Professional Documents

Culture Documents

Fire Detection System: Prior To BB-1439

Uploaded by

Alex GuáncOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fire Detection System: Prior To BB-1439

Uploaded by

Alex GuáncCopyright:

Available Formats

Fire Protection

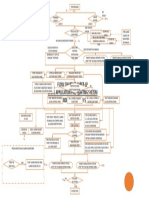

Fire Detection System

Prior to BB-1439

PRESS PRESS PRESS PRESS

MASTER MASTER MASTER MASTER

WARNING CAUTION CAUTION WARNING

TO RESET TO RESET TO RESET TO RESET

1

L ENG FIRE INVERTER CABIN DOOR ALT WARN R ENG FIRE

L FUEL PRESS R FUEL PRESS

BRT

L OIL PRESS L GEN OVHT AP TRIM FAIL R GEN OVHT R OIL PRESS

APPROACH L CHIP R CHIP

PLATE L BL AIR FAIL AP DISC R BL AIR FAIL PRESS

DETECT DETECT TO TEST

2 FIRE DETECTION CB

1 ANNUNCIATOR

PANEL

3 TEST SWITCH

FIRE DETECTORS

CONTROL

AMPLIFIERS

FIRE

DETECTORS

2 FIRE LEFT LEFT 3

5 5 7.5 3

DET

2

ICE FUEL

VANE CONTROL 1

CONTROL HEAT

5 7.5

OFF

RIGHT RIGHT TEST SWITCH

FIRE DET & FIRE EXT

King Air 200 Developed for Training Purposes 4D-1

October 1998

CAE SimuFlite

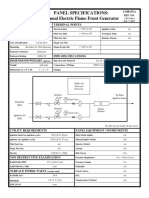

Fire Detection System

BB-1439, 1444 and subsequent;

BT-35 and subsequent;

BL-139 and subsequent

FIRE SENSOR

ELEMENT

PRINTED

CIRCUIT

CARDS

FIRE SENSOR

ELEMENT

SENSOR RESPONDER

1 SIMPLIFIED CIRCUIT

RESPONDER

28 V DC ALARM

SWITCH (N.O.)

TEST SWITCH

B

C

D SENSOR

ELEMENT

LEFT OR RIGHT

ENGINE INTEGRITY SWITCH

N.C. HELD CLOSED BY

NORMAL SENSOR PRESSURE

4D-2 Developed for Training Purposes King Air 200

October 1998

Fire Protection

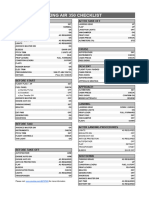

Fire Extinguishing System

PRESS PRESS PRESS PRESS

L ENG FIRE R ENG FIRE

PUSH TO EXT PUSH TO EXT MASTER

MASTER MASTER MASTER

WARNING CAUTION CAUTION WARNING

D OK D OK

TO RESET TO RESET TO RESET TO RESET

1

L ENG FIRE INVERTER CABIN DOOR ALT WARN R ENG FIRE

L FUEL PRESS R FUEL PRESS

BRT

L OIL PRESS L GEN OVHT AP TRIM FAIL R GEN OVHT R OIL PRESS

APPROACH L CHIP R CHIP PRESS

PLATE DETECT L BL AIR FAIL AP DISC R BL AIR FAIL DETECT TO TEST

2 TEST

SWITCH

1 ANNUNCIATOR

PANEL

3 FIRE EXTINGUISHER

SUPPLY CYLINDER

LEFT

MONITOR

MODULE

RIGHT

MONITOR

MODULE

PRESSURE

GAGE

2

LEFT

3

EXT

2

RIGHT

1

EXPLOSIVE

SQUIB

OFF

TEST SWITCH 3 FIRE EXTINGUISHER

FIRE DET & FIRE EXT SUPPLY CYLINDER

King Air 200 Developed for Training Purposes 4D-3

October 1998

CAE SimuFlite

4D-4 Developed for Training Purposes King Air 200

October 1998

Fire Protection

Fire Protection Systems

Fire protection systems include:

■ engine fire detection

■ engine fire extinguishing

■ bleed air warning.

Engine Fire Detection

Engine fire detection consists of either infrared sensitive photo-

cells or temperature sensing elements. With either system, an

engine fire illuminates the respective ENG FIRE or FIRE ENG

light on the glareshield panel.

