Professional Documents

Culture Documents

Astm b117 Testing v1

Uploaded by

madduma0 ratings0% found this document useful (0 votes)

82 views3 pagesTesting methods

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTesting methods

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

82 views3 pagesAstm b117 Testing v1

Uploaded by

maddumaTesting methods

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Corrosion Test Methodology

STANDARD: ASTM B117 Testing Method Statement

EQUIPMENT: All Ascott Corrosion Chambers

1. Scope Hand Held pH Meter (Ascott Accessory No: ACC11)

1.1 This methodology is to be used to perform the Digital pH meter, for measuring the pH of salt solution fallout over

range 0-14 pH with a resolution of 0.01 pH. Supplied complete with

ASTMB117-11 test standard in an Ascott corrosion buffers for calibration.

chamber. View all our accessories at www.ascott-analytical.com

This should be used in conjunction with the ASTM

B117 standard document. The test standard takes • Salinity Refractometer is calibrated using

precedence over this method statement and this Refractometer calibration liquid calibration

method may need to be altered in order to follow/ solution (3.5%).

comply with the standard.

• Conductivity meter is calibrated using standard

1.2 This method is based on ASTM B117 edition 2011 which solution, used for checking the conductivity of the

consists of: water used for the salt solution.

Continuous salt spray test exposure at 35C +/-2C with a 2.3 The chamber temperature may be continuously

salt concentration of 5% Sodium Chloride (NaCL) +/-1%. monitored if required, using an independently

1.3 The chamber will be loaded with test samples as calibrated data logger. For salt spray testing, it may be

required by the customer (or in accordance with satisfactory to record the chamber temperature using

ASTMB117). the Ascott chamber display on a daily basis.

2. Instrumentation Salinty Refractometer (Ascott Accessory No: ACC100)

2.1 All measuring equipment must be calibrated. The A salinity refractometer optimized to give a direct reading of

recalibration renewal date must not fall within the test percentage sodium chloride in the range 0 to 28%, with automatic

temperature compensation.

duration.

View all our accessories at www.ascott-analytical.com

2.1.1 The Ascott corrosion chamber should be calibrated

for chamber air temperature as a minimum.

2.4 Exposure to Salt Solution

If required, the following ‘chamber’ items may also

Collection rates are monitored manually using

be calibrated:

collection vessels of a suitable cross sectional area and

• Chamber air saturator temperature. capacity at sample height. The collection rates are to be

• Chamber air pressure gauge (atomiser pressure). within the range of range of 1-2ml/hr/80cm2.

Ascott corrosion chambers may be fitted with a relative 2.5 The salt solution exposure is by means of atomised

humidity sensor. Calibration is not required for as this is salt water solution using compressed air. The air

not in use during salt spray testing. delivered to the spray nozzle must be ‘heated and

2.2 Peripheral devices also should be calibrated prior to use moistened’ by passing the air through and air saturator,

and may include the following: the temperature of the chamber air saturator is set

according to the pressure at the atomiser gauge. (See

• Hand Held pH Meter – is calibrated using buffer ASTMB117 table for reference).

solutions and following manufacturers’ instructions.

Corrosion Test Chambers Testing climate resistance to the limit

Corrosion Test Methodology | ASTM B117 Testing Method Statement | All Ascott Corrosion Chambers | 2

3. Salt Solution Preparation 5. Operation

5.1 Pre-test evaluation.

CorroSalt for Salt Spray Testing (Accessory No: SALA530)

Run a 24 hour cycle of the test with the chamber

Highest purity salt for fully compliant testing. For all

UKAS empty and collection funnels positioned, record the

salt spray testing including the stringent ASTM B117.

Available in 25Kg (55lb) drums or bags.

ACCREDITED

temperature and ensure it remains in tolerance of

View all our accessories at www.ascott-analytical.com

35C+/-2C.

Ensure the salt fog collection rates are within the

3.1 Salt solution to be prepared in accordance with ASTM B117. expected range of 1-2ml/hr/80cm2. Record all results.

Check that the water conductivity is measured and Check that the collected solution pH falls within the

monitored to the requirements of the standard using a requirement of the standard. Record all results.

conductivity meter. If required, adjust the pH of the salt solution within the

Salt solution concentration is measured & monitored solution reservoir in order to offset any change to the

using a calibrated Salinity Refractometer. pH when collected; so that the collected, the solution is

within requirements of the standard.

Salt solution pH is measured & monitored using a

calibrated pH Meter. This may require additional testing to prove results

before testing with samples commences.

