Walthamstow Borough

Head Office Work Management IIC BY EDUCATION

Elizabeth House Plan

39 York Road WALTHAM FOREST

LONDON SE1 7NQ SCHOOLS PROJECT

Tel: 020 7401 0020

Frederick Bremer & Kelmscott

schools

Waltham Forest BSF

ORIGINATOR

TITLE

READY MIXED CONCRETE SUPPLY, TESTING & PLACING

Name Signature -

Designed JCU 27/04/07 Scale Format Proposed Status

Prepared by JCU 27/04/07

Checked DMR 27/04/2007 -

Approved Date of 1st issue File Name

AREA LEVEL TRADE SCHOOL ISSUER TYPE SEQUENCE INDEX REV.

0 SL E0 ALL BYG WMP XXX A

Page 1 of 16

� Walthamstow Borough

Head Office Work Management IIC BY EDUCATION

Elizabeth House Plan

39 York Road WALTHAM FOREST

LONDON SE1 7NQ SCHOOLS PROJECT

Tel: 020 7401 0020

1 General

1.1 Scope of the procedure & reference to other documents :

The particular scope of this document is to provide the reader with a general understanding of the procedure to be

followed for call-off ordering of fresh ready mixed concrete, concrete testing and placing on site.

This document should be red in conjunction with the following other documents:

- Project Specification for concrete and associated Building Regulation, British Standards – refer to

list of documents in Annex 6.

- The Project Management Plan, DOCUMENT NO: ALL/ SL/ A0/ ALL/ BYG/ PMP/01/last revision

- The [Link] for concrete structural works (Inspection Test Approval Plans) included in Q.V.F.

(Quality Verification Files)

1.2 Organisation and responsibilities :

A detailed organisation chart for the persons involved in the activity and their respective responsibilities can be

found in Annex 7.

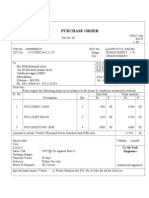

2 Call-off Ordering process :

2.1 Daily Orders

For daily orders not exceeding 100 m3 per site, the Superintendent in charge, or Engineer in charge of the activity,

shall fax orders, using the “Concrete Call-Off Order” form correctly and completely filled (See Annex 2) to the

Supplier on the previous working day by 2:00 p. m.

Where the daily order is expected to exceed this amount, at least 2 days notice must be given.

The Supplier must confirm his ability to meet the order by 5:00 p.m. on the working day before the delivery. Any

proposed amendments must be discussed and agreed with the site management before delivery.

Then, the exact timings of all orders are to be confirmed by phone or fax, on the day of delivery, by the

Supervisor using the same Daily Concrete Supply form and updating with the last accurate information – refer to

in Annex 2.

The respect in delivery times and frequencies by the supplier, or any other incidents, problems have to be

monitored and recorded on this form and faxed to the supplier for follow up of extra costs.

Concrete call-off order check:

Confirmation of Concrete order the previous day shall be faxed to the Supplier once the relevant persons in charge

(Superintendent, Site Engineer or Production Manager) have checked, approved and signed the form.

All Call-Off order forms shall be kept in the QVF file by the relevant Engineer in charge.

Page 2 of 16

� Walthamstow Borough

Head Office Work Management IIC BY EDUCATION

Elizabeth House Plan

39 York Road WALTHAM FOREST

LONDON SE1 7NQ SCHOOLS PROJECT

Tel: 020 7401 0020

2.2 Weekly concrete forecast :

A weekly schedule shall be prepared and sent by e-mail or faxed, for information, to the Supplier by the

Superintendent every Friday, or if not available by the Site Engineer. The purpose of this document is to inform

the supplier well in advance about the quantity and frequency of concrete expected to be ordered and poured each

day of the following week.

Refer to form in annex 3.

2 Conformity and Identity Testing

3.1 Concrete Delivery Notes Checks

The checks of concrete deliveries on site have to follow the flowchart in Annex 1.

A dedicated and trained operator on site in charge of the concrete checks (“the concrete operator“) has to verify

systematically the delivery notes against the call-off orders.

The concrete operator needs to ensure that the following information are available on the delivery dockets:

Name and full address of the delivery plant

Date and time of the delivery

Dispatch Note serial number / reference

Name of purchaser

Name and location of the delivery site

Details of the truck-mixer ( identification of the truck and/or driver )

Concrete details

Mix description as per BS 8500-1&2

Specified slump

Maximum water/cement ratio

Cement type

Minimum cement content (kg/m3)

Aggregate type and size

Type of admixture included

Concrete quantity (in m3)

Batching time (at the plant)

Site arrival reporting time

Time of loading

Time of completion of unloading

The signatures of the truck driver and BY UK person in charge ( The Superintendent, or the concrete

operator eventually )

Any comments added onto the delivery docket if necessary ( non-compliance or non-conformity,

concrete rejected, any problems occurred, etc. )

IMPORTANT NOTA :

-If the truck arrival time on site is more than 1 Hour after the batching time, then the concrete should be

REJECTED.

Page 3 of 16

� Walthamstow Borough

Head Office Work Management IIC BY EDUCATION

Elizabeth House Plan

39 York Road WALTHAM FOREST

LONDON SE1 7NQ SCHOOLS PROJECT

Tel: 020 7401 0020

- NO WATER TO BE ADDED ON SITE. If the consistence of the concrete is not suitable for the pour,

the concrete should be rejected and the delivery docket commented accordingly.

Once the concrete is accepted, the concrete delivery note is to be signed and passed to the Engineer in charge with

the Daily Concrete Supply sheet for monitoring.

3.2 Visual check of the concrete mixture :

The trained concrete operator has to carry out systematic visual checks of the followings for each concrete

delivery:

- visual aspect of the fresh concrete

- consistence of the concrete mixture

- quality of the mixing

3.3 Slump Tests

The slump of the concrete will be checked on site in accordance with BS EN 206-1, annex B and BS 8500-1,

annex B.

On site, slump tests will be carried out as per the controls & frequency defined in the relevant ITAP, each time a

set of concrete cubes will be made, and following any visual check if the concrete operator has doubt about the

expected consistence of the concrete delivered.

Any concrete with a slump measurement outside specified tolerance will be rejected.

Acceptance criteria for designated slump is:

SLUMP [mm] +/- (25mm) or +/- (1/3 SLUMP [mm])

Or

Acceptance criteria for class of consistence :

Class : Mmin. Slump Max.

S1 10 <= S <= 40

S2 50 <= S <= 90

S3 100 <= S <= 150

S4 160 <= S <= 210

S5 220 <= S

The method for the Slump test can be followed in Annex 5.

The record of the Slump results shall be recorded onto the delivery dockets and the “Concrete

Test Record” – refer to form in Annex 4

Page 4 of 16

� Walthamstow Borough

Head Office Work Management IIC BY EDUCATION

Elizabeth House Plan

39 York Road WALTHAM FOREST

LONDON SE1 7NQ SCHOOLS PROJECT

Tel: 020 7401 0020

3.4 Temperature limitation for concrete :

Normal temperature limitation for concrete placing: 30˚c (maximum) and 5˚c (minimum)

For external temperature 0˚c <T<5˚c:

Specific work precautions need to be taken when external temperature <5˚c.

- During cold spells, prefer CEMI or CEM II cement instead of CEMIII; the content of cement can be

increased as well; reduce ratio W/C and prefer admixtures (both concrete supplier and Structural consultant need

to be contacted for this and approve new mix designation).

- Surfaces exposed to cold temperatures and frost (shutters, formworks, blinding concrete, etc.) need to

be insulated and protected (tarpaulin for example).

- The concrete temperature at the point of delivery will be monitored during cold spells; concrete not

meeting the minimum temperature requirement (fresh concrete temperature =>10˚c) will be rejected. This

information shall be written down on the delivery docket and the “Concrete Test Record”.

- DO NOT PLACE concrete against frozen or frost covered surfaces.

When External Temperature < 0˚c:

Concreting HAS TO BE STOPPED.

For temperature > 25˚c:

During hot spells, prefer CEMII or CEMIII cement instead of CEMI.

Exposed surface of concrete pour needs to be damped down to avoid drying of fresh concrete (precast planks or

hollowcore slabs for example).

IMPORTANT:

- DO NOT ADD WATER ON SITE, use additional admixtures supplied by concrete supplier

- Use adequate curing product straight after the pour.

3.5 Concrete cubes preparation & compressive strength testing :

The compressive strength of the different concrete mixes incorporated to the definitive structure will be tested and

monitored.

Concrete cubes will be prepared on site by the concrete operator in accordance with BS EN 12390-2:2000 and as

per the type and frequency defined in the project specifications and ITAP.

From each sample of 4 cubes the following is carried out:

- 1 cube test at 7 days

- 2 cubes tested at 28 days

- 1 cube held in store, pending instruction from the Engineer

Page 5 of 16

� Walthamstow Borough

Head Office Work Management IIC BY EDUCATION

Elizabeth House Plan

39 York Road WALTHAM FOREST

LONDON SE1 7NQ SCHOOLS PROJECT

Tel: 020 7401 0020

For each set of 4 cubes cast, a consecutive number will be marked indelibly ranging from A-D for each one in the

set.

The Numbering reference for the Cubes is:

CUBE Number- A (for test at 7 days)

CUBE Number – B (for test at 28 days)

CUBE Number – C (for test at 28 days)

CUBE Number – D (for storage)

Concrete cubes will be collected and tested by a certified UKAS Laboratory in accordance with the

recommendation and frequency defined in the project Specifications or ITAP.

The method for the preparation of cube samples for cube testing is shown in Annex 5.

Result of Testing

The laboratory will provide three copies of the crush test results within one day of the completion of each test –

The Engineer in charge will keep record of the test results for each set of concrete cubes made with inherent

traceability in the Concrete Test Record (identification of the plant used for the batch, identification of numbers of

specimens, location of part of the structure, slump result, compressive strength results at 7, 28 days at least,

additional comments, refer to form in Annex 4 ), and will carry out a strength statistical analysis on a weekly

basis.

Broken cubes from failed identity tests :

Keep separately the pieces of each cube which fail to meet the conformity requirements for individual results for

further tests.

Any concrete strength failure will be reported immediately to the Structural Consultant and treated as a non-

conformance.

Refer to Project Management Plan for depth information about the non-conformance & remedial work process.

3.6 Concrete pouring monitoring:

The Foreman responsible for the pour will write the following information on the Delivery Docket: area, concrete

element type poured, slump test result and cube set numbers.

The Superintendent responsible for each area will complete “the sequence of pouring drawing“: based on a

structural layout drawings specifically dedicated for this use. The Superintendent will record on a daily basis the

concrete elements poured and the date of the pour by highlighting the area done on the drawings.

Once completed these drawings will be kept by the Engineer in charge in the main QVF.

Page 6 of 16

� Walthamstow Borough

Head Office Work Management IIC BY EDUCATION

Elizabeth House Plan

39 York Road WALTHAM FOREST

LONDON SE1 7NQ SCHOOLS PROJECT

Tel: 020 7401 0020

Annex 1 - Concrete delivery checks flowchart

Delivery note check:

Type, designation,

quantity, consistence

Concrete rejected Does the concrete mix

No comply with the order?

Yes

Does the plant used is an

No

approved one?

Yes

No

Does the time between the batch and the truck

arrival on site less than 1h 00?

Yes

Record the arrival time on

delivery docket

Second check of docket,

designation of concrete Does the visual aspect of the

No fresh concrete is as usually?

Are the modifications Yes

No acceptable? Yes

Does the visual consistence of the

fresh concrete satisfactory? Yes

Slump test measurement

Record slump result on Does the slump result within the

delivery docket tolerances?

Yes

Concrete mix can be used.

Cube tests can be prepared.

Record the element poured on

delivery docket.

Complete and sign the docket.

Page 7 of 16

� Walthamstow Borough

Head Office Work Management IIC BY EDUCATION

Elizabeth House Plan

39 York Road WALTHAM FOREST

LONDON SE1 7NQ SCHOOLS PROJECT

Tel: 020 7401 0020

Annex 2 - Concrete Call-off order form

Page 8 of 16

� Walthamstow Borough

Head Office Work Management IIC BY EDUCATION

Elizabeth House Plan

39 York Road WALTHAM FOREST

LONDON SE1 7NQ SCHOOLS PROJECT

Tel: 020 7401 0020

Annex 3 - Weekly concrete forecast form

Page 9 of 16

� Walthamstow Borough

Head Office Work Management IIC BY EDUCATION

Elizabeth House Plan

39 York Road WALTHAM FOREST

LONDON SE1 7NQ SCHOOLS PROJECT

Tel: 020 7401 0020

Annex 4 - Concrete Test Record form

Page 10 of 16

� Walthamstow Borough

Head Office Work Management IIC BY EDUCATION

Elizabeth House Plan

39 York Road WALTHAM FOREST

LONDON SE1 7NQ SCHOOLS PROJECT

Tel: 020 7401 0020

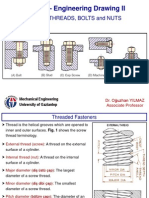

Annex 5

Slump Testing & concrete cubes making procedures

Slump Testing

Principle

Fresh concrete is compacted into a mould in the shape of a frustrum of a cone. When the cone is withdrawn

upwards, the distance the concrete has slumped provides a measure of the consistency of the concrete.

Apparatus

Piece of Apparatus Information

Mould Metal, not thinner than 1,5mm

Base diameter 200 mm

Top diameter 100 mm

Height 300 mm

Compacting rod Circular cross-section, straight, made of steel with rounded ends

16 mm diameter

600 mm length

Funnel Optional

Rule Graduated from 0 mm to 300 mm at intervals not exceeding 5 mm

Base plate / surface Rigid, flat, plate

Remixing container Flat tray of rigid construction

Shovel Square mouth (ensures proper mixing of material)

Moist cloth

Scoop 100 mm in width

Timer Capable of measuring 1 s.

Procedure

1. Place dampened mould on the dampened base plate

2. Fill mould while holding it firmly against the base plate

3. Fill mould in 3 layers of equal depths up to the top of the mould

4. Compact each layer with 25 uniformly distributed strokes of the tamping rod

5. Remove mould from concrete in 5-10 s. by raising it carefully in a vertical direction

6. Entire operation (from start of filling to mould removal) should be complete within 150 s.

7. Immediately after removal of the mould, measure and record the slump (h)

Test result

The test is only valid if it yields a true slump. If the specimen shears, another sample shall be taken. If two

consecutive tests show a portion of the concrete shearing off from the mass of the test specimen, the concrete

lacks the necessary plasticity and cohesiveness for the slump test to be suitable. Examples of True slump and

Shear slump are shown in Figure 1. The True slump (h) should be reported as shown in Figure 2, to the nearest

10 mm.

Page 11 of 16

� Walthamstow Borough

Head Office Work Management IIC BY EDUCATION

Elizabeth House Plan

39 York Road WALTHAM FOREST

LONDON SE1 7NQ SCHOOLS PROJECT

Tel: 020 7401 0020

Test report

The report is to include:

a) identification of the test sample;

b) location of performance of test;

c) date of performance of test;

d) type of slump – true/shear;

e) measured true slump, to nearest 10 mm;

f) any deviation from standard test method;

g) a declaration by the person carrying out the test that it was carried out in accordance with BS EN 12350-

2:2000, except as noted in item f).

Page 12 of 16

� Walthamstow Borough

Head Office Work Management IIC BY EDUCATION

Elizabeth House Plan

39 York Road WALTHAM FOREST

LONDON SE1 7NQ SCHOOLS PROJECT

Tel: 020 7401 0020

Cube Sample Preparation

Principle

Concrete test cubes are the basis of the most important quality control there is for checking on hardened concrete.

Cubes are made from a sample of fresh concrete using special moulds. These are then sent to a laboratory where

the compressive strength of the cubes is tested. The following information has been obtained from BS EN 12390-

2:2000. This standard covers the preparation and filling of moulds, compaction of the concrete, levelling the

surface, curing of test specimens and transporting test specimens. Typical specimen dimensions include 100 mm

and 150 mm cubes (Refer to Figure 5)

Apparatus

Piece of Apparatus Information

Mould Watertight and non-absorbent (in compliance with EN 12390-1)

Internal vibrator or 120 Hz minimum frequency

Vibrating table or 40 Hz minimum frequency

Compacting rod or Steel, 16 mm Ø circular cross-section, 600 mm length, rounded ends

Compacting bar Steel, 25 mm x 25 mm square cross-section, 380 mm length

Scoop Non-absorbent material, 100 mm width

Steel trowels or floats 2 No.

Remixing container Flat tray of non-absorbent material, appropriately dimensioned for re-mixing concrete

using square-mouthed shovel

Shovel Square-mouthed (to ensure proper mixing of material)

Non-reactive mould

release material

Procedure

1. Ensure all apparatus is clean and in good condition

2. Batches should be sampled at random times predefined at the start of each day

3. Collect the sample in the container using the scoop as the concrete is being discharged from the mixer/truck

mixer

4. Take one scoop after one fifth of the batch has been discharged, and then one from each remaining fifth of the

load.

5. A batch should be regarded as the discharge from a continuous mixer during one minute, and the scoopfuls

taken at 12 second intervals

6. Re-mix the sample in the remixing container with the square mouth shovel

7. Before filling the moulds, the inner surface of the mould should be covered with a thin film of non-reactive

release material to prevent the concrete from adhering to the mould

8. When filling the mould (Refer to Figure 3) with the remixed material, specimens shall be compacted in a

minimum of two layers, but no layer should be more than 100 mm in thickness

9. a) Mechanically vibrate the sample with the internal vibrator or the vibrating table

b) Manually compact the sample with at least 25 tamping strokes of the rod per layer (Refer to Figure

4)

10. To level the surface, remove excess concrete above the upper edge of the mould using two steel trowels or

floats, brought together with a sawing action, & carefully level the surface

11. The test specimens shall be marked clearly and indelibly, without damaging the specimen

12. Records shall be kept to ensure the traceability of the specimen from sampling to testing

Page 13 of 16

� Walthamstow Borough

Head Office Work Management IIC BY EDUCATION

Elizabeth House Plan

39 York Road WALTHAM FOREST

LONDON SE1 7NQ SCHOOLS PROJECT

Tel: 020 7401 0020

13. Leave test specimens in the mould for at least 16 hours, but not longer than 3 days, protected against shock,

vibration and dehydration at a temperature of approx. 20oC

14. After removal from the mould, cure the test specimens till immediately before testing, in water at a

temperature of 20oC

Test report

The report is to include:

a) identification of the test sample;

b) date and time of making the specimen

c) details of storage of specimens prior to de-moulding, including duration and conditions

d) method of curing specimens after de-moulding, during transportation, giving temperature range and duration

of curing (if appropriate)

e) any deviation from the standard method of making and curing specimens

f) a declaration by the person technically responsible, that the sample was obtained in accordance with BS EN

12390-2:2000, except as noted in item e).

Figure 3 – Mould

Figure 4 – Manual Compaction Figure 5 – Acceptable Specimen Dimensions

Page 14 of 16

� Walthamstow Borough

Head Office Work Management IIC BY EDUCATION

Elizabeth House Plan

39 York Road WALTHAM FOREST

LONDON SE1 7NQ SCHOOLS PROJECT

Tel: 020 7401 0020

Annex 6

Reference to other project documents & National Standards

Project documents :

- - Waltham Forest Project Management Plan : ALL-SL-A0-ALL-BYG-PMP-01-last revision

Concrete Specifications :

- Terrell, Structural Consultant :

BREMER Specification for concrete BR-TIL-SPE-100003-612-revision C

KELMSCOTT Specification for concrete KS-TIL-SPE-100003-612-revision B

Relevant British Standards for the activity:

- BS 8110: Structural Use of concrete. Alternative is Eurodode EC2 with UK NAD

- BS EN 206-1: Concrete. Specification, performance, production and conformity.

- BS 8204-1 and 2: Screeds, bases and in-situ floorings

- BS 8500-1 and 2: Method of specifying and guidance for the specifier

Specification for constituent materials and concrete

- BS EN 12350-2 : 2000: Testing fresh concrete – Slump test

- BS EN 12390-2 : 2000: Testing hardened concrete

Page 15 of 16

� Walthamstow Borough

Head Office Work Management IIC BY EDUCATION

Elizabeth House Plan

39 York Road WALTHAM FOREST

LONDON SE1 7NQ SCHOOLS PROJECT

Tel: 020 7401 0020

Annex 7 - Organisation chart & responsibilities for persons

involved in the activity

Frederick Bremer School Kelmscott School

Site Manager : Nicolas COURQUIN Site Manager : Lee WEST

Civil Works Manager : David MORIN Civil Works Manager : David MORIN

Site Engineer in charge : Thomas JUDE Site engineer in charge: Jeremy LEFEVRE

Structural engineer: Rabih Waked Structural engineer: Rabih Waked

Superintendent of works: Patrick Poupard Supervisor : to be defined -

Site Supervisor: Sebastien Renaude

Responsabilities :

Site Manager: who is in control of the overall activity of the project, makes sure that Health and Safety

requirements and the Project System Management is followed by any member of the team. Will review the

PMP, and can decide an update of the PMP or WMP with QSE Manager and Trades Manager whenever

necessary.

Civil Works Manager: is in direct charge of the civil works activity and its specific Health and Safety

requirements, prepares the WMP with Engineers and Superintendent. Can decide to review and update the

WMP whenever necessary.

QSE Manager: is in charge of the preparation and the updates of the Project System Management Plan (PMP);

will review the WMP.

Site Engineers: who are in charge of the activity on site and will make sure that the work done complies with

British Regulations, Project Specifications, approved documentations, and Company standard procedures. They

participate to the preparation and approval of WMP. They will prepare the relevant ITAPs.

They will make sure that PMP, WMP and ITAPs are fully followed by any member of their team and will carry

out quality controls and tests on site (fill in WIR).

Superintendents or Supervisors of Works: who supervise either a section of the job or the overall job; will

comment and approve the WMP. They will make sure that procedures described in WMP and ITAPs are fully

followed by any member of the team and will carry out quality and tests controls on site (fill in WIR).

Foremen; who supervise a part of the activity, and also supervise the skilled and trained workers involved in the

activity, will carry out quality controls on site (fill in WIR).

Page 16 of 16