Professional Documents

Culture Documents

Main Line Hydrostatic Test Procedure Pipeline Trans 10

Uploaded by

hamza laribi0 ratings0% found this document useful (0 votes)

13 views1 pageThe document outlines the minimum equipment required for hydrostatic testing of pipelines, including pumps, recorders, gauges, and other instrumentation. It specifies that tests require at least two pressure recorders, one temperature recorder, two dead weight testers, one pressure gauge, one thermometer, and a calibrated liquid measure. All recorders and gauges must be calibrated according to specified standards and dead weight testers and thermometers must be certified every three years.

Original Description:

Original Title

Main Line Hydrostatic test procedure pipeline trans 10

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document outlines the minimum equipment required for hydrostatic testing of pipelines, including pumps, recorders, gauges, and other instrumentation. It specifies that tests require at least two pressure recorders, one temperature recorder, two dead weight testers, one pressure gauge, one thermometer, and a calibrated liquid measure. All recorders and gauges must be calibrated according to specified standards and dead weight testers and thermometers must be certified every three years.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views1 pageMain Line Hydrostatic Test Procedure Pipeline Trans 10

Uploaded by

hamza laribiThe document outlines the minimum equipment required for hydrostatic testing of pipelines, including pumps, recorders, gauges, and other instrumentation. It specifies that tests require at least two pressure recorders, one temperature recorder, two dead weight testers, one pressure gauge, one thermometer, and a calibrated liquid measure. All recorders and gauges must be calibrated according to specified standards and dead weight testers and thermometers must be certified every three years.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

TERASEN PIPELINES (TRANS MOUNTAIN) INC.

ENGINEERING STANDARDS AND PRACTICES

MP4121 Revision 2 July 16, 1999 Page 9 of 23

Title: MAIN LINE HYDROSTATIC TEST PROCEDURE

4.5 Test Equipment

4.5.1 Equipment Required

The numbers of recorders, gauges, pumps, and other necessary

equipment are a function of the scope of a hydrostatic test. The

equipment listed in Table 4.5.1.A is the minimum required for either a

main line test or a test of prefabricated piping in a shop or yard.

TABLE 4.5.1.A -- MINIMUM EQUIPMENT REQUIREMENTS

Equipment Mainline Shop/Yard

Plunger type squeeze pump with or without 1

2

revolution counter as required (pump only)

Pressure recorder 4 1

Temperature recorder to record pipe, ground, and per test

2*

ambient temperatures schematic

Dead weight tester 2 1

Pressure gauge 1 1

Thermometer 1 1

Calibrated liquid measure to ± 10 ml 1 1

* pipe and ambient temperatures only

4.5.2 Equipment Calibration

All recorders and gauges shall be calibrated in accordance with EI

Procedure VII.A.1, Main Line Testing.

4.5.3 Certification

Dead weight testers and calibrated thermometers shall be certified to

a government standard every three years.

4.5.4 Instrumentation Arrangements

Refer to Figures 4.5.A and 4.5.B for typical instrumentation

arrangements.

4.5.5 Test Head Assemblies

Test head assemblies shall not be pressurized to a stress exceeding

75% of the SMYS of the test head material. The ancillary piping shall

not be pressurized to a stress exceeding 50% of the SMYS of the

piping.

You might also like

- Measurement of Temperature and Chemical Composition: Jones' Instrument TechnologyFrom EverandMeasurement of Temperature and Chemical Composition: Jones' Instrument TechnologyNo ratings yet

- Procedure de Test BOPDocument12 pagesProcedure de Test BOPkhireddineboulifaNo ratings yet

- Instrument Technology: Measurement of Pressure, Level, Flow and TemperatureFrom EverandInstrument Technology: Measurement of Pressure, Level, Flow and TemperatureRating: 4 out of 5 stars4/5 (1)

- Chapter 05 - Pipeline Pressure TestingOCR OKDocument16 pagesChapter 05 - Pipeline Pressure TestingOCR OKfabioalves8No ratings yet