After allowing the solution to stabilise for several

hours, the salinity and pH is measured and recorded. 5.2 Starting the test cycle

Any adjustments to the pH can be made using reagent 5.2.1 Test Exposure Conditions.

grade hydrochloric acid (HCL) to increase the acidity, or

• Position samples within the chamber in accordance

regent grade Sodium hydroxide (NaOH) to reduce the

of the test standard.

acidity. Record all results.

• Ensure that no samples ‘touch’ or ‘shadow’ other

Temperature & Humidity Profile during Testing

samples and that droplets from one sample cannot

fall on to other samples.

• Start the test cycle and record test parameters at start.

• Spray continuously with atomised salt water at a

constant chamber temperature of +35C.

• Exceptions to continuous testing are permitted

in order to record fallout collection rates and PH of

collected solution daily. Typically, this would be at the

same time daily and omitted at weekends.

4. Sample Preparation • Insert clean and empty salt spray collection vessels

4.1 Samples are prepared to customer requirements. around the samples, preferably at sample height

inside the chamber, and never underneath samples or

Photographs should be taken of each sample prior to anything else that could drip into them from above.

starting the test.

• Photographs may be taken of the samples at

customer specified intervals throughout the test.

Corrosion Test Chambers Testing climate resistance to the limit

Corrosion Test Methodology | ASTM B117 Testing Method Statement | All Ascott Corrosion Chambers | 3

5.3 Quality Control 5.4 After Exposure

5.3.1 Daily checks to ensure the standard is being 5.4.1 The test samples should be rinsed with deionised

followed with variable parameters within limits – water and carefully dried. Exact method

Record all parameters. determined by customer.

• Check that the chamber temperature is within Photographs of the samples should be taken.

acceptable limits. 5.5 Deviation Handling

• Check that air saturator temperature is within 5.5.1 General deviations such as downtime, out of

acceptable limits. tolerance recordings should be noted in the test

• Check that atomiser air pressure is within report, including details of any alterations made.

acceptable limits. For futher information, please contact us.

• Check that collected solution is within

acceptable limits for fallout rates.

• Check the reservoir salt solution is within 5.0%

Ascott Analytical Equipment Limited

+/-1.0% NaCl.

6-8 Gerard, Lichfield Road Industrial Estate,

• Record the reservoir salt solution pH. Tamworth, Staffordshire,

• Check that collected salt solution pH is within B79 7UW, Great Britain

acceptable limits. T +44 (0)1827 318040

• Record the conductivity of the DI water when F +44 (0)1827 318049

used. E sales@ascott-analytical.com

• Monitor the level of salt solution in the reservoir W www.ascott-analytical.com

and ensure that there is enough for the next

24/48 hours. (Allow extra for weekends).

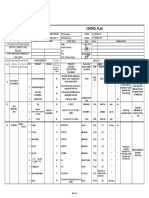

Typical Daily Checks

Hours Chamber Air Sat Collected ml/hr Collected Reservoir Pump Atomiser Initials Photos

Temp Temp (2 vessels per atomiser) Solution Salinity Speed Air Pressure Taken

°C °C pH % PSI

1 2

©Copyright 2019 Ascott Analytical Equipment Limited. Issue A: 2019

Corrosion Test Chambers Testing climate resistance to the limit

You might also like

- New CQI-9 4th EditionDocument6 pagesNew CQI-9 4th EditionDFLQMS50% (2)

- ISO 6270 2 2005 Testing Methodology V1 PDFDocument3 pagesISO 6270 2 2005 Testing Methodology V1 PDFFadi MagdyNo ratings yet

- 521+technical Data Sheet V-6Document2 pages521+technical Data Sheet V-6TeenTeen GaMingNo ratings yet

- Ti SPC Ohe Fasteners 0120 PDFDocument31 pagesTi SPC Ohe Fasteners 0120 PDFCounter RoverNo ratings yet

- Limestone Resources of Sri Lanka PDFDocument67 pagesLimestone Resources of Sri Lanka PDFmaddumaNo ratings yet

- PMA at A GlanceDocument10 pagesPMA at A GlancemaddumaNo ratings yet

- Deepstar - Multiphase FlowDocument1,122 pagesDeepstar - Multiphase Flowfebrian100% (1)

- Corrosion Testing and MeasurementsDocument9 pagesCorrosion Testing and MeasurementsVaish NaviNo ratings yet

- Fastener PDFDocument12 pagesFastener PDFdiegomilitojNo ratings yet

- Astm e 1251-2011Document10 pagesAstm e 1251-2011ERDA TPI REPORTNo ratings yet

- Complete Immersion Phosphating LineDocument8 pagesComplete Immersion Phosphating LineStay AwayNo ratings yet

