 258-5626 Fax: (918) 251-2809

PS 11.8 Rev. A

You might also like

- FAS Installation GuideDocument2 pagesFAS Installation GuideCarlos RinconNo ratings yet

- Flat Seat Co Installation GuideDocument2 pagesFlat Seat Co Installation GuideGabrielNo ratings yet

- CPI - ProFlo PFI Flyer Rev 8-12Document2 pagesCPI - ProFlo PFI Flyer Rev 8-12Juliatte UrianNo ratings yet

- Angular Co Installation GuideDocument2 pagesAngular Co Installation GuideGabrielNo ratings yet

- Inner Annular Plate (RADIRA)Document13 pagesInner Annular Plate (RADIRA)mohamed.eldesouky9120No ratings yet

- Sistomat-Pc: 1. Installation InstructionsDocument1 pageSistomat-Pc: 1. Installation InstructionsEric LarrondoNo ratings yet

- 40.20.31.pdf New Labrynth Input SealDocument2 pages40.20.31.pdf New Labrynth Input SealMichel FloresNo ratings yet

- Manual 245 U140F 060Document6 pagesManual 245 U140F 060Nacho Arroyo100% (2)

- CFR 2011 Title49 Vol3 Sec179 200Document1 pageCFR 2011 Title49 Vol3 Sec179 200AssemNo ratings yet

- KF Series 10 Check Valves: Installation, Operation, and MaintenanceDocument3 pagesKF Series 10 Check Valves: Installation, Operation, and MaintenanceestudiemosNo ratings yet

- 632g Chockfast Orange Sterntube Strut Installation GuideDocument7 pages632g Chockfast Orange Sterntube Strut Installation GuideVictor Pablo VadaláNo ratings yet

- Fluxx Auger Pan Feeding System: Installation, Operation and Parts Replacement Guide FLUXX 330 For The Following ModelsDocument24 pagesFluxx Auger Pan Feeding System: Installation, Operation and Parts Replacement Guide FLUXX 330 For The Following ModelsSachin AmbhoreNo ratings yet

- Epson WF C5790 WF C5790A WF C5710 ET 8700 WF C5210 WF C5290 WF C5290A Service Manuals 401 450Document50 pagesEpson WF C5790 WF C5790A WF C5710 ET 8700 WF C5210 WF C5290 WF C5290A Service Manuals 401 450조장현No ratings yet

- Dodge® Sleevoil®Rtl Pillow Blocks Sizes 3-7/16" Thru 12": Pre-Assembly InstructionsDocument8 pagesDodge® Sleevoil®Rtl Pillow Blocks Sizes 3-7/16" Thru 12": Pre-Assembly Instructionsjhgjhgjhgj100% (1)

- Proprietary Information: Downloaded From Manuals Search EngineDocument8 pagesProprietary Information: Downloaded From Manuals Search EngineManimaran MaranNo ratings yet

- KF Series 31 Checkvalves: Installation, Operation, and MaintenanceDocument2 pagesKF Series 31 Checkvalves: Installation, Operation, and MaintenanceVictor LopezNo ratings yet

- Replacement: - Front Brake PadDocument2 pagesReplacement: - Front Brake PadMiguel AngelNo ratings yet

- Inspection: 1. Vehicles Not Involved in CollisionDocument2 pagesInspection: 1. Vehicles Not Involved in CollisionsalusfrankNo ratings yet

- Refiner Dd3000 Beloit JonesDocument4 pagesRefiner Dd3000 Beloit Jonesmynor8josh8juarez100% (1)

- QMX IomDocument12 pagesQMX IomSebastian VaccaNo ratings yet

- Tas 85 Manual 1Document4 pagesTas 85 Manual 1Mauricio Ariel H. OrellanaNo ratings yet

- 106 Amot 4101 Product DocumentDocument4 pages106 Amot 4101 Product DocumentRicardo NapitupuluNo ratings yet

- Manual Freno Conveyors PDFDocument8 pagesManual Freno Conveyors PDFSamael Perez LunaNo ratings yet

- Pro 151 5001Document38 pagesPro 151 5001jdpardoNo ratings yet

- 5.0 VibrationdadDocument2 pages5.0 Vibrationdaddlanoj102999No ratings yet

- VB Om2 0Document5 pagesVB Om2 0THEO CHASIOTISNo ratings yet

- RTL Sleevoil Instruction Manual 499970Document11 pagesRTL Sleevoil Instruction Manual 499970गुंजन सिन्हाNo ratings yet

- BTV 2000Document12 pagesBTV 2000Felipe Gamboa GálvezNo ratings yet

- T REX - Installation - Manual - R1 5 30 17Document1 pageT REX - Installation - Manual - R1 5 30 17eyya 007No ratings yet

- Discharge Valve AssemblyDocument1 pageDischarge Valve AssemblyWuills GutierrezNo ratings yet

- BHKA - HalliburtonDocument8 pagesBHKA - HalliburtonAmbroise RichardNo ratings yet

- Sec 2-EatonAirflexModelWCBDDocument15 pagesSec 2-EatonAirflexModelWCBDRuben CondeNo ratings yet

- Flexco Bolt Solid Plate Fastening System: The Cement Industry Standard For Strong, Long-Lasting SplicesDocument4 pagesFlexco Bolt Solid Plate Fastening System: The Cement Industry Standard For Strong, Long-Lasting SplicesBanksyNo ratings yet

- Kfseriesfballvalves KF Series P3 Ball Valves: Superior Fluid Control ProductsDocument20 pagesKfseriesfballvalves KF Series P3 Ball Valves: Superior Fluid Control Productsdiego aguilarNo ratings yet

- FLR-30-FP/FLR-90-FP Rim Seal Foam Pourer: FeaturesDocument2 pagesFLR-30-FP/FLR-90-FP Rim Seal Foam Pourer: FeaturesMarcela DuckardtNo ratings yet

- Service Bulletin #TAS-129: Commercial Steering SystemsDocument4 pagesService Bulletin #TAS-129: Commercial Steering SystemsariaNo ratings yet

- MN4027 PDFDocument4 pagesMN4027 PDFAntonio Juan AntonioNo ratings yet

- 1986-1988 SuzukiSamurai Clutch ManualDocument10 pages1986-1988 SuzukiSamurai Clutch ManualHatnean CristianNo ratings yet

- Dodge 268700 Instruction SheetDocument20 pagesDodge 268700 Instruction SheetJOSE LOPEZNo ratings yet

- Rotary Jhonson.Document2 pagesRotary Jhonson.Yonas MuluNo ratings yet

- 12165-70 - 1 Sundry Instr.Document328 pages12165-70 - 1 Sundry Instr.kodrysNo ratings yet

- Preparation and Installation of The ULTRX HP (DD) Rupture Disc / ULTRX Double Disc Holder AssemblyDocument6 pagesPreparation and Installation of The ULTRX HP (DD) Rupture Disc / ULTRX Double Disc Holder AssemblyPaul LauNo ratings yet

- Return To TOC: Dowty Propellers Standard Practices ManualDocument2 pagesReturn To TOC: Dowty Propellers Standard Practices ManualNicolás PiratovaNo ratings yet

- 2010 - TOYOTA - Land - Cruiser - Prado - 150 - 155 - SM M - BP - 0090Document4 pages2010 - TOYOTA - Land - Cruiser - Prado - 150 - 155 - SM M - BP - 0090Angy SalasNo ratings yet

- Wood Propellers: Installation, Operation, & Maintenance Integral Flange CrankshaftsDocument4 pagesWood Propellers: Installation, Operation, & Maintenance Integral Flange CrankshaftsPOUETNo ratings yet

- Room Air Conditioner: Ax SeriesDocument16 pagesRoom Air Conditioner: Ax Seriessamer battatNo ratings yet

- ASA Landing GearDocument4 pagesASA Landing Gearajrio1785No ratings yet

- Respiraderos de Techo Tipo HongoDocument4 pagesRespiraderos de Techo Tipo HongoNicolás LondoñoNo ratings yet

- Alcon BobbinsDocument2 pagesAlcon BobbinsSatvik VatsaNo ratings yet

- Toyoya Land Crusier Prado 2010 M - BP - 0010Document1 pageToyoya Land Crusier Prado 2010 M - BP - 0010Angy SalasNo ratings yet

- 4.4.7 Other Electrical Interfaces On The ZFDocument3 pages4.4.7 Other Electrical Interfaces On The ZFThylaneNo ratings yet

- 2010 - TOYOTA - Land - Cruiser - Prado - 150 - 155 - SM M - BP - 0129Document12 pages2010 - TOYOTA - Land - Cruiser - Prado - 150 - 155 - SM M - BP - 0129Angy SalasNo ratings yet

- 11 2E 后悬架Document15 pages11 2E 后悬架Alexander cesar neyra sotoNo ratings yet

- 26 11 000 Removing and Installing Complete Propeller Shaft (Inserted - Flexible Disc at Rear)Document8 pages26 11 000 Removing and Installing Complete Propeller Shaft (Inserted - Flexible Disc at Rear)Bogdan SeciuNo ratings yet

- Clipsal Ceiling Fan Installation InstructionsDocument2 pagesClipsal Ceiling Fan Installation Instructionstestnation100% (1)

- Eaton Clutch Installation Guide EMEA CLIG-0050 0416Document32 pagesEaton Clutch Installation Guide EMEA CLIG-0050 0416Daniel EscobarNo ratings yet

- CEUSD-Series "M" CECON Clutches: Completely Enclosed Continuous OperationDocument8 pagesCEUSD-Series "M" CECON Clutches: Completely Enclosed Continuous OperationRoohalla AbkhoNo ratings yet

- Ultrix IO Board Upgrade Guide (2101DR-006)Document4 pagesUltrix IO Board Upgrade Guide (2101DR-006)Habtamu TadesseNo ratings yet

- What Is Coulomb's Electricity?Document4 pagesWhat Is Coulomb's Electricity?George Mpantes mathematics teacherNo ratings yet

- AMETEK, Inc.: Technical & Industrial Products DivisionDocument11 pagesAMETEK, Inc.: Technical & Industrial Products DivisionRolando LaferteNo ratings yet

- Day 1 Huzeifa Ismail Production Chemistry and Integrity Management and Leslie Malone Senior Staff En.8005Document27 pagesDay 1 Huzeifa Ismail Production Chemistry and Integrity Management and Leslie Malone Senior Staff En.8005Kent WaiNo ratings yet

- Functions and Service Conditions - Jeepney FlooringDocument2 pagesFunctions and Service Conditions - Jeepney FlooringRos Vincent AlvarezNo ratings yet

- P0090 Maruti Swift Dzire - Fuel Pressure Regulator Control Circuit (1) (1) - 1Document3 pagesP0090 Maruti Swift Dzire - Fuel Pressure Regulator Control Circuit (1) (1) - 1vivekpateljNo ratings yet

- Differential Selection Guide: IDP10 IDP25 IDP50 IDP15D (Draft Range) IDP31D (Fast Response Transmitter) IDP32DDocument3 pagesDifferential Selection Guide: IDP10 IDP25 IDP50 IDP15D (Draft Range) IDP31D (Fast Response Transmitter) IDP32Dsalmo83:18No ratings yet

- Astm G 185 2006Document8 pagesAstm G 185 2006JORGE ARTURO TORIBIO HUERTANo ratings yet

- 5 - Bit Hydraulic OptimizationDocument31 pages5 - Bit Hydraulic OptimizationFarouq EngNo ratings yet

- ANSYS Advantage Multiphysics AA V8 I2Document60 pagesANSYS Advantage Multiphysics AA V8 I2j_c_garcia_dNo ratings yet

- Voltage RegulationDocument90 pagesVoltage RegulationelhaffarNo ratings yet

- Ficha Tecnica Cable de FibraDocument1 pageFicha Tecnica Cable de FibraAnonymous 4kYNmixNo ratings yet

- API 1509 Technical Bulletin 1 17th Edition September 2012 Addendum 1 October 2014Document5 pagesAPI 1509 Technical Bulletin 1 17th Edition September 2012 Addendum 1 October 2014engrsurifNo ratings yet

- Photoelectric EffectDocument7 pagesPhotoelectric EffectSuleiman MkuluNo ratings yet

- Control & Instrumentation AT NTPC Singrauli (A Vocational Training Report)Document45 pagesControl & Instrumentation AT NTPC Singrauli (A Vocational Training Report)Manish Kumar SinghNo ratings yet

- Operational Qualification GL ReactorDocument3 pagesOperational Qualification GL Reactorjokish100% (2)

- VedicReport11 21 20139 07 41PMDocument32 pagesVedicReport11 21 20139 07 41PMsajtaurusNo ratings yet

- Nfpa Codes & StandardsDocument9 pagesNfpa Codes & StandardsPradip SharmaNo ratings yet

- Eca Lab ManualDocument158 pagesEca Lab ManualRamarao Gude50% (2)

- Hydraulic Pneumatic Oxygen Some Aspect of The SytemsDocument10 pagesHydraulic Pneumatic Oxygen Some Aspect of The SytemsGauri ShindeNo ratings yet

- The Bodyof Lightand Magick LampDocument32 pagesThe Bodyof Lightand Magick LampAlexGLeon67% (3)

- MMS - KTU - Module 1Document111 pagesMMS - KTU - Module 1philchris007No ratings yet

- EVA - HF 525: Technical DescriptionDocument10 pagesEVA - HF 525: Technical DescriptionFouad Inr100% (1)

- Lillgrund Offshore Wind Farm OptimizationDocument11 pagesLillgrund Offshore Wind Farm OptimizationyousreoNo ratings yet

- Measuring, Sampling, and Testing Crude Oil: ARCO Oil & C&S CO.Document8 pagesMeasuring, Sampling, and Testing Crude Oil: ARCO Oil & C&S CO.Jonathan SemperteguiNo ratings yet

- Datasheet PSV PDPDEDocument8 pagesDatasheet PSV PDPDERicardo NapitupuluNo ratings yet

- Procedure For Bunkering Operation On ShipsDocument12 pagesProcedure For Bunkering Operation On Shipsstamatis100% (2)

- Gen Items Price List 13 TH July 2021Document132 pagesGen Items Price List 13 TH July 2021Muhammad Ahmad HayatNo ratings yet

- Wireline Logging ReportDocument2 pagesWireline Logging Reportramadhan13maretNo ratings yet

- List of Clearances, Approvals Required For Power Projects in IndiaDocument3 pagesList of Clearances, Approvals Required For Power Projects in Indiapandetarun100% (1)