Professional Documents

Culture Documents

13p Blistering

13p Blistering

Uploaded by

Richard0 ratings0% found this document useful (0 votes)

1 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

1 views2 pages13p Blistering

13p Blistering

Uploaded by

RichardCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

CIP 13 - Concrete Blisters

WHAT are Blisters?

DENSE TROWELED SURFACE

Blisters are hollow, low-profile bumps on the concrete

surface, typically from the size of a dime up to 1 inch

(25 mm), but occasionally even 2 or 3 inches (50 – 75

mm) in diameter. A dense troweled skin of mortar

about 1/8 in. (3 mm) thick covers an underlying void

that moves around under the surface during troweling.

Blisters may occur shortly after the completion of fin-

ishing operation. In poorly lighted areas, small blisters AIR AND BLEED WATER

may be difficult to see during finishing and may not be

detected until they break under traffic.

WHY do Blisters Form?

Blisters may form on the surface of fresh concrete

when either bubbles of entrapped air or bleed water

migrate through the concrete and become trapped un-

der the surface, which has been sealed prematurely

during the finishing operations. These defects are not

easily repaired after concrete hardens.

Blisters are more likely to form if: Concrete Blister

1. Insufficient or excessive vibration is employed. 4. Entrained air is used or is higher than normal. Rate

Insufficient vibration prevents the entrapped air of bleeding and quantity of bleed water is greatly

from being released and excessive use of vibrat- reduced in air-entrained concrete giving the ap-

ing screeds works up a thick mortar layer on the pearance that the concrete is ready to float and

surface. further finish causing premature finishing.

2. An improper tool is used for floating the surface 5. The subgrade is cooler than concrete. The top

or it is used improperly. The surface should be surface sets faster than the concrete in the bot-

tested to determine which tool, whether it be wood tom and the surface appears ready to be floated

or magnesium bull float, does not seal the surface. and further finished.

The floating tool should be kept as flat as possible.

6. The slab is thick and it takes a longer time for the

3. Excessive evaporation of bleed water occurs and entrapped air and bleed water to rise to the sur-

the concrete appears ready for final finishing op- face.

erations (premature finishing), when, in fact, the

7. The concrete is cohesive or sticky from higher

underlying concrete is still releasing bleed water

content of cementitious materials or excessive fines

and entrapped air. High rate of bleed water evapo-

in the sand. These mixtures also bleed less and at

ration is especially a problem during periods of high

a slower rate. Concrete mixtures with lower con-

ambient temperatures, high winds and/or low hu-

tents of cementitious materials bleed rapidly for a

midity.

shorter period, have higher total bleeding and tend

to delay finishing.

8. A dry shake is prematurely applied, particularly

over air-entrained concrete.

9. The slab is placed directly on top of a vapor re-

tarder or an impervious base, preventing bleed

water from being absorbed by the subgrade.

HOW To Prevent Blisters?

The finisher should be wary of a concrete surface that

appears to be ready for final finishing before it would

normally be expected. Emphasis in finishing opera-

tions should be on placing, striking off and bull floating

the concrete as rapidly as possible and without work-

ing up a layer of mortar on the surface. After these

operations are completed, further finishing should be References

delayed as long as possible and the surface covered 1. Guide for Concrete Floor and Slab Construction, ACI

with polyethylene or otherwise protected from evapo- 302.1R, American Concrete Institute, Farmington Hills,

ration. If conditions for high evaporation rates exist, MI. www.concrete.org

place a cover on a small portion of the slab to judge if 2. Slabs on Grade, ACI Concrete Craftsman Series, CCS

the concrete is still bleeding. In initial floating, the float 1, American Concrete Institute, Farmington Hills, MI.

blades should be flat to avoid densifying the surface 3. Hot weather Concreting, ACI 305R, American Con

too early. Use of an accelerating admixture or heated crete Institute, Farmington Hills, MI.

concrete often prevents blisters in cool weather. It is 4. Concrete Slab Surface Defects: Causes,

recommended that non-air entrained concrete be used Prevention,Repair, IS 177, Portland Cement Associa

in interior slabs and that air entrained concrete not be tion, Skokie, IL. www.cement.org

steel troweled. 5. Concrete Surface Blistering—Causes and Cures, Carl

O. Peterson, Concrete Construction, September 1970.

If blisters are forming, try to either flatten the trowel

www.concreteconstruction.net

blades or tear the surface with a wood float and delay

6. CIP 14 - Finishing Concrete Flatwork; CIP 20 -

finishing as long as possible. Under conditions causing Delamination of Troweled Concrete Surfaces, NRMCA

rapid evaporation, slow evaporation by using wind CIP Series. www.nrmca.org.

breaks, water misting of the surface, evaporation re- 7. Finishing, Concrete Construction, August 1976, p. 369.

tarders, or a cover (polyethylene film or wet burlap) 8. Finishing Problems and Surface Defects in Flatwork,

between finishing operations. Further recommenda- Concrete Construction, April 1979.

tions are given in ACI 302.1R and ACI 305.