- Operating Salt Spray (Fog) Apparatus: Standard Practice ForDocument11 pagesOperating Salt Spray (Fog) Apparatus: Standard Practice ForFelipeMoriNo ratings yet

- MIL-STD-810G Salt Spray Portion OnlyDocument10 pagesMIL-STD-810G Salt Spray Portion Onlyeklock01No ratings yet

- ImpregnationDocument9 pagesImpregnationsivamettNo ratings yet

- Olympus Inspector Software PDFDocument12 pagesOlympus Inspector Software PDFFALRepresentaionesNo ratings yet

- Geomet 500 PDFDocument2 pagesGeomet 500 PDFKaran Chadha100% (1)

- Data Sheet HV-HR ItDocument3 pagesData Sheet HV-HR ItKemo TufoNo ratings yet

- Effect of Input Cutting Parameters on Geometric Runout ControlsDocument5 pagesEffect of Input Cutting Parameters on Geometric Runout ControlserwindNo ratings yet

- Industrial Fasteners, Nuts & BoltsDocument79 pagesIndustrial Fasteners, Nuts & BoltsMudduKrishna shettyNo ratings yet

- TL245 English 2004Document8 pagesTL245 English 2004Elliott RussellNo ratings yet

- Carbon Steel Billets, Blooms, Slabs and Bars For Forgings - Specification (Fifth Revision)Document12 pagesCarbon Steel Billets, Blooms, Slabs and Bars For Forgings - Specification (Fifth Revision)SreenathaNo ratings yet

- FastenerDocument46 pagesFastenerTechproNo ratings yet

- Coating Weight and Chemical Analysis of Zinc-Nickel Alloy Electrolytically Coated On Steel SheetDocument6 pagesCoating Weight and Chemical Analysis of Zinc-Nickel Alloy Electrolytically Coated On Steel SheetROHITNo ratings yet

- Specs and Operation of Salt Spray Test ChamberDocument5 pagesSpecs and Operation of Salt Spray Test ChamberRoyNo ratings yet

- Hexalubulour BoltDocument20 pagesHexalubulour BoltMitesh MakvanaNo ratings yet

- ASTM A563 - Portland BoltDocument5 pagesASTM A563 - Portland BoltamrNo ratings yet

- Shot Peening Coverage Requirements: Academic StudyDocument6 pagesShot Peening Coverage Requirements: Academic StudyUmit AytarNo ratings yet

- Austempered Ductile Iron Castings: Standard Specification ForDocument9 pagesAustempered Ductile Iron Castings: Standard Specification ForRaja Hone0% (1)

- CS-11000Document17 pagesCS-11000Engenharia APedro100% (1)

- Effect of Boron PDFDocument8 pagesEffect of Boron PDFKishan krNo ratings yet

- AQL 2.5 acceptance sampling tableDocument3 pagesAQL 2.5 acceptance sampling tableJahidul IslamNo ratings yet

- High Tensile FastenersDocument1 pageHigh Tensile FastenersSandeep Kumar0% (1)

- D271389 F' PDFDocument13 pagesD271389 F' PDFReza AbdolahiNo ratings yet

- JIS B 0405 General TolerancesDocument1 pageJIS B 0405 General TolerancesGiang Nguyễn BáNo ratings yet

- Rubber Products in Automotive Applications: Standard Classification System ForDocument53 pagesRubber Products in Automotive Applications: Standard Classification System Fordavid dawoudNo ratings yet

- The New Era in Corrosion TestingDocument4 pagesThe New Era in Corrosion Testingnikopigni2No ratings yet

- Iso 6508 3 2015 en PDFDocument8 pagesIso 6508 3 2015 en PDFMohan.v100% (1)

- Etq 114Document12 pagesEtq 114Patricio100% (1)

- D2 Tool Steel - CrucibleDocument2 pagesD2 Tool Steel - CrucibleRockWagonNo ratings yet

- Is 209 - 1992 Zinc Ingot - SpecificationDocument5 pagesIs 209 - 1992 Zinc Ingot - SpecificationRam NiwasNo ratings yet

- ATE N 553 81.09 (En)Document11 pagesATE N 553 81.09 (En)Miguel QueirosNo ratings yet

- Computer-Aided Casting Design and Simulation PDFDocument9 pagesComputer-Aided Casting Design and Simulation PDFmonish KrishnaNo ratings yet

- M6x1.0x23 Long HHS Control PlanDocument2 pagesM6x1.0x23 Long HHS Control PlanDhanluxmi AutomaticsNo ratings yet

- Automotive Gray Iron Castings: Standard Specification ForDocument5 pagesAutomotive Gray Iron Castings: Standard Specification ForJosé Ramón GutierrezNo ratings yet

- Chemical Analysis of Steel Products: Standard Test Methods, Practices, and Terminology ForDocument6 pagesChemical Analysis of Steel Products: Standard Test Methods, Practices, and Terminology ForoslatNo ratings yet

- Aisi 1018Document1 pageAisi 10188085roNo ratings yet

- Engineering Material Specification: Not To Be Used For New DesignDocument5 pagesEngineering Material Specification: Not To Be Used For New Designjavier ortizNo ratings yet

- Heat Treatment - Self Assessment - CQ 9Document12 pagesHeat Treatment - Self Assessment - CQ 9sunil mathewNo ratings yet

- White Paper Automated Ultrasonic Inspection of Tube To Tube Sheet WeldsDocument7 pagesWhite Paper Automated Ultrasonic Inspection of Tube To Tube Sheet WeldsdanemsalNo ratings yet

- Hammer Drive ScrewDocument1 pageHammer Drive ScrewNisa BN QANo ratings yet

- Automotive Porosity Sealing by Design - LoctiteDocument20 pagesAutomotive Porosity Sealing by Design - LoctiteRaghavendra SarafNo ratings yet

- ISO Managementsysteme Seminare & Audits AIAG CQI Standards Automotive SupportDocument31 pagesISO Managementsysteme Seminare & Audits AIAG CQI Standards Automotive SupportMohamed Haris100% (1)

- Principles of Almen Strip Selection: Academic StudyDocument5 pagesPrinciples of Almen Strip Selection: Academic StudyUmit AytarNo ratings yet

- Validation of Salt Spray Corrosion TestDocument7 pagesValidation of Salt Spray Corrosion TestMateiNo ratings yet

- Astm E1558.24503Document13 pagesAstm E1558.24503Juan Shevchenko100% (1)

- Engineering Standards: Material Specification Metals GM6435MDocument6 pagesEngineering Standards: Material Specification Metals GM6435MAkmal NizametdinovNo ratings yet

- 3455 1971 Reff2020Document17 pages3455 1971 Reff2020Ashish DubeyNo ratings yet

- Sno Product Indian British German American Japanese RussianDocument6 pagesSno Product Indian British German American Japanese Russianyoge1130No ratings yet

- Surface Pretreatment by Phosphate Conversion CoatiDocument49 pagesSurface Pretreatment by Phosphate Conversion CoatiJhon QsacNo ratings yet

- Metal Solid IronDocument48 pagesMetal Solid IronX800XL100% (1)

- ISO 7253 2001 Method Statement PDFDocument4 pagesISO 7253 2001 Method Statement PDFFadi MagdyNo ratings yet

- ISO9227 Method Statement PDFDocument4 pagesISO9227 Method Statement PDFFadi MagdyNo ratings yet

- Change Request Form:: Objectives Product / Service Budget MilestonesDocument1 pageChange Request Form:: Objectives Product / Service Budget MilestonesmaddumaNo ratings yet

- Wall PDFDocument87 pagesWall PDFEmil SánchezNo ratings yet

- Accelerated Corrosion Testing EquipmentDocument1 pageAccelerated Corrosion Testing EquipmentmaddumaNo ratings yet

- Astm b117 Testing v1Document3 pagesAstm b117 Testing v1maddumaNo ratings yet

- Phase I Templates v4.0Document12 pagesPhase I Templates v4.0maddumaNo ratings yet

- Phase II Templates v4.0Document7 pagesPhase II Templates v4.0maddumaNo ratings yet

- Phase III Action&Dec Log v4.0Document1 pagePhase III Action&Dec Log v4.0maddumaNo ratings yet

- Activity List - PMA Phase III v4.0Document1 pageActivity List - PMA Phase III v4.0maddumaNo ratings yet

- ACI 201.1R-08 Guide For Conducting A Visual Inspection of Concrete in ServiceDocument19 pagesACI 201.1R-08 Guide For Conducting A Visual Inspection of Concrete in ServicehoustonhimselfNo ratings yet

- PMA OverviewDocument18 pagesPMA OverviewmaddumaNo ratings yet

- Holcim DPW - Project Management PDFDocument33 pagesHolcim DPW - Project Management PDFmaddumaNo ratings yet

- Holcim DPW - Project Management PDFDocument33 pagesHolcim DPW - Project Management PDFmaddumaNo ratings yet

- Pressure Test Plan - Direct Team - 180809Document41 pagesPressure Test Plan - Direct Team - 180809maddumaNo ratings yet