On S/Ns BB-2 to 1438; BB-1440 to 1443; BL-1 to 138, the

detection system consists of three photo-cells strategically

placed in each engine compartment. When sufficient infrared

radiation strikes a cell, a control amplifier relay closes to illumi-

nate the respective ENG FIRE or FIRE ENG light and the MAS-

TER WARNING flashing lights. Once the fire extinguishes and

infrared radiation decreases below a set level, the system

resets and the FIRE light extinguishes.

On S/Ns BB-1439; BB-1444 and subsequent; BL-130 and

subsequent, each engine’s temperature sensing element con-

sists of a sealed stainless steel tube. Within this tube is an inert

gas and an inner core with an active gas. The sensing element

connects to a responder that contains an alarm switch for

detection and and integrity switch for testing.

Exposing a sensing element to temperatures of 450°F (232°C)

along its entire length or 900°F (482°C) along a one-foot section

expands the element’s core gases. This closes the responder

alarm switch to illuminate the respective ENG FIRE light and

trigger the MASTER WARNING flashing lights. Once the sens-

ing element cools below its trigger temperature, the ENG FIRE

light extinguishes. The MASTER WARNING lights, however, do

not extinguish until they are reset.

King Air 200 Developed for Training Purposes 4D-5

October 1998

CAE SimuFlite

Engine Fire Extinguishing

If installed, the engine fire extinguishing system consists of a fire

extinguisher bottle in each main wheel well. Spray nozzles con-

nected to each bottle direct fire extinguishing agent to the engine

accessory section and power sections. Each bottle contains

approximately 2.5 lbs of Halon 1301 pressurized with dry nitrogen

to 450 PSI at 60°F (pressurization is directly proportional to OAT).

The fire detection system illuminates the ENG FIRE PUSH

TO EXT light. Pressing that light supplies DC power to the

extinguisher bottle’s explosive squib. The squib’s detonation

dislodges a sealing disc so that bottle contents flow to the spray

nozzles. Once a bottle discharges, the respective D or DISCH

caption illuminates.

Testing

Aircraft with a photo-cell detection system have a rotary TEST

SWITCH with six positions: L and R EXT on left side of switch;

3, 2, 1 on right side of switch, and OFF. Aircraft with sensing

elements have a switch labeled TEST SWITCH FIRE DET &

EXT with positions of EXT L-R and DET L-R (BB-1439, BB-144

to 1462) or a switch labeled TEST SWITCH ENG FIRE SYS

with OFF, EXT L-R and DET L-R positions (BB-1463 and sub-

sequent; BL-139 and subsequent). Aircraft without extin-

guishing systems eliminate the EXT labels on the switches.

Rotating the TEST switch through positions 3, 2, and 1 or DET

L-R illuminates the left and right red MASTER WARNING flash-

ers, the red L and R ENG FIRE annunciators, and the red L and

R ENG FIRE PUSH TO EXT lights (if installed). If any of the fire

detection annunciators fail to illuminate at each test position, a

malfunction exists in the detector circuits.

Rotating the switch to the L/R EXT or EXT L-R positions tests

the fire extinguishing system. Illumination of the ENG FIRE

light’s D (DISCH) caption indicates the bulb is functioning; illu-

mination of the OK caption indicates detector circuitry and

squib-firing circuits are operational.

4D-6 Developed for Training Purposes King Air 200

October 1998

Fire Protection

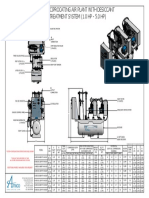

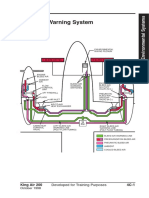

Engine Bleed Air Warning

Polyflow tubing that parallels the bleed air lines from the firewall

into the cabin provides a warning system for a bleed air leak.

These parallel tubing lines are pressurized with instrument

bleed air at approximately 18 PSI.

If a bleed air line ruptures, excessive heat (200°F) melts the

adjacent tubing to release pressure. When pressure is reduced,

a switch in the line under the copilot floor closes to illuminate

the respective BL AIR FAIL annunciator.