- Automatic Controls for Heating and Air Conditioning: Principles and ApplicationsFrom EverandAutomatic Controls for Heating and Air Conditioning: Principles and ApplicationsRating: 4 out of 5 stars4/5 (2)

- On-Site Acceptance Test ProgramDocument7 pagesOn-Site Acceptance Test ProgramDaniel CorreaNo ratings yet

- Working Guide to Petroleum and Natural Gas Production EngineeringFrom EverandWorking Guide to Petroleum and Natural Gas Production EngineeringRating: 5 out of 5 stars5/5 (2)

- Unidirectional ProverDocument2 pagesUnidirectional ProverGanjar Al Kaspandi100% (1)

- 2. Forsthoffer's Rotating Equipment Handbooks: PumpsFrom Everand2. Forsthoffer's Rotating Equipment Handbooks: PumpsRating: 1 out of 5 stars1/5 (1)

- P-T4061-016 Rev. 02 - Hydrotest ProcedureDocument4 pagesP-T4061-016 Rev. 02 - Hydrotest ProcedureBudhi SuharnantoNo ratings yet

- Annex 2 Qualification of GC EquipmentDocument12 pagesAnnex 2 Qualification of GC EquipmentHaroon Rasheed100% (1)

- Prepaid Meter Testing Stds. PM - IS-15884Document8 pagesPrepaid Meter Testing Stds. PM - IS-15884Boson FreelancerNo ratings yet

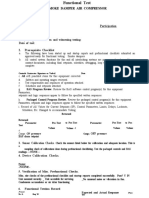

- Functional Test-Smoke Damper Air CompressorDocument4 pagesFunctional Test-Smoke Damper Air Compressorlong minn2No ratings yet

- Qualification of Equipment Annex 2 Qualification of GC Equipment PAPHOMCL (16) 17 R1Document11 pagesQualification of Equipment Annex 2 Qualification of GC Equipment PAPHOMCL (16) 17 R1Jhon Edison Briceño Peñuela100% (1)

- Form 70 Fire Hydrant and SprinklersDocument2 pagesForm 70 Fire Hydrant and SprinklersmkdholkiyaNo ratings yet

- PM Is 13095Document5 pagesPM Is 13095Tanmoy DuttaNo ratings yet

- Product Manual For A.C. Static Transformer Operated Watthour and Var-Hour Smart Meters, Class 0.2S, 0.5S and 1S ACCORDING TO IS 16444 (PART 2) :2017Document11 pagesProduct Manual For A.C. Static Transformer Operated Watthour and Var-Hour Smart Meters, Class 0.2S, 0.5S and 1S ACCORDING TO IS 16444 (PART 2) :2017SammoonNo ratings yet

- Technical Repot-LabDocument2 pagesTechnical Repot-LabmrlaeluNo ratings yet

- Item Inspected: CBLT-TPI-00F-186-12623Document16 pagesItem Inspected: CBLT-TPI-00F-186-12623Zulfadli RaniNo ratings yet

- Sample Pre Operation ChecklistDocument3 pagesSample Pre Operation Checklistatif majeedNo ratings yet

- Probador Bidireccional Smith MeterTM ProversDocument2 pagesProbador Bidireccional Smith MeterTM Proversboa144No ratings yet

- Multiflash: The Single Solution For All Flash Point TestsDocument5 pagesMultiflash: The Single Solution For All Flash Point TestsGISELLENo ratings yet

- Pump Performance Test 3Document8 pagesPump Performance Test 3tunlinooNo ratings yet

- Bharat Oman QAPDocument6 pagesBharat Oman QAPJJ VAPINo ratings yet

- Product Manual For Electric Immersion Water Heaters ACCORDING TO IS 368:2014Document7 pagesProduct Manual For Electric Immersion Water Heaters ACCORDING TO IS 368:2014Mani DhamodharanNo ratings yet

- Qualification Documents PDFDocument14 pagesQualification Documents PDFDoan Chi ThienNo ratings yet

