Professional Documents

Culture Documents

Pumps: Air-Powered Pumps For Safe Handling

Uploaded by

alexander_1985Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pumps: Air-Powered Pumps For Safe Handling

Uploaded by

alexander_1985Copyright:

Available Formats

Pumps

Air-powered pumps for safe handling

Air-powered pumps – for safe handling of

liquids under difficult condition

Both clean and polluted liquids

Pumps used for both clean and polluted liquids in

the construction, mining and process industries have

to satisfy stringent demands for quality and reliable

operation. They must be able to withstand difficult

conditions with regard to both the surroundings

and the media being conveyed, with a minimum

of maintenance.

Atlas Copco´s air-powered pumps meet the

strictest requirements. They are available in two

basic designs, DIP centrifugal pumps and DOP

diaphragm pumps. Both types share a number

of advantages.

• Robust

Air-powered operation ensures superior

resistance to dirt, damp and impurities.

• Cannot be damaged by overloading

An air-powered pump never runs the risk of

damage from overloading.

• Suitable in all kinds of environments

These pumps contain no electrical components

which can cause sparks, and do not leak oil or Capacity diagram for DIP and DOP pumps

need any inflammable fuel. at 6 bar (90 psi)

• Efficient

Delivery head

Air-powered operation gives very high capacity in

relation to weight, which makes the pumps easy feet m

229 70

to transport and use in confined spaces.

196 60

• Simple design

164 50 DIP 65

Atlas Copco´s air-powered pumps are of very

simple design, which means simple handling, 131 40

reliable operation and low maintenance 98 30 DIP 35

requirements. 66 20

DIP 25

33 10

DOP 15

0 0 flow

0 5 10 15 20 25 30 l/s

0 65 132 198 264 330 396 imp gal/min

Technical data

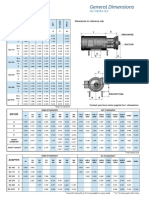

Type Max. Max. Max. air Weight Dimensions Connection thread 1) Ordering No.

head flow reguirement Height Length Width Fluid Air Air

outlet inlet outlet

m ft l/s l/s cfm kg ib mm in mm in mm in in in in

DIP 25 25 82 28 70 148 23 51 435 17 235 91/4 288 111/4 G 21/2 G3/4 G 11/2 8492 0103 20 2)

DIP 35 35 115 22 70 148 23 51 435 17 235 9 /4

1

288 11 /4

1

G 2 /2

1

G /4

3

G 1 /2

1

8492 0103 38 3)

DIP 65 59 194 11 70 148 23 51 435 17 235 91/4 288 111/4 G 21/2 G3/4 G 11/2 8492 0106 19 4)

DOP 15N 59 194 7 34 72 31 68 585 23 390 151/4 330 13 G 21/2 G3/4 – 8492 0101 48 5)

DOP 15F 59 194 7 34 72 31 68 585 23 390 151/4 330 13 G 21/2 G3/4 – 8492 0101 63

Data at 6 bar (90 psi). 1) According to ISO 228/1.

Remark Ordering number when fitted with US universal claw couplings: 2) 8492 0103 21, 3) 8492 0103 39, 4) 8492 0106 20, 5) 8492 0101 49.

DIP centrifugal pumps Air intake

With a strainer that

outlet (Thread G 2 1/2)

With a connection for hoses.

prevents contaminants

entering the pump.

DIP centrifugal pumps are specially designed for

relatively clean low-viscosity liquids such as water,

cooling fluids, solvents, light oil or petrol. A specially Large grip

designed rotating mechanical seal prevents leakage. For easy handling.

• Flexible – three pumps in one. A simple change of

impeller and intake ring makes it possible to adjust

to the desired capacity and head.

• Compact design and a high-output air motor give

the DIP pumps very high capacity in relation to

petrol and electric motors of the same weight.

• Submersible with a non-return valve (optional)

mounted, or alternatively a hose connected so that

the air outlet is above the surface.

Air outlet (Thread G 1 1/2)

• With the possibility to connect a non-return

valve (optional) that makes the pump

submersible.

• Possibility to attach a silencer (optional).

Intake

With a strainer at the base that prevents

larger particles passing through the pump

and which gives the pump good stability.

DOP diaphragm pumps Large grip

For easy handling.

Air outlet

• Built in non-return valve which

makes the pump submersible

Air intake and independent of orientation.