King Air 200 Developed for Training Purposes 4D-7

October 1998

CAE SimuFlite

Fire Protection System

Power Source No. 1 Dual-Fed bus – fire detection

Hot Battery bus – optional fire extinguishing

Portable hand fire extinguishers

Distribution Extinguisher bottle to corresponding engine

(no crossfiring)

Control TEST SWITCH FIRE DET (& EXT, if installed)

ENG FIRE-PUSH TO EXT (L/R) lens/switch

(if installed)

Monitor ENG FIRE (L/R) annunciators

Red ENG FIRE-PUSH TO EXT (L/R) lens

(if installed)

Amber D lens to confirm electrical wiring

continuity (if installed)

Green OK lens to test system (if installed)

MASTER WARNING (L/R) flashers

Protection FIRE DET CB (5A)

FIRE extinguisher fuse (if installed)

(prior to BB-1096)

FIRE EXTINGUISHER CB (5A) (if installed)

(BB-1096 and subsequent)

4D-8 Developed for Training Purposes King Air 200

September 2002

You might also like

- Practical Applications Circuits HandbookFrom EverandPractical Applications Circuits HandbookRating: 5 out of 5 stars5/5 (1)

- 07 Fire ProtectionDocument8 pages07 Fire ProtectionSteven GaitanNo ratings yet

- Tabel Semne Imo PDFDocument1 pageTabel Semne Imo PDFAlexandru Si Larisa Serb-AlexeNo ratings yet

- Overhead Panel: Decel DecelDocument1 pageOverhead Panel: Decel DecelMateusz BąkNo ratings yet

- Flow Chart of Hyper-Lp Local Application Fire Fighting System (Unattended Machinery Space)Document1 pageFlow Chart of Hyper-Lp Local Application Fire Fighting System (Unattended Machinery Space)Mohammad Jahid AlamNo ratings yet

- Handling Dual HYD Failures Copy LMDocument24 pagesHandling Dual HYD Failures Copy LMDevdatt Sonde67% (3)

- Hawker 00XPC-Master Warning SystemDocument14 pagesHawker 00XPC-Master Warning SystemJose LaraNo ratings yet

- AMM - A318, A319, A320, A321 - Rev. Num - 39 - 01-Aug-2023 - Figure 36-10-00-11700-00-B (SHEET 1) - Pneumatic System - SchematicDocument1 pageAMM - A318, A319, A320, A321 - Rev. Num - 39 - 01-Aug-2023 - Figure 36-10-00-11700-00-B (SHEET 1) - Pneumatic System - SchematicMuhammad Luthfi FadhilahNo ratings yet

- Fire ProtectionDocument11 pagesFire ProtectionMichel Garandán PizzornoNo ratings yet

- Piping and Instrumentation DrawingDocument1 pagePiping and Instrumentation Drawingeke23No ratings yet

- Fire Protection System Hawker 800XPDocument1 pageFire Protection System Hawker 800XPClive Rudd FernandezNo ratings yet

- 3508B Engine Controls: 992G Wheel LoaderDocument40 pages3508B Engine Controls: 992G Wheel LoaderFrancisco BeizaNo ratings yet

- On-Board Diagnostic Wiring Diagram (Instrument Cluster)Document3 pagesOn-Board Diagnostic Wiring Diagram (Instrument Cluster)yanivyehezkelNo ratings yet

- Fire Control EquipmentDocument1 pageFire Control EquipmentJephthah Jude Tadeo GaleosNo ratings yet

- Construction: Engine - 3Uz-Fe Engine 67Document3 pagesConstruction: Engine - 3Uz-Fe Engine 67bob loblawNo ratings yet

- CHECKLIST A340-600-ToLiss-V003Document8 pagesCHECKLIST A340-600-ToLiss-V003Raul Paul100% (1)

- EXAVATORDocument1 pageEXAVATORrochimun0% (1)

- Beechcraft B200 POH - 05. Supplemental InfoDocument8 pagesBeechcraft B200 POH - 05. Supplemental InfoAgustinNo ratings yet

- 747-400 Checklist PDFDocument3 pages747-400 Checklist PDFJuan GuerreroNo ratings yet

- B737CL Fire ProtectionDocument17 pagesB737CL Fire ProtectionDan StroescuNo ratings yet

- Avr GeneralDocument67 pagesAvr GeneralRukma Goud Shakkari100% (2)