- Astm D1160Document18 pagesAstm D1160Ryuzo GotoNo ratings yet

- Product Manual For Ac Motor Capacitors ACCORDING TO IS 2993:1998 / IEC 252:1993Document6 pagesProduct Manual For Ac Motor Capacitors ACCORDING TO IS 2993:1998 / IEC 252:1993Ankit PatelNo ratings yet

- ASTM ConductivityDocument14 pagesASTM ConductivityjohncramosNo ratings yet

- Guideline Qualification of Equipment Annex 9 PH-meter October 2015Document4 pagesGuideline Qualification of Equipment Annex 9 PH-meter October 2015Parkhomyuk50% (2)

- Procedure For Hydro TestDocument7 pagesProcedure For Hydro TestM SaddikinNo ratings yet

- Product Manual For A.C. Static Direct Connected Watthour Smart Meter - Class 1 and Class 2 ACCORDING TO IS 16444 (PART 1) :2015Document11 pagesProduct Manual For A.C. Static Direct Connected Watthour Smart Meter - Class 1 and Class 2 ACCORDING TO IS 16444 (PART 1) :2015SammoonNo ratings yet

- Firepumps 111103130333 Phpapp01Document9 pagesFirepumps 111103130333 Phpapp01Gabriel ArriolaNo ratings yet

- MANTENIMIENTODocument5 pagesMANTENIMIENTOalextlv1996cvNo ratings yet

- Work Method StatementDocument6 pagesWork Method StatementbnmqweNo ratings yet

- Pour Point of Petroleum Products (Robotic Tilt Method) : Standard Test Method ForDocument5 pagesPour Point of Petroleum Products (Robotic Tilt Method) : Standard Test Method ForNguyễn Bằng NộiNo ratings yet

- Standard Operating Procedure For Earth Pit MaintenanceDocument2 pagesStandard Operating Procedure For Earth Pit MaintenanceMANOJ KUMARNo ratings yet

- Distillation of Petroleum Products at Reduce PressureDocument18 pagesDistillation of Petroleum Products at Reduce PressureMurtaza Amir AliNo ratings yet

- Bidirectional Sphere Type Prover: Smith Meter ProversDocument2 pagesBidirectional Sphere Type Prover: Smith Meter Proversk ONo ratings yet

- IS 14846 Product ManualDocument5 pagesIS 14846 Product ManualKrishna Prasad KanchojuNo ratings yet

- Process Table I-Dry Contact Press HardeningDocument9 pagesProcess Table I-Dry Contact Press HardeningMickloSoberanNo ratings yet

- TTLA0669Document533 pagesTTLA0669KonstantinNo ratings yet

- Astm b117 Testing v1Document3 pagesAstm b117 Testing v1maddumaNo ratings yet

- Procedure For Pipeline De-OilingDocument9 pagesProcedure For Pipeline De-Oilinginyene ekereNo ratings yet

- NRC Inspection Manual: Issue Date: 05/12/86 - 1 - 61705Document6 pagesNRC Inspection Manual: Issue Date: 05/12/86 - 1 - 61705elsayed abdemagiedNo ratings yet

- ISO 7253 2001 Method Statement PDFDocument4 pagesISO 7253 2001 Method Statement PDFFadi MagdyNo ratings yet

- PM Is-13779Document8 pagesPM Is-13779dduraisamymanikandanNo ratings yet

- Product Manual For Compression Testing Machine Used For Testing of Concrete and Mortar ACCORDING TO IS 14858: 2000Document5 pagesProduct Manual For Compression Testing Machine Used For Testing of Concrete and Mortar ACCORDING TO IS 14858: 2000Utpal MajiNo ratings yet

- Annex 2 Qualification of GC EquipmentDocument11 pagesAnnex 2 Qualification of GC EquipmentBrian Williams100% (1)

- EG 15-14-1.1 Inspection and Testing of InstrumentsDocument3 pagesEG 15-14-1.1 Inspection and Testing of Instrumentsamin100% (1)

- Mersin CFB Boiler Test ProcedureDocument8 pagesMersin CFB Boiler Test ProcedureFaruk OcalNo ratings yet

