Professional Documents

Culture Documents

UK2211if 10143

UK2211if 10143

Uploaded by

MAMI RAKOTOMAHANINAOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

UK2211if 10143

UK2211if 10143

Uploaded by

MAMI RAKOTOMAHANINACopyright:

Available Formats

Belzona 2211

FN10143 (MP HI-BUILD ELASTOMER)

INSTRUCTIONS FOR USE

1. TO ENSURE AN EFFECTIVE MOLECULAR Under no circumstances should application of Belzona®

2211 take place after the maximum overcoating time of

WELD 24 hours.

a) SURFACE PREPARATION NOTE: Belzona® 2911 has an 18 month shelf life and Belzona®

(i) Metallic Surfaces 2921 has a 24 month shelf life from date of manufacture when

Remove all loose surface contamination and degrease with stored at 41 - 77°F (5 - 25°C) and must be used before the

Belzona® 9111 (Cleaner/Degreaser) or any other effective stated “use by” date.

cleaner which does not leave a residue, e.g. methyl ethyl

ketone (MEK). When using Belzona® 2211 to overcoat a surface which has

been treated with a Belzona® 1000 Series product (except

Grit blast to a minimum 3 mil (75 microns) profile. Where Belzona® 1221 (Super E-Metal), the Belzona® 1000 Series

blasting is not practical, thorough mechanical grinding may product must first be allowed to fully cure, the surface prepared

be considered, except for applications involving tensile as outlined in section 1 (a) (i), and Belzona® 2911 or Belzona®

loads, such as expansion joints, and all applications 2921 applied as outlined in section 1 (b).

involving immersion and/or fluid flow.

Application of Belzona® 2211 over Belzona® 1221 can be

(ii) Flexible Surfaces (e.g. rubbers) carried out up to 4 hours after the application of Belzona® 1221

NOTE: Belzona® 9111 can draw processing oils and waxes without the need of any surface treatment other than removal of

to the surface of some rubbers, particularly when new, contamination. When overcoating Belzona® 1221 after this time,

which then impairs adhesion of Belzona® 2211. Test for this the surface should be abraded, followed by conditioning as in

on a small area. If, on rubbing with a rag moistened with Section 1 (b).

Belzona® 9111, a greasy film appears, the surface should

not be degreased, but simply abraded. Undercut fine edges WHERE BELZONA® 2211 SHOULD NOT ADHERE

with a sharp knife and scuff the surface with a rotary wire Brush on a thin layer of Belzona® 9411 (Release Agent) and

brush or suitable roughing tool. allow to dry for 15 - 20 minutes before proceeding to step 2.

Brush away loose contamination and degrease again.

2. COMBINING THE REACTIVE

b) CONDITIONING COMPONENTS

Immediately, apply a thin, even coat of Belzona® 2911

(Elastomer QD Conditioner) or Belzona® 2921 (Elastomer Complete mixing is the most important step in the use of

GP Conditioner) onto the surface. A brush should be used Belzona® 2211.

as a stipple to ensure a practical coverage rate of 13 sq.ft.

(1.25 m²) per unit, on steel and most metallic substrates. On a) Transfer the entire contents of the Base and Solidifier

well roughened rubber substrates this could be reduced by containers onto the Belzona® Working Surface.

as much as 50%.

b) Mix together for at least 3 minutes until the material is of an

The Belzona® Conditioner must be touch dry before even color and consistency.

overcoating with Belzona® 2211. This will depend on the

Belzona® Conditioner selected, prevailing temperature, For mixing small quantities of Belzona® 2211 the mixing ratio is:

relative humidity and substrate. 3.0 parts Base: 1 part Solidifier by Volume, or

2.3 parts Base: 1 part Solidifier by Weight.

At 50% relative humidity, the touch dry state will be It is important that the mixing ratios are accurately utilized.

achieved after the times given below when applied to a steel

surface. These times may be extended when applied to (i) Remove the plastic cover from the top of the Base container

rubber substrates. but make sure it is replaced after measuring out has been

completed.

