Professional Documents

Culture Documents

PTC B1.1 Notes - Sub Module 17.2 (Propeller Construction)

PTC B1.1 Notes - Sub Module 17.2 (Propeller Construction)

Uploaded by

Interogator5Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PTC B1.1 Notes - Sub Module 17.2 (Propeller Construction)

PTC B1.1 Notes - Sub Module 17.2 (Propeller Construction)

Uploaded by

Interogator5Copyright:

Available Formats

PIA TRAINING CENTRE (PTC) Module 17A – PROPELLER

Category – A/B1 Sub Module 17.2 – Propeller Construction

MODULE 17A

Sub Module 17.2

PROPELLER CONSTRUCTION

ISO 9001 - 2008 Certified For Training Purpose Only

PTC/CM/B1.1 Basic/M17A/01 Rev. 01

17.2 Nov 2017

PIA TRAINING CENTRE (PTC) Module 17A – PROPELLER

Category – A/B1 Sub Module 17.2 – Propeller Construction

Contents

CONSTRUCTION METHODS AND MATERIALS USED IN WOODEN,

COMPOSITE AND METAL PROPELLERS -------------------------------- 1

BLADE STATION, BLADE FACE, BLADE SHANK, BLADE BACK AND

HUB ASSEMBLY ------------------------------------------------------------10

FIXED PITCH, CONTROLLABLE PITCH AND CONSTANT SPEED

PROPELLERS ----------------------------------------------------------------13

PROPELLER INSTALLATION----------------------------------------------17

SPINNER INSTALLATION -------------------------------------------------19

ISO 9001 - 2008 Certified For Training Purpose Only

PTC/CM/B1.1 Basic/M17A/01 Rev. 01

17.2 - i Nov 2017

PIA TRAINING CENTRE (PTC) Module 17A – PROPELLER

Category – A/B1 Sub Module 17.2 – Propeller Construction

Page Intentionally Left Blank

ISO 9001 - 2008 Certified For Training Purpose Only

PTC/CM/B1.1 Basic/M17A/01 Rev. 01

17.2 - ii Nov 2017

PIA TRAINING CENTRE (PTC) Module 17A – PROPELLER

Category – A/B1 Sub Module 17.2 – Propeller Construction

CONSTRUCTION METHODS AND MATERIALS USED IN

WOODEN, COMPOSITE AND METAL PROPELLERS

Propellers have been constructed using wood, metal and The condition is infectious so the only remedy is to burn the

composite materials. We will take a look at each of these wood. Decay normally reveals itself as dry brown patches that

materials starting with simple wooden and metal propeller either flake or come out in chunks. It is often referred to as ‘dry

construction. rot’ because the fungus that causes it feeds on moisture in the

wood. Shakes are splits that run along sap lines or around

Wooden Propellers annular rings. They may occur during the growth of the tree or

during seasoning. They can also be caused by frost if the wood

Wooden propellers are generally fixed pitch or ground is wet. Shakes are hard to spot and often are not seen until the

adjustable and have two blades. They are normally to be found wood is varnished. Knots appear in several forms but ail will

installed on single engine, light aircraft. Variable pitch wooden cause problems. A thorough inspection is essential to save a lot

propellers have a metal hub and pitch change mechanism. The of wasted effort.

individual wooden blades are fitted with metal root fittings

designed to mate with the hub. We will concentrate on the all A propeller is not carved from a block of solid wood, it is

wood, two blade fixed pitch propeller at this stage. laminated. The construction process commences by gluing and

clamping together seasoned planks that have been roughly

The wood most frequently used these days is yellow birch but profiled to form a blank shape containing a minimum of five

other woods such as mahogany, cherry, maple or walnut have layers of the selected wood. The use of a laminated

been used either singly or in combination. Mahogany was construction is designed to reduce the risk of the wood warping

extensively used in earlier times. Prior to its use the wood must during the service life of the propeller. Gluing is carried out

be inspected to ensure that it is free from knots, shakes, cracks, using plastic resin glue under carefully controlled pressure and

signs of decay, mildew, wormholes or staining. The grain should temperature conditions. The glued blank is then left for a further

be straight and the wood correctly seasoned. period to allow the layers to season together. Seasoning is a

drying process carried out to reduce the possibility of shrinkage

The more common defects that can be found in wood are worth and warping of the propeller after manufacture. It also improves

noting. Dote disease is the worst condition and can be the strength of the timber and its resistance to decay. The blank

recognized by the presence of oily brownish yellow spots should be kept horizontal during this time to ensure even

scattered over the wood. The affected areas appear soggy and moisture distribution or the shrinkage will be uneven.

the wood will break out in pieces when picked with a knife.