- Panel Specifications: Manual Electric Flame Front Generator: CoronaDocument1 pagePanel Specifications: Manual Electric Flame Front Generator: CoronaOscarNo ratings yet

- Excitation and GeneratorDocument74 pagesExcitation and GeneratorRam Singh100% (1)

- CHECKLIST A340-600-ToLiss-V002Document8 pagesCHECKLIST A340-600-ToLiss-V002its not meNo ratings yet

- Engineering & Installation ManualDocument61 pagesEngineering & Installation ManualThameem AnsariNo ratings yet

- Brother MFC Scanner19042017 - 0003Document1 pageBrother MFC Scanner19042017 - 0003jovanNo ratings yet

- JSEADocument33 pagesJSEAheryane.endahpratiwiNo ratings yet

- 434 590169 0005 - SuppInfoDocument10 pages434 590169 0005 - SuppInfomehmood khanNo ratings yet

- B737-400 Apu Fire: Slide 1 of 73Document10 pagesB737-400 Apu Fire: Slide 1 of 73Mufid Denico DwiseptaNo ratings yet

- Emission Control System: Parts LocationDocument2 pagesEmission Control System: Parts LocationmiketolNo ratings yet

- Primo4 GBDocument9 pagesPrimo4 GBAlaa TebaNo ratings yet

- 2azfe 12 PDFDocument20 pages2azfe 12 PDFmasakpNo ratings yet

- Engine Control System 4B1 MitsubishiDocument6 pagesEngine Control System 4B1 MitsubishimanhNo ratings yet

- Diagrama Nuevo QuemadorDocument1 pageDiagrama Nuevo QuemadorHector0412No ratings yet

- Adcom gtp-830 SMDocument56 pagesAdcom gtp-830 SMrajaNo ratings yet

- Fire Pump Scheme & SLD NewDocument2 pagesFire Pump Scheme & SLD Newalex setiabudiNo ratings yet

- Beechcraft B200 POH - 03. Emergency ProceduresDocument20 pagesBeechcraft B200 POH - 03. Emergency ProceduresAgustinNo ratings yet

- Engine Control System 4a91 3Document1 pageEngine Control System 4a91 3abirNo ratings yet

- Checklist EF Tecnam P-MentorDocument2 pagesChecklist EF Tecnam P-MentorjonathanaldazmNo ratings yet

- Airbus A310 ChecklistDocument4 pagesAirbus A310 ChecklistJonathan NoriegaNo ratings yet

- Operating Manual: 2, 4, 8 Zone Fire Alarm Control PanelDocument5 pagesOperating Manual: 2, 4, 8 Zone Fire Alarm Control Panelparallax1957No ratings yet

- Daily Painting & Inspection Report (WI-05-A2) 170&pipe 1Document1 pageDaily Painting & Inspection Report (WI-05-A2) 170&pipe 1pstechnical_43312697No ratings yet

- Manual Utilizare JuniorDocument15 pagesManual Utilizare JuniorAndrei Chihaia100% (4)

- King350 ChecklistDocument2 pagesKing350 ChecklistVinicyus MartinsNo ratings yet

- Datasheet Pump - 3205ABDocument2 pagesDatasheet Pump - 3205ABprocess1plecoNo ratings yet

- Muster ListDocument2 pagesMuster ListImamFaisalBurhanNo ratings yet

- Electronic Control System 1. Construction: Chassis - A650E Automatic TransmissionDocument1 pageElectronic Control System 1. Construction: Chassis - A650E Automatic Transmissionbob loblawNo ratings yet

- Ete602 Kompetensi 2 Fire AlarmDocument11 pagesEte602 Kompetensi 2 Fire Alarmsabri Wan IbrahimNo ratings yet

- TierrasDocument2 pagesTierrasPedro ArrietaNo ratings yet

- Compresor Duplex.....Document1 pageCompresor Duplex.....Hospital General ManzanilloNo ratings yet

- Data CenterDocument1 pageData CenternadzirulfikriNo ratings yet

- Isceon 49plus RetrofitDocument18 pagesIsceon 49plus RetrofitShirley Gonzalez100% (1)

- Ocp-100 Operation Us 01Document46 pagesOcp-100 Operation Us 01Javier Sanchez SanchezNo ratings yet