Belzona 2911 Belzona 2921

50°F (10°C) 90 mins 120 mins (ii) Apply one portion of Solidifier to the Belzona ® Working

68°F (20°C) 45 mins 75 mins Surface followed by three equally sized portions of Base.

86°F (30°C) 25 mins 40 mins

104°F (40°C) 20 mins 25 mins (iii) Mix as in (b) above.

For lower relative humidity, the touch dry times will increase,

for higher humidity they will be reduced.

www.belzona.com Publication No. 20-08-19

NOTES: 4. COMPLETION OF THE MOLECULAR

1. MIXING AT LOW TEMPERATURES

To ease mixing when the material temperature is below 41°F REACTION

(5°C), warm the Base and Solidifier containers until the contents

attain a temperature of 68 - 70°F (20 - 25°C). Allow Belzona® 2211 to solidify as below before subjecting it to

the conditions indicated:

2. WORKING LIFE

From the commencement of mixing, Belzona® 2211 must be Light loading Full mechanical Immersion in

loading chemicals

used within the times shown below.

50°F/10°C 24 hours 72 hours 5 days

68°F/20°C 12 hours 36 hours 3 days

Temperature 50°F 68°F 86°F 104°F 86°F/30°C 9 hours 32 hours 2.5 days

(10°C) (20°C) (30°C) (40°C) 104°F/40°C 6 hours 28 hours 2 days

Use all material

25 min. 15 min. 10 min. 7 min. These times are for a thickness of approximately 0.10 ins

within

(0.25 cm); they will be reduced for thicker sections and extended

for thinner sections.

3. VOLUME CAPACITY OF MIXED BELZONA® 2211

28.5 cu.in. (467 cm³) per 550 g unit.

5. STORAGE

3. APPLYING THE BELZONA® 2211 Once opened, Belzona® 2211 should be used as soon as

possible. To maximize shelf life (up to 4 weeks at 68°F (20°C))

FOR BEST RESULTS of partially used product, the Base container should be re-sealed

Do not apply when:- using the plastic overcap provided. A surface skin may result

(i) The temperature is below 41°F (5°C) or the relative humidity during this period but after removal the remaining material can

is above 90%. be used in the normal way.

(ii) Rain, snow, fog or mist is present.

(iii) There is moisture on the surface or is likely to be deposited Containers should be stored in a dry environment at a

by subsequent condensation. temperature of not more than 86°F (30°C).

(iv) The working environment is likely to be contaminated by

oil/grease from adjacent equipment or smoke from

kerosene heaters or tobacco smoking. 6. OVERCOATING

a) Apply the Belzona® 2211 directly onto the prepared surface Application of subsequent layers of Belzona® 2211 can be

with the plastic applicator or spatula provided. Press down carried out without need of any surface treatment other than

firmly to remove entrapped air and to ensure maximum removal of contamination in accordance with the below

contact with the surface. maximum overcoat times:

b) Contour the Belzona® 2211 to the correct profile with the Temperature <50% Relative >50% Relative

humidity humidity

plastic applicator.

10°C/50°F 32 hrs 24 hrs

20°C/68°F 16 hrs 12 hrs

CLEANING 30°C/86°F 12 hrs 9 hrs

Mixing tools should be cleaned immediately after use with 40°C/104°F 10 hrs 6 hrs

Belzona® 9111 or any other effective solvent e.g. Methyl ethyl

ketone (MEK). Application tools should be cleaned using a If the maximum overcoat time is exceeded or for overcoating of

suitable solvent such as Belzona® 9121, MEK, acetone or aged or weathered Belzona® 2211, the surface preparation

cellulose thinners. techniques for flexible surfaces described in Section 1 should be

followed.

HEALTH & SAFETY INFORMATION

Please read and make sure you understand the relevant Safety Data Sheets.

