Professional Documents

Culture Documents

Brochure Adv NDT - Prominent

Uploaded by

Rizki YudaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Brochure Adv NDT - Prominent

Uploaded by

Rizki YudaCopyright:

Available Formats

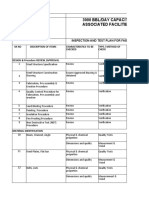

Prominent Energy Services

Advanced Non Destructive Testing & Inspection

PT Prominent Energy Services Pulsed Eddy Current Testing Advantages:

(PECT) • Can be performed at elevated

A local company with main temperatures up to 100’C

activities , Pipe & is a NDT method to inspect the • Provides information on

Equipment Inspection : corrosion and measure the feature position and size

thickness under insulation • Capability to evaluate

• Metal Magnetic Memory Method • Through up to 250 mm (10”) corrosion distribution around

• Pulsed Eddy Current (PEC) insulation, concrete, brick wall pipe circumference

• Long Range Ultrasonic Testing • On ferrous in-service pressure • Economic

• Short Range Ultrasonic Testing pipes, vessels, tanks • Suitable for small diameter

• Tube Inspection • On 3-50 mm (0.12” – 4”) wall • For non pig-able pipelines

• Online Tank Inspection thickness of pipe • Used on in-service pipelines

• Acoustic Emission (AE) • Accuracy 100% • Both internal and external

• Other Advanced NDT

Metal Magnetic Memory

(MMM)

is a NDT method to inspect the

buried and above ground pipeline

based on the measurement and

analysis of the distribution of Scan over:

residual magnetic fields in metallic

• Cladding – Stainless,

materials. MMM is used by

Aluminium, Galvanize Short Range Ultrasonic Testing

scanning the pipeline for

• Steel surface up to 550 C (SRUT)

determination of the SCZ (Stress

• Protective of Polymer coating,

Concentration Zones) to find the

bitumen is an Ultrasonic test method

anomaly and detect the corrosions

and flaws. The tool is intended for wherein the ultrasonic waves are

inspection of buried pipelines at the transmitted in the form of pulsed

depth to 2-3 m (or 10 x diameter of guided laminar waves using special

the pipe). This technology can purpose ultrasonic probes,

replace or compliment with conducted on an ambient

intelligent pigging. Suitable for any temperature. When laminar waves

pipeline including non pig-able hit discontinuities they are mode

and high temperature pipelines. converted and the reflection of the

waves are detected by the

transducer. Developed for detecting

metal loss in difficult-to-access

Advantages of PECT: (hidden) locations of tanks,

• Non-radioactive method, vessels, and piping, such as:

• Inspection during operation under pipe supports, clamps,

• No need preparation composite repairs, the annular

• Accurate to detect the flaw plate of above ground storage

tanks, steel plates, and pipe walls;

• Calculate the metal loss,

within 2 meter of the probe

An illustrative magnetogram (remaining thickness).

displacement (depending upon the

is shown in the figure. plate condition)

Long Range Ultrasonic Testing

(LRUT)

is a screening tool for rapidly

testing long lengths of pipe from a

single inspection point. It is used for

carrying out in-service pipeline

survey for corrosion & erosion

using ultrasonic guided waves.

LRUT employs low frequency

guided waves, propagated from a

ring of transducers fixed around the Places That Can Be Inspected

Advantages of MMM Method: pipe and these waves propagate in • Tank floor

• Non Destructive Method both directions of ring. This • Testing under pipe supports

• Quicker Measurement technique scans 100% of pipeline • Tank dyke piping interfaces

• Provide real time result surface and is equally sensitive to • Scan under vessel supports

• Inspection during operation metal loss on both inside and

• No need preparation outside of pipe.

• Accurate to detect the flaw

• Calculate the metal loss,

MAOP and remaining life,

• and less cost.

Prominent Energy Services

Advanced Non Destructive Testing & Inspection

Advantages ferromagnetic (carbon steel) heat (AST) smaller than 40 feet diameter

✓

Inspection is done online. exchanger tubes. (depending on the position of the

✓ man-way).

Tests 100% of surface area

✓ Internal Rotating Inspection

Identify areas of corrosion

✓ System (IRIS)

Data / analysis using a laptop

✓

Scan defects under supports,

annular plates etc.

Tube Inspection

Tube Inspections accurately

examine heat exchanger tubes to

detect damage or defects

wherein ensuring the tubes are Acoustic Emission

safe to continue use.

1. Eddy Current Testing (ECT) IRIS is an ultrasonic nondestructive is a non-destructive testing method

2. Remote Field Testing (RFT) testing method for the inspection of for integral detection and location of

3. Near Field Testing (NFT) a wide range of materials including material defects and flaws. The

4. Internal Rotating Inspection both non-ferromagnetic and principle of this method consists in

System (IRIS) ferromagnetic tubing. interpretation of AE response signals

generated by processes activated in

Eddy Current Testing (ECT) Online Tank Inspection the equipment, that is to say during

pressure test or a normal operation of

Is an online inspection system the equipment.

that inspects and assesses the

condition of bottom plate in above

ground storage tanks. It is specially

designed to evaluate the integrity of

tank floor bottoms and complies

with the American Petroleum

Institute’s (API) tank floor

ECT is an electromagnetic testing inspection guidelines. These

technique that usually used to guidelines are detailed in the API

inspect non-ferromagnetic 653 in document.

materials, such as copper, brass, Application

and copper-nickel alloys for Advantages

inspecting steam generator tubing • Measure real thickness

Determination of material integrity,

in nuclear plants and heat • Inspection during operation flaw detection, monitoring of damage

exchangers tubing; can be used • Avoid production loss initiation and growth and monitoring of

only with conductive tubing • Reduce emissions by venting system leakage by Acoustic Emission

material, although the tubes may • Achieve inspection compliance

have a non-conductive coating. • Inspection without entering tank

ECT is very sensitive to detect and

size pits. Wall loss or corrosion can There are 2 types of online tank

be detected but sizing is not inspection; 1) The Online Robotic

accurate. Inspection System for tanks with

larger diameter and 2) the Online

Probe Inspection System for tanks

smaller than 40 feet diameter.

Online Robotic Inspection

System

Fields of use:

The Online Robotic Inspection - Oil and Gas; Energy

System has an array of 8 ultrasonic - Petrochemistry;

Remote Field Testing (RFT) - Water; Transportation

transducers that collects thickness

measurements at .1” (2.54 mm) - Chemistry; Metallurgy

RFT is a through electromagnetic - Science and research activity

and it collects thousands of data

transmission testing method samples. This information is then

wherein the receiver coil detects examined to determine the life In-Situ Metallography Test

electromagnetic field which has expectancy of the tank floor and

traversed through the tube wall. It is calculate the next inspection

used to detect discontinuities interval.

in small diameter with Is a non-desctructive testing method

ferromagnetic metal, such as for examine microstructure damage of

carbon steel and pipes, and can be metallic equipment.

applied toward prime surface or low The principle of this method is made a

fin tubing. replica (method consists of making a

copy of a ground, polished and

Near Field Testing (NFT) etched area of interest) of

Online Probe Inspection System microstructure from metal component

NFT is one of the electromagnetic and the replica using to identification

testing method used to detect Online Probe Inspection System with electrical microscope.

discontinuities on the internal performs an API 653 inspection of

surface of fin-fan type small Above Ground Storage Tanks

Prominent Energy Services

Advanced Non Destructive Testing & Inspection

Advantages

• Lower Cost

• On-Site Evaluation

• Measure Microstructure of

metallic eq.

• Easily replicate speciments of

Large or irregularly-shaped

• No need to destroy metallic

component in order to get

metallurgical information.