Follow These Rules to Avoid Blisters

1. Do not seal surface before air or bleed water from below have had a chance to escape.

2. Avoid dry shakes on air-entrained concrete.

3. Use heated or accelerated concrete to promote even setting throughout the depth of the slab in cooler

weather.

4. Do not place slabs directly on vapor retarders. If vapor retarders are essential (CIP 28) take steps to avoid

premature finishing.

5. Protect surface from premature drying and evaporation.

6. Do not use a jitterbug or excessive vibration such as a vibratory screed on slumps over 5 inches (125 mm).

7. Air entrained concrete should not be steel troweled. If required by specifications, extreme caution should be

exercised when timing the finishing operation.

1983, 2001, 2005

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- PrEN 13043 - Aggregates For Bituminous Mixtures and SurfaceDocument45 pagesPrEN 13043 - Aggregates For Bituminous Mixtures and SurfacePedja100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Comparisons Between GRP Pipes With Various Metallic by NadeemDocument16 pagesComparisons Between GRP Pipes With Various Metallic by NadeemAli ZarehNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ashirvad CPVC - Price List - 1st March 2021Document14 pagesAshirvad CPVC - Price List - 1st March 2021Ujwal Elijah Gurram100% (1)

- Petar Subotic - Prirucnik Za Asfalt I DeoDocument308 pagesPetar Subotic - Prirucnik Za Asfalt I DeoPedjaNo ratings yet

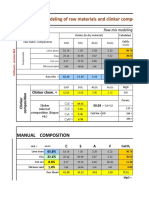

- Cement Calculus 28Document2 pagesCement Calculus 28PedjaNo ratings yet

- PrEN 13020 - Road Surface Treatment MachinesDocument20 pagesPrEN 13020 - Road Surface Treatment MachinesPedjaNo ratings yet

- Klinker Composition CalculationProt 231bDocument28 pagesKlinker Composition CalculationProt 231bPedjaNo ratings yet

- NRMC CIP 26pDocument2 pagesNRMC CIP 26pPedjaNo ratings yet

- PrEN 12273 - Slurry Surfacing - Product StandardDocument25 pagesPrEN 12273 - Slurry Surfacing - Product StandardPedjaNo ratings yet

- NRMC CIP 23pDocument2 pagesNRMC CIP 23pPedjaNo ratings yet

- PrEN 12271-10 - Factory Production ControlDocument17 pagesPrEN 12271-10 - Factory Production ControlPedjaNo ratings yet

- NRMC CIP 20pDocument2 pagesNRMC CIP 20pPedjaNo ratings yet

- NRMC CIP 18pDocument2 pagesNRMC CIP 18pPedjaNo ratings yet

- Methylene Blue Index of Clay: Standard Test Method ForDocument2 pagesMethylene Blue Index of Clay: Standard Test Method ForPedjaNo ratings yet

- Excell VBA - Macro Training Excell VBA - Macro Training Practices 1 I 2 FORMS Eng Ratkovic PDocument5 pagesExcell VBA - Macro Training Excell VBA - Macro Training Practices 1 I 2 FORMS Eng Ratkovic PPedjaNo ratings yet

- AASHTO Designation T315 10 DSR ManualDocument32 pagesAASHTO Designation T315 10 DSR ManualPedjaNo ratings yet

- DDC Road Markings Dubai Drivin LicenceDocument4 pagesDDC Road Markings Dubai Drivin LicencePedjaNo ratings yet

- DDC Road Markings Dubai Drivin LicenceDocument4 pagesDDC Road Markings Dubai Drivin LicencePedjaNo ratings yet

- Catalog NanoamorDocument44 pagesCatalog NanoamorJuan AlfaroNo ratings yet

- Better Aluminium Mirrors by Integrating Plasma Pretreatment, Sputtering, and Plasma Polymerization For Large-Scale Car Headlight Production KDocument10 pagesBetter Aluminium Mirrors by Integrating Plasma Pretreatment, Sputtering, and Plasma Polymerization For Large-Scale Car Headlight Production Kani putkaradzeNo ratings yet

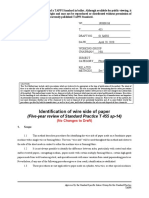

- t455 - Identification of Wire SideDocument4 pagest455 - Identification of Wire Sidetsvmpm1765No ratings yet

- E Catlog Citizen Metals IndiaDocument14 pagesE Catlog Citizen Metals IndiaVarun ChandanNo ratings yet