ISO 9001 - 2008 Certified For Training Purpose Only

PTC/CM/B1.1 Basic/M17A/01 Rev. 01

17.2 - 1 Nov 2017

PIA TRAINING CENTRE (PTC) Module 17A – PROPELLER

Category – A/B1 Sub Module 17.2 – Propeller Construction

Figure 17.2.01

ISO 9001 - 2008 Certified For Training Purpose Only

PTC/CM/B1.1 Basic/M17A/01 Rev. 01

17.2 - 2 Nov 2017

PIA TRAINING CENTRE (PTC) Module 17A – PROPELLER

Category – A/B1 Sub Module 17.2 – Propeller Construction

The blank is then roughly shaped using an automatic profiling Three small holes are drilled into the blade tip to act as a vent

machine. This rough shape is called a ‘white’. The roughly for moisture allowing the wood in that region to breathe. The

shaped block is then shaved into its correct form using propeller will finally be checked for correct static and dynamic

templates and blade protractors to check the shape and pitch. balance.

This part of the process requires a highly skilled craftsman. The

thin tip region of each blade is then bound with cotton fabric to On simple wooden propellers, applying and smoothing solder

prevent splitting and doped to avoid moisture ingress. A sheet onto the light blade tip metal cap may trim horizontal static

brass anti-erosion sheath covering the leading edge and the tip balance. Vertical static balance may be adjusted by screwing a

of each blade is screwed into position. The leading edge will brass or lead compensating balance plate onto the light side of

have been rebated to accept the sheath. the propeller boss face. Very small balance adjustments may be

carried out by the application of additional coats of clear varnish

The countersunk screws securing the leading-edge sheath are to the light blade.

normally locked using solder to till the countersink depressions

over the screw heads. Copper rivets are sometimes used to During the post manufacture testing of wooden propellers, it is

secure the metal cap onto the thin sections near the blade tip. important to check for vibration and that they do not suffer

These are also capped with solder to prevent loosening in use. resonance in any part of the operating range. With piston

engines, this test should take into account the effects of

The hub center bore and the holes for the propeller mounting misfiring or inoperative cylinders.

bolts are drilled through the center boss. The most frequently

used surface finish for wooden propellers is waterproof clear

varnish and this is applied over the whole of the propeller using

several coats. Alternatively, cellulose paint may be used. The

appropriate metal hub is then inserted and secured to the

propeller with through bolts and a faceplate. The hub assembly

adapts the propeller for installation onto the engine drive shaft.

There are a number of different propeller drive methods. The

hub may be adapted to accept shaft splines, a flange plate or a

keyed taper shaft. A typical example only is shown in the figure

17.2.02.

ISO 9001 - 2008 Certified For Training Purpose Only

PTC/CM/B1.1 Basic/M17A/01 Rev. 01

17.2 - 3 Nov 2017

PIA TRAINING CENTRE (PTC) Module 17A – PROPELLER

Category – A/B1 Sub Module 17.2 – Propeller Construction

Figure 17.2.02

ISO 9001 - 2008 Certified For Training Purpose Only

PTC/CM/B1.1 Basic/M17A/01 Rev. 01

17.2 - 4 Nov 2017

PIA TRAINING CENTRE (PTC) Module 17A – PROPELLER

Category – A/B1 Sub Module 17.2 – Propeller Construction

Metal Propellers

Improvements in metallurgy and manufacturing techniques have Some propellers have blades made of steel with the blade

enabled metal propellers to replace wood propellers for modern halves stamped of thin sheet steel and brazed together along

commercially manufactured aircraft. Figure 17.2.03 shows a the leading and trailing edges. The blade shell is then installed

metal construction propeller blade. over a tubular steel shank. A few propellers with hollow steel

blades are still flying, but these are usually found only on

Metal propellers are forged from high-strength aluminium alloy, special purpose aero planes.

and after being ground to their finished dimensions and pitch,

are anodized to protect them from corrosion. Metal propellers

cost more than wood for the same engine and aero plane, but

their increased durability, resistance to weathering, and ability to

be straightened after minor damage have made them more cost

effective in the long term.

ISO 9001 - 2008 Certified For Training Purpose Only

PTC/CM/B1.1 Basic/M17A/01 Rev. 01

17.2 - 5 Nov 2017

PIA TRAINING CENTRE (PTC) Module 17A – PROPELLER

Category – A/B1 Sub Module 17.2 – Propeller Construction

Figure 17.2.03

ISO 9001 - 2008 Certified For Training Purpose Only

PTC/CM/B1.1 Basic/M17A/01 Rev. 01

17.2 - 6 Nov 2017

PIA TRAINING CENTRE (PTC) Module 17A – PROPELLER

Category – A/B1 Sub Module 17.2 – Propeller Construction

Composite Propellers

Laminated wood, forged aluminium alloy, and brazed sheet The outer shell is held in place on the aluminium alloy shank by

steel propellers have been standard for decades. But the Kevlar filaments impregnated with epoxy resin wound around

powerful turboprop engines and the demands for higher-speed the portion of the shell that grips the shank. Some Hartzell

flight and quieter operation have caused propeller blades have a stainless-steel mesh under the final layer of

manufacturers to exploit the advantages of modern advanced Kevlar to protect against abrasion, and a nickel leading edge

composite materials in modern turbo-prop engines. erosion shield is bonded in place. The entire blade is put into a

blade press and cured under computer-controlled heat and

Composite materials used in the propeller manufacturing pressure.

consist of two constituents: the fibres and the matrix. The fibres

most generally used are glass, graphite and aramid (Kevlar), Hamilton-Standard Blade Construction

and the matrix is a thermosetting resin such as epoxy. The

strength and stiffness of the blades are determined by the The Hamilton-Standard blade has tremendous strength and

material, diameter and orientation of the fibres. The matrix fatigue resistance because of its solid aluminium alloy spar

material supports the fibers, holds them in place and completely enclosed in a glass fibre shell (Figure 17.2.05).

encapsulates them for environmental protection. Because the

fibres have strength only parallel to their length, they are The spar is machined to its correct configuration and placed in a

arranged in such a way that they can sustain tensile loads. mould cavity, and the core foam is injected around it. The foam

is cured and removed from the mould. Glass fibre cloth, with the

Hartzell Blade Construction correct number of plies and the proper ply orientation, is then

laid over the cured core. The complete item is then placed in a

The typical Hartzell composite propeller, like that in figure second mould that has the shape of the finished blade. The

17.2.04 has a machined aluminium alloy shank, and molded resin matrix is injected to impregnate all the fibres, and is cured

into this shank is a low density foam core. Slots are cut into the with heat and pressure.

foam core and unidirectional Kevlar shear webs are inserted.

The leading and trailing edges are solid sections made of

unidirectional Kevlar and laminations of pre-impregnated

material are cut and laid up over the core foundation to provide

the correct blade thickness, aerofoil shape, pitch distribution,

planform and ply orientation.

ISO 9001 - 2008 Certified For Training Purpose Only

PTC/CM/B1.1 Basic/M17A/01 Rev. 01

17.2 - 7 Nov 2017

PIA TRAINING CENTRE (PTC) Module 17A – PROPELLER

Category – A/B1 Sub Module 17.2 – Propeller Construction

Figure 17.2.05

Figure 17.2.04

ISO 9001 - 2008 Certified For Training Purpose Only

PTC/CM/B1.1 Basic/M17A/01 Rev. 01

17.2 - 8 Nov 2017

PIA TRAINING CENTRE (PTC) Module 17A – PROPELLER

Category – A/B1 Sub Module 17.2 – Propeller Construction

Dowty Rotol Blade Construction

The Dowty Rotol composite propeller blade has two carbon fibre

spars that run the length of the blade on both the face and back

and come smoothly together at the blade root.

The carbon fibres and pre-impregnated glass fibre cloth are laid

with the correct number of plies and the correct ply orientation

and are placed in a mould. Polyurethane foam is injected into

the inside of the blade, and the entire unit is cured under heat

and pressure.

The Dowty Rotol blade is secured in the hub by expanding the

carbon fibre spars with tapered glass fibre wedges and locking

them between the inner and outer sleeves (Figure 17.2.07).

Figure 17.2.07

Figure 17.2.06

ISO 9001 - 2008 Certified For Training Purpose Only

PTC/CM/B1.1 Basic/M17A/01 Rev. 01

17.2 - 9 Nov 2017

PIA TRAINING CENTRE (PTC) Module 17A – PROPELLER

Category – A/B1 Sub Module 17.2 – Propeller Construction

BLADE STATION, BLADE FACE, BLADE SHANK, BLADE

BACK AND HUB ASSEMBLY

The typical propeller blade can be described as a twisted

aerofoil of irregular planform, as shown in the figure 17.2.08.

For the purposes of analysis, a blade can be divided into

segments, which are located by station numbers in inches from

the centre of the blade hub. The blade hub assembly is the

supporting unit for the blades. The blade shank and the blade

butt are also identified the figure 17.2.08.

Figure 17.2.08

ISO 9001 - 2008 Certified For Training Purpose Only

PTC/CM/B1.1 Basic/M17A/01 Rev. 01

17.2 - 10 Nov 2017

PIA TRAINING CENTRE (PTC) Module 17A – PROPELLER

Category – A/B1 Sub Module 17.2 – Propeller Construction

The aircraft propeller consists of two or more blades and a

central hub to which they are attached. Propeller blades have a

shank, butt, hub, tip, trailing edge, leading edge, face and a

back. The blade shank is the thick, rounded portion of the

propeller blade near the hub, which is designed to give strength

to the blade. The blade butt, also called the blade base or root,

is that end of the blade, which fits in the propeller hub. The

blade tip is that part of the propeller blade farthest from the hub,

generally defined as the last 6 inches of the blade. The

cambered side of a blade is called the blade back. The flat side

of the blade is called the blade face.

ISO 9001 - 2008 Certified For Training Purpose Only

PTC/CM/B1.1 Basic/M17A/01 Rev. 01

17.2 - 11 Nov 2017

PIA TRAINING CENTRE (PTC) Module 17A – PROPELLER

Category – A/B1 Sub Module 17.2 – Propeller Construction

Figure 17.2.09

ISO 9001 - 2008 Certified For Training Purpose Only

PTC/CM/B1.1 Basic/M17A/01 Rev. 01

17.2 - 12 Nov 2017

PIA TRAINING CENTRE (PTC) Module 17A – PROPELLER

Category – A/B1 Sub Module 17.2 – Propeller Construction

FIXED PITCH, CONTROLLABLE PITCH AND CONSTANT

SPEED PROPELLERS

There are various types or classes of propellers, the simplest of Ground-Adjustable Propeller

which are the fixed-pitch and ground-adjustable propellers. The

complexity of propeller systems increases from these simpler The ground-adjustable propeller operates as a fixed-pitch

forms to controllable pitch and complex automatic systems. propeller. The pitch or blade angle can only be changed when

the propeller is not running. It is done by loosening the clamping

mechanism, which holds the blades in place. After the clamping

Fixed-Pitch Propeller mechanism has been tightened, the pitch of the blades cannot

be changed in flight to meet variable flight requirements. Like

As the name implies, a fixed-pitch propeller has the blade pitch, the fixed-pitch propeller, the ground-adjustable propeller is used

or blade angle, built into the propeller. The blade angle cannot on aircraft of low power, speed, range, or altitude.

be changed after the propeller is built. Generally, this type of

propeller is one piece and is constructed of laminated wood or A ground adjustable propeller may have blades made of wood

aluminium alloy. or metal. The hub is usually of two-piece steel construction with

clamps or large nuts used to hold the blade securely in place.