- Emcy-003b TFFP - GalleyDocument2 pagesEmcy-003b TFFP - GalleyCosminNo ratings yet

- Avr General3Document61 pagesAvr General3Devendr Prakash100% (1)

- Parts Location: Engine Room Relay BlockDocument3 pagesParts Location: Engine Room Relay BlockPedro Javier Castro SanchezNo ratings yet

- Advanced Technician'S Course: Fuel SystemDocument10 pagesAdvanced Technician'S Course: Fuel SystemFajri Nur HidayatNo ratings yet

- Counter: AWS 50 G1 Single Line Diagram Pakai CompressorDocument1 pageCounter: AWS 50 G1 Single Line Diagram Pakai CompressorroozeipiNo ratings yet

- Bombardier Dash 8 Q400 Fire - Protection PDFDocument21 pagesBombardier Dash 8 Q400 Fire - Protection PDFSwapnil kapadiaNo ratings yet

- Habitat ERP For FIP-058 at DLD Rev03Document8 pagesHabitat ERP For FIP-058 at DLD Rev03Khairi KKamarNo ratings yet

- Windshield Anti-Ice System: King Air 200 4G-1Document14 pagesWindshield Anti-Ice System: King Air 200 4G-1Alex GuáncNo ratings yet

- Auxiliary Fuel Transfer System: Before Engine Start - No TransferDocument14 pagesAuxiliary Fuel Transfer System: Before Engine Start - No TransferAlex GuáncNo ratings yet

- Rudder Boost System: From No. 2 Dual-Fed BusDocument8 pagesRudder Boost System: From No. 2 Dual-Fed BusAlex GuáncNo ratings yet

- Isceon 49plus RetrofitDocument18 pagesIsceon 49plus RetrofitShirley Gonzalez100% (1)

- Schematic Symbols: ON OFFDocument16 pagesSchematic Symbols: ON OFFAlex GuáncNo ratings yet

- BE20 Cockpit Reference PDFDocument438 pagesBE20 Cockpit Reference PDFmalsr100% (1)

- UWG IT Security PlanDocument111 pagesUWG IT Security PlanManuel SantanaNo ratings yet

- Praktikum Modul 7 IPv4 Dan IPv6Document20 pagesPraktikum Modul 7 IPv4 Dan IPv6Joshia Agrisa Anrhiely LutherNo ratings yet

- MOTHERBOARDDocument9 pagesMOTHERBOARDMUQADDAS ABBASNo ratings yet

- B Msgs Server PDFDocument806 pagesB Msgs Server PDFsabkhNo ratings yet

- eCATT Chaining, Parameterization, Creation of Test Data, Test Configuration, System Data (PART IV)Document18 pageseCATT Chaining, Parameterization, Creation of Test Data, Test Configuration, System Data (PART IV)kalidasmNo ratings yet

- Listening Test 25% Intento 1Document11 pagesListening Test 25% Intento 1Adriana LoaizaNo ratings yet

- Service ContractsDocument92 pagesService Contractssantosh7ck0% (2)

- Iec 61000-2-13-2005Document46 pagesIec 61000-2-13-2005D SaiRajaNo ratings yet

- REVA University Bangalore, India: Arjun Haragaller, Rajeev RanjanDocument1 pageREVA University Bangalore, India: Arjun Haragaller, Rajeev RanjanmeghaNo ratings yet

- HILTI Catalogue 2012Document314 pagesHILTI Catalogue 2012Marius RizeaNo ratings yet

- Approach of Image Processing in Diagnosis and Medication of Fungal Infections in Pet AnimalsDocument15 pagesApproach of Image Processing in Diagnosis and Medication of Fungal Infections in Pet AnimalsJohn SnowNo ratings yet

- Mini-Link™ PT 6010 Etsi: Microwave Packet Terminal For High CapacitiesDocument4 pagesMini-Link™ PT 6010 Etsi: Microwave Packet Terminal For High CapacitiesTafadzwa Comfort NyambiraNo ratings yet

- Module 1: Introduction To Operating System: Need For An OSDocument15 pagesModule 1: Introduction To Operating System: Need For An OSNiresh MaharajNo ratings yet