DOP diaphragm pumps are designed for the most With a strainer that • Silencer for low noise levels.

prevents contaminants

polluted and viscous media, as well as highly abrasive entering the pump.

and inflammable fluids.

DOP 15N – an all-round pump for construction,

mining and industrial applications. The diaphragm and

valve flaps are made of nitrile rubber.

DOP 15F – specially designed for the process

industry, with fluorine (viton) rubber diaphragm and

valve flaps.

• Can handle large solid particles up to 30 mm in

diameter.

• Submersible

• Self-priming which means that unnecessary

handling is avoided.

• Can be connected in series to increase the head.

Outlet (Thread G 2 1/2)

With a pivoting connection

pipe which gives a reduced stress

on the hose.

Intake (Thread G 2 1/2)

• Pivoting intake coupling to which a

suction hose (optional) can be connected to

reach liquids in tight corners.

• With a strainer at the base that prevents larger

particles passing through the pump and which

gives the pump good stability.

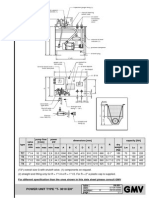

Equipment DIP 25, DIP 35, DIP 65

Pos Description Included Ordering No. 3

in kit, qty.

25 35 65

4

DIP 25 kit 8492 0103 53 2

DIP 35 kit 8492 0103 61

DIP 65 kit 8492 0106 27 6

1 Pump 1 1 1

2 Outlet hose 76 mm x 25 m

(3 in x 82 ft) incl. fittings 1 3330 0034 91

2 Outlet hose 63 mm x 32 m 5

(2 1/2 in x 105 ft) incl. fittings 1 2 4950 0191 90

2 Reinforced outlet hose

63 mm x 25 m

(2 1/2 in x 82 ft) incl. fittings 4950 0196 90

Coupling for connecting + 1

hose to pump 3330 0040 00

3 Lubricator CLG 30 for

synthetic oil (Air-oil) or

mineral oil* 1 1 1 8202 5102 39

4 Connection parts for

lubricator CLG 30. Valve,

air hose 20 mm x 3 m

(3/4 in x 10 ft) incl. fittings* 9030 0500 90

5 Non-return valve with pipe.

Thread G 1 1/2A 1 1 1 3330 0032 91

6 Silencer for dry air, incl.

connection parts 3330 0033 91

6 Silencer for damp air, incl.

connection parts 3330 0072 91

European standard claw couplings

*

The pumps can also be delivered as complete pump systems. In

addition, there are a number of optional equipments. The illustration

Equipment DOP 15N, DOP 15F shows a DOP 15N kit plus connection parts for the lubricator.

Pos Description Included in kit, qty Ordering No

DOP 15N kit 8492 0101 55 3

1 Pump 1

4

2 Outlet hose 63 mm x 32 m 2

(2 1/2 in x 105 ft) incl. fittings. 1 4950 0191 90

2 Reinforced outlet hose 63 mm x 25 m

9800 0237 01a © 2004, Atlas Copco Construction Tools AB, Stockholm, Sweden. Intellecta 2006 07

(2 1/2 mm x 82 ft) incl. fittings 4950 0196 90

3 Lubricator CLG 30 for synthetic oil

(Air-oil) or mineral oil. 1 8202 5102 39

4 Connection parts for lubricator CLG 30.

Valve, air hose 20 mm x 3 m

(3/4 in x 10 ft) incl. fittings* 9030 0500 90 5

5 Reinforced spiral suction hose

63 mm x 5 m (2 1/2 in x 16 ft)

incl. fittings and strainer* 3330 0069 90 1

European standard claw couplings

*

Use only authorized parts. Any damage or malfunction caused by the use of unauthorized parts is not covered by Warranty or Product Liability.

www.atlascopco.com

You might also like

- Engine Familiarization 4-39: Number 1 and 2 Bearing Support SubDocument6 pagesEngine Familiarization 4-39: Number 1 and 2 Bearing Support SubKishan MalhotraNo ratings yet

- Flooring MaterialsDocument57 pagesFlooring MaterialsMohammed FazilNo ratings yet

- Rodillos Hamm PDFDocument25 pagesRodillos Hamm PDFalexander_198592% (12)

- Physical Chemistry ExamDocument1 pagePhysical Chemistry ExamRaymond Yabut100% (1)

- 950f - 950f - Series - II - and - 960fDocument5 pages950f - 950f - Series - II - and - 960falexander_1985100% (1)