- Instrument Field Engineering: Prepared By: M.P.ALAMDocument99 pagesInstrument Field Engineering: Prepared By: M.P.ALAMsakendos torrosNo ratings yet

- Thermal Power Plant AuditingDocument29 pagesThermal Power Plant Auditingsenthil1386100% (3)

- Section Cover Page: Section 15399 Sprinkler System 2005-02-08 Inspection, Testing, and MaintenanceDocument5 pagesSection Cover Page: Section 15399 Sprinkler System 2005-02-08 Inspection, Testing, and MaintenancekusdiyantaNo ratings yet

- GLP & Analytical Quality AssuranceDocument44 pagesGLP & Analytical Quality AssuranceAnonymous 6dRZtw2zJNo ratings yet

- MuthyfDocument20 pagesMuthyfMuthu KumarNo ratings yet

- Instruments For Storage Tanks and Vessels IP 15-1-3: ScopeDocument4 pagesInstruments For Storage Tanks and Vessels IP 15-1-3: ScopeLuis Alonso Aguirre LopezNo ratings yet

- 1391 Part 2 Second RevisionDocument10 pages1391 Part 2 Second RevisionArindam ChandaNo ratings yet

- Product Manual For Resilient Seated Cast Iron Air Relief Valves For Water Works Purposes ACCORDING TO IS 14845: 2000Document5 pagesProduct Manual For Resilient Seated Cast Iron Air Relief Valves For Water Works Purposes ACCORDING TO IS 14845: 2000Tanmoy DuttaNo ratings yet

- Pressure TestDocument41 pagesPressure TestJoshua WeeNo ratings yet

- Critical Analysis Gas and Oil Pressure Drop AnalysisDocument6 pagesCritical Analysis Gas and Oil Pressure Drop Analysishamza laribiNo ratings yet

- ELEvation Effect Pipeline NodalanaleffectDocument11 pagesELEvation Effect Pipeline Nodalanaleffecthamza laribiNo ratings yet

- Laser Scantender - Admin - 15-12-17Document18 pagesLaser Scantender - Admin - 15-12-17hamza laribiNo ratings yet

- Docssier 3D LASER SCNA12397Document48 pagesDocssier 3D LASER SCNA12397hamza laribiNo ratings yet

- Bayou Products NO-AEGDocument4 pagesBayou Products NO-AEGhamza laribiNo ratings yet

- VIII Paper 16Document16 pagesVIII Paper 16hamza laribiNo ratings yet

- Property Risk Consulting GuidelinesDocument1 pageProperty Risk Consulting Guidelineshamza laribiNo ratings yet

- Oilplantlayoutandspacingv1 5Document1 pageOilplantlayoutandspacingv1 5hamza laribiNo ratings yet

- Elbolet ButtweldDocument1 pageElbolet Buttweldhamza laribiNo ratings yet

- SweepoletDocument1 pageSweepolethamza laribiNo ratings yet

- Main Line Hydrostatic Test Procedure Pipeline Trans 19Document1 pageMain Line Hydrostatic Test Procedure Pipeline Trans 19hamza laribiNo ratings yet

- Itoh Phase UnwrapDocument1 pageItoh Phase UnwrapsuperbuchNo ratings yet

- Lesson 1 Intellectual Revolutions That Defined SocietyDocument15 pagesLesson 1 Intellectual Revolutions That Defined SocietyCharlene BolandresNo ratings yet

- Measuring Performance of Microfinance Institutions A Framework For Reporting Analysis and Monitoring ToolkitDocument271 pagesMeasuring Performance of Microfinance Institutions A Framework For Reporting Analysis and Monitoring Toolkitigga d johnNo ratings yet

- Pass Trinity Now 12 - Teacher BookDocument47 pagesPass Trinity Now 12 - Teacher BookMarina Mora GarciaNo ratings yet

- EQUATIONSDocument34 pagesEQUATIONSveer pratap mauryaNo ratings yet

- Ch-12 Surface TensionDocument21 pagesCh-12 Surface Tensionpandya.mamta1981No ratings yet

