Professional Documents

Culture Documents

Ice and Rain Protection Systems

Uploaded by

Alex GuáncOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ice and Rain Protection Systems

Uploaded by

Alex GuáncCopyright:

Available Formats

Ice and Rain Protection

Windshield Anti-Ice System

G

E

N 50A

B

U

S

TEMP

CONTROLLER

(100-105° F)

NORMAL

OFF

5A

WINDSHIELD HIGH NORMAL SWITCH POSITION

HEAT SWITCH 360 IN2 AT 2.4 WATTS/IN2

G

E

N 50A

B

U

S

TEMP

CONTROLLER

(100-105° F)

NORMAL

OFF

5A

WINDSHIELD HIGH HIGH SWITCH POSITION

HEAT SWITCH 265 IN2 AT 4.5 WATTS/IN2

King Air 200 Developed for Training Purposes 4G-1

October 1998

CAE SimuFlite

Propeller Deice System

King Air 200 BB-6 to BB-815; BB-817 to BB-824;

BL-1 to BL-29

RH PROP

LH PROP

OUTER INNER

MANUAL MANUAL

OVERRIDE OVERRIDE

RELAY RELAY

PROP

TIMER

(34 SECS)

PROP

OUTER INNER AMMETER

LH SHUNT

MANUAL

PROP 20A

DEICE

N N N

O O O

20A 4 3 1

D D D

RH MANUAL U U U

PROP DEICE A A 20A A

L L L

5A F F AUTO F

E E PROP E

D D DEICE D

MANUAL

PROP DEICE B B B

CONTROL U U U

S S S

4G-2 Developed for Training Purposes King Air 200

October 1998

Ice and Rain Protection

Propeller Deice System

King Air 200 BB-816; BL-30 and Subsequent

RH PROP LH PROP

RIGHT LEFT

MANUAL MANUAL

OVERRIDE OVERRIDE

RELAY RELAY

PROP

TIMER

(90 SEC)

MANUAL

PROP DEICE PROP

CONTROL AMMETER

SWITCH

SHUNT

N N N

O O O

4 3 1

20A 20A

D D D

U U U

LH A MANUAL A 20A A

MANUAL L PROP L L

PROP

DEICE F 5A F AUTO F

E E PROP E

D D DEICE D

MANUAL

B PROP DEICE B B

U CONTROL U U

S S S

King Air 200 Developed for Training Purposes 4G-3

October 1998

CAE SimuFlite

Dual-Motor Inertial

Ice Separation System

BB-1439, 1444 and subsequent;

BT-35 and subsequent;

BL-139 and subsequent

DUAL MOTOR

ELECTRIC ACTUATOR SCREEN

INDUCTION AIR

FORWARD LOWER

COWLING

INERTIAL

OIL BYPASS ACCESS ICE VANE

COOLER DOOR PLATE

AFT LOWER

COWLING

4G-4 Developed for Training Purposes King Air 200

October 1998

Ice and Rain Protection

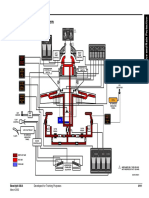

Deice System

FROM NO. 1 FROM NO. 2

DUAL-FED BUS RIGHT P 3

DUAL-FED BUS INSTRUMENT AIR

SINGLE RIGHT BRAKE

TO TAIL BOOTS CYCLE DEICE MANIFOLD

N.

RUDDER

BOOST

O. INSTRUMENT AIR VALVE

5A

OFF

MANUAL 5A

N. C. RIGHT BRAKE DEICE VALVE BRAKE

DEICE

TO OFF SWITCH

WING DEICE TIMER 10 MIN

BOOTS DISTRIBUTOR TIME DELAY

VALVE BLEED AIR VALVES

OPEN PCB

5A LEFT RIGHT

FROM NO. 1 N

BRAKE DEICE ON O

DUAL-FED BUS

ENVIR 1

5A OFF

FROM NO. 2 INSTR & ENVIR OFF D

U

DUAL-FED BUS A

5A L

LH MLG F

E

UPLOCK D

FROM NO. 1 SWITCH

R BL AIR FAIL B

DUAL-FED BUS U

S

PNEUMATIC RIGHT RUDDER

PRESSURE FROM NO. 2 BOOST SERVO

GAGE 5A DUAL-FED BUS RUDDER

N. C.

10

18 PSI 15 PSI

0

PNEUMATIC

20 PRESSURE PRESSURE

PRESSURE

REG REG

SUCTION FILTER N. C.