- Diagrama Electrico CP224 - Rev ADocument13 pagesDiagrama Electrico CP224 - Rev Aalexander_198580% (5)

- Insurance Claims Manual For Brokers and CustomersDocument43 pagesInsurance Claims Manual For Brokers and CustomersSUNIL PUJARI0% (1)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- 777F - Serv1828 - TXTDocument272 pages777F - Serv1828 - TXTalexander_198575% (4)

- Pavientadora CAT AP500E and BG500EDocument10 pagesPavientadora CAT AP500E and BG500Ealexander_1985100% (1)

- JLG 450 A AJ II Parts 3121243 4-15-08 Global EnglishDocument492 pagesJLG 450 A AJ II Parts 3121243 4-15-08 Global EnglishCarlos E. Delius SciaroniNo ratings yet

- Aiv Test ReportDocument6 pagesAiv Test Reportrus67% (6)

- RS-13 5-8-5m Annular BOP Operaion ManualDocument6 pagesRS-13 5-8-5m Annular BOP Operaion ManualAlexsandro Cordeiro100% (2)

- Plano de Implementos d11tDocument2 pagesPlano de Implementos d11talexander_1985No ratings yet

- Paint ProductionDocument40 pagesPaint ProductionNemerem Ignatius80% (5)

- Flowserve Durco CatalogDocument36 pagesFlowserve Durco CatalogbryandownNo ratings yet

- Plano Power Train D8TDocument2 pagesPlano Power Train D8Talexander_1985100% (3)

- Engine Repair 667TA 87519804naDocument150 pagesEngine Repair 667TA 87519804naalexander_198587% (23)

- Hitachi Ex5600 6Document1 pageHitachi Ex5600 6Edinson Rojas AlarcónNo ratings yet

- Connector Industry: A Profile of the European Connector Industry - Market Prospects to 1999From EverandConnector Industry: A Profile of the European Connector Industry - Market Prospects to 1999No ratings yet

- Model 10 10fb 11 Carbon HousingsDocument4 pagesModel 10 10fb 11 Carbon HousingsrezNo ratings yet

- Fisa Tehnica Pompe MultifreeDocument10 pagesFisa Tehnica Pompe MultifreeDogan SoiumNo ratings yet

- Metropolis DGT - ENG PDFDocument30 pagesMetropolis DGT - ENG PDFpaulnorton2No ratings yet

- Pilot Operated NRVDocument1 pagePilot Operated NRVBiswanath LenkaNo ratings yet

- Prince Valve rd2575 t3 Esa 1Document4 pagesPrince Valve rd2575 t3 Esa 1Rousdi AndraosNo ratings yet

- UNITED Y8PCugjDocument2 pagesUNITED Y8PCugjFadhilNo ratings yet

- Padova Submersible Deep Well 2018 3 Inchi Compressed1-2cc88-2584 1579Document5 pagesPadova Submersible Deep Well 2018 3 Inchi Compressed1-2cc88-2584 1579George CobraNo ratings yet

- T70 Quick Exhaust Valves: Medium: Operating Pressure: Port Size: Mounting: Ambient/Media Temperature: MaterialsDocument2 pagesT70 Quick Exhaust Valves: Medium: Operating Pressure: Port Size: Mounting: Ambient/Media Temperature: Materialsbiswasdipankar05No ratings yet

- Air Leak Test Machine Cobra .2Document1 pageAir Leak Test Machine Cobra .2Tinu SebastianNo ratings yet

- Cac+ Rac Submittal-A4848Document179 pagesCac+ Rac Submittal-A4848MUBASHIRNo ratings yet

- SCSAGA - DOROT - MultiJet Chorro Unico MJDocument2 pagesSCSAGA - DOROT - MultiJet Chorro Unico MJMiguel CruzNo ratings yet

- QC General DimensionsDocument12 pagesQC General DimensionsJoaquin CortésNo ratings yet

- 181-1-2 Water Motor GongDocument4 pages181-1-2 Water Motor GongCkaal74No ratings yet

- Lennox Air Conditioner g20!01!01-2003Document12 pagesLennox Air Conditioner g20!01!01-2003Boldie LutwigNo ratings yet

- NAMUR New Valve 9730000-StocksDocument6 pagesNAMUR New Valve 9730000-StocksamirulNo ratings yet

- Solenoid Valves & Coils for Refrigerant ApplicationsDocument2 pagesSolenoid Valves & Coils for Refrigerant Applicationshector martinezNo ratings yet