- Braking Unit Braking Resistor Unit CDBR Lkeb Instructions (Toe-C726-2g)Document54 pagesBraking Unit Braking Resistor Unit CDBR Lkeb Instructions (Toe-C726-2g)Pan TsapNo ratings yet

- APPLMC001 - ATX Catalog EnglishDocument519 pagesAPPLMC001 - ATX Catalog EnglishJuanje Tres CantosNo ratings yet

- PC57 12 91 PDFDocument2 pagesPC57 12 91 PDFAlexander Cortez EspinozaNo ratings yet

- Le Veritable Dragon RougeDocument142 pagesLe Veritable Dragon RougeDavid GourmetNo ratings yet

- A3-PageWide F2F Deck 2 28 17 final-ENDocument129 pagesA3-PageWide F2F Deck 2 28 17 final-ENkadirNo ratings yet

- Sean DeCraneDocument59 pagesSean DeCraneMujeeb Ur Rehman KhalilNo ratings yet

- Method of Statement For ThermographerDocument2 pagesMethod of Statement For ThermographerBabu75% (4)

- 2012 - Fail-Over ClusteringDocument34 pages2012 - Fail-Over ClusteringAbdul KasimNo ratings yet

- Key Factors For The Pwa Solution: Agam SetiawanDocument18 pagesKey Factors For The Pwa Solution: Agam SetiawanYsn ArrfNo ratings yet

- Interdomain Multicast Soln Guide 1587050838Document336 pagesInterdomain Multicast Soln Guide 1587050838Balaji RajagopalNo ratings yet

- BHMN SVI3 IOM 34587C 0421 EnglishDocument123 pagesBHMN SVI3 IOM 34587C 0421 Englishgasser ahmedNo ratings yet

- Rohit Bhai RateDocument3 pagesRohit Bhai RateYogesh AryaNo ratings yet

- Al115c Mio Sporty CarburetorDocument2 pagesAl115c Mio Sporty CarburetorDidi IswantoNo ratings yet

- 1st Quarter ICT ReviewerDocument5 pages1st Quarter ICT ReviewerazrielgenecruzNo ratings yet

- DriveCompatibility WikiDocument1 pageDriveCompatibility Wikishida67No ratings yet

- What Is The Difference Between 0.2 and 0.2S Class CTDocument5 pagesWhat Is The Difference Between 0.2 and 0.2S Class CTshaik abdulaleemNo ratings yet

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Machine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsFrom EverandMachine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsRating: 4 out of 5 stars4/5 (4)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Heavy and Extra-heavy Oil Upgrading TechnologiesFrom EverandHeavy and Extra-heavy Oil Upgrading TechnologiesRating: 4 out of 5 stars4/5 (2)

- The Petroleum Engineering Handbook: Sustainable OperationsFrom EverandThe Petroleum Engineering Handbook: Sustainable OperationsRating: 3.5 out of 5 stars3.5/5 (5)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesFrom EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNo ratings yet

- Advanced Production Decline Analysis and ApplicationFrom EverandAdvanced Production Decline Analysis and ApplicationRating: 3.5 out of 5 stars3.5/5 (4)

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsFrom EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsRating: 4 out of 5 stars4/5 (6)

- Guide to the Practical Use of Chemicals in Refineries and PipelinesFrom EverandGuide to the Practical Use of Chemicals in Refineries and PipelinesRating: 5 out of 5 stars5/5 (1)

- Petroleum Production Engineering, A Computer-Assisted ApproachFrom EverandPetroleum Production Engineering, A Computer-Assisted ApproachRating: 4.5 out of 5 stars4.5/5 (11)

- Advanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityFrom EverandAdvanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityRating: 3 out of 5 stars3/5 (2)

- Gas and Oil Reliability Engineering: Modeling and AnalysisFrom EverandGas and Oil Reliability Engineering: Modeling and AnalysisRating: 4.5 out of 5 stars4.5/5 (6)

- Essentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesFrom EverandEssentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesRating: 5 out of 5 stars5/5 (5)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Reservoir Engineering: The Fundamentals, Simulation, and Management of Conventional and Unconventional RecoveriesFrom EverandReservoir Engineering: The Fundamentals, Simulation, and Management of Conventional and Unconventional RecoveriesRating: 5 out of 5 stars5/5 (7)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet