Professional Documents

Culture Documents

40mm Fact Vs Folklore

Uploaded by

Nattapong DanaisawasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

40mm Fact Vs Folklore

Uploaded by

Nattapong DanaisawasCopyright:

Available Formats

Fact vs.

Folklore; the 40mm “L-60” Bofors Gun

By CMSgt Bill Walter, USAF (Ret.)

The 40mm M2A1 gun currently used on the AC-130 machined steel and alloy parts. They also discovered the

Gunship has Swedish roots dating back to the 1930s. gun was built in the old world craftsman tradition of

Originally invented by Bofors Ordnance, Karlskoga, machining parts slightly oversized and using “file to fit

Sweden as the Model 1934, you could say the gun was at assembly” production techniques. Unfortunately,

truly in the right place at the right time at the beginning hand-fitted parts are very problematic for mass

of WWII. The outbreak of hostilities caught the United production manufacturing methods. The first US

States and Great Britain woefully unequipped with company contracted to build the naval version of the

Bofors gun was York Safe & Lock, York, Pennsylvania.

A contract was formally awarded in April of 1941 even

though work began months earlier using “acquired”

Dutch machine drawings. The first problem encountered

was conversion of the Dutch drawings to American

measurements which resulted in “uniquely dimensioned

parts” compared to the original Bofors gun. As

production began, many technical problems were

encountered resulting in slow progress and low

production quantities. The final gun produced by York

Safe & Lock was functionally identical, but

dimensionally unique in comparison with the original

Swedish gun. These guns served on US Navy ships

throughout WWII.

Coinciding with the Navy gun production effort, the US

Army ran a similar unlicensed 40mm gun acquisition

program for the Army version of the Bofors gun. To

meet projected demands, The Army decided to award a

contract to Chrysler Corporation. Chrysler was very

experienced in mass production methods in their

automotive assembly plants, but building guns differs

greatly from building automobiles. Their first problem

suitable air defense guns. Both countries needed followed the experience of York Safe & Lock. Chrysler

guns…many guns, and quickly. Trouble is there was dedicated a great deal of work to convert drawings

nothing “quick” about building the Bofors gun. A single acquired from Great Britain to American measurements.

gun took Bofors 450 man-hours to produce and they As the program progressed, Chrysler engineers decided

could only produce limited quantities of guns per month. simplification of the complex functional design was not

The US and Great Britain needed many thousands of possible. As such, Chrysler re-designed components and

guns. To meet heavy production demands, the US sought materials only enough to enable mass production within

a license to build the gun themselves, but was the capability of their production lines, tooling and

unsuccessful in establishing a contract with Bofors. foundry. Chrysler was confident they could meet

Undeterred and desperate for guns, the US decided to production goals but experienced extreme difficulties

produce unlicensed copies of the gun. After obtaining standing up a production line. It took Chrysler one year

metric drawings from the Dutch government, Navy to produce their first unique version of the Bofors gun.

engineers discovered the Swedish gun was a highly Within a few months of full production, Chrysler was

complex mechanical masterpiece of more than 1500 manufacturing a complete gun from start to finish in ten

man-hours. This was an amazing feat that would be 40mm Guns on the AC-130

difficult to do today even with modern machinery.

The L-60 40mm gun was first considered for AC-130

Eventually, Chrysler took the lead of all 40mm gun

use in 1969 during the Vietnam War. It was meant to

production and standardized both Army and Navy guns.

increase stand-off distance and improve overall combat

The demand for guns at the production height of WWII

effectiveness. Contrary to popular belief, the original

was so great it surpassed Chrysler’s capacity as well. To

AC-130A 40mm guns used in flight testing were Army

meet the wartime demand, Pontiac was awarded a

M1 guns not a Navy Mk-series guns pulled from ships.

contract to build 40mm guns. Pontiac built both M1 and

These guns were heavy and cumbersome, but they

M2 (dual) guns for the US Army. When it was all said

existed…and looked like they could fill a rapid combat

and done, production of all versions of the US 40mm

capabilities need. Mounting the 1000 lb. gun to an

gun exceeded 60,000 until production ceased in the

AC-130 was not easy. Aeronautical engineers designed

1950s. These guns served US and allied nations well

an incredibly robust gun mount from plate steel, placed a

into the early 1990s. Today, the AFSOC AC-130 fleet is

gun in it and ground tested the assembly. Blast

the sole remaining user of the gun in the entire DoD and

overpressure problems were encountered initially but

only one of a handful of users of the 40mm “L-60”

solved with extensive study and analysis. When ready

Bofors gun remaining in the world.