The technical data contained herein is based on the results of long term tests carried out in our laboratories and to the best of our knowledge is Belzona products are

true and accurate on the date of publication. It is however subject to change without prior notice and the user should contact Belzona to verify

the technical data is correct before specifying or ordering. No guarantee of accuracy is given or implied. We assume no responsibility for rates of manufactured under an

coverage, performance or injury resulting from use. Liability, if any, is limited to the replacement of products. No other warranty or guarantee of ISO 9001 Registered

any kind is made by Belzona, express or implied, whether statutory, by operation of law or otherwise, including merchantability or fitness for a

particular purpose.

Quality Management System

Nothing in the foregoing statement shall exclude or limit any liability of Belzona to the extent such liability cannot by law be excluded or limited.

Copyright © 2019 Belzona International Limited. Belzona® is a registered trademark.

Belzona 2211 - Instructions for Use - (2) Publication No. 20-08-19

You might also like

- Spectrophotometric Determination of IronDocument3 pagesSpectrophotometric Determination of IronDozdi93% (15)

- UK2211if 10143Document2 pagesUK2211if 10143MAMI RAKOTOMAHANINANo ratings yet

- Belzona 1311: Instructions For UseDocument2 pagesBelzona 1311: Instructions For UserobertomaleoNo ratings yet

- Belzona 1511 Instruction For UseDocument2 pagesBelzona 1511 Instruction For UseNitin AggarwalNo ratings yet

- 2 Belzona 1511 Instruction For UseDocument2 pages2 Belzona 1511 Instruction For UseNaveen Dev MadhavanNo ratings yet

- Belzona 1151: Instructions For UseDocument2 pagesBelzona 1151: Instructions For UseIrvansyah RazadinNo ratings yet

- Benzola 1311Document2 pagesBenzola 1311vanduongNo ratings yet

- Belzona 1341-3 - UnlockedDocument2 pagesBelzona 1341-3 - UnlockedimtiazNo ratings yet

- 1111 IfDocument2 pages1111 IfMithun NandanNo ratings yet

- Belzona 2211: Instructions For UseDocument2 pagesBelzona 2211: Instructions For UseEnrique MurgiaNo ratings yet

- Belzona Fluid ElastomerDocument2 pagesBelzona Fluid Elastomergacm98No ratings yet

- Belzona 5111: Instructions For UseDocument2 pagesBelzona 5111: Instructions For UsePedro RuizNo ratings yet

- Belzona 4341: Instructions For UseDocument2 pagesBelzona 4341: Instructions For UseSagysm Hotmarx MarvaugNo ratings yet

- Benzona 1511Document2 pagesBenzona 1511Dia Putranto HarmayNo ratings yet

- Instructions For Use: 1. To Ensure An Effective Molecular WeldDocument2 pagesInstructions For Use: 1. To Ensure An Effective Molecular WeldQuy RomNo ratings yet

- Belzona 1321: Instructions For UseDocument2 pagesBelzona 1321: Instructions For UserobertomaleoNo ratings yet

- Instructions For Use: 1. To Ensure An Effective Molecular WeldDocument2 pagesInstructions For Use: 1. To Ensure An Effective Molecular WeldQuy RomNo ratings yet

- Belzona 1321Document2 pagesBelzona 1321GabrielNo ratings yet

- Belzona 1121: Instructions For UseDocument2 pagesBelzona 1121: Instructions For UseMinhas ArshadNo ratings yet

- UK3111if 10134Document2 pagesUK3111if 10134VPN NetworkNo ratings yet

- Belzona 1391Document2 pagesBelzona 1391AsadAliNo ratings yet

- UK1111if 10132 PDFDocument2 pagesUK1111if 10132 PDFAdeImanudinNo ratings yet

- Belzona 1341 (Supermetalglide) - Instructions For UseDocument2 pagesBelzona 1341 (Supermetalglide) - Instructions For Usevangeliskyriakos8998No ratings yet

- Belzona 4131: Instructions For UseDocument2 pagesBelzona 4131: Instructions For UsecodozinhoNo ratings yet

- Belzona 3921Document2 pagesBelzona 3921Santosh Iim LucknowNo ratings yet

- Belzona 1321 (Ceramic S-Metal) - Instructions For UseDocument2 pagesBelzona 1321 (Ceramic S-Metal) - Instructions For Usevangeliskyriakos8998No ratings yet

- UK5892if 10106Document2 pagesUK5892if 10106mrashid286No ratings yet

- UK1391Tif 10034Document2 pagesUK1391Tif 10034Deepak YadavNo ratings yet

- Interline 921+ds+eng PDFDocument4 pagesInterline 921+ds+eng PDFMohamed NouzerNo ratings yet

- 1391 T Belzona Instruction - UseDocument0 pages1391 T Belzona Instruction - UseSds Mani SNo ratings yet

- Belzona 5831: Instructions For UseDocument2 pagesBelzona 5831: Instructions For UseVippin Kumar RanaNo ratings yet

- Belzona Know-How: For Bonding and Grouting Tiles and Wear PlatesDocument2 pagesBelzona Know-How: For Bonding and Grouting Tiles and Wear PlatesArthurNo ratings yet

- Gebruiksinstructie 7111Document4 pagesGebruiksinstructie 7111Achwan FebNo ratings yet

- Belzona 1831 Instruction For UseDocument2 pagesBelzona 1831 Instruction For UseshambhoiNo ratings yet

- Ceilcote 2000 Flakeline+ds+engDocument4 pagesCeilcote 2000 Flakeline+ds+englivefreakNo ratings yet

- Ceilcote 242AR Flakeline+ds+engDocument4 pagesCeilcote 242AR Flakeline+ds+englivefreakNo ratings yet

- Ceilcote 2000 FlakelineDocument4 pagesCeilcote 2000 FlakelineAhmet GözübüyükNo ratings yet

- Ceilcote 2000 Flakeline: Epoxy NovolacDocument4 pagesCeilcote 2000 Flakeline: Epoxy Novolacshakeel ahmedNo ratings yet

- Ceilcote - 2000 InternationalDocument4 pagesCeilcote - 2000 InternationalAjay RanganathanNo ratings yet

- Enviroline 199+ds+eng PDFDocument4 pagesEnviroline 199+ds+eng PDFMohamed NouzerNo ratings yet

- Ceilkote 2000Document4 pagesCeilkote 2000Anwar MdNo ratings yet

- Interline 975+ds+eng PDFDocument4 pagesInterline 975+ds+eng PDFMohamed NouzerNo ratings yet

- Ceilcote 242 Flakeline Eng A4 20180219Document4 pagesCeilcote 242 Flakeline Eng A4 20180219Cuong Nguyen ManhNo ratings yet

- Resina - TDS - 10200005 - EN - EN-WEICON-F2Document2 pagesResina - TDS - 10200005 - EN - EN-WEICON-F2kakonauta1No ratings yet

- Ceilcote 232 Flakeline+ds+engDocument4 pagesCeilcote 232 Flakeline+ds+engMohamed NouzerNo ratings yet

- Ceilcote 222GF Flakeline+ds+engDocument4 pagesCeilcote 222GF Flakeline+ds+englivefreakNo ratings yet

- Ceilcote 180 Flakeline+ds+engDocument4 pagesCeilcote 180 Flakeline+ds+englivefreakNo ratings yet

- Ceilcote 505 Coroline+ds+engDocument4 pagesCeilcote 505 Coroline+ds+englivefreakNo ratings yet

- Celcote 242Document4 pagesCelcote 242Anwar MdNo ratings yet

- Ceilcote 282 Flakeline+ds+engDocument4 pagesCeilcote 282 Flakeline+ds+engMohamed NouzerNo ratings yet

- E MULTIFILL EPOXY THIXO 12Document4 pagesE MULTIFILL EPOXY THIXO 12Dimitrija GalapchevNo ratings yet

- Belzona 1212Document2 pagesBelzona 1212faridNo ratings yet

- Veetagrout V71 Instruction Manual - New Format V 2Document3 pagesVeetagrout V71 Instruction Manual - New Format V 2Alirio Ramirez VelasquezNo ratings yet

- Interline 399+ds+eng PDFDocument4 pagesInterline 399+ds+eng PDFMohamed NouzerNo ratings yet

- 315 UkDocument4 pages315 UkAhmed IbrahimNo ratings yet

- Ficha Tecnica Carboline Semstone - 110 - PDSDocument3 pagesFicha Tecnica Carboline Semstone - 110 - PDSUlises Sanchez PavianNo ratings yet

- Interline 984+ds+eng PDFDocument4 pagesInterline 984+ds+eng PDFMohamed NouzerNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- 3512B (50 HZ)Document9 pages3512B (50 HZ)MAMI RAKOTOMAHANINANo ratings yet

- Drawing 1680280914304 ChassisDocument3 pagesDrawing 1680280914304 ChassisMAMI RAKOTOMAHANINANo ratings yet

- DoccDocument1 pageDoccMAMI RAKOTOMAHANINANo ratings yet

- Rolling 412 Standard enDocument2 pagesRolling 412 Standard enMAMI RAKOTOMAHANINANo ratings yet

- PRESTIGE INDUSTRIES (Rectangular Planetary Reducer Instruction ALIMENTATEUR A CHINEDocument6 pagesPRESTIGE INDUSTRIES (Rectangular Planetary Reducer Instruction ALIMENTATEUR A CHINEMAMI RAKOTOMAHANINANo ratings yet

- Investigation of Micropitting and WearDocument45 pagesInvestigation of Micropitting and WearMAMI RAKOTOMAHANINANo ratings yet

- pl6000k RentalDocument2 pagespl6000k RentalMAMI RAKOTOMAHANINANo ratings yet

- SERVO Machinery OilsDocument1 pageSERVO Machinery OilsMAMI RAKOTOMAHANINANo ratings yet

- Plastique Material Acoustic PropertiesDocument1 pagePlastique Material Acoustic PropertiesMAMI RAKOTOMAHANINANo ratings yet

- Dry Fluid Is Better: Reservoir Air DryerDocument2 pagesDry Fluid Is Better: Reservoir Air DryerMAMI RAKOTOMAHANINANo ratings yet

- UK2211if 10143Document2 pagesUK2211if 10143MAMI RAKOTOMAHANINANo ratings yet

- Data Sheet TRAP BreatherDocument2 pagesData Sheet TRAP BreatherMAMI RAKOTOMAHANINANo ratings yet

- Special Products: Product Information MR 750 Ultrasonic Coupling AgentDocument1 pageSpecial Products: Product Information MR 750 Ultrasonic Coupling AgentMAMI RAKOTOMAHANINANo ratings yet

- E494 Multiplicateur de CoupleDocument76 pagesE494 Multiplicateur de CoupleMAMI RAKOTOMAHANINANo ratings yet

- SKF Induction Heater TIH 030mDocument116 pagesSKF Induction Heater TIH 030mMAMI RAKOTOMAHANINANo ratings yet

- BOSCH GLM 80 Laser Mesuring ToolDocument1 pageBOSCH GLM 80 Laser Mesuring ToolMAMI RAKOTOMAHANINANo ratings yet

- Catalogue Flexacier 9000Document4 pagesCatalogue Flexacier 9000MAMI RAKOTOMAHANINANo ratings yet

- Organic Chemistry Structural EffectsDocument3 pagesOrganic Chemistry Structural EffectsOrlando Angelo Cerezo100% (2)

- Polybenzimidazole (PBI) and Benzimidazole-Linked Polymer (BILP) MembranesDocument50 pagesPolybenzimidazole (PBI) and Benzimidazole-Linked Polymer (BILP) MembranesZillur Rahman SaykatNo ratings yet

- Document Research PaperDocument6 pagesDocument Research PaperJustin jeav suicoNo ratings yet

- Physical Chemistry: SO H O H SODocument11 pagesPhysical Chemistry: SO H O H SOavmurugan87No ratings yet