- Wascomat Flatwork Ironer Specifications IC5019 LF OC5021 R LF IC5025 R LF IC5028 R LF IC5032 R LFDocument2 pagesWascomat Flatwork Ironer Specifications IC5019 LF OC5021 R LF IC5025 R LF IC5028 R LF IC5032 R LFmairimsp2003No ratings yet

- Busch Jost Pilot ValveDocument4 pagesBusch Jost Pilot ValveLuis Eduardo Albarracin RugelesNo ratings yet

- Quick Exhaust Valves Technical Data and Ordering InformationDocument4 pagesQuick Exhaust Valves Technical Data and Ordering InformationAbhayy DevNo ratings yet

- gb04 001 20060529Document1 pagegb04 001 20060529Claudio JustinianoNo ratings yet

- En Daten MS-MFDocument20 pagesEn Daten MS-MFcazan93No ratings yet

- Sch80tech CRF-1 T D Glpog TDocument2 pagesSch80tech CRF-1 T D Glpog TSony CNo ratings yet

- Sch40tech DCVRF-1 T D Glpo TDocument2 pagesSch40tech DCVRF-1 T D Glpo TSony CNo ratings yet

- Olups Static l20 SchematicsDocument1 pageOlups Static l20 SchematicsaananthuajaysNo ratings yet

- Saveco Gritsep DS en 0320 EditDocument4 pagesSaveco Gritsep DS en 0320 EditagustinNo ratings yet

- RTN 24 - Rtfs 24 - Rtfs 28 CTN 24 F - Ctfs 24 F - Ctfs 28 F: Installation Use and MaintenanceDocument36 pagesRTN 24 - Rtfs 24 - Rtfs 28 CTN 24 F - Ctfs 24 F - Ctfs 28 F: Installation Use and MaintenanceAnastasia KazaNo ratings yet

- Parts Catalog: Outdoor UnitDocument4 pagesParts Catalog: Outdoor UnitZulkipli MarasabessyNo ratings yet

- G1/4 to G1 MaxFlow filters and regulatorsDocument5 pagesG1/4 to G1 MaxFlow filters and regulatorsGopalakrishnan Raju100% (1)

- Lighting and Power Panel 80AT/100AF, 18kAIC, 2P, 230V, 60Hz, MCBDocument1 pageLighting and Power Panel 80AT/100AF, 18kAIC, 2P, 230V, 60Hz, MCBramNo ratings yet

- En 5 3 450 40200 40300Document4 pagesEn 5 3 450 40200 40300anyád baszomNo ratings yet

- MICROFILTERDocument7 pagesMICROFILTERAhmed Essam El-DinNo ratings yet

- AASHTO D. T 98-99 - 2001, Fin. of P.Cement by TurbidimeterDocument15 pagesAASHTO D. T 98-99 - 2001, Fin. of P.Cement by TurbidimeterBestoon RamadhanNo ratings yet

- FRCLMDocument3 pagesFRCLMBiswanath LenkaNo ratings yet

- W1100 1200 1310broDocument4 pagesW1100 1200 1310broGleiziano BouzasNo ratings yet

- W1100 1200 1310broDocument4 pagesW1100 1200 1310brokdpmansiNo ratings yet

- Ball Valves BVG4-..LDocument3 pagesBall Valves BVG4-..Lkocho79No ratings yet

- U-Match GOOD R410A SpecificationsDocument20 pagesU-Match GOOD R410A SpecificationsmiguelNo ratings yet

- Piranha - 08 - 110 - TDS EngleskiDocument4 pagesPiranha - 08 - 110 - TDS EngleskiZoran CirjakovicNo ratings yet

- Product Catalog 3Document71 pagesProduct Catalog 3Elmalki SihamNo ratings yet

- AB-PR Part-Turn Gear SeriesDocument6 pagesAB-PR Part-Turn Gear SeriesSrinivasanArumugamvenkatachalamNo ratings yet

- Series L145 2-2 NC Pilot Operated Solenoid Valve G3-8 To G1Document2 pagesSeries L145 2-2 NC Pilot Operated Solenoid Valve G3-8 To G1donwload bunkNo ratings yet

- Qty. Description NKG 350-300-305/342 W1-F-A-E-BQQE: Company Name: Created By: Phone: DateDocument4 pagesQty. Description NKG 350-300-305/342 W1-F-A-E-BQQE: Company Name: Created By: Phone: DateRektorUnitelNo ratings yet