5A

GAGE FROM NO. 1

4 PSI DUAL-FED BUS

3

4

6 REG

COPILOT'S COPILOT'S

TURN & SLIP

GYRO

ATTITUDE

SUCTION

INCHES OF MERCURY LEFT RUDDER

INDICATOR INDICATOR N. BOOST SERVO

P SWITCH

O.

AFT

PRESSURE

L R

VACUUM TO L BL AIR FAIL

DOOR BULKHEAD

REGULATOR

SEAL

10 10

20 20

AIR

VACUUM FLIGHT

AIR FILTER FLT HOUR

CABIN 1000

N.C. HOURS 1/10

METER N. C. LEFT BRAKE DEICE VALVE

045 62

ALT

7 8

FT

DUMP

SOLENOID

6

9

5

30

25

TO OUTFLOW

10

4

TO DUMP

19 21 2

35

11

VALVE

ACFT ALT

3

100 FT

RATE CABIN

VALVE N. INSTRUMENT AIR VALVE

2

13

17

ALT

15

O.

1

N.O.

15

M

I

M

A

0

UNREGULATED LEFT BRAKE

PRESET

N X

DEICE MANIFOLD

CABIN PRESSURIZATION SOLENOID REGULATED

AIR FILTER CONTROLLER LEFT P 3

INSTRUMENT AIR VACUUM

King Air 200 Developed for Training Purposes 4G-5

September 2002

CAE SimuFlite

4G-6 Developed for Training Purposes King Air 200

October 1998

Ice and Rain Protection

Ice and Rain Protection

Ice and rain protection systems include:

■ wing and stabilizer deice boots

■ engine air inlet lip heat

■ engine inertial separators

■ window and windshield heating

■ pitot heat.

Wing and Stabilizer Deice Boots

A distributor valve controls the instrument air that inflates and

deflates the wing and stabilizer deice boots. Engine bleed air

regulated to 18 PSI supplies the pressure for inflation when the

DEICE switch is in the SINGLE or MANUAL position. To deflate

the boots, bleed air operates a venturi ejector to create a vacu-

um that deflates and holds the boots down when not in use.

The SINGLE cycle inflates the wing boots for six seconds. A

timer switch then deflates the wing boots and inflates the hori-

zontal stabilizer boots for four seconds. With the switch held in

MANUAL, all boots inflate simultaneously and remain inflated

until the switch is released.

Engine Air Inlet Lip Heat

On S/Ns BB-2 to 1265; BL-1 to 28, hot exhaust gases heat the

lip around each air inlet to prevent ice formation during

inclement weather. A scupper in each engine exhaust stack

deflects the hot exhaust gases downward into the hollow lip

(overboard at the 6 o’clock position) tube that encircles the

engine air inlet.

On S/N BB-1266 and subsequent and those with Kit 101-

9048, the engine exhaust scupper in the left exhaust stack

deflects hot gases into the hollow lip and out through the right

exhaust stack.

King Air 200 Developed for Training Purposes 4G-7

October 1998

CAE SimuFlite

Engine Inertial Separators

An electrically actuated inertial vane system on each engine

prevents ice or other foreign objects such as dust or sand from

entering the engine inlet or ice from accumulating on the engine

inlet screen. The system extends an ice vane and bypass door

to accelerate ice and moisture laden air past the engine screen

area to exit overboard through the bypass door.

The ice vane and bypass doors extend or retract simultane-

ously through a linkage system connected to electric actuators.

When the ICE VANE switches are in EXTEND, two green advi-

sory annunciators illuminate as the vane and door extend.

When the ice vanes and bypass doors retract (switch in

RETRACT), the annunciators extinguish.