Fixed-pitch propellers are designed for best efficiency at one When the angle of the blade is to be changed, the clamp or

rotational and forward speed. blade nuts are loosened and the blades rotated to the desired

angle as indicated by a propeller protractor. The angle markings

They are designed to fit a set of conditions of both aircraft and on the hub are not considered accurate enough to provide a

engine speeds, and any change in these conditions reduces the good reference for blade adjustment, so they are only used for

efficiency of both the propeller and the engine. The fixed-pitch reference.

propeller is used on aircraft of low power, speed, range, or

altitude.

ISO 9001 - 2008 Certified For Training Purpose Only

PTC/CM/B1.1 Basic/M17A/01 Rev. 01

17.2 - 13 Nov 2017

PIA TRAINING CENTRE (PTC) Module 17A – PROPELLER

Category – A/B1 Sub Module 17.2 – Propeller Construction

Figure 17.2.10

ISO 9001 - 2008 Certified For Training Purpose Only

PTC/CM/B1.1 Basic/M17A/01 Rev. 01

17.2 - 14 Nov 2017

PIA TRAINING CENTRE (PTC) Module 17A – PROPELLER

Category – A/B1 Sub Module 17.2 – Propeller Construction

Controllable Pitch Propeller

Ground-adjustable propellers were a step in the right direction,

but with only minor added weight and complexity, the propeller

could be made far more efficient by allowing the pilot to change

the pitch of the blades in flight.

The first popular controllable-pitch propellers were hydraulically

actuated by engine lubricating oil supplied through a hollow

crankshaft. A counterweight on an arm is attached to each

blade root so that centrifugal force rotates the blade into a high

pitch angle. A fixed piston in the end of the propeller shaft is

covered by a movable cylinder attached through bearings to the

counterweight arms.

For takeoff, the two-position propeller control is placed in the

low pitch position that directs engine oil into the cylinder and

moves it forward over the piston. This pulls the counterweights

in and rotates the blades into their low pitch position. When the

airplane is set up for cruise flight, the pitch control is moved to Figure 17.2.11

the high pitch position. This opens an oil passage, allowing the

oil in the propeller cylinder to drain back into the engine sump.

Centrifugal force on the counterweights moves them outward

into the plane of rotation, and rotates the blades into their high

pitch position.

This same configuration of propeller, when equipped with a

flyweight governor to control the oil into and out of the cylinder,

is a popular constant speed propeller.

ISO 9001 - 2008 Certified For Training Purpose Only

PTC/CM/B1.1 Basic/M17A/01 Rev. 01

17.2 - 15 Nov 2017

PIA TRAINING CENTRE (PTC) Module 17A – PROPELLER

Category – A/B1 Sub Module 17.2 – Propeller Construction

Constant-Speed Propeller

A constant speed propeller system is a system in which the

propeller blade angle is varied by the action of a governor to

maintain a constant speed. The pitch changing devices for

constant speed propellers include electric motors, hydraulic

cylinders, and devices in which centrifugal forces act on

flyweights and combinations of these methods. The tremendous

advantage of being able to change pitch in flight opened new

possibilities for increased efficiency. Replacing the two-position

valve with a flyweight-controlled valve in a governor allows the

blade pitch angle to be continuously and automatically adjusted

in flight to maintain a constant and efficient engine speed.

Throughout and immediately after World War II, an electrically

controlled constant speed propeller was used with some degree

of success. A small reversible DC motor mounted in the centre

of the propeller hub drove a speed reducer with an attached

bevel gear. This gear meshed with bevel gears on the root of

each blade to change the pitch so the propeller could maintain

an air load on the engine that produced the RPM called for by

the governor. The large amount of maintenance required for

electric propellers caused their demise.

There are only two types of propellers installed on current

production airplanes: fixed-pitch propellers for the small and

simple airplanes, and hydraulically actuated constant-speed

propellers for complex airplanes. The blades of constant-speed

propellers are held in high-strength steel hubs, with roller or ball

type thrust bearings that enable their pitch angle to be changed Figure 17.2.12

with a minimum of force.