- A244 A244X A246 Solenoid Valves PDFDocument1 pageA244 A244X A246 Solenoid Valves PDFMehmet KahyaNo ratings yet

- Asco Keystone CompatibilityDocument2 pagesAsco Keystone CompatibilityalexmontellNo ratings yet

- Flow Control ValveDocument2 pagesFlow Control ValveBiswanath LenkaNo ratings yet

- Air CooledDocument34 pagesAir Coolededward m. limenNo ratings yet

- FG-FGS enDocument9 pagesFG-FGS enAnonymous DPkjxLvYmRNo ratings yet

- Susin I Tork Heavy Duty 1Document12 pagesSusin I Tork Heavy Duty 1dharmendrabholeNo ratings yet

- R250G 0829en - 2016-05Document2 pagesR250G 0829en - 2016-05JMigRodNo ratings yet

- SOV - 97300 Namur PDFDocument7 pagesSOV - 97300 Namur PDFNani TamizhaNo ratings yet

- Flotect Vane Operated Flow Switches: Field Adjustable - 1 To 6 Inch Pipe, Leak Proof Body, Chemical ResistanceDocument1 pageFlotect Vane Operated Flow Switches: Field Adjustable - 1 To 6 Inch Pipe, Leak Proof Body, Chemical ResistanceMadhan MohanNo ratings yet

- Sulzer Ejector For Priming: Save Energy While Reducing Your Total Cost of Ownership (TCO)Document2 pagesSulzer Ejector For Priming: Save Energy While Reducing Your Total Cost of Ownership (TCO)David Bottassi PariserNo ratings yet

- 5/2 and 5/3 Valves Solenoid and Pilot Actuated Sub-Base Mounted ISO 5599-1 #1, #2, #3, #4Document8 pages5/2 and 5/3 Valves Solenoid and Pilot Actuated Sub-Base Mounted ISO 5599-1 #1, #2, #3, #4Hdhm TdhNo ratings yet

- C.R.I. G-Flow Submersible PumpsDocument18 pagesC.R.I. G-Flow Submersible PumpsIwan KurniawanNo ratings yet

- Piranha 08 110 TDSDocument4 pagesPiranha 08 110 TDSchu42No ratings yet

- Roll-to-Roll Manufacturing: Process Elements and Recent AdvancesFrom EverandRoll-to-Roll Manufacturing: Process Elements and Recent AdvancesJehuda GreenerNo ratings yet

- Operators Handbook: Pneumatic Breakers and DrillsDocument24 pagesOperators Handbook: Pneumatic Breakers and Drillsalexander_1985No ratings yet

- Compressed Air in Mobile SystemsDocument28 pagesCompressed Air in Mobile Systemsalexander_1985No ratings yet

- TEX Pneumatic Breakers: When Quality CountsDocument16 pagesTEX Pneumatic Breakers: When Quality Countsalexander_1985No ratings yet

- Easy On-Site Crushing: Atlas Copco BC Bucket CrusherDocument4 pagesEasy On-Site Crushing: Atlas Copco BC Bucket Crusheralexander_1985No ratings yet

- Get A Real Grip On Vibro-Reduction: Atlas Copco TEX PE Pneumatic HammersDocument8 pagesGet A Real Grip On Vibro-Reduction: Atlas Copco TEX PE Pneumatic Hammersalexander_1985No ratings yet

- TEX 3 and TEX 05 Chipping HammersDocument2 pagesTEX 3 and TEX 05 Chipping Hammersalexander_1985No ratings yet

- Operator Manual NV1-NV3 T3 PDFDocument177 pagesOperator Manual NV1-NV3 T3 PDFalexander_1985No ratings yet

- TEX 07PE Pneumatic Pick Hammer: Combining Chisel Control and Vibro-ReductionDocument4 pagesTEX 07PE Pneumatic Pick Hammer: Combining Chisel Control and Vibro-Reductionalexander_1985No ratings yet

- TEX 3 and TEX 05 Chipping HammersDocument2 pagesTEX 3 and TEX 05 Chipping Hammersalexander_1985No ratings yet

- Maintenance CA15Document54 pagesMaintenance CA15alexander_1985No ratings yet

- TEX 09 and TEX 12 Pick HammersDocument2 pagesTEX 09 and TEX 12 Pick Hammersalexander_1985No ratings yet