A manual mechanical backup system operates the system by

flexible cable. If the vanes and doors do not move with 15 sec-

onds after actuation, an amber annunciator illuminates. Pull the

ICE VANE CBs on the copilot CB panel to disable electric

power and pull the manual T- handle for the appropriate engine

to activate the system. If the manual positioning is successful,

the amber annunciator extinguishes and the green annuncia-

tors illuminate.

Do not attempt to retract or extend electrically until the linkage

is properly reset. The vane may be retracted with the manual

system. With the manual system, the electric motor switch posi-

tion must match the manual handle position for a correct

annunciator readout. Maximum airspeed for manual extension

of ice vanes is 160 kts.

On S/Ns BB-1439, 1444 and subsequent; BL-139 and sub-

sequent, the vanes and bypass door are extended or retracted

through a linkage system connected to an electric dual-motor

actuator. Two switches with positions of MAIN or STANDBY

control both the left and right engine system. When either posi-

tion is selected, the remaining position is used to actuate the

backup motor when the main motor is inoperable.

4G-8 Developed for Training Purposes King Air 200

October 1998

Ice and Rain Protection

Propeller Deicing

An electrically heated boot for each propeller blade provides

automatic and manual anti-ice protection for the propellers. The

No. 1 Dual-fed bus powers the automatic system while the No.

3 and 4 Dual-fed bus powers the manual switch.

On BB-2 to 815, 817 to 824, and 991; BL-1 to 29, the propeller

deicing system is an inner and outer heating element on each

propeller blade. With the PROP switch in AUTO, the deicer

timer cycles power for approximately 30 seconds each to the

RH outboard, RH inboard, LH outboard, and LH inboard heat-

ing elements. If the automatic system fails, hold the PROP

MAN switch in either INNER or OUTER to power the corre-

sponding heating elements through a manual override relay.

On BB-816, 825 to 990, 992 and subsequent; BL-30 and

subsequent, and all four-bladed props, each propeller blade

has a single heating element. With the PROP switch in AUTO,

the deicer timer cycles power to the right and then left propeller

heating elements for 90 seconds each. If the automatic system

fails, hold the PROP MAN in MANUAL to power the heating ele-

ments through the manual override relays.

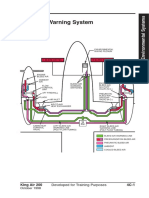

Windshield Anti-Icing

Electric heating elements embedded in the windshield lamina-

tions provide protection against the formation of ice, while air

from the cabin heating system prevents fogging. Heavy duty

windshield wipers provide improved visibility during rainy flight

conditions.

With the pilot or copilot WSHLD ANTI-ICE switch in NORMAL,

an automatic temperature controller senses the windshield

temperature and then attempts to maintain it at approximately

100 to 105°F by energizing the normal heat relay as necessary.

In this mode, both the inboard and outboard areas of the wind-

shield are heated.

King Air 200 Developed for Training Purposes 4G-9

October 1998

CAE SimuFlite

With the switch in HI, the “high” heat relay switch is energized to

apply heat to a more concentrated, essential viewing area of the

windshield. The outboard two-thirds of the windshield is heated.

If the NORMAL position is insufficient to raise the windshield

temperature above freezing, switching to HI nearly doubles the

available heat to the smaller windshield area.

Brake Deice

An optional brake deice system uses instrument bleed air to

warm the main wheel brakes to prevent ice and slush build-up.

With the BRAKE DEICE switch in ON, the left and right sole-

noid shutoff valves in the wheel well open to admit bleed air to

a distributor manifold. The manifold then directs bleed air

toward the brake assembly.

To prevent overheat damage, a timing circuit turns the deice

system off 10 minutes after gear is retracted by closing the

solenoid valve.

CAUTION: Use of brake deice during engine-out proce-

dures substantially reduces the effectiveness of rudder

boost assistance. Turn brake deice off for takeoff.

4G-10 Developed for Training Purposes King Air 200

October 1998

Ice and Rain Protection

Pitot and Stall Warning Vane Anti-Icing

Electrical heating warms the pitot masts and stall warning vane.

The static plates are unheated.