ISO 9001 - 2008 Certified For Training Purpose Only

PTC/CM/B1.1 Basic/M17A/01 Rev. 01

17.2 - 16 Nov 2017

PIA TRAINING CENTRE (PTC) Module 17A – PROPELLER

Category – A/B1 Sub Module 17.2 – Propeller Construction

PROPELLER INSTALLATION Tapered Shaft Propeller Installation

Flanged Shaft Propeller Installation Tapered shaft crankshafts are found on older model engines of

low horsepower. This type of crankshaft requires a hub insert to

Flanged propeller shafts are used on most flat/horizontally adapt the propeller to the shaft. The method used to attach the

opposed and some turboprop engines. The front of the propeller to the engine crankshaft will vary with the design of the

crankshaft is formed into a flange four-to-eight inches across crankshaft.

and perpendicular to the crankshaft centre line. Mounting bolt

holes and dowel pin holes are machined into the flange and, on

some flanges, threaded inserts are pressed into the bolt holes.

Figure 17.2.14

Figure 17.2.13

ISO 9001 - 2008 Certified For Training Purpose Only

PTC/CM/B1.1 Basic/M17A/01 Rev. 01

17.2 - 17 Nov 2017

PIA TRAINING CENTRE (PTC) Module 17A – PROPELLER

Category – A/B1 Sub Module 17.2 – Propeller Construction

Splined Shaft Propeller Installation

Splined crankshafts are found on most radial engines and some

flat/ horizontally opposed, inline, and even popular for large

turboprop engines. The splined shaft has grooves and splines of

equal dimensions, and a master, or double-width, spline so that

a hub will fit on the shaft in only one position.

Figure 17.2.15

ISO 9001 - 2008 Certified For Training Purpose Only

PTC/CM/B1.1 Basic/M17A/01 Rev. 01

17.2 - 18 Nov 2017

PIA TRAINING CENTRE (PTC) Module 17A – PROPELLER

Category – A/B1 Sub Module 17.2 – Propeller Construction

SPINNER INSTALLATION

All modern propeller-driven airplanes have spinners over their

propeller hubs. These spinners have the dual aerodynamic

function of streamlining the engine installation and directing cool

air into the openings in the Cowling.

Figure 17.2.18 shows a typical spinner installation over a

constant-speed propeller. The spinner bulkhead is installed on

the propeller shaft flange and held in place by six spinner

attaching bolts. The propeller is then installed so that the dowel

pins in the propeller hub align with the holes in the flange. The

propeller attaching nuts are installed and tightened to the torque

value specified in the airframe maintenance manual.

If a spinner support is required, it is installed and the spinner is

secured to the bulkhead with the proper machine screws. The

propeller spinner and bulkhead are critical components, and

cracks in either one can be repaired only if they do not exceed

the allowable limits. Repair them using the procedures specified

in the airframe maintenance manual and take special care not

to add weight where it could cause vibration.

ISO 9001 - 2008 Certified For Training Purpose Only

PTC/CM/B1.1 Basic/M17A/01 Rev. 01

17.2 - 19 Nov 2017

PIA TRAINING CENTRE (PTC) Module 17A – PROPELLER

Category – A/B1 Sub Module 17.2 – Propeller Construction

Figure 17.2.18

ISO 9001 - 2008 Certified For Training Purpose Only

PTC/CM/B1.1 Basic/M17A/01 Rev. 01

17.2 - 20 Nov 2017

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Hammerless Washpipe ManualDocument50 pagesHammerless Washpipe ManualEdisson Mojica Bolivar100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Belarus Tractor Operators Manual Be o t40Document7 pagesBelarus Tractor Operators Manual Be o t40Goran Marija Stosic100% (1)

- PIA B2 - Module 2 (PHYSICS) SubModule 2.3 (Thermodynamics) FiDocument36 pagesPIA B2 - Module 2 (PHYSICS) SubModule 2.3 (Thermodynamics) FiInterogator5No ratings yet

- IOM Manual Compresor FLSDocument196 pagesIOM Manual Compresor FLSRaymond BarriosNo ratings yet

- FFS-1 2016 Errata 1 PDFDocument47 pagesFFS-1 2016 Errata 1 PDFdoctNo ratings yet