Differences of Navy and Army Guns

for production, engineers selected the M2A1 gun from

the US Army M42A1 “Duster” tracked anti-aircraft

system. Duster used “mirror imaged” guns bolted

together with left and right hand controls. The pair was

functionally identical but was loaded and operated from

opposite sides of the Duster turret. Mounting the two

guns bolted together was not practical or desirable for

AC-130 use, so right hand and left hand guns were

separated and modified for individual mounts. The first

Naval guns carried the traditional Navy “Mk” (Mark) M2A1 (modified) guns were installed on AC-130A

designation while Army guns carried the “M” (Model) Gunships under the “Surprise Package” program. These

designation. The principal differences between Navy guns served on AC-130A aircraft until aircraft retirement

and Army guns were the location of the trunions in the mid 1990s when all the left hand guns were

(elevation pivots), the barrel and the breech casing overhauled for use on the AC-130U. These original

design. Naval Mk-1 and Mk-2 guns used “water AC-130A guns, mostly manufactured in the 1950s,

jacketed” barrels and trunions near the center of gravity continue to serve AC-130U crews in Afghanistan today.

of the elevating mass. Trunions of all Army models and

the Naval Mk-5 (submarine/ patrol craft model) were

located well aft of the center of gravity to lower mount

profile and all guns were equipped with air-cooled

barrels.

Back to the Future? remove old paint and corrosion. Once cleaned and

inspected, the breech casings were modified and

During 2002, as Operation Enduring Freedom reached

machined in AFRL’s Model Shop to original AC-130

full swing, the Air Staff realized there were not enough

“Surprise Package” drawing specifications. Once all

AC-130 gunships to meet demands. In response, they

modifications were complete, the unpainted guns were

initiated what was called the “Plus Four” program to

taken to an AFRL range at Eglin for test firing. Using

rapidly build four additional AC-130U gunships. By

an original AC-130A gun mount and a firing rod

then, the once prolific M42A1 Duster system had long

borrowed from the “The First Lady” (AC-130A

since been retired. There were no guns available in the

53-3129) at the USAF Armament Museum. Both guns

supply system for the “Plus Four” program. It appeared

test fired perfectly in both single and rapid fire modes. A

all viable sources for guns were depleted. An attempt

subsequent trip to Nellis AFB netted three more guns.

was made to award a contract to produce newly

These were shipped, inspected and modified to the same

manufactured guns, but production and financial reality

standard as the first two.

of building a “unique-new-old-gun” was deemed

unrealistic and unaffordable. After testing was completed, the guns were

disassembled, re-inspected, painted flat black, re-

Recognizing the problem, several AC-130 gunners

assembled and turned into the supply system. Since

stepped forward to assist the old fashioned

these guns were manufactured by the same company at

way…scrounging. In the past, they had seen many

the same time that current AC-130 guns were originally

M42A1 Duster systems sitting on target ranges on Nellis

built, they are matching in all respects with the current

Air Force Base. The guns on the M42A1s appeared to be

fleet of guns. The entire project took about six months

in very good condition and “ripe for the picking”. With

to complete at a cost of $130K. The real cost of these

this bit of intelligence, staff officers from the HQ

guns if procured today exceeds $8.6M. A great level of

AFSOC Gunship Requirements Branch contacted Nellis

credit goes to the “out of the box” thinkers whose ideas

Range Operations personnel to arrange a visit to inspect

and hard-work filled a critical requirement for a fraction

the guns. After approval, several gun technicians and a

of projected cost, delivering guns at least four years

program analyst quickly arranged a trip to Nellis. The

sooner than planned.

guns were inspected, found to be in good condition and

two dual guns were successfully recovered.

40mm Gun Facts

The guns were then shipped to Eglin Air Force Base for Not a single 40mm gun used by the US was actually

detailed inspection and modifications. Air Force built by Bofors in Sweden.

Research Lab (AFRL) technicians disassembled and

inspected the guns and components inspected. They Commonly called the Bofors “L-60”, our gun is actually

found that with few exceptions, most parts were in an L-56 (caliber x 56 = barrel length).

serviceable condition. Critical parts were metal About the Author: Chief Walter served as AC-130H/U

particulate inspected and re-finished with a zinc Aerial Gunner for 26 years. He currently works at HQ

phosphate finish. Breech casings were water-blasted to AFSOC, Gunship Requirements, as a Program Analyst.

You might also like

- Vol 2. Part 3 - Hunter Weapons 103111Document94 pagesVol 2. Part 3 - Hunter Weapons 103111David Griffin80% (5)

- Bofors 40 MM: Navigation Search Improve This Article Reliable Sources Challenged RemovedDocument17 pagesBofors 40 MM: Navigation Search Improve This Article Reliable Sources Challenged RemovedNazir ShamsNo ratings yet

- Tactical Knives Combat KnivesDocument2 pagesTactical Knives Combat KnivesGurpreet Singh100% (1)

- 5.56mm - DuPont, Olin and ... The Great Propellant ControversyDocument5 pages5.56mm - DuPont, Olin and ... The Great Propellant Controversyblowmeasshole1911No ratings yet

- The Bombsight War Norden Vs SperryDocument6 pagesThe Bombsight War Norden Vs Sperrymarco100% (1)

- SpiwDocument5 pagesSpiwsmashzionism12345No ratings yet

- SpiwDocument6 pagesSpiwsmashzionism12345No ratings yet

- The Sperry Bombsight: A Pioneering Rival to NordenDocument6 pagesThe Sperry Bombsight: A Pioneering Rival to NordenPaul DupontNo ratings yet

- The 5.56 X 45mm 1957 - 1962 - A Chronology of Development - by Daniel WattersDocument35 pagesThe 5.56 X 45mm 1957 - 1962 - A Chronology of Development - by Daniel Wattersblowmeasshole1911No ratings yet

- Gun Digest Guide to the Modern AK: Gear, Accessories & Upgrades for the AK-47 and Its VariantsFrom EverandGun Digest Guide to the Modern AK: Gear, Accessories & Upgrades for the AK-47 and Its VariantsRating: 5 out of 5 stars5/5 (1)

- History of The Johnson RifleDocument16 pagesHistory of The Johnson Rifleblowmeasshole1911No ratings yet

- Amm 20mm Cannon CartridgesDocument7 pagesAmm 20mm Cannon Cartridgesenrico50% (2)

- Bofors Automatic CannonDocument9 pagesBofors Automatic CannonRahmad MorangNo ratings yet

- Kalashnikov Assault RiflesDocument4 pagesKalashnikov Assault RiflesTimia TalashekNo ratings yet

- HOW IT WORKS: The Caliber .50. M2 Browning Machine Gun: The Caliber .50 M2 Browning Machine GunFrom EverandHOW IT WORKS: The Caliber .50. M2 Browning Machine Gun: The Caliber .50 M2 Browning Machine GunNo ratings yet

- M1911 PistolDocument14 pagesM1911 Pistolblowmeasshole19110% (1)

- Origin of A Primer BallisticDocument6 pagesOrigin of A Primer BallisticWilbert ReyesNo ratings yet

- Artillery of The Red Army Part IIIDocument8 pagesArtillery of The Red Army Part IIIClaus Jørgen PetersenNo ratings yet

- British Enfield Rifles - NRA - 2004Document28 pagesBritish Enfield Rifles - NRA - 2004giuliva67100% (8)

- History: Accuracy InternationalDocument12 pagesHistory: Accuracy InternationalH2AKNo ratings yet

- History of the Americanization of the Bofors 40mm Automatic Antiaircraft GunDocument53 pagesHistory of the Americanization of the Bofors 40mm Automatic Antiaircraft GundunmunroNo ratings yet

- Commando, Fleetwing BT 12, Douglas A 20 Havoc,: JL Mcclellan: P51 Draft P 1 of 32Document32 pagesCommando, Fleetwing BT 12, Douglas A 20 Havoc,: JL Mcclellan: P51 Draft P 1 of 32Kliment VoroshilovNo ratings yet

- Forgotten Handguns of The U.S. MilitaryDocument5 pagesForgotten Handguns of The U.S. MilitaryRobReedNo ratings yet

- Weapons of WW1 TaskDocument5 pagesWeapons of WW1 TaskPaul ChoiNo ratings yet

- Field Artillery Journal - May 1926Document116 pagesField Artillery Journal - May 1926CAP History LibraryNo ratings yet

- Seminarski o TenkovimaDocument10 pagesSeminarski o TenkovimaAndrija JestrovicNo ratings yet

- Best Handguns MadeDocument10 pagesBest Handguns Madejpes100% (2)

- World War 1 1Document6 pagesWorld War 1 1api-254472149No ratings yet

- M-24 Sniper Weapon SystemDocument14 pagesM-24 Sniper Weapon Systemمحمد على100% (1)

- 40mm Bofors AAA GunDocument2 pages40mm Bofors AAA GunMoulin Kubis100% (2)

- Steel Thunder on the Eastern Front: German and Russian Artillery in WWIIFrom EverandSteel Thunder on the Eastern Front: German and Russian Artillery in WWIINo ratings yet

- Mauser Oberndorf PDFDocument15 pagesMauser Oberndorf PDFgglocksterNo ratings yet

- U.S. Service Weapons Using .30-06Document14 pagesU.S. Service Weapons Using .30-06Erich Eshelman100% (1)

- Collector's Manual For Cartridges PDFDocument192 pagesCollector's Manual For Cartridges PDFEnriquenf100% (4)

- Jagdpanzer IV - German Army and Waffen-SS Tank Destroyers: Western Front, 1944–1945From EverandJagdpanzer IV - German Army and Waffen-SS Tank Destroyers: Western Front, 1944–1945Rating: 5 out of 5 stars5/5 (1)

- The AKDocument6 pagesThe AKjeffreycalhounNo ratings yet

- Fallschirmjagergewehr 42 (FG42) Light Machine Gun (NAZI)Document7 pagesFallschirmjagergewehr 42 (FG42) Light Machine Gun (NAZI)blowmeasshole1911No ratings yet

- Axis Armoured Fighting Vehicles of the Second World WarFrom EverandAxis Armoured Fighting Vehicles of the Second World WarRating: 4 out of 5 stars4/5 (1)

- Battle RiflesDocument9 pagesBattle RiflesYorgos KordoniasNo ratings yet

- US Air ForceDocument76 pagesUS Air ForceAbdullah OmerNo ratings yet

- The Top 5 Navy SEALs Weapons For Kids: Navy SEALs Special Forces Leadership and Self-Esteem Books for KidsFrom EverandThe Top 5 Navy SEALs Weapons For Kids: Navy SEALs Special Forces Leadership and Self-Esteem Books for KidsRating: 1 out of 5 stars1/5 (1)

- Assault Rifles IndexDocument254 pagesAssault Rifles IndexGeorge Bailey75% (8)

- W m1 CarbineDocument18 pagesW m1 CarbineBruce Lee Hutfless100% (1)

- The History of the Panzerjäger: Volume 2: From Stalingrad to Berlin 1943–45From EverandThe History of the Panzerjäger: Volume 2: From Stalingrad to Berlin 1943–45No ratings yet

- Pedersen RifleDocument14 pagesPedersen Rifleblowmeasshole1911100% (1)

- SAFN 49 Venezuala DevelopmentDocument3 pagesSAFN 49 Venezuala Developmentp317No ratings yet

- History and Development of the Lee Enfield Rifle and .303 British CartridgeDocument41 pagesHistory and Development of the Lee Enfield Rifle and .303 British CartridgeClaude CaiafaNo ratings yet

- Civil War Ironclad Ships: ModelingDocument170 pagesCivil War Ironclad Ships: Modelingjns1606100% (1)

- EPISODE-1-2-3FIREARMSDocument2 pagesEPISODE-1-2-3FIREARMSMoreno Plaza RodolfoNo ratings yet

- The Book of the Springfield: A Textbook Covering all the Various Military and Sporting Rifles Chambered for the Caliber .30 Model 1906 Cartridge; Their Metallic and Telescopic Sights and the Ammunition Suited to ThemFrom EverandThe Book of the Springfield: A Textbook Covering all the Various Military and Sporting Rifles Chambered for the Caliber .30 Model 1906 Cartridge; Their Metallic and Telescopic Sights and the Ammunition Suited to ThemRating: 2 out of 5 stars2/5 (1)

- John Browning's Automatic RifleDocument6 pagesJohn Browning's Automatic Rifleblowmeasshole1911100% (1)

- I9I8: Browning Automatic RifleDocument18 pagesI9I8: Browning Automatic RifleJustCallMe_ALNo ratings yet

- Lagertha Hoja PersonajeDocument2 pagesLagertha Hoja PersonajeDaniel SangreloboNo ratings yet

- TSC NiyamawaliDocument7 pagesTSC NiyamawaliconXn Communication & Cyber100% (1)

- History of Brgy. MilitarDocument5 pagesHistory of Brgy. Militarcare samontina100% (1)

- Depression, New Deal, WWII: HIS 315L Unit 3 Study GuideDocument9 pagesDepression, New Deal, WWII: HIS 315L Unit 3 Study GuideSweat StickNo ratings yet

- How To Use Isf-Trb & School RequirementsDocument7 pagesHow To Use Isf-Trb & School RequirementsNathalieBarbosaBarbatoNo ratings yet

- Chieftain Volume 3 Pamphlet 33Document294 pagesChieftain Volume 3 Pamphlet 33scribd91390% (21)

- MallaroyDocument2 pagesMallaroyHyperLanceite XNo ratings yet

- Notes in NSTP .R.A. 9163 1987 and R.A.7077Document14 pagesNotes in NSTP .R.A. 9163 1987 and R.A.7077Nicole Eliang SimbilloNo ratings yet

- 42-Donald Marshall CLONE VAMPIRE PDFDocument101 pages42-Donald Marshall CLONE VAMPIRE PDFJamesComeyJustaBitchNo ratings yet

- When Britain Goes To War - Adaptability and Mobility (Liddell Hart - 1935) A PDFDocument337 pagesWhen Britain Goes To War - Adaptability and Mobility (Liddell Hart - 1935) A PDFtayl5720No ratings yet

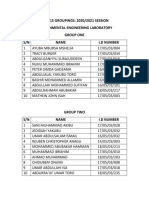

- CWE415 GROUPINGS: 2020/2021 SESSION Environmental Engineering Laboratory Group One S/N Name I.D NumberDocument6 pagesCWE415 GROUPINGS: 2020/2021 SESSION Environmental Engineering Laboratory Group One S/N Name I.D NumberSunday Obidah GwaryNo ratings yet

- PsyOps DoctrineDocument113 pagesPsyOps DoctrineSteven HoraitesNo ratings yet

- TransactionalDocument4 pagesTransactionalLea Condalo TantaoNo ratings yet

- Paranoia - XmasCheerDocument4 pagesParanoia - XmasCheerTron TronNo ratings yet

- EWU. GEN 226. Lecture 18. StudentsDocument12 pagesEWU. GEN 226. Lecture 18. StudentsMd SafiNo ratings yet

- Rwby RPG A1.0Document32 pagesRwby RPG A1.0Aaron ThomasNo ratings yet

- The Last Flight of S/Sgt. Linwood W. WhiteDocument6 pagesThe Last Flight of S/Sgt. Linwood W. Whiteandtodo2No ratings yet

- Data BDSDocument11 pagesData BDShuong phamNo ratings yet

- Uk Intelligence and Security ReportDocument61 pagesUk Intelligence and Security ReporteliahmeyerNo ratings yet

- Monroe DoctrineDocument4 pagesMonroe DoctrineBigMamaTEANo ratings yet

- The Golden Book of India 1893 PDFDocument616 pagesThe Golden Book of India 1893 PDFTareq Aziz100% (1)

- Marketing Concepts and Industry OverviewDocument37 pagesMarketing Concepts and Industry Overviewjassi7nishadNo ratings yet

- Osprey - Warrior 088 - British Light Infanfryman of The Seven Years' War - North America 1757-63 (E-Book)Document67 pagesOsprey - Warrior 088 - British Light Infanfryman of The Seven Years' War - North America 1757-63 (E-Book)Miguel Angel Martinez100% (8)

- Records of The Past 02Document226 pagesRecords of The Past 02Stjepan PalajsaNo ratings yet

- Major Irvin Oliver, U.S. ArmyDocument9 pagesMajor Irvin Oliver, U.S. ArmytatataetaeaeeNo ratings yet

- Army Field Feeding SystemsDocument13 pagesArmy Field Feeding SystemsKelvin EmmanuelNo ratings yet

- Lynx Akciya2Document66 pagesLynx Akciya2Suburban2012_2992069No ratings yet

- Volume 22 - Prologue of Disturbance (II)Document216 pagesVolume 22 - Prologue of Disturbance (II)karolco75% (4)