With the PITOT switches on, the No. 1 Dual-fed (left pitot) and

No. 2 Dual-fed (right pitot) buses power the heating elements

with 28V DC

With the STALL WARN switch on, the No. 2 Dual-fed bus pow-

ers the vane heating element. To prevent stall warning vane

from overheating, a safety switch through the left main landing

gear limits voltage. With weight-on-wheels, the heating element

only receives 12V DC. Once airborne, the heating element

receives 28V DC.

King Air 200 Developed for Training Purposes 4G-11

October 1998

CAE SimuFlite

Ice and Rain Protection

Surface Deice System

Power Source Bleed air

No. 1 Dual-Fed bus

Distribution Wing leading edge boots

Horizontal stabilizer leading edge boots

Control DEICE CYCLE switch

SINGLE – inflation/deflation of wing boots,

then horizontal stabilizer boots

MANUAL – inflation of all boots

simultaneously

Monitor Visual monitoring for wing

Pneumatic gages

Protection Circuit breakers

Prop Heat System

Power Source No. 1 Dual-Fed bus (auto)

No. 3 and 4 Dual-Fed bus (manual)

Distribution Heated boot for each propeller blade

Control Switches

PROP AUTO

PROP MANUAL

INNER/OUTER (200 only)

Monitor Prop ammeter

Loadmeters

Protection Circuit breakers/circuit breaker switch (auto)

4G-12 Developed for Training Purposes King Air 200

September 2002

Ice and Rain Protection

Brake Deice

Power Source Engine P3 bleed air

Control BRAKE DEICE switch

Monitor BRAKE DEICE ON annunciator

Protection 10-minute timer, CB

Pitot Heat

Power Source Dual-Fed buses Nos 1/2

Control PITOT circuit breaker switches

Protection 2-minute ground operation limit

Stall Warning Heat

Power Source Dual-Fed bus No. 2

Control STALL WARN circuit breaker switches

Landing Gear safety switch

Protection CIRCUIT BREAKER SWITCH

Fuel Vent Heat

Power Source Dual-Fed buses Nos 1/2

Control FUEL VENT circuit breaker switches

King Air 200 Developed for Training Purposes 4G-13

September 2002

CAE SimuFlite

Windshield Heat

Power Source L/R GEN bus

Control WSHLD ANTI-ICE switches

Protection Circuit breaker (5A)

Temperature sensing element

Temperature controller

50A current limiters

Ice Vanes

Power Source Dual-Fed buses Nos 1/2

Control ICE VANE switches

VANE MANUAL PULL handle

Monitor ICE VANE amber and green annunciators

Protection Circuit breakers

Manual override system

4G-14 Developed for Training Purposes King Air 200

October 1998

You might also like

- Rudder Boost System: From No. 2 Dual-Fed BusDocument8 pagesRudder Boost System: From No. 2 Dual-Fed BusAlex GuáncNo ratings yet

- Cat Dcs Sis Controller4Document15 pagesCat Dcs Sis Controller4Seba BoreseNo ratings yet

- Rungta Mines - Query List - To CustomerDocument4 pagesRungta Mines - Query List - To CustomerkritikaNo ratings yet

- Kenwood-KAF1010 - 3010 AmpDocument17 pagesKenwood-KAF1010 - 3010 AmpmikisdNo ratings yet

- Eil Job No.: A545: OwnerDocument35 pagesEil Job No.: A545: OwnerSandip SurNo ratings yet

- Uniden Bearcat BC9000XLT (Manual)Document57 pagesUniden Bearcat BC9000XLT (Manual)Theodor EikeNo ratings yet

- Air-Handler-Wiring-Diause c3Document38 pagesAir-Handler-Wiring-Diause c3Beltazor HellboyNo ratings yet

- TV LG KCP 29C85Document18 pagesTV LG KCP 29C85Anonymous lQyR2IWNo ratings yet

- P68C Cockpit PanelsDocument2 pagesP68C Cockpit PanelsHistoric ArchivesNo ratings yet

- Technical Information Series D3A General Description: Directional Control ValvesDocument3 pagesTechnical Information Series D3A General Description: Directional Control Valvess bNo ratings yet

- Renr7948renr7948 01 P PDFDocument12 pagesRenr7948renr7948 01 P PDFTbgrhvNo ratings yet

- MECHATRO HANDBOOK SELF DIAGNOSIS AND TROUBLESHOOTING GUIDEDocument40 pagesMECHATRO HANDBOOK SELF DIAGNOSIS AND TROUBLESHOOTING GUIDEPaul Galvez100% (6)

- SD130 - Ground DistributionDocument5 pagesSD130 - Ground Distributionjanuar1983No ratings yet

- 32-Tap Digitally Programmable Potentiometer (DPP™) Features: Logen FreeDocument12 pages32-Tap Digitally Programmable Potentiometer (DPP™) Features: Logen Freejorge gerNo ratings yet

- 610A-FB Operator's Instruction ManualDocument7 pages610A-FB Operator's Instruction ManualAlfonso LeónNo ratings yet

- DPAS_10E-550EDocument4 pagesDPAS_10E-550EThành Long NguyễnNo ratings yet

- Egurko Io Module Wiring ChartDocument1 pageEgurko Io Module Wiring ChartFrancisco AlcaideNo ratings yet

- 7000 / 9000 Series: 7075 7085 90105 90115 Is/arDocument4 pages7000 / 9000 Series: 7075 7085 90105 90115 Is/arPicek30No ratings yet

- Theft Deterrent System DiagnosticsDocument2 pagesTheft Deterrent System DiagnosticssalusfrankNo ratings yet

- DOCUMENT Schematic Volume 1Document50 pagesDOCUMENT Schematic Volume 1Mario Jose Murrugarra CorreaNo ratings yet

- Repfllr Pflrts . . I: at BoschDocument4 pagesRepfllr Pflrts . . I: at BoschEng-Mohammed SalemNo ratings yet

- Group 17 Hyper Dat (Option) : 1. InstallationDocument2 pagesGroup 17 Hyper Dat (Option) : 1. Installationhamdi galipNo ratings yet

- Cat Dcs Sis Controller7Document32 pagesCat Dcs Sis Controller7Alaa HosnyNo ratings yet

- Fiat Grande Punto 1 2 PDFDocument3 pagesFiat Grande Punto 1 2 PDFredNo ratings yet

- 6 Mini Satellite-Antenna Rotator MkIIDocument20 pages6 Mini Satellite-Antenna Rotator MkIIRADIO LU5HANo ratings yet

- POD Go Wireless Owner's Manual - EnglishDocument45 pagesPOD Go Wireless Owner's Manual - EnglishBoris GolicNo ratings yet

- DBGVCC631-3DL: ModelDocument2 pagesDBGVCC631-3DL: ModeldieselmotorsbogotasasNo ratings yet

- Environmental Bleed Air Warning SystemDocument18 pagesEnvironmental Bleed Air Warning SystemShirley Gonzalez100% (1)

- Io ListDocument12 pagesIo ListKrishNo ratings yet

- 3Document1 page3sudhansu8beheraNo ratings yet

- Kenwood rsg7Document25 pagesKenwood rsg7János TóthNo ratings yet

- Control Generator Unit ModuleDocument2 pagesControl Generator Unit ModuleEli SharmaNo ratings yet

- LCD 8M35S chassis service manualDocument39 pagesLCD 8M35S chassis service manualDiegoD'AmbrosioNo ratings yet

- IO ListDocument2 pagesIO List4cvnwvf26pNo ratings yet

- EB 06 LightingDocument45 pagesEB 06 LightingTamNo ratings yet

- Ac Prostar 2007Document12 pagesAc Prostar 2007franciscoNo ratings yet

- Manual Checklist 3094Document2 pagesManual Checklist 3094MARTIN GONZALEZNo ratings yet

- Hoja de Datos XV-5025Document1 pageHoja de Datos XV-5025dgii.oftec.car2No ratings yet

- Bhel SGDocument17 pagesBhel SGShubham ChaurasiaNo ratings yet

- AMPLIFIER SERVICE MANUALDocument8 pagesAMPLIFIER SERVICE MANUALLuis Tellez CedeñoNo ratings yet

- Ice and Rain Protection System: Beechjet 400A 4H-1Document10 pagesIce and Rain Protection System: Beechjet 400A 4H-1Miguel Angel MartinNo ratings yet

- SCADA TrainingDocument53 pagesSCADA TrainingCojjo XenonNo ratings yet

- PureBilge Bilgewater Cleaning System - Alarms and Fault Finding - 2012Document38 pagesPureBilge Bilgewater Cleaning System - Alarms and Fault Finding - 2012Centrifugal SeparatorNo ratings yet

- Fuse in XpandercrossDocument16 pagesFuse in XpandercrossMUHAMMAD IKHWANUDINNo ratings yet

- Kenwood KRFV 7510 D Service ManualDocument33 pagesKenwood KRFV 7510 D Service ManualOscar RNo ratings yet

- HR A10vDocument8 pagesHR A10vMichail ArmitageNo ratings yet

- Hydraulic Flanges and Components CatalogDocument4 pagesHydraulic Flanges and Components CatalogHuy NguyễnNo ratings yet

- Ip200 enDocument2 pagesIp200 ensalawasna92No ratings yet

- Yuken 8 EDFHG-AMN English LeafletDocument4 pagesYuken 8 EDFHG-AMN English LeafletJose2806No ratings yet

- Motor Certification SampleDocument1 pageMotor Certification Sampleyasseralwasabi2016No ratings yet

- SchematicDocument117 pagesSchematicalcoholahmed0% (1)

- HRV RU5 Climate Control System Circuit DiagramDocument13 pagesHRV RU5 Climate Control System Circuit DiagramTomyNo ratings yet

- HT - HP SystemDocument12 pagesHT - HP SystemTaufik TajudinNo ratings yet

- 4000 Series (Includes 4100, 4200 & 4900)Document40 pages4000 Series (Includes 4100, 4200 & 4900)Noman ArifNo ratings yet

- Features: Microprocessor-Compatible, 5-1/2 Digit A/D ConverterDocument14 pagesFeatures: Microprocessor-Compatible, 5-1/2 Digit A/D ConvertercalinvaNo ratings yet

- R-Z220ARU7 Refrigerator Service ManualDocument11 pagesR-Z220ARU7 Refrigerator Service ManualFuadNo ratings yet

- Dkdr8: Model Normally Closed, Balanced Poppet, Logic Element With Integral T-8A Control Cavity - Vent-To-OpenDocument2 pagesDkdr8: Model Normally Closed, Balanced Poppet, Logic Element With Integral T-8A Control Cavity - Vent-To-OpensnsnagarajanNo ratings yet

- Model: Injection Pump Specification Customer Part No. 266512Document2 pagesModel: Injection Pump Specification Customer Part No. 266512dieselmotorsbogotasasNo ratings yet

- Marine Gyro-Compasses and Automatic Pilots: A Handbook for Merchant Navy OfficersFrom EverandMarine Gyro-Compasses and Automatic Pilots: A Handbook for Merchant Navy OfficersRating: 5 out of 5 stars5/5 (2)

- Auxiliary Fuel Transfer System: Before Engine Start - No TransferDocument14 pagesAuxiliary Fuel Transfer System: Before Engine Start - No TransferAlex GuáncNo ratings yet

- Fire Detection System: Prior To BB-1439Document8 pagesFire Detection System: Prior To BB-1439Alex GuáncNo ratings yet

- Environmental Bleed Air Warning SystemDocument18 pagesEnvironmental Bleed Air Warning SystemShirley Gonzalez100% (1)

- Schematic Symbols: ON OFFDocument16 pagesSchematic Symbols: ON OFFAlex GuáncNo ratings yet

- BE20 Cockpit Reference PDFDocument438 pagesBE20 Cockpit Reference PDFmalsr100% (1)

- Propeller Thrust Breakdown CharacteristicsDocument51 pagesPropeller Thrust Breakdown CharacteristicsAbhishek AroraNo ratings yet

- Applications MixerDocument27 pagesApplications MixerFilipe Gama FreireNo ratings yet

