Professional Documents

Culture Documents

Autonomous Inspections in Mining

Autonomous Inspections in Mining

Uploaded by

Rogério AdrianoCopyright:

Available Formats

You might also like

- Organizational Change in Vale - EditedDocument13 pagesOrganizational Change in Vale - EditedBaisakhi ChatterjeeNo ratings yet

- IbmDocument6 pagesIbmhoangminh87No ratings yet

- Balance Scorecard For Finance DepttDocument10 pagesBalance Scorecard For Finance DepttVeenu SharmaNo ratings yet

- PWC Mine 2020 PDFDocument32 pagesPWC Mine 2020 PDFjspada84No ratings yet

- 1220 Jordan Workman Milliken 1220 1255 Foodsure America Psbym 2018Document34 pages1220 Jordan Workman Milliken 1220 1255 Foodsure America Psbym 2018Rahul SinghNo ratings yet

- Investor Strategy Day - Projects and Studies PDFDocument89 pagesInvestor Strategy Day - Projects and Studies PDFJordan PetreskiNo ratings yet

- Digitizing Underground MiningDocument5 pagesDigitizing Underground MiningRizky PratamaNo ratings yet

- IEE Value Chain With Predictive ScorecardsDocument7 pagesIEE Value Chain With Predictive ScorecardspasticcioNo ratings yet

- ERP Centric Data MiningDocument42 pagesERP Centric Data MiningsonnyvaNo ratings yet

- Bloomberg Barclays Methodology1Document126 pagesBloomberg Barclays Methodology1Edwin ChanNo ratings yet

- Ey Global Becoming An Analytics Driven OrganizationDocument28 pagesEy Global Becoming An Analytics Driven OrganizationJessica RiveraNo ratings yet

- Communication Systems in Underground MinesDocument4 pagesCommunication Systems in Underground MinesFredrickNo ratings yet

- The Executive Strategy Manager™ (ESM)Document9 pagesThe Executive Strategy Manager™ (ESM)Sapri PamuluNo ratings yet

- Industry Overview Metal&Mining 201505 - v4bDocument38 pagesIndustry Overview Metal&Mining 201505 - v4bsowjanyaNo ratings yet

- Business Case TemplateDocument9 pagesBusiness Case TemplateVenkatesh NenavathNo ratings yet

- Responsible Supply ChainsDocument11 pagesResponsible Supply ChainsADBI EventsNo ratings yet

- QPR For Balanced ScorecardDocument2 pagesQPR For Balanced ScorecardSUDARMADINo ratings yet

- IconsDocument8 pagesIconsKhalilGhenimiNo ratings yet

- How The Mining Industry Benefits From ERP SystemsDocument6 pagesHow The Mining Industry Benefits From ERP SystemsJamil Gesulga Matanog100% (1)

- Maturity Model Grade ControlDocument12 pagesMaturity Model Grade ControlvanpatoNo ratings yet

- A Formula For Calculating The ROI of BPMDocument5 pagesA Formula For Calculating The ROI of BPMSteven BonacorsiNo ratings yet

- Practical Implementation of Iot Using ArduinoDocument29 pagesPractical Implementation of Iot Using ArduinoJoydeep ChakrabortyNo ratings yet

- Capability Maturity FrameworkDocument12 pagesCapability Maturity FrameworkClaudio VélizNo ratings yet

- BCG Why Cement Producers Need To Embrace Industry 4.0 Dec 2018 - tcm9 208964Document7 pagesBCG Why Cement Producers Need To Embrace Industry 4.0 Dec 2018 - tcm9 208964ISA SOINDNo ratings yet

- Enterprise Networking Product IconsDocument15 pagesEnterprise Networking Product Iconsjoks1mNo ratings yet

- Winning Cloud Strategies GBE03890USENDocument24 pagesWinning Cloud Strategies GBE03890USENJeff ChauNo ratings yet

- Metals Sector - Value ChainDocument11 pagesMetals Sector - Value ChainAmitOtwaniNo ratings yet

- Business Case SCMDocument20 pagesBusiness Case SCMsreeks456100% (1)

- February 2019 Cop Webinar Building Maturity Using The Change Management Maturity Audit To Build A Plan 190205035446Document31 pagesFebruary 2019 Cop Webinar Building Maturity Using The Change Management Maturity Audit To Build A Plan 190205035446Spil_vv_IJmuidenNo ratings yet

- ERBD Extractive Mining Industry Strategy-European BankDocument46 pagesERBD Extractive Mining Industry Strategy-European BankAylin PolatNo ratings yet

- Customer Retantion in Mall MritunjayDocument48 pagesCustomer Retantion in Mall MritunjaymritunjaysharmaNo ratings yet