Phased Array Ultrasonic

Testing (PAUT)

PAUT is a NDT method to inspect

the components failure such as

cracks and defect, and can be

apllied for welding checking,

thickness measurement, corrosion

checking, and detecting defects.

• Thickness Range : 3.5 mm –

300 mm

• Diameter range : 38 mm –

unlimited

• Material : Carbon Stee, Low

Alloy Steel, and Stainless Steel

Advantages of PAUT:

• Non-destructive method,

• Inspection during operation

• No need preparation

• Can be applied for welding

checking

• More effective than

Conventional UT

• Calculate the rmaining

thickness

Contact :

PT Prominent Energy Services Jl.

Raya Mandiri Tengah M4D No 12

Jakarta Utara

Telp. : +62 21 450 1483

Fax : +62 21 450 1483

Mobile : +62 811 134 095

+62 813 164 77166

E-mail :

sugembong@prominentenergy.co.id

sugembongcf@yahoo.com

kukuh@prominentenergy.co.id

yuda@prominentenergy.co.id

You might also like

- OQ-0305-Study List For OQ-0305 - Pipe InspectionDocument467 pagesOQ-0305-Study List For OQ-0305 - Pipe InspectionRobin ZubererNo ratings yet

- Section 1 Inspection and NDTDocument84 pagesSection 1 Inspection and NDTariyamanjula2914100% (1)

- An Week2Document30 pagesAn Week2Tania NoorNo ratings yet

- Advanced Inspection Techniques and Best PracticesDocument33 pagesAdvanced Inspection Techniques and Best PracticesriysallNo ratings yet

- Long Range Ultrasonic Technologies: Part of TWI's Non-Destructive Testing Technology GroupDocument8 pagesLong Range Ultrasonic Technologies: Part of TWI's Non-Destructive Testing Technology GroupNesanNo ratings yet

- Eddy Current TestingDocument43 pagesEddy Current Testingsurajagtap01100% (2)

- Advance NDTDocument17 pagesAdvance NDTGOUTHAM RATHINAMNo ratings yet

- Casing and Tubing Inspection BasicsDocument15 pagesCasing and Tubing Inspection BasicsYousuf Memon100% (1)

- Advanced Technologies For Heat Exchanger Tubing Karl MarxDocument46 pagesAdvanced Technologies For Heat Exchanger Tubing Karl MarxLuis Muñoz100% (1)

- Load Test ProcedureDocument70 pagesLoad Test ProcedureMohammed Rizwan Ahmed75% (4)

- Piping Engineer CVDocument3 pagesPiping Engineer CVArshed Jawad Al-mansori100% (2)

- Remote Field TestingDocument11 pagesRemote Field TestingvibinkumarsNo ratings yet

- Astm E1417 - E1417m - 13Document11 pagesAstm E1417 - E1417m - 13Teddy HariyantoNo ratings yet

- Near Field TestingDocument5 pagesNear Field TestingvibinkumarsNo ratings yet

- Tube Inspection TrainingDocument21 pagesTube Inspection Trainingvibinkumars100% (2)

- 3-Eddy CuRRENT WORKSHOP 2016Document51 pages3-Eddy CuRRENT WORKSHOP 2016Asif Hameed100% (4)

- Itp For Structural Steel WorkDocument12 pagesItp For Structural Steel Worknguyen thangNo ratings yet

- LRUTDocument6 pagesLRUTimranajmiNo ratings yet

- ASNT Level IIIDocument1 pageASNT Level IIIrongohcolemanNo ratings yet

- 8 - 2!1!042 - Magnetic Testing Examination Guide For Initial CertificationDocument32 pages8 - 2!1!042 - Magnetic Testing Examination Guide For Initial CertificationSrikanth PanchalNo ratings yet

- CatalogEddyfi Surface ECA Probes 01Document28 pagesCatalogEddyfi Surface ECA Probes 01Vikram VibrantNDTServicesNo ratings yet

- Tube Inspection A4Document2 pagesTube Inspection A4Cepi Sindang KamulanNo ratings yet