- TEX 10 Pneumatic Pick Hammer: Long Stroke. Hard Hitting. Low WeightDocument4 pagesTEX 10 Pneumatic Pick Hammer: Long Stroke. Hard Hitting. Low Weightalexander_1985No ratings yet

- Operation CA15Document71 pagesOperation CA15alexander_1985100% (1)

- Maintenance Manual CA15Document76 pagesMaintenance Manual CA15alexander_198567% (3)

- Operating CA15Document37 pagesOperating CA15alexander_1985No ratings yet

- Dcas & DcoDocument16 pagesDcas & Dcoalexander_1985No ratings yet

- DCO Manual E2017enDocument22 pagesDCO Manual E2017enalexander_1985No ratings yet

- Paviemntadora de Asfalto CAT AP500E and BG500EDocument19 pagesPaviemntadora de Asfalto CAT AP500E and BG500Ealexander_1985100% (1)

- Plano Tren de Fuerza d11tDocument2 pagesPlano Tren de Fuerza d11talexander_1985No ratings yet

- A Coordination Framework For Sales and Operations PlanningDocument20 pagesA Coordination Framework For Sales and Operations PlanningprasannaNo ratings yet

- 250 - C30R, U Operation and Maintenance: Export ControlledDocument8 pages250 - C30R, U Operation and Maintenance: Export ControlledturboshaftNo ratings yet

- 1,6l Simos (AEH+AKL) 1Document10 pages1,6l Simos (AEH+AKL) 1Tremalone SemionelaNo ratings yet

- iAXE624-BK P0826 I ENDocument6 pagesiAXE624-BK P0826 I ENMichael KarakoNo ratings yet

- 09c01 Fuel Injection Pump (Rotor)Document6 pages09c01 Fuel Injection Pump (Rotor)hbpate3No ratings yet

- Deep-Learning Based SAR Ship Detection With Generative Data AugmentationDocument9 pagesDeep-Learning Based SAR Ship Detection With Generative Data AugmentationRana UsmanNo ratings yet

- Operating Instructions for Diesel Pile Hammers D6-D180Document110 pagesOperating Instructions for Diesel Pile Hammers D6-D180Jhousep steven Mesia gonzalesNo ratings yet

- Wedge Anchor BZplus A4Document4 pagesWedge Anchor BZplus A4francisbautistaNo ratings yet

- Fyp ProjectDocument5 pagesFyp ProjectUsman PashaNo ratings yet

- DTR Leaflet 02 R5Document2 pagesDTR Leaflet 02 R5Razzi HamzahNo ratings yet

- BSBEdge Report PDFDocument165 pagesBSBEdge Report PDFMITHUN KUMAR BEHERANo ratings yet

- Unit Testing Assignment Using JUnitDocument5 pagesUnit Testing Assignment Using JUnitkorapradeepNo ratings yet

- 2 User Interface 2: Menu 2 General Options 2 Create SVG Map: The SVG Map Creation Wizard 3Document10 pages2 User Interface 2: Menu 2 General Options 2 Create SVG Map: The SVG Map Creation Wizard 3Appolinaire EmaniNo ratings yet

- EXP5Document2 pagesEXP5UsamaIjaz100% (1)

- Refractive Index of Different Liquids Using Hollow PrismDocument18 pagesRefractive Index of Different Liquids Using Hollow PrismAbhiram ChaturvediNo ratings yet

- Pedestrian Stacker Truck: P-SeriesDocument4 pagesPedestrian Stacker Truck: P-SeriesTRINDADENo ratings yet

- Reaction Rate Unit 1 NotesDocument40 pagesReaction Rate Unit 1 NotesdrsinagNo ratings yet

- SATRACK Guidance System for Missiles & SatellitesDocument15 pagesSATRACK Guidance System for Missiles & SatellitesVarun Gv100% (1)

- Injection of Nitrogen Foam For Improved Oil Recovery in Viscous Oil Reservoirs Offshore Bohai Bay ChinaDocument14 pagesInjection of Nitrogen Foam For Improved Oil Recovery in Viscous Oil Reservoirs Offshore Bohai Bay ChinaRoberticoZeaNo ratings yet

- New Aluminium FormworkDocument34 pagesNew Aluminium FormworkSandip Jagdale0% (1)

- AOPEN Hardware Brochure 2017Document60 pagesAOPEN Hardware Brochure 2017Marisagarcia2014No ratings yet