- Mining Exploration & Geochemical Analysis of Mining Samples With A Thermo Scientific Niton XL3t GOLDD XRF AnalyzerDocument4 pagesMining Exploration & Geochemical Analysis of Mining Samples With A Thermo Scientific Niton XL3t GOLDD XRF Analyzerahmed_alfurqanuNo ratings yet

- Green Project Business Case ExampleDocument2 pagesGreen Project Business Case ExampleJulianto TandionoNo ratings yet

- 9622 3 ERP Architecture IntroDocument42 pages9622 3 ERP Architecture IntroGitanjali SinghNo ratings yet

- Performance Measurement, Attribution Analysis and GIPS Modelling CourseDocument6 pagesPerformance Measurement, Attribution Analysis and GIPS Modelling CourseHamedbNo ratings yet

- Working Capital Cycle and Ratio Analysis of NalcoDocument74 pagesWorking Capital Cycle and Ratio Analysis of NalcoNabinSundar NayakNo ratings yet

- Permenpan Nomor 54 Tahun 2018Document20 pagesPermenpan Nomor 54 Tahun 2018amirhamzahmsNo ratings yet

- Agile DevelopmentDocument27 pagesAgile DevelopmentNikhil SatavNo ratings yet

- Managing The Total Cost of Ownership of Business Intelligence (US)Document15 pagesManaging The Total Cost of Ownership of Business Intelligence (US)ranciidNo ratings yet

- UltraTech ESGDocument7 pagesUltraTech ESGHarsh ShahNo ratings yet

- Management Accountant Nov 2019Document124 pagesManagement Accountant Nov 2019ABC 123No ratings yet

- Organization DesignDocument10 pagesOrganization Designjlt2014No ratings yet

- Dealer Effectiveness: Breaking The Growth Ceiling For Automotive DealershipsDocument4 pagesDealer Effectiveness: Breaking The Growth Ceiling For Automotive DealershipsSouradeep SanyalNo ratings yet

- 2020-11-02 ESG Discussion PaperDocument154 pages2020-11-02 ESG Discussion PaperAdriana CarpiNo ratings yet

- Introduction To ERPDocument20 pagesIntroduction To ERPLalrinchhana KhiangteNo ratings yet

- Resources Policy: José A. Botín, Marcelo A. VergaraDocument7 pagesResources Policy: José A. Botín, Marcelo A. VergaraFelipe Zeballos GuiñezNo ratings yet

- Information Technology Director Head IT in Dubai United Arab Emirates Resume Nabil KawwaDocument5 pagesInformation Technology Director Head IT in Dubai United Arab Emirates Resume Nabil KawwaNabilKawwaNo ratings yet

- Chapter 1 Competing With OperationsDocument37 pagesChapter 1 Competing With OperationsTina WongNo ratings yet

- ERP Benefits and RiskDocument13 pagesERP Benefits and Riskchitu1992No ratings yet

- Case Study - Global Construction CompanyDocument2 pagesCase Study - Global Construction Companymsfayas0% (1)

- Brochure UC Berkeley DigitalTransformation 7 Jan 18 V25Document14 pagesBrochure UC Berkeley DigitalTransformation 7 Jan 18 V25WalterNo ratings yet

- Predictive Modelling Foropave - NZ RR PDFDocument87 pagesPredictive Modelling Foropave - NZ RR PDFGaneshNo ratings yet

- Senior Project Engineer Rio TintoDocument3 pagesSenior Project Engineer Rio TintoluceroNo ratings yet

- PMP s14 2020 v65 Agile Practice GuideDocument13 pagesPMP s14 2020 v65 Agile Practice GuideofficeNo ratings yet

- An Agile Performance ManagementDocument2 pagesAn Agile Performance ManagementadarshrNo ratings yet

- From Business Strategy To IT ActionDocument3 pagesFrom Business Strategy To IT ActionFirdausNo ratings yet

- Bureau Veritas CAD Fee Schedule 2022Document53 pagesBureau Veritas CAD Fee Schedule 2022celikdemirmehmetNo ratings yet

- Slope Stability Prism Monitoring: A Guide For Practising Mine SurveyorsDocument136 pagesSlope Stability Prism Monitoring: A Guide For Practising Mine SurveyorsGeorgeNo ratings yet

- Intelligent Inspection Robot Solution: Industry ApplicationDocument1 pageIntelligent Inspection Robot Solution: Industry ApplicationJoséNo ratings yet

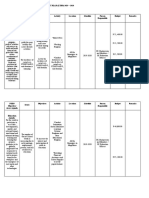

- R4A Permit To Operate RequirementsDocument2 pagesR4A Permit To Operate RequirementsMykka ArtillagaNo ratings yet

- Tool 5 Gender Analysis Tools For Safe Water, Sanitation, and HygieneDocument52 pagesTool 5 Gender Analysis Tools For Safe Water, Sanitation, and HygieneGirly MeudeNo ratings yet