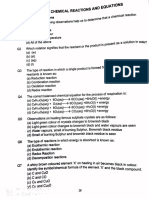

- Chapter 1: Chemical Reactions AND: Multiple Choice QuestionsDocument5 pagesChapter 1: Chemical Reactions AND: Multiple Choice QuestionsTatti Rha haiNo ratings yet

- Ch27 Pka and Pi ValuesDocument1 pageCh27 Pka and Pi ValuesVeronicaNo ratings yet

- Tugas Kimia Kelas A - RevisiDocument2 pagesTugas Kimia Kelas A - RevisiYudha Pratama SitumorangNo ratings yet

- Holiday Homework of Social ScienceDocument5 pagesHoliday Homework of Social Scienceafnangetppyqes100% (2)

- Basic Concepts of Chemistry A0x49QVl3BT5Ko2KDocument20 pagesBasic Concepts of Chemistry A0x49QVl3BT5Ko2Krineeth22745No ratings yet

- Principles and Applications Of: PyrometallurgyDocument19 pagesPrinciples and Applications Of: PyrometallurgyChamel Jamora RuperezNo ratings yet

- Compaction Control Test OR Determination of Field Unit Weight of CompactionDocument11 pagesCompaction Control Test OR Determination of Field Unit Weight of CompactionMusfiqur RahmanNo ratings yet

- Crane FS FM463 FA463 FM466 Wafer Check Valves IOM 1020Document2 pagesCrane FS FM463 FA463 FM466 Wafer Check Valves IOM 1020Septiana DamayantiNo ratings yet

- Further Investigations Into The PH ScaleDocument3 pagesFurther Investigations Into The PH Scaletjqxqpxzx5No ratings yet

- F.Y.B.Sc Practical SyllabusDocument4 pagesF.Y.B.Sc Practical SyllabusGanesh ThorboleNo ratings yet

- Forensic Chem Modules CompleteDocument62 pagesForensic Chem Modules CompleteMirachelle BalisiNo ratings yet

- List of Customers Reference: FRP Storage Tank & Process TankDocument11 pagesList of Customers Reference: FRP Storage Tank & Process TankDyah Ayu widatiNo ratings yet

- STP 518-1983Document173 pagesSTP 518-1983ahmadmubarakaliasNo ratings yet

- Day-3 - In-Class Assignment - : Phase-1Document4 pagesDay-3 - In-Class Assignment - : Phase-1Arnab DasNo ratings yet

- Chennai Requirements-345Document2 pagesChennai Requirements-345bhaskarNo ratings yet

- Laws of StoichiometryDocument11 pagesLaws of StoichiometrySujal NepalNo ratings yet

- Ucrete Ud200 AseanDocument2 pagesUcrete Ud200 AseanDoby YuniardiNo ratings yet

- Commercial SterilizationDocument6 pagesCommercial SterilizationTeya Park100% (1)

- Colour Coding of The Most Important Gas Cylinders - CompressDocument1 pageColour Coding of The Most Important Gas Cylinders - CompressMOHAMEDNo ratings yet

- Rules For Handling Chemicals Safely: Know The Chemicals You UseDocument1 pageRules For Handling Chemicals Safely: Know The Chemicals You UseSreekumarNo ratings yet

- Preparing A Purification Summary TableDocument6 pagesPreparing A Purification Summary TableAngeles Uribe JiménezNo ratings yet

- Energy and Chemistry: Larry Brown Tom HolmeDocument61 pagesEnergy and Chemistry: Larry Brown Tom Holmemuhammad ali shakeelNo ratings yet

- Khari Amos Master Resume - Feb 23Document2 pagesKhari Amos Master Resume - Feb 23api-516842830No ratings yet

- Qin Materials Today Physics 2021Document156 pagesQin Materials Today Physics 2021Noel BeatsNo ratings yet

- Inorganic Chemistry: Nitrogen and Its CompoundsDocument46 pagesInorganic Chemistry: Nitrogen and Its CompoundsLooi Chui Yean100% (1)