Professional Documents

Culture Documents

MUI FATT-pe-up-to-18pe

Uploaded by

shafiqCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MUI FATT-pe-up-to-18pe

Uploaded by

shafiqCopyright:

Available Formats

Wastewater treatment always calls for sense of responsibilities towards the environment and public health.

The

PE Bio-Filter Wastewater Treatment System answer this call of the industry as well as building owners.

Designed with the local conditions in mind, PE Bio-Filter suits all local environment, including coastal and high

water-table areas. Manufactured under stringent quality control, strong, durable materials septic tanks operate

efficiently even under harshest conditions.

Characteristics

PE Bio-Filter are leakproof and resistant to rust as well as most chemicals containes in soil and sewerage.

PE Bio-Filter Wastewater Treatment System features an effective anaerobic up-flow filtration system using Plastic as

biomedia. Even fine particles and dissolved matter are strained and removed to give wastewater a total treatment.

As a result, effluent from PE Bio-Filter is virtually harmless and fit for discharge into a public drain. Available in

different models, the PE Bio-Filter Wastewater Treatment System is economical and ideal for use in all types of

housing units, shop houses, light industrial factories and other buildings.

Easy Handling, Transportation and Installation

Being a light and compact tank, the PE Bio-Filter Wastewater Treatment System is easy to handle, transport and

install even with a limited working space. It facilitates easy inspection as well.

Easy De-Sludging

Easy de-sludging is made possible through an isolated, direct access to the settling zone of the PE Bio-Filter as well

as a large outlet facilitating attachment of the desludging pipe.

Maintenance-free

Free of any moving parts or lift pump whatsoever, the PE Bio-Filter is a non mechanical system requiring virtually

zero maintenance. Besides, the up-flow filtration system by nature, non-clogging and thus trouble-free.

Special Features And Advantages :

PE Bio-Filter is designed for a high flexural strength capability

to withstand a harsh environment :

1. Wide range of types & models to suit various needs in the

sewerage industry.

2. Cheaper treatment system and cost effectiveness.

3. High Quality due to stringent Quality Control &quality materials.

Quality Standard and approval

All PE Bio-Filter manufacture to Malaysian Sewerage

Industry Guidelines Volume V-Septic Tanks by :

1. National Water Services Commission (SPAN)

2. Manufactured accordance to MS 1228 : 1991 Code

of Pratice for Design and Installation.

3. Product Certification by SIRIM QAS (International) Sdn. Bhd.

(Standard : MS 2441-1 : 2012)

J.

Product Warranty AtlAa

AC CRED I TED

American Systems

All PE Bio-Filter are warranty strictly against manufacturing SIRIM

..... liairi f4

MANAGEMENT SYSTEMS

CERT IFICATIO N BODY REG Is TR. AR.

defects for a period of 5 years. Which covers only product

workmanship and does not include damage due to improper

usage and installation which not according to our installation ISOMETRIC VIEW

which not according to our installation manual and guideline. PROCESS FLOW MANUFACTURED ACCORDANCE TO :

SIRIM Standard

www.muifatt.com

Email : sales@muifatt.com.my BUATAN MALAYSIA

MUI FATT Specifications and warranty conditions subject to change without prior notice. MADE IN MALAYSIA

PE BIO-FILTER

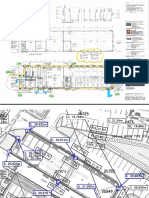

Series Up to 18 PE Installation Instructions

1. Allow for working space of 300m to 600m all around the "MF"

P.E. Bio-Filter when excavating the pit.

l D

2. Construct a 150mm thick grade 30 N concrete base reinforced with one (1)

layer of BRC-A9, wire mesh on top of a 50mm thick lean concrete.

Top View

J A1

3. Four (4) nos, of stainless steel anchor hook 012mm coasted in concrete

base. (Refer Standard Bio-Filter Standard Drawing)

MFR2-PE

DI~), 1200

H1, 1200

L , 2060

4. Unload the Bio-Filter on a well leveled and cured 150mm thick Grade 30N

Concrete base reinforced with one (1) layer of BRC-9 wire mesh.