- 20% Discount On This Title: Ship Resistance and PropulsionDocument1 page20% Discount On This Title: Ship Resistance and Propulsionaun7328No ratings yet

- ZF 9000 Series: Product DetailsDocument4 pagesZF 9000 Series: Product DetailsArama Eduard AlexandruNo ratings yet

- Paper LiuDocument4 pagesPaper LiuRoshan ShanmughanNo ratings yet

- SEAM FINALS Master CompilationDocument233 pagesSEAM FINALS Master CompilationNovem NacarioNo ratings yet

- Troubleshooting: Sterndrive Unit Will Not Slide Into Bell HousingDocument1 pageTroubleshooting: Sterndrive Unit Will Not Slide Into Bell Housingbetabet GeorgeNo ratings yet

- COMPAC For LifeDocument5 pagesCOMPAC For LifeDanar BayuNo ratings yet

- Reintjes - Operating ManualDocument70 pagesReintjes - Operating Manualmoshe levingerNo ratings yet

- Lec Notes 4Document16 pagesLec Notes 4yetNo ratings yet

- Sea trials testing all ship systems and equipmentDocument7 pagesSea trials testing all ship systems and equipmentdeepak16051988No ratings yet

- Simplex Compact Seal PDFDocument81 pagesSimplex Compact Seal PDFKaushalKishore100% (3)

- Ship Hull Vibration NAME 431Document17 pagesShip Hull Vibration NAME 431Ashik Mahmud TuhinNo ratings yet

- Intermediate Bearing: Case Study 4Document1 pageIntermediate Bearing: Case Study 4thiha aungNo ratings yet

- 2 DOF and 3 DOF Helicopter System Specifications v1.1Document4 pages2 DOF and 3 DOF Helicopter System Specifications v1.1Laura PrietoNo ratings yet

- Service Bulletin: Dowty PropellersDocument9 pagesService Bulletin: Dowty PropellersMuhammad Ashraful KabirNo ratings yet

- Deck Carrying Capacity Deck Strength 3 MT PerDocument1 pageDeck Carrying Capacity Deck Strength 3 MT PerAamir SirohiNo ratings yet

- Technical Analysis of Kort Nozzle Application ForDocument7 pagesTechnical Analysis of Kort Nozzle Application ForMuhammad KamranNo ratings yet

- De-Dhd: Stern Drive Service ManualDocument25 pagesDe-Dhd: Stern Drive Service ManualMake50% (2)

- 6.6 Interaction Between A Hull & A Propeller: in Which The Propeller Is Working? (Later We Will Also Study TheDocument31 pages6.6 Interaction Between A Hull & A Propeller: in Which The Propeller Is Working? (Later We Will Also Study Thebehzad parsiNo ratings yet

- Is 11228 1985Document20 pagesIs 11228 1985Bhaskar Reddy100% (1)

- Axial Flow Pumps InformationDocument7 pagesAxial Flow Pumps InformationsofyanNo ratings yet

- Design Method of A Vertical Screw Conveyor Based oDocument11 pagesDesign Method of A Vertical Screw Conveyor Based odark nightNo ratings yet

- Thesis CDU 41657 Hanna WDocument136 pagesThesis CDU 41657 Hanna Wpepinillod13No ratings yet

- Scientific American Supplement, No. 633, February 18, 1888 by VariousDocument81 pagesScientific American Supplement, No. 633, February 18, 1888 by VariousGutenberg.orgNo ratings yet

- 1 s2.0 S0029801815005089 MainDocument7 pages1 s2.0 S0029801815005089 MainAhmad RidhoNo ratings yet

- Simple Calculation of Boat Propeller: ISO 9001:2008 CertifiedDocument4 pagesSimple Calculation of Boat Propeller: ISO 9001:2008 CertifiedshahjadaNo ratings yet

- XT0425 Special ToolsDocument14 pagesXT0425 Special ToolsG SNo ratings yet

- 7748655w (1) Installation D5 D16Document212 pages7748655w (1) Installation D5 D16Siding Barro100% (1)

- Ka Ipc b200 Uqq06dDocument4,108 pagesKa Ipc b200 Uqq06dGustavo HofstatterNo ratings yet