- First Evidence of LifeDocument3 pagesFirst Evidence of Lifemercelisa d. duldolNo ratings yet

- Statement of Purpose: Nur Aziz Octoviawan For The Mcdonnell International Scholars AcademyDocument1 pageStatement of Purpose: Nur Aziz Octoviawan For The Mcdonnell International Scholars AcademyNur Aziz OctoviawanNo ratings yet

- Lesson - 12 If All The Seas Were One SeaDocument9 pagesLesson - 12 If All The Seas Were One Sea12D04- AJIT 1605No ratings yet

- James Edrian A. Rubio Bsce - 1A Engr. Maria May Q. PaceteDocument7 pagesJames Edrian A. Rubio Bsce - 1A Engr. Maria May Q. PaceteJamED ALRubioNo ratings yet

- MEPC 1 Circ 736 Rev 2Document12 pagesMEPC 1 Circ 736 Rev 2Markus SitanggangNo ratings yet

- Chị gửi em full bài để em tham khảo nhé Bài 1Document2 pagesChị gửi em full bài để em tham khảo nhé Bài 1Nhật LệNo ratings yet

- Local Youth Development Plan (Lydp) 2019 - 2020: Health AgendaDocument8 pagesLocal Youth Development Plan (Lydp) 2019 - 2020: Health AgendaMaria Karina FerrerasNo ratings yet

- Msds Bopp Packing TapeDocument3 pagesMsds Bopp Packing TapeTran Tuan anhNo ratings yet

- Product Safety-Data-Sheets Ah-Sds Diazinon Formulation AH JP 6NDocument21 pagesProduct Safety-Data-Sheets Ah-Sds Diazinon Formulation AH JP 6NAndi SupriyonoNo ratings yet

- Marketing Environment Simulation and Summary Week 1Document7 pagesMarketing Environment Simulation and Summary Week 1Serena100% (1)

- GRI G4 Event Organizers Sector DisclosuresDocument94 pagesGRI G4 Event Organizers Sector DisclosuresMaximillian AgustarNo ratings yet

- We Effect Reducing Poverty Through AgricultureDocument32 pagesWe Effect Reducing Poverty Through Agriculturekamba bryanNo ratings yet

- Africa Regional Assessment Report On DRRDocument115 pagesAfrica Regional Assessment Report On DRRMoses ObboNo ratings yet

- SFRFRC: Ination# 501Document3 pagesSFRFRC: Ination# 501LinaceroNo ratings yet

- Places - Threats To NatureDocument6 pagesPlaces - Threats To NatureJEEHAN DELA CRUZNo ratings yet

- Material Safety Data Sheet: 1 Identification of SubstanceDocument5 pagesMaterial Safety Data Sheet: 1 Identification of Substancemaha muhammedNo ratings yet

- Using Bambusa Vulgaris As Replacement For Expandable Straw1Document9 pagesUsing Bambusa Vulgaris As Replacement For Expandable Straw1Bverde MenorNo ratings yet

- Exam QuestionsDocument7 pagesExam QuestionsElites ChoraleNo ratings yet

- Stormwater Drainage SpecificationDocument1 pageStormwater Drainage SpecificationSeeni GovindNo ratings yet

- Determining Drivers of Dragonfly Diversity Patterns and The Implications For Conservation in South AfricaDocument4 pagesDetermining Drivers of Dragonfly Diversity Patterns and The Implications For Conservation in South AfricaArt Julius D. HallazgoNo ratings yet

- Presentation by Harshal Sethiya N Mitul UpadhyayDocument26 pagesPresentation by Harshal Sethiya N Mitul Upadhyaysanket jain100% (1)

- Chapter Vi Global CityDocument20 pagesChapter Vi Global CityEva faith RemalanteNo ratings yet

- Safety Data Sheet: ACM Cyberthrin 5.5Document7 pagesSafety Data Sheet: ACM Cyberthrin 5.5aleem_80No ratings yet

- Permit Issued in Dec 2015: Job Number Permit Type Property AddressDocument180 pagesPermit Issued in Dec 2015: Job Number Permit Type Property AddressBrian PetranoNo ratings yet

- TDS 2020 08 25 Bangladesh MAI 5 - 09 cd8b5c 25082020213207 Uxz PDFDocument1 pageTDS 2020 08 25 Bangladesh MAI 5 - 09 cd8b5c 25082020213207 Uxz PDFdjhfvbsadjhjkcfbsd jdbdhNo ratings yet

- Assignment 3Document2 pagesAssignment 3779052308No ratings yet

- Monthly Dashboard - Exemplar File To Copy FromDocument37 pagesMonthly Dashboard - Exemplar File To Copy Fromإسلام عليNo ratings yet

- Seribumi Development Sdn. BHD.: Work Schedule NO Task Name Duration Start Finish PreliminariesDocument3 pagesSeribumi Development Sdn. BHD.: Work Schedule NO Task Name Duration Start Finish PreliminariesshafiqNo ratings yet

Autonomous Inspections in Mining

Autonomous Inspections in Mining

Uploaded by

Rogério AdrianoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Autonomous Inspections in Mining

Autonomous Inspections in Mining

Uploaded by

Rogério AdrianoCopyright:

Available Formats

Autonomous inspections in mining

Top 10 use cases on driving productivity and increasing safety

Contents

1 Introduction 3

1.1 Challenges inspecting mines 3

1.2 Autonomous mine inspection 4

What is an autonomous inspection and monitoring solution?

2 Top 10 use cases 6

2.1 Stockpile measurements 6

2.2 Tailings dam inspection 7

2.3 Shutdowns and project management 7

2.4 Environmental monitoring 7

2.5 Coal temperature monitoring 8

2.6 Emergency response and security 8

2.7 Haul road inspection 8

2.8 Pre and post blast analysis 9

2.9 Stock yard and port monitoring 9

2.10 Fixed and mobile plant inspection & monitoring 9

3 Benefits of automating mining inspections 10

Autonomous inspections redefine safety and efficiency standards in mining 2

Challenges inspecting mines

Safety Productivity Availability

A mining facility is one of the most When mining assets aren’t inspected Typically, mines are located in challenging

dangerous facilities, with the International frequently, it often results in failures and environments, with extreme temperatures

Council on Mining and Metals (ICMM) unplanned shutdowns. Furthermore, and weather conditions. Getting someone

reporting ~7,000 injuries in 2020 alone. sending an employee out in the field for out in the field can be quite difficult

For most managers, sending an employee inspections requires them to abandon especially because mines are often in

out to monitor or inspect a facility requires their main jobs, reducing employee remote locations.

special permits, and even so is undesirable. productivity.

The result is - inspections at mines are often done when necessary, and very rarely on a scheduled, preemptive basis.

So facilities are responding to failures, and the desire to inspect facilities regularly holds the promise of preventing failures

and therefore downtime.

Autonomous inspections redefine safety and efficiency standards in mining 3

Autonomous mine inspections

One of the biggest advantages of autonomous mine inspections is that employees aren’t required to be on site to inspect and

monitor the mine. That means first and foremost that employees can perform their jobs safer and more efficiently.

It also means that site managers can monitor any of their facilities from one remote operations center. So, what does an autonomous

inspection look like at a mine? An employee, say an environmental compliance coordinator, wants to closely monitor the tailings

dams at the mine. They would select specific tailings dams they want to monitor, set an inspection schedule, parameters they want to

monitor and that’s it. They would then receive weekly or even daily reports detailing tailings dams volumes, dam height and more.

That means:

Minimized risk Increased inspection High quality Data

frequency inspections democratization

Employees don’t have to Inspections are performed AI powered inspections Employees across the

go out to perform risky more frequently, reducing significantly enhance the company can request data

inspections the risk of failures going quality of inspections, and review the insights

unnoticed detecting the slightest gathered from anywhere in

faults and failures the world

Autonomous inspections redefine safety and efficiency standards in mining 4

What is an autonomous

inspection and monitoring

solution

An autonomous inspection and monitoring system

consists of 2 parts:

• Autonomous robots: fully autonomous drones or

robots capture and collect visual data, automatically

navigating around a facility. Autonomous robots are

available 24/7 and withstand extreme weather or

dust and can be operated remotely.

• Visual data management software: data captured

by autonomous robots is uploaded to the cloud

where it is organized and analyzed. Users can

request insights, and automatically receive detailed

reports when the insights are ready.

Autonomous inspections redefine safety and efficiency standards in mining 5

TOP 10 USE CASES

Autonomous inspections at a typical mine

Stockpile measurements

USE CASE 01

Autonomous drones can scan stockpiles on a weekly or evenly daily basis.

When you need to monitor materials for transport, planning or productivity -

having frequent, accurate volumetric measurements is invaluable. Whether

you're mining for iron ore or precious metals, drones can be dispatched

to scan piles of dirt or other materials to ensure the heights, slopes and

clearances are up to regulatory standards.

Autonomous stockpile measurements enable:

• Optimized financial planning and reporting

• Enhanced productivity and up-to-date productivity benchmarks

• Accurate materials transport

• Streamlined regulatory compliance

Autonomous inspections redefine safety and efficiency standards in mining 6

USE CASE 02 USE CASE 03 USE CASE 04

Tailings dam inspection Shutdowns and project Environmental monitoring

Monitoring tailings dams is extremely management Environmental hazards arise at almost

important, yet also really risky for An autonomous inspection and every stage of the open-pit mining

employees. monitoring solution provides 24/7 process.

Autonomous robots can perform those situational awareness and significantly That’s why it’s so critical to have an

inspections more frequently, efficiently slims down project timelines. autonomous robot perform inspections.

and also much safer. Robots can report With autonomous inspections, you cut out Not only can they monitor tailings dams,

on tailings dam wall integrity, amount of the majority of manual project planning leaks and wastewater, but they also allow

solids in the dam, water levels in regards - as drones and robots identify assets site employees to safely perform site

to the dam, deposition patterns and more needing maintenance. During projects, an inspections, without being exposed to

- ensuring you know exactly what’s going autonomous monitoring solution provides radioactive or toxic elements.

on and can prevent serious failures. frequent daily productivity reports,

ensuring you stay on top of your teams

and projects.

Autonomous inspections redefine safety and efficiency standards in mining 7

USE CASE 05 USE CASE 06 USE CASE 07

Coal temperature monitoring Emergency response and Haul road inspection

Autonomous drones and robots security Autonomous inspections detect

equipped with thermal cameras safely Autonomous robots count people during displacements that can lead to haul road

monitor coal temperatures evacuations, ensure areas are clear of structure collapse.

And they're the available 24/7 to safely personnel during emergencies. Autonomous drones and robots ensure

inspect and report back to employees. They also constantly check for hazards roads are free from debris, rocks, spillage,

Autonomous coal temperature monitoring such as rock slides - making them your puddles and potholes. They also aid

prevents explosions and ensures employee team's newest first responder. Those in haul road planning, construction

safety, by monitoring heat and alerting same robots perform automated security and improvement. That includes slope

employees in the event of a hazard. patrols - boosting deterrence and allowing monitoring, critical to ensure compliance

security personnel to remain safely indoors and minimize risk.

while the drone scans for intruders.

Autonomous inspections redefine safety and efficiency standards in mining 8

USE CASE 08 USE CASE 09 USE CASE 10

Pre and post blast analysis Stock yard and port monitoring Fixed and mobile plant

Accurately analyzing and improving Autonomous inspection and monitoring inspection & monitoring

the blast process is critical to improve solutions fully monitor stackers, Autonomous inspections detect changes

productivity at open-pit mines. stockpiles, reclaimers, and conveyor belts. and slight faults for all plant assets and

Drones provide a unique, safe method Robots and drones provide complete equipment.

to monitor and analyze blasts, providing monitoring of material stacking and Drones and robots can be dispatched to

elevation models pre and post blast and transporting. Ensuring all materials are monitor conveyor belts, detect corrosion,

particle size measurements - empowering accounted for, autonomous drones identify overheating, assess pipelines and

teams to improve drilling and blasting. capture aerial imagery of all port monitor autonomous truck fleets. When

operations, and deliver reports with inspected on a daily basis with AI-powered

volumetric measurements to relevant change detection, plants can be properly

stakeholders. maintained, preventing costly downtime.

Autonomous inspections redefine safety and efficiency standards in mining 9

Benefits of autonomous

mining inspections

The benefits of automating inspections and

monitoring with autonomous robots are far and

wide. Companies benefit from the automation of

a large variety of tasks across the site lifecycle.

We’ve put together the top 8 benefits of

automating site inspection and monitoring at

mining facilities.

Autonomous inspections redefine safety and efficiency standards in mining 10

01 Increase safety

Autonomous robots perform risky inspections

and detect failures early on, preventing potential

03 Maximize efficiency

Ensure efficiency across mining operations -

from better blast planning to efficient materials

accidents. transport.

Boost productivity Minimize downtime

02 By automating inspections, employees boost

productivity and streamline operations and

04 With high frequency and high quality

inspections, failures are detected early on,

maintenance workflows. preventing downtime.

Autonomous inspections redefine safety and efficiency standards in mining 11

05 Reduce environmental footprint

With high frequency inspections, no

environmental breach goes unnoticed.

07 Ensure business continuity

Maintaining assets with regular inspections

and maintenance during disasters enables your

facility to stay up and running in top shape.

Enhance emergency response

Bolster security

06 08

Provide your teams with the intel they need to

respond safely to hazards and security breaches. Automated security patrols not only boost

deterrence, but also allow for security personnel

to remain safely indoors while the drone scans

for intruders.

Autonomous inspections redefine safety and efficiency standards in mining 12

About Percepto

Percepto is at the forefront of redefining how Founded in 2014

industrial sites are inspected and monitored.

Offices in Israel, US, Australia

We do this by harnessing remote robotics to

autonomously collect, aggregate, and analyze visual Operating in 6 continents

data. Our flagship robot, the Sparrow, is the most

deployed drone-in-a-box on the market. Deployed in multiple Fortune 500 organizations

info@percepto.co I www.percepto.co

Autonomous inspections redefine safety and efficiency standards in mining 13

You might also like

- Organizational Change in Vale - EditedDocument13 pagesOrganizational Change in Vale - EditedBaisakhi ChatterjeeNo ratings yet

- IbmDocument6 pagesIbmhoangminh87No ratings yet

- Balance Scorecard For Finance DepttDocument10 pagesBalance Scorecard For Finance DepttVeenu SharmaNo ratings yet

- PWC Mine 2020 PDFDocument32 pagesPWC Mine 2020 PDFjspada84No ratings yet

- 1220 Jordan Workman Milliken 1220 1255 Foodsure America Psbym 2018Document34 pages1220 Jordan Workman Milliken 1220 1255 Foodsure America Psbym 2018Rahul SinghNo ratings yet

- Investor Strategy Day - Projects and Studies PDFDocument89 pagesInvestor Strategy Day - Projects and Studies PDFJordan PetreskiNo ratings yet

- Digitizing Underground MiningDocument5 pagesDigitizing Underground MiningRizky PratamaNo ratings yet

- IEE Value Chain With Predictive ScorecardsDocument7 pagesIEE Value Chain With Predictive ScorecardspasticcioNo ratings yet

- ERP Centric Data MiningDocument42 pagesERP Centric Data MiningsonnyvaNo ratings yet

- Bloomberg Barclays Methodology1Document126 pagesBloomberg Barclays Methodology1Edwin ChanNo ratings yet

- Ey Global Becoming An Analytics Driven OrganizationDocument28 pagesEy Global Becoming An Analytics Driven OrganizationJessica RiveraNo ratings yet

- Communication Systems in Underground MinesDocument4 pagesCommunication Systems in Underground MinesFredrickNo ratings yet

- The Executive Strategy Manager™ (ESM)Document9 pagesThe Executive Strategy Manager™ (ESM)Sapri PamuluNo ratings yet

- Industry Overview Metal&Mining 201505 - v4bDocument38 pagesIndustry Overview Metal&Mining 201505 - v4bsowjanyaNo ratings yet

- Business Case TemplateDocument9 pagesBusiness Case TemplateVenkatesh NenavathNo ratings yet

- Responsible Supply ChainsDocument11 pagesResponsible Supply ChainsADBI EventsNo ratings yet

- QPR For Balanced ScorecardDocument2 pagesQPR For Balanced ScorecardSUDARMADINo ratings yet

- IconsDocument8 pagesIconsKhalilGhenimiNo ratings yet

- How The Mining Industry Benefits From ERP SystemsDocument6 pagesHow The Mining Industry Benefits From ERP SystemsJamil Gesulga Matanog100% (1)

- Maturity Model Grade ControlDocument12 pagesMaturity Model Grade ControlvanpatoNo ratings yet

- A Formula For Calculating The ROI of BPMDocument5 pagesA Formula For Calculating The ROI of BPMSteven BonacorsiNo ratings yet

- Practical Implementation of Iot Using ArduinoDocument29 pagesPractical Implementation of Iot Using ArduinoJoydeep ChakrabortyNo ratings yet

- Capability Maturity FrameworkDocument12 pagesCapability Maturity FrameworkClaudio VélizNo ratings yet

- BCG Why Cement Producers Need To Embrace Industry 4.0 Dec 2018 - tcm9 208964Document7 pagesBCG Why Cement Producers Need To Embrace Industry 4.0 Dec 2018 - tcm9 208964ISA SOINDNo ratings yet

- Enterprise Networking Product IconsDocument15 pagesEnterprise Networking Product Iconsjoks1mNo ratings yet

- Winning Cloud Strategies GBE03890USENDocument24 pagesWinning Cloud Strategies GBE03890USENJeff ChauNo ratings yet

- Metals Sector - Value ChainDocument11 pagesMetals Sector - Value ChainAmitOtwaniNo ratings yet

- Business Case SCMDocument20 pagesBusiness Case SCMsreeks456100% (1)

- February 2019 Cop Webinar Building Maturity Using The Change Management Maturity Audit To Build A Plan 190205035446Document31 pagesFebruary 2019 Cop Webinar Building Maturity Using The Change Management Maturity Audit To Build A Plan 190205035446Spil_vv_IJmuidenNo ratings yet

- ERBD Extractive Mining Industry Strategy-European BankDocument46 pagesERBD Extractive Mining Industry Strategy-European BankAylin PolatNo ratings yet

- Customer Retantion in Mall MritunjayDocument48 pagesCustomer Retantion in Mall MritunjaymritunjaysharmaNo ratings yet

- Mining Exploration & Geochemical Analysis of Mining Samples With A Thermo Scientific Niton XL3t GOLDD XRF AnalyzerDocument4 pagesMining Exploration & Geochemical Analysis of Mining Samples With A Thermo Scientific Niton XL3t GOLDD XRF Analyzerahmed_alfurqanuNo ratings yet

- Green Project Business Case ExampleDocument2 pagesGreen Project Business Case ExampleJulianto TandionoNo ratings yet

- 9622 3 ERP Architecture IntroDocument42 pages9622 3 ERP Architecture IntroGitanjali SinghNo ratings yet

- Performance Measurement, Attribution Analysis and GIPS Modelling CourseDocument6 pagesPerformance Measurement, Attribution Analysis and GIPS Modelling CourseHamedbNo ratings yet

- Working Capital Cycle and Ratio Analysis of NalcoDocument74 pagesWorking Capital Cycle and Ratio Analysis of NalcoNabinSundar NayakNo ratings yet

- Permenpan Nomor 54 Tahun 2018Document20 pagesPermenpan Nomor 54 Tahun 2018amirhamzahmsNo ratings yet

- Agile DevelopmentDocument27 pagesAgile DevelopmentNikhil SatavNo ratings yet

- Managing The Total Cost of Ownership of Business Intelligence (US)Document15 pagesManaging The Total Cost of Ownership of Business Intelligence (US)ranciidNo ratings yet

- UltraTech ESGDocument7 pagesUltraTech ESGHarsh ShahNo ratings yet

- Management Accountant Nov 2019Document124 pagesManagement Accountant Nov 2019ABC 123No ratings yet

- Organization DesignDocument10 pagesOrganization Designjlt2014No ratings yet

- Dealer Effectiveness: Breaking The Growth Ceiling For Automotive DealershipsDocument4 pagesDealer Effectiveness: Breaking The Growth Ceiling For Automotive DealershipsSouradeep SanyalNo ratings yet

- 2020-11-02 ESG Discussion PaperDocument154 pages2020-11-02 ESG Discussion PaperAdriana CarpiNo ratings yet

- Introduction To ERPDocument20 pagesIntroduction To ERPLalrinchhana KhiangteNo ratings yet

- Resources Policy: José A. Botín, Marcelo A. VergaraDocument7 pagesResources Policy: José A. Botín, Marcelo A. VergaraFelipe Zeballos GuiñezNo ratings yet

- Information Technology Director Head IT in Dubai United Arab Emirates Resume Nabil KawwaDocument5 pagesInformation Technology Director Head IT in Dubai United Arab Emirates Resume Nabil KawwaNabilKawwaNo ratings yet

- Chapter 1 Competing With OperationsDocument37 pagesChapter 1 Competing With OperationsTina WongNo ratings yet

- ERP Benefits and RiskDocument13 pagesERP Benefits and Riskchitu1992No ratings yet

- Case Study - Global Construction CompanyDocument2 pagesCase Study - Global Construction Companymsfayas0% (1)

- Brochure UC Berkeley DigitalTransformation 7 Jan 18 V25Document14 pagesBrochure UC Berkeley DigitalTransformation 7 Jan 18 V25WalterNo ratings yet

- Predictive Modelling Foropave - NZ RR PDFDocument87 pagesPredictive Modelling Foropave - NZ RR PDFGaneshNo ratings yet

- Senior Project Engineer Rio TintoDocument3 pagesSenior Project Engineer Rio TintoluceroNo ratings yet

- PMP s14 2020 v65 Agile Practice GuideDocument13 pagesPMP s14 2020 v65 Agile Practice GuideofficeNo ratings yet

- An Agile Performance ManagementDocument2 pagesAn Agile Performance ManagementadarshrNo ratings yet

- From Business Strategy To IT ActionDocument3 pagesFrom Business Strategy To IT ActionFirdausNo ratings yet

- Bureau Veritas CAD Fee Schedule 2022Document53 pagesBureau Veritas CAD Fee Schedule 2022celikdemirmehmetNo ratings yet

- Slope Stability Prism Monitoring: A Guide For Practising Mine SurveyorsDocument136 pagesSlope Stability Prism Monitoring: A Guide For Practising Mine SurveyorsGeorgeNo ratings yet

- Intelligent Inspection Robot Solution: Industry ApplicationDocument1 pageIntelligent Inspection Robot Solution: Industry ApplicationJoséNo ratings yet

- R4A Permit To Operate RequirementsDocument2 pagesR4A Permit To Operate RequirementsMykka ArtillagaNo ratings yet

- Tool 5 Gender Analysis Tools For Safe Water, Sanitation, and HygieneDocument52 pagesTool 5 Gender Analysis Tools For Safe Water, Sanitation, and HygieneGirly MeudeNo ratings yet

- First Evidence of LifeDocument3 pagesFirst Evidence of Lifemercelisa d. duldolNo ratings yet

- Statement of Purpose: Nur Aziz Octoviawan For The Mcdonnell International Scholars AcademyDocument1 pageStatement of Purpose: Nur Aziz Octoviawan For The Mcdonnell International Scholars AcademyNur Aziz OctoviawanNo ratings yet

- Lesson - 12 If All The Seas Were One SeaDocument9 pagesLesson - 12 If All The Seas Were One Sea12D04- AJIT 1605No ratings yet

- James Edrian A. Rubio Bsce - 1A Engr. Maria May Q. PaceteDocument7 pagesJames Edrian A. Rubio Bsce - 1A Engr. Maria May Q. PaceteJamED ALRubioNo ratings yet

- MEPC 1 Circ 736 Rev 2Document12 pagesMEPC 1 Circ 736 Rev 2Markus SitanggangNo ratings yet

- Chị gửi em full bài để em tham khảo nhé Bài 1Document2 pagesChị gửi em full bài để em tham khảo nhé Bài 1Nhật LệNo ratings yet

- Local Youth Development Plan (Lydp) 2019 - 2020: Health AgendaDocument8 pagesLocal Youth Development Plan (Lydp) 2019 - 2020: Health AgendaMaria Karina FerrerasNo ratings yet

- Msds Bopp Packing TapeDocument3 pagesMsds Bopp Packing TapeTran Tuan anhNo ratings yet

- Product Safety-Data-Sheets Ah-Sds Diazinon Formulation AH JP 6NDocument21 pagesProduct Safety-Data-Sheets Ah-Sds Diazinon Formulation AH JP 6NAndi SupriyonoNo ratings yet

- Marketing Environment Simulation and Summary Week 1Document7 pagesMarketing Environment Simulation and Summary Week 1Serena100% (1)

- GRI G4 Event Organizers Sector DisclosuresDocument94 pagesGRI G4 Event Organizers Sector DisclosuresMaximillian AgustarNo ratings yet

- We Effect Reducing Poverty Through AgricultureDocument32 pagesWe Effect Reducing Poverty Through Agriculturekamba bryanNo ratings yet

- Africa Regional Assessment Report On DRRDocument115 pagesAfrica Regional Assessment Report On DRRMoses ObboNo ratings yet

- SFRFRC: Ination# 501Document3 pagesSFRFRC: Ination# 501LinaceroNo ratings yet

- Places - Threats To NatureDocument6 pagesPlaces - Threats To NatureJEEHAN DELA CRUZNo ratings yet

- Material Safety Data Sheet: 1 Identification of SubstanceDocument5 pagesMaterial Safety Data Sheet: 1 Identification of Substancemaha muhammedNo ratings yet

- Using Bambusa Vulgaris As Replacement For Expandable Straw1Document9 pagesUsing Bambusa Vulgaris As Replacement For Expandable Straw1Bverde MenorNo ratings yet

- Exam QuestionsDocument7 pagesExam QuestionsElites ChoraleNo ratings yet

- Stormwater Drainage SpecificationDocument1 pageStormwater Drainage SpecificationSeeni GovindNo ratings yet

- Determining Drivers of Dragonfly Diversity Patterns and The Implications For Conservation in South AfricaDocument4 pagesDetermining Drivers of Dragonfly Diversity Patterns and The Implications For Conservation in South AfricaArt Julius D. HallazgoNo ratings yet

- Presentation by Harshal Sethiya N Mitul UpadhyayDocument26 pagesPresentation by Harshal Sethiya N Mitul Upadhyaysanket jain100% (1)

- Chapter Vi Global CityDocument20 pagesChapter Vi Global CityEva faith RemalanteNo ratings yet

- Safety Data Sheet: ACM Cyberthrin 5.5Document7 pagesSafety Data Sheet: ACM Cyberthrin 5.5aleem_80No ratings yet

- Permit Issued in Dec 2015: Job Number Permit Type Property AddressDocument180 pagesPermit Issued in Dec 2015: Job Number Permit Type Property AddressBrian PetranoNo ratings yet

- TDS 2020 08 25 Bangladesh MAI 5 - 09 cd8b5c 25082020213207 Uxz PDFDocument1 pageTDS 2020 08 25 Bangladesh MAI 5 - 09 cd8b5c 25082020213207 Uxz PDFdjhfvbsadjhjkcfbsd jdbdhNo ratings yet

- Assignment 3Document2 pagesAssignment 3779052308No ratings yet

- Monthly Dashboard - Exemplar File To Copy FromDocument37 pagesMonthly Dashboard - Exemplar File To Copy Fromإسلام عليNo ratings yet

- Seribumi Development Sdn. BHD.: Work Schedule NO Task Name Duration Start Finish PreliminariesDocument3 pagesSeribumi Development Sdn. BHD.: Work Schedule NO Task Name Duration Start Finish PreliminariesshafiqNo ratings yet