- NDT Eddy Current Testing ModuleDocument67 pagesNDT Eddy Current Testing Moduleyashwant vermaNo ratings yet

- Eddy Current White PaperDocument25 pagesEddy Current White PapervrapciudorianNo ratings yet

- NDT Techniques: Pulsed Eddy Current (PEC) & Long Range Ultrasonic Test (LRUT)Document10 pagesNDT Techniques: Pulsed Eddy Current (PEC) & Long Range Ultrasonic Test (LRUT)abhi9792No ratings yet

- Olympus Multiscan MS 5800 Tube Inspection System PDFDocument8 pagesOlympus Multiscan MS 5800 Tube Inspection System PDFThiru RajaNo ratings yet

- Remote Field Technique (RFT)Document2 pagesRemote Field Technique (RFT)Abdul Moeed KalsonNo ratings yet

- NDT Case StudyDocument64 pagesNDT Case StudyRikkinNo ratings yet

- All Techniques - in BriefDocument87 pagesAll Techniques - in BriefWmfaiz KarcelloNo ratings yet

- EMAT Inspection Services PDFDocument1 pageEMAT Inspection Services PDFCepi Sindang KamulanNo ratings yet

- Teletest Focus Case StudiesDocument55 pagesTeletest Focus Case StudiesPradeepNo ratings yet

- GWUTDocument23 pagesGWUTdoctor_arvind2003100% (1)

- TUBE INSPECTION by RFETDocument8 pagesTUBE INSPECTION by RFETTusar Kole100% (1)

- TWI 3.2 TRAINING SPEC 12-15 Rev3.5 - StudentDocument49 pagesTWI 3.2 TRAINING SPEC 12-15 Rev3.5 - StudentMusa Çelik33% (3)

- The Eddy Current Inspection Method Pt4Document4 pagesThe Eddy Current Inspection Method Pt4vrapciudorianNo ratings yet

- Brochure Adv NDT - PT. Prominent Energy ServicesDocument2 pagesBrochure Adv NDT - PT. Prominent Energy ServicesRizki YudaNo ratings yet

- Assessment of The Capabilities of Long-Range Guided-Wave Ultrasonic InspectionsDocument23 pagesAssessment of The Capabilities of Long-Range Guided-Wave Ultrasonic InspectionsKaithi Vivekvardhan ReddyNo ratings yet

- NDT PresentationDocument6 pagesNDT PresentationBighneswar PatraNo ratings yet

- Ect, Eca, NFT, RFT, Iris: ApplicationsDocument2 pagesEct, Eca, NFT, RFT, Iris: ApplicationsGistek MarcoNo ratings yet

- IntroductionDocument13 pagesIntroductioncakravartin servicesNo ratings yet

- Andt Thank AlgerieDocument28 pagesAndt Thank AlgerieChristian BarNo ratings yet

- T-03 - TP-04 - Data Gathering Non Destructive Testing and Destructive Testing Procedures For Structural EngineersDocument57 pagesT-03 - TP-04 - Data Gathering Non Destructive Testing and Destructive Testing Procedures For Structural EngineersLimar SetstraNo ratings yet

- NDT TestDocument18 pagesNDT TestDhaarini SriNo ratings yet

- Applus+K2 - CHIME and CUPSDocument1 pageApplus+K2 - CHIME and CUPSGistek MarcoNo ratings yet

- Crack Detection Techniques in Concrete StructuresDocument23 pagesCrack Detection Techniques in Concrete Structuresrameshbabu_1979No ratings yet

- E03f PDFDocument62 pagesE03f PDFYuniar SyahadhatinNo ratings yet

- Table of Eddy Current Methods ComparisonDocument1 pageTable of Eddy Current Methods Comparisonhamdi hamdiNo ratings yet

- Assessment of The Capabilities of Long-Range Guided-Wave Ultrasonic InspectionsDocument23 pagesAssessment of The Capabilities of Long-Range Guided-Wave Ultrasonic InspectionsExsan OthmanNo ratings yet

- Immersion Ultrasonic Testing On EUROFER Welded Joints For Determination of The Minimum Detectable Flaw SizeDocument9 pagesImmersion Ultrasonic Testing On EUROFER Welded Joints For Determination of The Minimum Detectable Flaw SizeJanak LalNo ratings yet

- White Paper Automated Ultrasonic Inspection of Tube To Tube Sheet WeldsDocument7 pagesWhite Paper Automated Ultrasonic Inspection of Tube To Tube Sheet WeldsdanemsalNo ratings yet

- Aiche 38-011Document8 pagesAiche 38-011ejremediosNo ratings yet

- Tube & Tank Inspection: MRUT (Medium Range UT)Document2 pagesTube & Tank Inspection: MRUT (Medium Range UT)Professional TrustNo ratings yet

- Automatic Inspection of Welded Pipes With Ultrasound: ECNDT 2006 - Tu.2.3.1Document14 pagesAutomatic Inspection of Welded Pipes With Ultrasound: ECNDT 2006 - Tu.2.3.1Jeremy BeltranNo ratings yet

- Long Range Guided Wave Ultrasonic Inspection: BenefitsDocument2 pagesLong Range Guided Wave Ultrasonic Inspection: BenefitsNDT Training WorldWideNo ratings yet

- HeatExchangers ModifydDocument31 pagesHeatExchangers ModifydsafwanNo ratings yet

- NDTtests On ConcreteDocument79 pagesNDTtests On ConcreteAparna SwaminathanNo ratings yet

- Ematscan Helps Lower Costs and Raise Crack-Detection Confidence For Gas-Pipeline OperatorsDocument2 pagesEmatscan Helps Lower Costs and Raise Crack-Detection Confidence For Gas-Pipeline OperatorsDani JoeNo ratings yet

- Corrosion Monitoring in Petroleum Refineries: K.R. Soni, Saga Global ConsultantsDocument40 pagesCorrosion Monitoring in Petroleum Refineries: K.R. Soni, Saga Global Consultantsokoro matthewNo ratings yet

- How Can You Use Eddy Current NDT For Tube InspectionDocument2 pagesHow Can You Use Eddy Current NDT For Tube InspectionWoodrow FoxNo ratings yet

- ECT of TubesDocument9 pagesECT of TubesShunmugavel ANo ratings yet

- Conventional Corrosion Detection MethodDocument7 pagesConventional Corrosion Detection MethodAmir HoseiniNo ratings yet

- Damage Assessment & Evaluation of StructuresDocument18 pagesDamage Assessment & Evaluation of StructuresHarrajdeep SinghNo ratings yet

- Application Note Assessing Flow Accelerated Corrosion With Pulsed Eddy CurrentDocument2 pagesApplication Note Assessing Flow Accelerated Corrosion With Pulsed Eddy CurrentZoran TripunovskiNo ratings yet

- Si EvertDocument4 pagesSi EvertLaxmikant TiwariNo ratings yet

- Tube & Tank Inspection: MRUT (Medium Range UT)Document2 pagesTube & Tank Inspection: MRUT (Medium Range UT)Professional TrustNo ratings yet

- Use of Long Range Ultrasonic Testing (Lrut) Technique For Health Assessment of Critical Piping in LPG Service in A Petroleum RefineryDocument5 pagesUse of Long Range Ultrasonic Testing (Lrut) Technique For Health Assessment of Critical Piping in LPG Service in A Petroleum RefinerySefliadi StNo ratings yet

- Long-Range Guided-Wave Ultrasonics A New Age in Pipeline Inspection - 2007 - Birch, Baker - Un PDFDocument5 pagesLong-Range Guided-Wave Ultrasonics A New Age in Pipeline Inspection - 2007 - Birch, Baker - Un PDFNazriNo ratings yet