- Pressure Test Plan Access (DL Nagollagama) 09082018Document66 pagesPressure Test Plan Access (DL Nagollagama) 09082018maddumaNo ratings yet

- ITI Test Report - Setting Time An Other TestsDocument2 pagesITI Test Report - Setting Time An Other TestsmaddumaNo ratings yet

- SCC Meeting Points TemplateDocument1 pageSCC Meeting Points TemplatemaddumaNo ratings yet

- How Chemistry Underpins LifeDocument27 pagesHow Chemistry Underpins LifeDemi RoseNo ratings yet

- SEAFARERS TRAINING CENTER FIRE PREVENTION AND FIRE FIGHTINGDocument106 pagesSEAFARERS TRAINING CENTER FIRE PREVENTION AND FIRE FIGHTINGTulia TapiaNo ratings yet

- Heat and Mass Balance (Desinged)Document9 pagesHeat and Mass Balance (Desinged)abdulfetahNo ratings yet

- Rich Gas and Lean GasDocument7 pagesRich Gas and Lean GasManish GautamNo ratings yet

- Microsoft Word - 4-State of Matter - Gaseous StateDocument5 pagesMicrosoft Word - 4-State of Matter - Gaseous StateSatya KamNo ratings yet

- Alkanes HQDocument28 pagesAlkanes HQHaslimi Bin HassanNo ratings yet

- Sulfur DegassingDocument15 pagesSulfur DegassingAbdullahNo ratings yet

- Advanced Process Design in High Volume Kneader Reactors Using Multiple Feed Ports To Avoid Crust Forming Foaming and Low Heat TransferDocument10 pagesAdvanced Process Design in High Volume Kneader Reactors Using Multiple Feed Ports To Avoid Crust Forming Foaming and Low Heat TransferRaja WajahatNo ratings yet

- Version ThreeDocument35 pagesVersion Threeerick kanyiNo ratings yet

- Advanced Solid State Physics by Philip Phillips PPDocument2 pagesAdvanced Solid State Physics by Philip Phillips PPSubhadip PalNo ratings yet

- FKCH 8 HHM BYSJxe F8 ZG 74Document45 pagesFKCH 8 HHM BYSJxe F8 ZG 74MahaNo ratings yet

- Membrane PotentialsDocument7 pagesMembrane PotentialsJessica Leika MatibagNo ratings yet

- Advanced Fluid Characterization (Schlumberger)Document8 pagesAdvanced Fluid Characterization (Schlumberger)Astrid Hardtke100% (1)

- Molecular Weight - What Average to UseDocument12 pagesMolecular Weight - What Average to Usebilal sheikhNo ratings yet

- Theoretical Chemistry ProblemsDocument65 pagesTheoretical Chemistry Problemstun lykoungNo ratings yet

- Acid Bases & SaltDocument16 pagesAcid Bases & SaltKK patel0% (1)

- Adsorption Isotherms in Liquid PhaseDocument33 pagesAdsorption Isotherms in Liquid PhasetarisaiNo ratings yet

- Physical Chemistry Part 1 PPT NOTESDocument85 pagesPhysical Chemistry Part 1 PPT NOTESKrizzia Anne ShengNo ratings yet

- 2-Atomic BookletDocument91 pages2-Atomic BookletManashNo ratings yet

- What Are Valence ElectronsDocument3 pagesWhat Are Valence ElectronsJeanisil CerenoNo ratings yet

- Engineering Thermodynamics ProblemsDocument3 pagesEngineering Thermodynamics Problemsdhruv0010% (1)

- Practical Guide Edexcel2Document42 pagesPractical Guide Edexcel2Hady JawadNo ratings yet

- Phenol Evaluation - FinalDocument23 pagesPhenol Evaluation - FinalCristian TorrezNo ratings yet

- Exercise 1Document4 pagesExercise 1Soh Ming LunNo ratings yet

- Spettro Infrarosso Del KCLO3Document6 pagesSpettro Infrarosso Del KCLO3AlessandroNo ratings yet

- C Topic 3 OxidesDocument10 pagesC Topic 3 Oxidesapi-546066323No ratings yet

- Chem Lab#11 PostlabDocument5 pagesChem Lab#11 PostlabAthia Ava Luna100% (1)

- Sample Heat Load Calculation For General Office Meeting RoomDocument6 pagesSample Heat Load Calculation For General Office Meeting RoomArun PrakashNo ratings yet

- Practice Set 19 (Fins)Document2 pagesPractice Set 19 (Fins)Nibir SahaNo ratings yet