- Quality Characteristics of Glass Fiber Reinforced Polymer (GFRP) RebarDocument9 pagesQuality Characteristics of Glass Fiber Reinforced Polymer (GFRP) RebarAadarsh SharmaNo ratings yet

- 2.4 Avogadro's Hypothesis+ Equivalent MassesDocument12 pages2.4 Avogadro's Hypothesis+ Equivalent MassesSantosh MandalNo ratings yet

- KAT-A 5023 Klamflex VARIplus-RFA Flangeadaptor Edition01 28-05-2014 EN AIeditDocument3 pagesKAT-A 5023 Klamflex VARIplus-RFA Flangeadaptor Edition01 28-05-2014 EN AIeditSonny LuuNo ratings yet

- Equivalent SpecificationsDocument3 pagesEquivalent SpecificationsYudha Andrie Sasi ZenNo ratings yet

- SSPC-SP 11Document5 pagesSSPC-SP 11topdrive100% (3)

- Extraction of ZincDocument15 pagesExtraction of ZincAmit MishraNo ratings yet

- The Effect of Saba Banana (Musa Acuminata X Balbisiana) Peel Ash and Lime On The Stability of Expansive SoilDocument21 pagesThe Effect of Saba Banana (Musa Acuminata X Balbisiana) Peel Ash and Lime On The Stability of Expansive SoilKimberly Joy TulinNo ratings yet

- Quickneasy 5 Car Fleet Fire EngineDocument17 pagesQuickneasy 5 Car Fleet Fire EngineZosmo Simiao CostaNo ratings yet

- Dissolution Study of Salt of Long Chain Fatty Acids (Soap Scum) in Surfactant Solutions. Part I: Equilibrium DissolutionDocument7 pagesDissolution Study of Salt of Long Chain Fatty Acids (Soap Scum) in Surfactant Solutions. Part I: Equilibrium DissolutionCao LongNo ratings yet

- Crumb Rubber Modified Bitumen A ProjectDocument52 pagesCrumb Rubber Modified Bitumen A ProjectAthira RaghavanNo ratings yet

- Intertherm 1181Document4 pagesIntertherm 1181deepan govindasamyNo ratings yet

- Solution Manual For Chemistry For Today General Organic and Biochemistry 9th Edition by Seager Slabaugh Hansen ISBN 1305960068 9781305960060Document6 pagesSolution Manual For Chemistry For Today General Organic and Biochemistry 9th Edition by Seager Slabaugh Hansen ISBN 1305960068 9781305960060lindseyallenizqtgdakmw100% (34)

- VerticalrepmeanstatisticsDocument37 pagesVerticalrepmeanstatisticsspotlight_brianNo ratings yet

- Welding Procedure Specification: JOINTS (QW-402)Document3 pagesWelding Procedure Specification: JOINTS (QW-402)Nitin KurupNo ratings yet

- Colalube 3410Document3 pagesColalube 3410mndmattNo ratings yet

- Stepan Polyester Polyols For Rigid: Polyisocyanurate (PIR) and Polyurethane (PUR Foam)Document4 pagesStepan Polyester Polyols For Rigid: Polyisocyanurate (PIR) and Polyurethane (PUR Foam)s0n1907No ratings yet

- García-Martínez Et Al. - 2020 - Influence of Graphene Nanoplatelets On Curing Kine PDFDocument9 pagesGarcía-Martínez Et Al. - 2020 - Influence of Graphene Nanoplatelets On Curing Kine PDFAnonymous eaJQKWkNo ratings yet

- CN Aquatherm, The One Stop Supplier For Aqua-Therm Products & Building MaterialsDocument128 pagesCN Aquatherm, The One Stop Supplier For Aqua-Therm Products & Building MaterialsYang XianjieNo ratings yet

- ButiboriDocument4 pagesButiboriRAASHID SYEDNo ratings yet

- MODULE 5 TBCHEM StudentsDocument5 pagesMODULE 5 TBCHEM StudentsPearly Ann R. EgeNo ratings yet

- Conductometry Method: By: Rohayati, S.PD Translated By: Nurul Kusumawati., S.PD SMK Negeri 13 BandungDocument8 pagesConductometry Method: By: Rohayati, S.PD Translated By: Nurul Kusumawati., S.PD SMK Negeri 13 BandungAgung GunandarNo ratings yet

- ADIP StandardsDocument359 pagesADIP Standardsgaso99No ratings yet

- TNA & Pre-Production StatusDocument10 pagesTNA & Pre-Production StatusMahibur RahmanNo ratings yet

- Cycle Water Chemistry by Sudhanshu DashDocument31 pagesCycle Water Chemistry by Sudhanshu DashSudhanshu Sekhar Dash100% (1)