- Bio StatisticsDocument164 pagesBio StatisticsJiregnaNo ratings yet

- Method Statement For Tank Survey (MFL) and RepairDocument14 pagesMethod Statement For Tank Survey (MFL) and RepairMG67% (3)

- PbO Al2O3 TeO2 GeO2 SiO2 CuODocument9 pagesPbO Al2O3 TeO2 GeO2 SiO2 CuOhanumatharao kNo ratings yet

- Assignment 1Document17 pagesAssignment 1api-723710078100% (1)

- The Idea of ProgressDocument1 pageThe Idea of Progressvictor carre poussinNo ratings yet

- ASTM C881 2013 - Epoxy Resin Base Bonding System For ConcreteDocument6 pagesASTM C881 2013 - Epoxy Resin Base Bonding System For Concretetsalemnoush100% (1)

- Class 6 Term 1 Curriculum Break Up and MYE SyallabiDocument3 pagesClass 6 Term 1 Curriculum Break Up and MYE SyallabiSyed Nasir AbbasNo ratings yet

- The Roman Conquest of Wales AD 47-410Document64 pagesThe Roman Conquest of Wales AD 47-410Gamer4242No ratings yet

- DPB10023 Principles of Management Problem Scenario Chapter 6 Staffing Chapter 7 Decision MakingDocument8 pagesDPB10023 Principles of Management Problem Scenario Chapter 6 Staffing Chapter 7 Decision MakingSiti NurSyahirah 1071No ratings yet

- Department of Defense: Test Method Standard MicrocircuitsDocument196 pagesDepartment of Defense: Test Method Standard MicrocircuitsgokulNo ratings yet

- Lexium 05 & Motors - VW3M5102R500Document2 pagesLexium 05 & Motors - VW3M5102R500suman.pNo ratings yet

- Domestic Diversity at Kincaid MoundsDocument34 pagesDomestic Diversity at Kincaid MoundstamirabNo ratings yet

- How To Write Case Comment - Simple GuideDocument3 pagesHow To Write Case Comment - Simple GuidepranjalNo ratings yet

- Science FinalDocument3 pagesScience Finalapi-577230763No ratings yet

- In The Developed WorldDocument4 pagesIn The Developed WorldThanh Thanh DoanNo ratings yet

- Sydney Boys 2019 Chemistry Trial PaperDocument30 pagesSydney Boys 2019 Chemistry Trial PaperYuanfeng WeiNo ratings yet

- Simplified Performance Models of Photovoltaic - Diesel Generator - Battery System Considering Typical Control StrategiesDocument13 pagesSimplified Performance Models of Photovoltaic - Diesel Generator - Battery System Considering Typical Control StrategiesMoathFrajNo ratings yet

- Contractor Daily Construction Report DEC13Document10 pagesContractor Daily Construction Report DEC13Kei-Ar MahiyaNo ratings yet

- Inertia and Momentu GroupDocument10 pagesInertia and Momentu GroupayydenNo ratings yet

- NFS Concoctions Revised Oa NC IiDocument8 pagesNFS Concoctions Revised Oa NC IiArts IanNo ratings yet

- Zorlu Zemin Şartlarında EPB TBM Tünelciliği: Ataköy - İkitelli Metro Tünelinde Örnek Bir Çalışma, TürkiyeDocument7 pagesZorlu Zemin Şartlarında EPB TBM Tünelciliği: Ataköy - İkitelli Metro Tünelinde Örnek Bir Çalışma, TürkiyecemalbalciNo ratings yet

- Applications: Mathematics and ArtDocument2 pagesApplications: Mathematics and ArtJohn Kenneth BentirNo ratings yet

- RC Grail SampleDocument32 pagesRC Grail SampleMario Supr100% (3)

- #2-Crash Course World History The Indus Valley CivilizationDocument2 pages#2-Crash Course World History The Indus Valley CivilizationBrian RappNo ratings yet