- Module 9 (Human Factors) Sub Module 9.2 (Human PerformanceDocument25 pagesModule 9 (Human Factors) Sub Module 9.2 (Human PerformanceInterogator5No ratings yet

- Module 9 (Human Factors) Sub Module 9.3 (Social Psychology)Document20 pagesModule 9 (Human Factors) Sub Module 9.3 (Social Psychology)Interogator5No ratings yet

- Module 9 (Human Factors) Sub Module 9.7 (Communication) - RevDocument13 pagesModule 9 (Human Factors) Sub Module 9.7 (Communication) - RevInterogator5No ratings yet

- PIA B2 - Module 2 (PHYSICS) SubModule 2.1 (Matter) FinalDocument20 pagesPIA B2 - Module 2 (PHYSICS) SubModule 2.1 (Matter) FinalInterogator5No ratings yet

- PIA B2 - Module 2 (PHYSICS) SubModule 2.2 (Mechanics) FinalDocument57 pagesPIA B2 - Module 2 (PHYSICS) SubModule 2.2 (Mechanics) FinalInterogator5No ratings yet

- PIA B1.1 - Module 2 (PHYSICS) SubModule 2.1 (Matter) Final1Document20 pagesPIA B1.1 - Module 2 (PHYSICS) SubModule 2.1 (Matter) Final1Interogator5No ratings yet

- PIA B1.1 - Module 2 (PHYSICS) SubModule 2.4 (Optics) FinalDocument25 pagesPIA B1.1 - Module 2 (PHYSICS) SubModule 2.4 (Optics) FinalInterogator5No ratings yet

- Sub Module 3.12 DC Gen MotorsDocument51 pagesSub Module 3.12 DC Gen MotorsInterogator5No ratings yet

- Sub Module 3.17 AC GENDocument24 pagesSub Module 3.17 AC GENInterogator5No ratings yet

- Sub Module 3.10 MagnetismDocument20 pagesSub Module 3.10 MagnetismInterogator5No ratings yet

- PIA B1.1 - Module 2 (PHYSICS) SubModule 2.2 (Mechanics) FinalDocument79 pagesPIA B1.1 - Module 2 (PHYSICS) SubModule 2.2 (Mechanics) FinalInterogator5No ratings yet

- Sub Module 3.18 AC MotorsDocument22 pagesSub Module 3.18 AC MotorsInterogator5No ratings yet

- Sub Module 3.15 TransformersDocument23 pagesSub Module 3.15 TransformersInterogator5No ratings yet

- Sub Module 3.11 Inductance FinalDocument17 pagesSub Module 3.11 Inductance FinalInterogator5No ratings yet

- Sub Module 3.13 AC THEORYDocument26 pagesSub Module 3.13 AC THEORYInterogator5No ratings yet

- PTC B1.1 Notes - Sub Module 15.11 (Fuel Systems)Document35 pagesPTC B1.1 Notes - Sub Module 15.11 (Fuel Systems)Interogator5No ratings yet

- Sub Module 3.7 (Resistance) Final2Document19 pagesSub Module 3.7 (Resistance) Final2Interogator5No ratings yet

- Sub Module 3.9 Capacitance FinalDocument26 pagesSub Module 3.9 Capacitance FinalInterogator5No ratings yet

- Sub Module 3.3 (Electrical Terminology) FinalDocument20 pagesSub Module 3.3 (Electrical Terminology) FinalInterogator5No ratings yet

- Sub Module 3.4 Gen of Electricity FinalDocument8 pagesSub Module 3.4 Gen of Electricity FinalInterogator5No ratings yet

- PTC B1.1 Notes - Sub Module 15.8 (Bearings and Seals)Document22 pagesPTC B1.1 Notes - Sub Module 15.8 (Bearings and Seals)Interogator5No ratings yet

- Sub Module 3.2 ElectrostaticsDocument25 pagesSub Module 3.2 ElectrostaticsInterogator5No ratings yet

- PTC B1.1 Notes - Sub Module 15.5 (Combustion Section)Document19 pagesPTC B1.1 Notes - Sub Module 15.5 (Combustion Section)Interogator5No ratings yet