- Long Range Ultrasonic To Detect Corrosion in Tank Annular PlatesDocument2 pagesLong Range Ultrasonic To Detect Corrosion in Tank Annular PlatesGistek MarcoNo ratings yet

- Vertiscan For Boiler Water Wall Tubes Inspection: How It WorksDocument1 pageVertiscan For Boiler Water Wall Tubes Inspection: How It WorksassurendranNo ratings yet

- Provision of Global QA-QC Services - PHMDocument1 pageProvision of Global QA-QC Services - PHMRizki YudaNo ratings yet

- Company Profile Pt. Danalam Cipta Pratama Technical Inspection and CertificationDocument58 pagesCompany Profile Pt. Danalam Cipta Pratama Technical Inspection and CertificationRizki YudaNo ratings yet

- Company Profile PT. RUPDocument38 pagesCompany Profile PT. RUPRizki YudaNo ratings yet

- Tugas Pressure DrawdownDocument12 pagesTugas Pressure DrawdownRizki YudaNo ratings yet

- Prefabricación Tubería, MontajeDocument26 pagesPrefabricación Tubería, MontajeGilberto Montiel CornelioNo ratings yet

- NC 5000Document14 pagesNC 5000AnilNo ratings yet

- COMPANY PRESENTATION With Sister Concern Jan 2020Document53 pagesCOMPANY PRESENTATION With Sister Concern Jan 2020Mahaveer JainNo ratings yet

- Project Monitoring - ALL Rev 3Document91 pagesProject Monitoring - ALL Rev 3Moch FaridNo ratings yet

- Nfpa 1914 InglesDocument33 pagesNfpa 1914 InglesLuis Correa VargasNo ratings yet

- HDFO-30 Technial BookDocument20 pagesHDFO-30 Technial BookMao SequeirosNo ratings yet

- Fabrication Work For The Construction of Chenab Bridge Part IDocument2 pagesFabrication Work For The Construction of Chenab Bridge Part IIndra Mishra100% (2)

- General Specs For Building (HK)Document26 pagesGeneral Specs For Building (HK)PcEngNo ratings yet

- Chime and Multiskip InspectionDocument10 pagesChime and Multiskip InspectionVignesh VelNo ratings yet

- ASTM E 94 - 04 (Reapproved 2010)Document13 pagesASTM E 94 - 04 (Reapproved 2010)Martin Chimenti - ARO SANo ratings yet

- Amit Mishra - QualityDocument4 pagesAmit Mishra - QualitypkguptaqaqcNo ratings yet

- Elevator Lifting Ears MPIDocument1 pageElevator Lifting Ears MPIRanjithNo ratings yet

- Casting Inspection PDFDocument8 pagesCasting Inspection PDFamol koteNo ratings yet

- Buildings Department Practice Note For Authorized Persons, Registered Structural Engineers and Registered Geotechnical Engineers APP-53Document11 pagesBuildings Department Practice Note For Authorized Persons, Registered Structural Engineers and Registered Geotechnical Engineers APP-53Dave LiNo ratings yet

- Validation of Process For Production and Service Provision (7.5.2)Document2 pagesValidation of Process For Production and Service Provision (7.5.2)Kamal Mulchandani100% (1)

- Api 653 Tank Inspection SummaryDocument2 pagesApi 653 Tank Inspection SummaryalgoreNo ratings yet

- Interpreting SNT TC 1a - Part9Document2 pagesInterpreting SNT TC 1a - Part9அன்புடன் அஸ்வின்No ratings yet

- NDT Ultrasonic Phased Array Examination (NDT Examen de Ultrasonido Arreglo de Fases)Document2 pagesNDT Ultrasonic Phased Array Examination (NDT Examen de Ultrasonido Arreglo de Fases)reyserNo ratings yet

- M UdhayaDocument4 pagesM UdhayaUDHAYAKUMARNo ratings yet

- What Is The Purpose of Turbine?Document7 pagesWhat Is The Purpose of Turbine?sathesh waranNo ratings yet