5. Tie the 020mm stainless steel (SS 304) anchor strap over "MF"

P.E. Bio-Filter and tighten using stainless steel turnbuckle.

[fil

6. Fill in "MF" P.E. Bio-Filter with water up to top water level.

7. Back fill the space around the Bio-Filter with sand compacted in 150mm

B

MF2-PE

[

MF3A-PE

D

MF12-PE

E

MF3-PE

F

MF18-PE

layers, up to the opening lid/rim.

DI¢) , 1440 DI¢) , 1645 DI¢) '1585 Dl•I, 1900 DI¢), 1910

H1 , 1910 H1 '1870 H1 , 2240 H1, 2100 H1 , 2460

8. Make sure the backfills at the inlet and outlet are well compacted and

allow for a drop gradient of two (2) degress @1:100 for both the inlet and

outlet pipes.

9. Lay over the "MF" Bio-Filter with 100mm thick slab, with manhole

openings of 1:2:4 concrete reinforced with one layer of BRC-A9 wire mesh.

SPECIFICATIONS 10. Construct the manhole neck connections with bricks sump up to the

A1 A2. B C D E F

specified design platform level.

UNITS MFR2-PE MF6-PE MF2-PE MF3A-PE MF12-PE MF3-PE MF18-PE

Septic Tank Type Horizontal Vertical Vertical Vertical Vertical Vertical Vertical

h V\iN

I :*""'' "

11. Backfill with sand up to the designed platform level and install the

Process Upflow Anaerobic Filtration (Bio-Media)

Type of Waste

Population Equivalent PE 6 6

Domestic

8 10 12 15 18

- '

manhole cover.

13. Fill the "MF" P.E. Bio-Filter with water to full capacity.

Diameter (D) mm 01,200 01,450 01,440 01,645 01,585 01,900 01,910 Note: Also do so everytime affer desludging later on.

Length (L) mm 2,060 NIA N/A N/A NIA N/A NIA Please refer to the re/event drawings for the proper way of installation.

Height (H1) mm 1,200 1,530 1,910 1,870 2,240 2,100 2,460

Water Level (H2) mm 950 1,240 1,610 1,535 1,950 1,800 2,120

Inlet and Outlet Pipe mm 100 100 100 100 100 100 100

Desludging Frequency Yrs Once in 2 Years

REMARKS:

Standard limited warranty covers only on product workmanship and does not include damage due to improper usage

and installation if not according to installation manual and guideline.

Specifications, terms and conditions subject to change without prior notice. Specifications, terms and conditions subject to change without prior notice.

All dimension is mm unless otherwise stated. All dimension is mm unless otherwise stated.

You might also like

- Water Tank - SpecificationDocument2 pagesWater Tank - SpecificationKai Nee NgNo ratings yet

- Complaince Statement - 01 - CMS AF-TDCS050404523 - R04Document7 pagesComplaince Statement - 01 - CMS AF-TDCS050404523 - R04Arun CDNo ratings yet

- Filmtec BW30-400Document2 pagesFilmtec BW30-400PT Purione MegatamaNo ratings yet

- Complaince Statement - 01Document9 pagesComplaince Statement - 01Arun CDNo ratings yet

- Bituthene 6000 EIMDocument2 pagesBituthene 6000 EIMSenthilkumar NarayananNo ratings yet

- Beta PMDocument2 pagesBeta PMSeif el dean MamdouhNo ratings yet

- Oxicell Pe TDS FDocument2 pagesOxicell Pe TDS FMuhammad hussainNo ratings yet

- TDS MY MacTex C2S July2013Document1 pageTDS MY MacTex C2S July2013Sherene HoNo ratings yet

- Dr. Fixit Bathseal Range 169 1 PDFDocument3 pagesDr. Fixit Bathseal Range 169 1 PDF41464147No ratings yet

- ICC-ES Evaluation Report ESR-1184: Most Widely Accepted and TrustedDocument5 pagesICC-ES Evaluation Report ESR-1184: Most Widely Accepted and TrustedMark DingalNo ratings yet

- Bray Butterfly Valves Catalog JECDocument23 pagesBray Butterfly Valves Catalog JECRawadabdoNo ratings yet

- Fiber reinforcement technical specificationsDocument6 pagesFiber reinforcement technical specificationsTheLady InblackNo ratings yet

- 407 Mapefoam GBDocument4 pages407 Mapefoam GBAndrius KulvietisNo ratings yet

- Complaince Statement - 01 - CMS AF-TDCS050404523 - R03Document7 pagesComplaince Statement - 01 - CMS AF-TDCS050404523 - R03Arun CDNo ratings yet

- Bitumode APP P 180,200,250Document2 pagesBitumode APP P 180,200,250Raha Trading and ContactingNo ratings yet

- Sika® Fibermesh®-150: Product Data SheetDocument3 pagesSika® Fibermesh®-150: Product Data SheetVikram ManeNo ratings yet

- Viledon MVPGTE10-LDocument2 pagesViledon MVPGTE10-LmsafwanizzudinNo ratings yet

- MX 75-98Document2 pagesMX 75-98Compras WConexNo ratings yet

- Bitumode Flex SBS PDFDocument2 pagesBitumode Flex SBS PDFsouravrobinNo ratings yet

- Polyboard: Bitumen Impregnated Compressible Fibre Filler BoardDocument2 pagesPolyboard: Bitumen Impregnated Compressible Fibre Filler Boardmpandy1984No ratings yet

- Product BITUMODE FLEX (-10) Technical Data V5Document2 pagesProduct BITUMODE FLEX (-10) Technical Data V5Jamsheed apNo ratings yet

- Catalogo IusaDocument190 pagesCatalogo IusaAlfa CentauroNo ratings yet

- Mini Split Kit Fix-it-Foot-SpecDocument2 pagesMini Split Kit Fix-it-Foot-SpecAmic BanatNo ratings yet

- Polyboard: Bitumen Impregnated Compressible Fibre Filler Board)Document49 pagesPolyboard: Bitumen Impregnated Compressible Fibre Filler Board)shahidNo ratings yet

- PT Polythene-Builders-Film PDSDocument2 pagesPT Polythene-Builders-Film PDSGloria ZhuNo ratings yet

- MKT Apac Tds Fleximesh Feb 2022 enDocument2 pagesMKT Apac Tds Fleximesh Feb 2022 enIvanRomanovićNo ratings yet

- Kimitech BS ST 400: Basalt Fiber Reinforcement Fabrics For FRCM ReinforcementsDocument2 pagesKimitech BS ST 400: Basalt Fiber Reinforcement Fabrics For FRCM ReinforcementsIzetNo ratings yet

- Dual FittingDocument19 pagesDual FittingmontanovillarroelfabiolalourdeNo ratings yet

- Polietileno 100% SolidoDocument4 pagesPolietileno 100% Solidohector stackNo ratings yet

- Pipe Wrap Insulation: Technical Data Sheet Product CodeDocument4 pagesPipe Wrap Insulation: Technical Data Sheet Product CodegemazizNo ratings yet

- Veri Lite: Deadend & Suspension Insulators For 15-69kV ApplicationsDocument8 pagesVeri Lite: Deadend & Suspension Insulators For 15-69kV ApplicationsE PenaNo ratings yet

- Waterproofing Membranes Under 40 CharactersDocument4 pagesWaterproofing Membranes Under 40 CharactersshashiNo ratings yet

- Fiber Glass Systems Installation Instructions B2160Document30 pagesFiber Glass Systems Installation Instructions B2160NadaNo ratings yet

- Business and Engineering Trends in Pakistan's Fiberglass IndustryDocument61 pagesBusiness and Engineering Trends in Pakistan's Fiberglass IndustryMunir Ahmed MusianiNo ratings yet

- Maktex Py 500: Product DescriptionDocument1 pageMaktex Py 500: Product DescriptionHatem ElGabryNo ratings yet

- Bituthene® 4000Document2 pagesBituthene® 4000hajisotoudehNo ratings yet

- Polystrong Material: Superior Corrosion ProtectionDocument2 pagesPolystrong Material: Superior Corrosion ProtectionherikNo ratings yet

- Basf Masterfiber 018 TdsDocument2 pagesBasf Masterfiber 018 TdsfffffffgggNo ratings yet

- Salient Features: Imperflex (S)Document2 pagesSalient Features: Imperflex (S)Engr KamalNo ratings yet

- E Cellflex TDSDocument1 pageE Cellflex TDSrony 2222No ratings yet

- Mbrace CF 130: Unidirectional High Strength Carbon Fiber Fabric For The Mbrace Composite Strengthening SystemDocument4 pagesMbrace CF 130: Unidirectional High Strength Carbon Fiber Fabric For The Mbrace Composite Strengthening SystemAhmd MhmdNo ratings yet

- Macformer Tublar Type Mfm-IIIDocument1 pageMacformer Tublar Type Mfm-IIIDeny SuryantoNo ratings yet

- MAKTEX PY 150 Non-Woven Geotextile Product SpecificationsDocument1 pageMAKTEX PY 150 Non-Woven Geotextile Product SpecificationsHatem ElGabryNo ratings yet

- 60 Mil FiberTite-SM PDFDocument2 pages60 Mil FiberTite-SM PDFAlberto CoppelliNo ratings yet

- Polypropylene Sediment CartridgesDocument5 pagesPolypropylene Sediment CartridgesNermeen ElmelegaeNo ratings yet

- BituBOND Manual DigitalDocument19 pagesBituBOND Manual DigitalisuruNo ratings yet

- SikaProof A Method StatementDocument41 pagesSikaProof A Method StatementNUR AIN ROSDINo ratings yet

- TDS Polybit-Easyfelt-P en Mea 1Document2 pagesTDS Polybit-Easyfelt-P en Mea 1dinescNo ratings yet

- Abe. Flex: Polymer Bonded E-Glass YarnDocument1 pageAbe. Flex: Polymer Bonded E-Glass Yarncremildo maetinhoNo ratings yet

- Construction Materials Technical Data SheetDocument2 pagesConstruction Materials Technical Data SheetSHAIK ASIMUDDIN100% (1)

- Bitumen Mixing Plant Supplier: Jiaxing Mide Machinery Co.,LtdDocument23 pagesBitumen Mixing Plant Supplier: Jiaxing Mide Machinery Co.,LtdsuryadevarasarathNo ratings yet

- Maktex Py 110: Product DescriptionDocument1 pageMaktex Py 110: Product DescriptionHatem ElGabryNo ratings yet

- 2015 12 09 WSS-M15P20-B1Document6 pages2015 12 09 WSS-M15P20-B1jose luisNo ratings yet

- Tehnički List - KIMITECH 550+Document3 pagesTehnički List - KIMITECH 550+MARKO MATUHANo ratings yet

- Sludge Transfer Pump - Netzsch Screw IFD-Stator 2.0 PDFDocument4 pagesSludge Transfer Pump - Netzsch Screw IFD-Stator 2.0 PDFeko saifullohNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- A Study of the Supply Chain and Financial Parameters of a Small Manufacturing BusinessFrom EverandA Study of the Supply Chain and Financial Parameters of a Small Manufacturing BusinessNo ratings yet

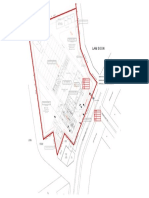

- Attachment (A)Document2 pagesAttachment (A)shafiqNo ratings yet

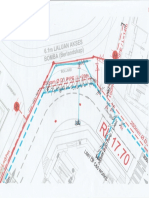

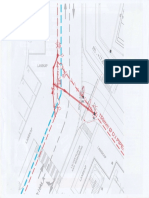

- Pro 30 19 C&s Osd STD 01 Layout1.PDF SectionDocument1 pagePro 30 19 C&s Osd STD 01 Layout1.PDF SectionshafiqNo ratings yet

- PRO 12 2021 C&S SW LP 01 Layout1Document1 pagePRO 12 2021 C&S SW LP 01 Layout1shafiqNo ratings yet

- Oil trap washing bay facilityDocument1 pageOil trap washing bay facilityshafiqNo ratings yet

- Oil trap washing bay facilityDocument1 pageOil trap washing bay facilityshafiqNo ratings yet

- Combined .. Utar, ABC, M&e, PBSB, Rfic, 130 .. 7.5.21Document3 pagesCombined .. Utar, ABC, M&e, PBSB, Rfic, 130 .. 7.5.21shafiqNo ratings yet

- 425-445 Watt: Cheetah Plus HC 78MDocument2 pages425-445 Watt: Cheetah Plus HC 78MshafiqNo ratings yet

- Malaysia Sewerage Industry Guideline Volume 1Document281 pagesMalaysia Sewerage Industry Guideline Volume 1Asiff Razif100% (1)

- Aashto M-180 PDFDocument11 pagesAashto M-180 PDF48181No ratings yet

- Design Guidelines for Water Supply ProjectDocument5 pagesDesign Guidelines for Water Supply ProjectNyu123456No ratings yet

- Price List Valves, Hydrants & Fittings OCT 2020Document38 pagesPrice List Valves, Hydrants & Fittings OCT 2020Mohd Naim Bin KaramaNo ratings yet

- Contact Us: Prestressed SpunDocument2 pagesContact Us: Prestressed Spunconcrete engineeringNo ratings yet

- BS 5950Document224 pagesBS 5950engmgm3000100% (3)

- UTAR Infra Works Memo Highlights Obstructions & Completion DateDocument4 pagesUTAR Infra Works Memo Highlights Obstructions & Completion DateshafiqNo ratings yet

- 4 PDFDocument3 pages4 PDFMustafa OmarNo ratings yet

- Design Guidelines for Water Supply ProjectDocument5 pagesDesign Guidelines for Water Supply ProjectNyu123456No ratings yet

- Gmail - RE - UTAR HOSPITAL - KM Approval Pending Items (Sumbangan Saliran)Document3 pagesGmail - RE - UTAR HOSPITAL - KM Approval Pending Items (Sumbangan Saliran)shafiqNo ratings yet

- Seribumi Development Sdn. BHD.: Work Schedule NO Task Name Duration Start Finish PreliminariesDocument3 pagesSeribumi Development Sdn. BHD.: Work Schedule NO Task Name Duration Start Finish PreliminariesshafiqNo ratings yet

- 17.defect Liability Period and Account Closing - en .Wan SaipallahDocument34 pages17.defect Liability Period and Account Closing - en .Wan SaipallaherickyfmNo ratings yet

- Layout 1Document1 pageLayout 1shafiqNo ratings yet

- 7Document1 page7shafiqNo ratings yet

- Layout 2Document1 pageLayout 2shafiqNo ratings yet

- LAWS OF MALAYSIA ACT 520Document73 pagesLAWS OF MALAYSIA ACT 520May OngNo ratings yet

- 7Document1 page7shafiqNo ratings yet

- Concrete EC2Document186 pagesConcrete EC2Ivan GradNo ratings yet

- 20191023-Bq For UpdateDocument20 pages20191023-Bq For UpdateshafiqNo ratings yet

- Egg Production Poultry Growing Image Big Dutchman enDocument6 pagesEgg Production Poultry Growing Image Big Dutchman enBalbir SinghNo ratings yet

- 7es Science 1Document3 pages7es Science 1Antonette Lee - BritaniaNo ratings yet

- Water and Wastewater Sludge Treatment MethodsDocument12 pagesWater and Wastewater Sludge Treatment MethodsShahul14No ratings yet

- Characteristics of Runoff - Factors Affecting Peak Flows & Hydrograph ShapeDocument22 pagesCharacteristics of Runoff - Factors Affecting Peak Flows & Hydrograph ShapeSaima SiddiquiNo ratings yet

- An Introduction To Environmental Law and PolicyDocument34 pagesAn Introduction To Environmental Law and PolicySharifa OraibieNo ratings yet

- Wastewater Treatment Technologies For The Textile Industry-FINAL PDFDocument119 pagesWastewater Treatment Technologies For The Textile Industry-FINAL PDFShohan ParvezNo ratings yet

- Water Pollution Script 2.0Document2 pagesWater Pollution Script 2.0api-312818964No ratings yet

- Waste Management-EnvsDocument25 pagesWaste Management-EnvsMarula SiddappaNo ratings yet

- Wl2000it Brochure ENGDocument2 pagesWl2000it Brochure ENGSantos RodriguezNo ratings yet

- Secondary Treatment System: Trickling FilterDocument5 pagesSecondary Treatment System: Trickling FilterMaryrose GalapNo ratings yet

- Water Tank Inspection ChecklistDocument4 pagesWater Tank Inspection ChecklistSrinivasan Enterprises100% (1)

- Impact of Small Municipal Solid Waste Landfill On GroundwaterDocument20 pagesImpact of Small Municipal Solid Waste Landfill On GroundwaterfesadeNo ratings yet

- Groundwater Quality Assessment in Eliozu Community, Port Harcourt, Niger Delta, NigeriaDocument9 pagesGroundwater Quality Assessment in Eliozu Community, Port Harcourt, Niger Delta, NigeriaGaniyuNo ratings yet

- Indonesia's Waste Problem and 4R SolutionsDocument4 pagesIndonesia's Waste Problem and 4R SolutionsLú Dí ChatryNo ratings yet

- TYM: Is That All? Are There Any Other Causes?Document8 pagesTYM: Is That All? Are There Any Other Causes?MT20622 TAN YEE MOINo ratings yet

- Polluter Pay Principle Applied in Indian Council for Enviro-Legal vs Union of IndiaDocument2 pagesPolluter Pay Principle Applied in Indian Council for Enviro-Legal vs Union of IndiaAbhisek DashNo ratings yet

- Capacity of Plant 16KLDDocument4 pagesCapacity of Plant 16KLDSandeep KNo ratings yet

- GROUNDWATER MON. BORE MATDocument10 pagesGROUNDWATER MON. BORE MATAadil KhanNo ratings yet

- Case Study 1Document6 pagesCase Study 1jitenderNo ratings yet

- LANDFILL DESIGN OVERVIEWDocument2 pagesLANDFILL DESIGN OVERVIEWAni P PNo ratings yet

- Geography 9 PDFDocument63 pagesGeography 9 PDFKumar GauravNo ratings yet

- CH 11 - Hydrologic Design Concepts PDFDocument11 pagesCH 11 - Hydrologic Design Concepts PDFDaniel YongNo ratings yet

- Ic AguaDocument12 pagesIc AguagheijoNo ratings yet

- Effects of Water PollutionDocument5 pagesEffects of Water PollutionVishal Vishwakarma100% (3)

- WWTF Improvements Project Design Report Technical Memorandum - INFLUENT PUMP STATIONDocument60 pagesWWTF Improvements Project Design Report Technical Memorandum - INFLUENT PUMP STATIONveliger100No ratings yet

- ECOLAB P3 Ultrasil 110 Alkaline Membrane Detergent LenntechDocument7 pagesECOLAB P3 Ultrasil 110 Alkaline Membrane Detergent LenntechDC A EdNo ratings yet

- Improper Garbage DisposalDocument2 pagesImproper Garbage DisposalYo1No ratings yet

- NOAA Comments - USACE Port Everglades Navigation Improvements Draft EISDocument93 pagesNOAA Comments - USACE Port Everglades Navigation Improvements Draft EISEd TichenorNo ratings yet

- ML 072920082Document269 pagesML 072920082garbagepatchNo ratings yet

- Turbidite MuttiDocument47 pagesTurbidite MuttiDedi ApriadiNo ratings yet

- Example Terms of Reference For Environmental Impact Assessment of Solid Waste Management FacilityDocument15 pagesExample Terms of Reference For Environmental Impact Assessment of Solid Waste Management FacilityMartin MambuNo ratings yet