- Servomechanism: PIA Training Centre (PTC)Document13 pagesServomechanism: PIA Training Centre (PTC)Interogator5No ratings yet

- Printed Circuit Boards: PIA Training Centre (PTC)Document9 pagesPrinted Circuit Boards: PIA Training Centre (PTC)Interogator5No ratings yet

- Seismic Design of Reinforced Concrete and Masonry Buildings - T.paulay, M.priestley (1992) - +Document764 pagesSeismic Design of Reinforced Concrete and Masonry Buildings - T.paulay, M.priestley (1992) - +Freddy Mauricio Lucay88% (8)

- Piaggio X7 125 - MaintenanceDocument80 pagesPiaggio X7 125 - MaintenanceZoilo Dominguez100% (2)

- TEMA Standards Inquiries 2020Document24 pagesTEMA Standards Inquiries 2020Nisarg Patel100% (1)

- Behaviour of Laterally Loaded Piles in C PDFDocument3 pagesBehaviour of Laterally Loaded Piles in C PDFdesigner STRNo ratings yet

- HVACwork3L3L3 PDFDocument69 pagesHVACwork3L3L3 PDFZeeshan HasanNo ratings yet

- Dynamic of HS Railway BridgesDocument8 pagesDynamic of HS Railway BridgesNuno Telmo Lopes100% (1)

- C-Beam Mini Mite BOMDocument4 pagesC-Beam Mini Mite BOMyinat24979No ratings yet

- Exercise6 Stripper SolutionDocument8 pagesExercise6 Stripper SolutionHoney AlarconNo ratings yet

- Science Form 1 NoteDocument5 pagesScience Form 1 NoteDaniel ChanNo ratings yet

- Advantages of Pressure Independent Control ValvesDocument3 pagesAdvantages of Pressure Independent Control ValvesMohamed Aboobucker Mohamed IrfanNo ratings yet

- Genuine: Choose Every Time!Document40 pagesGenuine: Choose Every Time!DinamikaMarine50% (2)

- Design of Truss Roof: University of Engineering & Technology, TaxilaDocument42 pagesDesign of Truss Roof: University of Engineering & Technology, TaxilaNicko Jay BajaoNo ratings yet

- Explosive Forming Process PDFDocument2 pagesExplosive Forming Process PDFStevenNo ratings yet

- Parker PDFDocument48 pagesParker PDFcguillermosmNo ratings yet

- Magnetic Float Level Switch - KleevDocument2 pagesMagnetic Float Level Switch - KleevRAMZI ALJILANYNo ratings yet

- Tutorials PTT 205Document2 pagesTutorials PTT 205Celine NathaliaNo ratings yet

- Gem General CatDocument56 pagesGem General Catvalerio.garibayNo ratings yet

- SAMDocument38 pagesSAMCHELVASERNo ratings yet

- Lecture 8-Shearing Forces and Bending Moments in Beams (DELIVERED)Document30 pagesLecture 8-Shearing Forces and Bending Moments in Beams (DELIVERED)Naledi KetlogetsweNo ratings yet

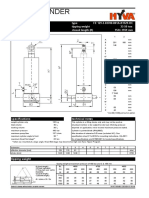

- Hywa Tipping Cylinder-71534201Document2 pagesHywa Tipping Cylinder-71534201manoj_doshi_1No ratings yet

- Beam Torsion CheckDocument9 pagesBeam Torsion CheckSamir PrajapatiNo ratings yet

- Vacuum Requirements For Cryogenic Vessels: A Journal of From Practical and Useful Vacuum TechnologyDocument2 pagesVacuum Requirements For Cryogenic Vessels: A Journal of From Practical and Useful Vacuum TechnologyEduardo LopesNo ratings yet

- ABAQUS TutorialDocument3 pagesABAQUS TutorialFernando CastroNo ratings yet

- Electrode Brand Name and Class MirfaDocument13 pagesElectrode Brand Name and Class MirfaAnonymous rYZyQQot55No ratings yet

- Operation and Maintenance of Diesel Elec-1Document317 pagesOperation and Maintenance of Diesel Elec-1Bala RajuNo ratings yet